Surface-mounting fuse and production method thereof

A surface mount and fuse technology, applied in emergency protection devices, electrical components, circuits, etc., can solve problems such as high thermal conductivity layer or uneven thickness of adhesive, unsatisfactory arc extinguishing effect, and affecting product fusing characteristics. Achieve the effects of improving arc extinguishing effect, controllable fusing characteristics, and improving arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

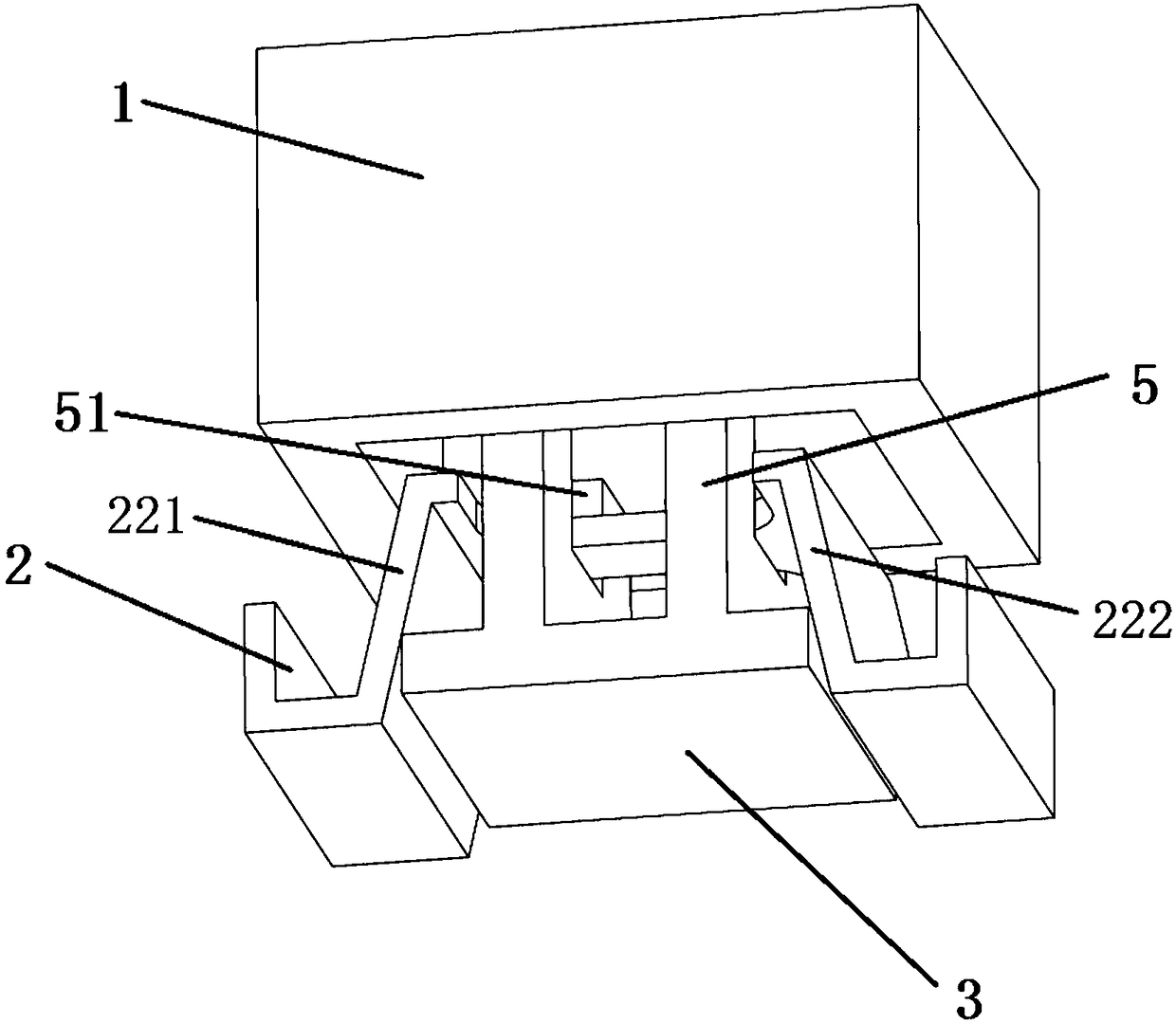

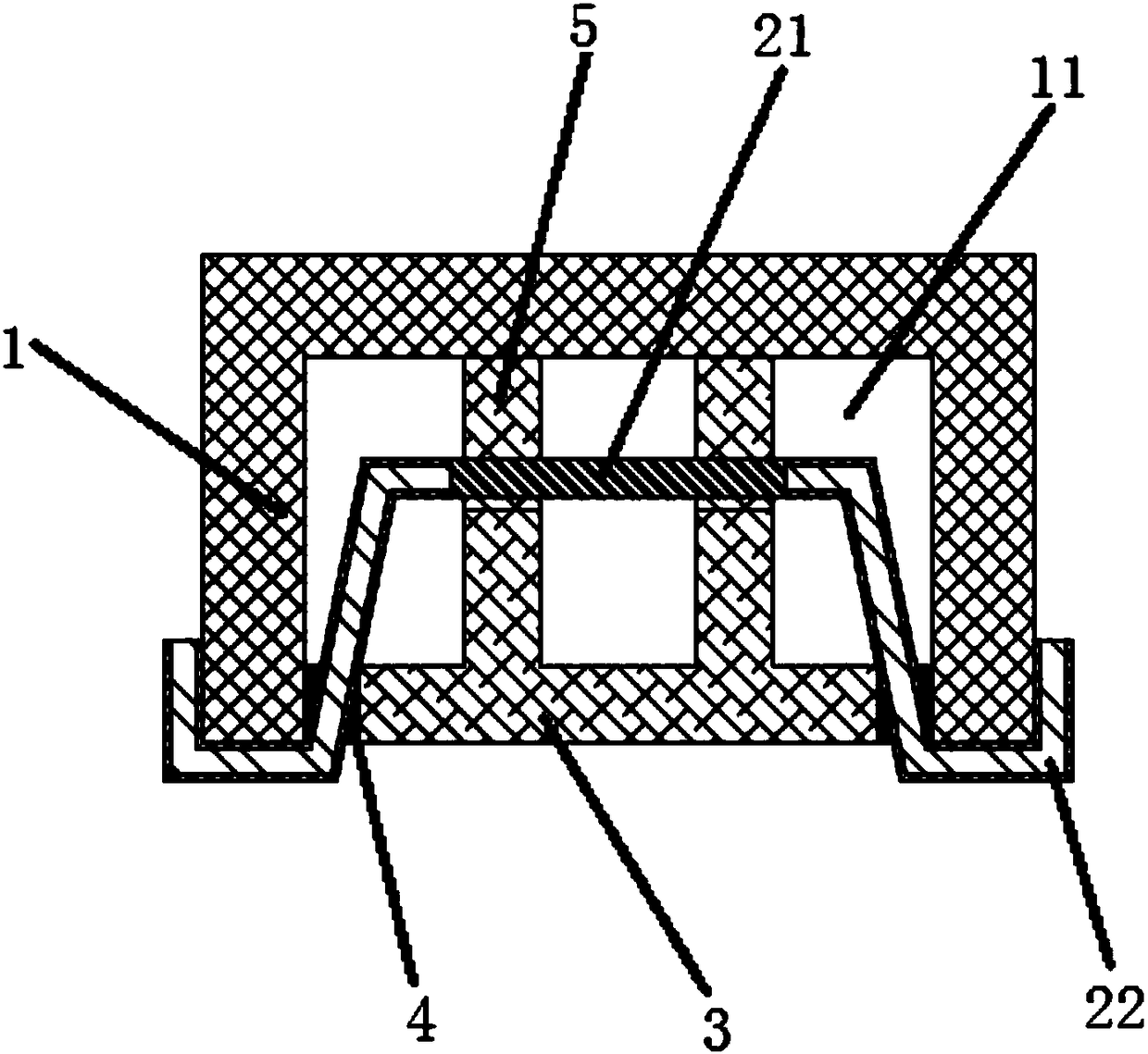

[0049] Such as Figure 1-2 As shown, this embodiment provides a surface mount fuse, which includes an insulating case 1 with an accommodating cavity 11 formed by indenting on one side, two conductive electrodes 22 and a fuse arranged between the two conductive electrodes 22. The fuse main body 2 of the part 21, the insulating cover 3 covered on the accommodating cavity 11 and the adhesive 4 filling the gap between the periphery of the insulating cover 3 and the side wall of the insulating case 1, two conductive The electrodes 22 are respectively a first conductive electrode and a second conductive electrode. There is a first bending part 221 between the first conductive electrode and the fuse part 22, and a second bend part 221 between the second conductive electrode and the fuse part 22. The bent portion 222 , the first bent portion 221 and the second bent portion 222 are located in the accommodating cavity, and the conductive electrode 22 extends out of the accommodating cav...

Embodiment 2

[0060] Such as image 3 As shown, this embodiment provides a surface mount fuse, which includes an insulating case 1 with an accommodating cavity 11 formed by indenting on one side, two conductive electrodes 22 and a fuse arranged between the two conductive electrodes 22. The fuse main body 2 of the part 21, the insulating cover 3 covered on the accommodating cavity 11 and the adhesive 4 filling the gap between the periphery of the insulating cover 3 and the side wall of the insulating case 1, two conductive The electrodes 22 are respectively a first conductive electrode and a second conductive electrode. There is a first bending part 221 between the first conductive electrode and the fuse part 22, and a second bend part 221 between the second conductive electrode and the fuse part 22. The bent portion 222 , the first bent portion 221 and the second bent portion 222 are located in the accommodating cavity, and the conductive electrode 22 extends out of the accommodating cavity...

