Turbine rotor fork-shaped blade mounting structure and mounting method thereof

A technology for the installation of steam turbine rotors and blades. It is applied to the supporting elements, mechanical equipment, and engine elements of blades. It can solve the problems of weak installation structure and easy existence of gaps, and achieve the effect of preventing loosening and ensuring installation firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

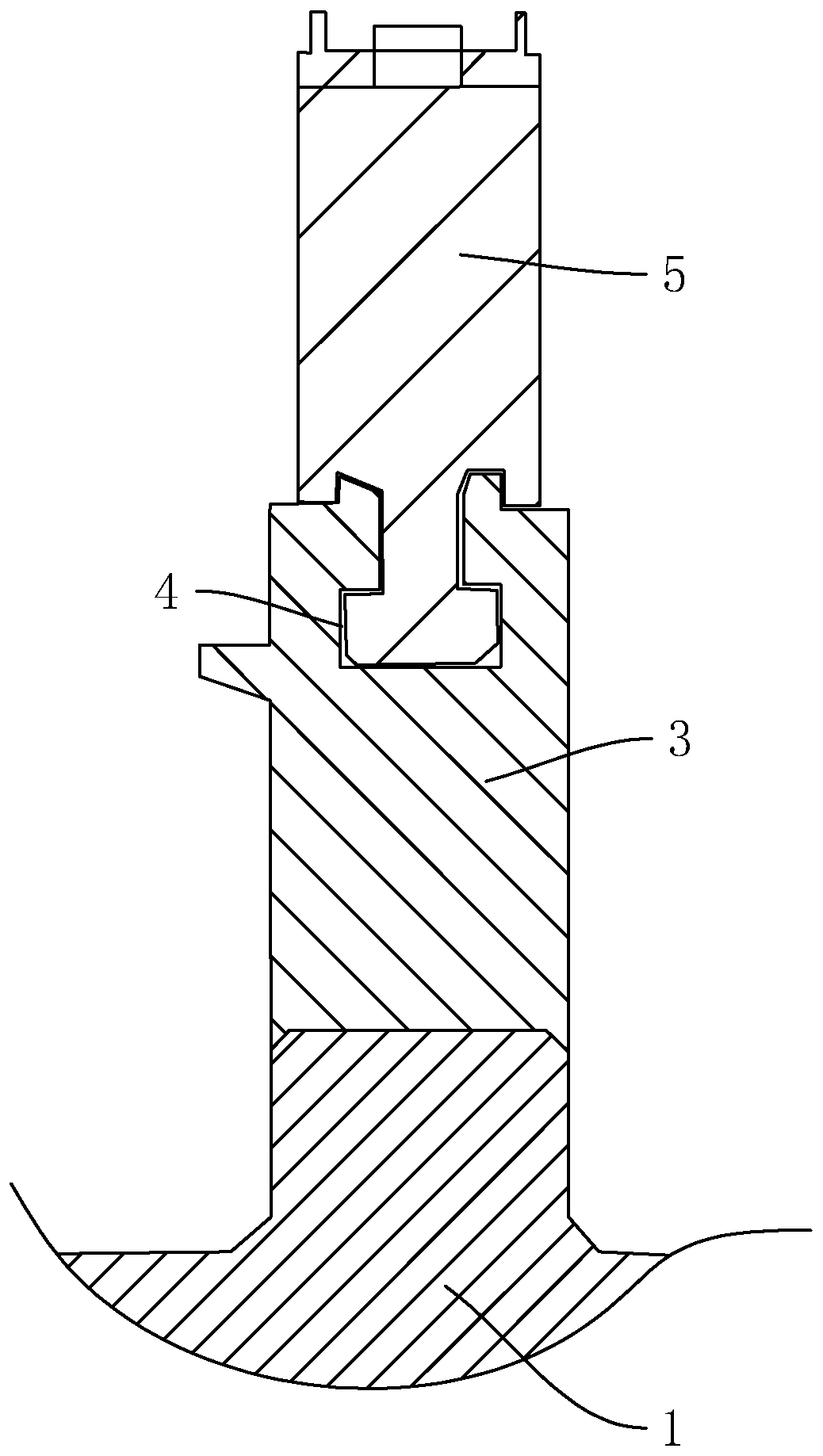

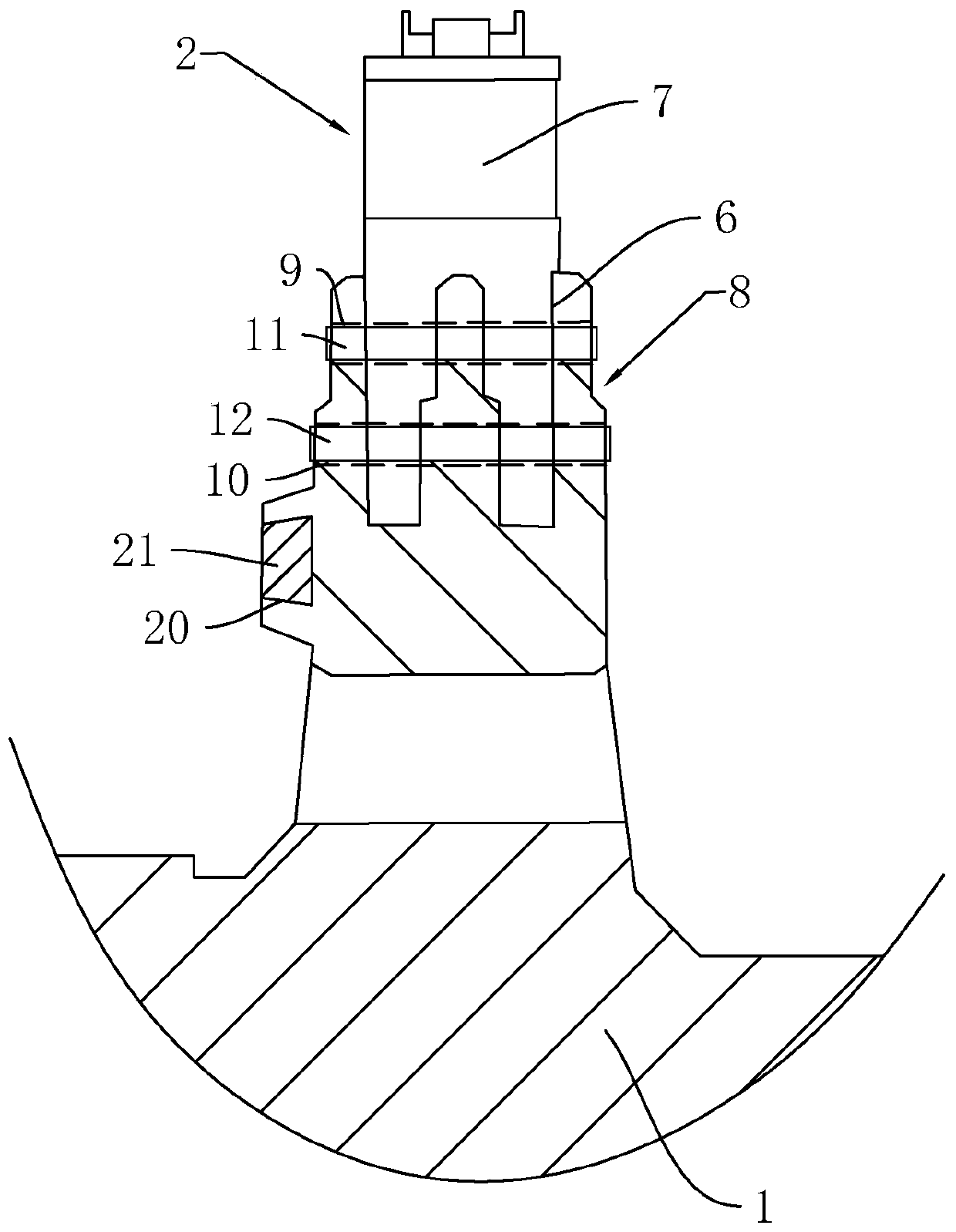

[0048] refer to figure 1 and figure 2 , is a steam turbine rotor fork-shaped blade installation structure disclosed in the present invention, including a rotor 1 and a fork-shaped blade 2 connected to the periphery of the rotor 1, and a mounting seat 3 is integrally formed on the side wall of the rotor 1, and the mounting seat 3 is annular. And coaxial with the rotor 1, a fork-shaped wheel groove 4 is provided, and a number of intermediate blades 5 are slidably engaged in the fork-shaped wheel groove 4, and the blade roots of the intermediate blades 5 are slidably engaged in the fork-shaped wheel groove 4. The side wall of the wheel groove 4 is provided with a wheel groove 6 along the radial direction of the rotor 1, and the last blade 7 is pierced in the wheel groove 6, and a locking assembly for locking the last blade 7 is also arranged on the wheel groove 6 8. After inserting the middle blade 