Embodiment 3

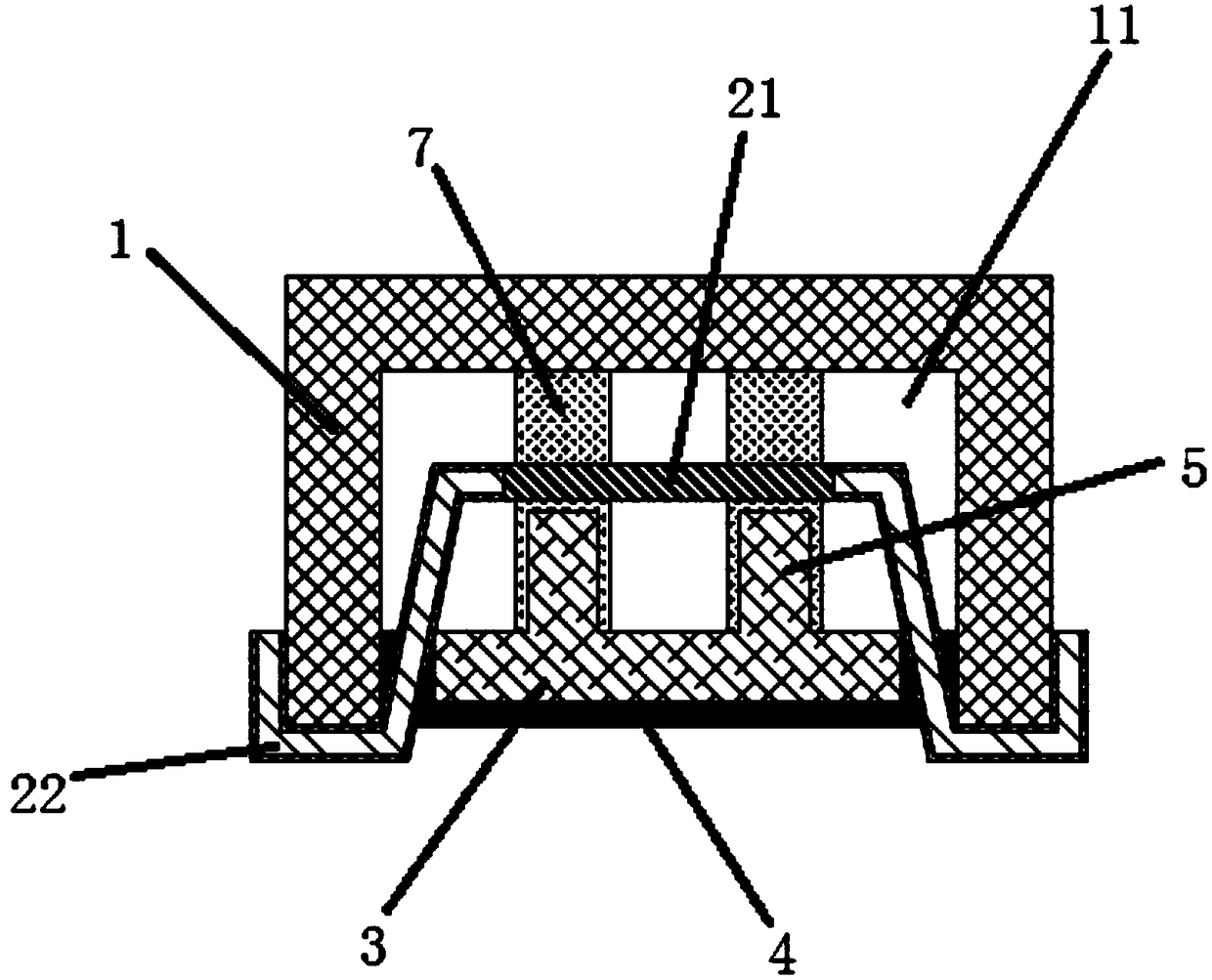

[0073] Such as Figure 4 As shown, this embodiment provides a surface mount fuse, which includes an insulating case 1 with an accommodating cavity 11 formed by indenting on one side, two conductive electrodes 22 and a fuse arranged between the two conductive electrodes 22. The fuse main body 2 of the part 21, the insulating cover 3 covered on the accommodating cavity 11 and the adhesive 4 filling the gap between the periphery of the insulating cover 3 and the side wall of the insulating case 1, two conductive The electrodes 22 are respectively a first conductive electrode and a second conductive electrode. There is a first bending part 221 between the first conductive electrode and the fuse part 22, and a second bend part 221 between the second conductive electrode and the fuse part 22. The bent portion 222 , the first bent portion 221 and the second bent portion 222 are located in the accommodating cavity, and the conductive electrode 22 extends out of the accommodating cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com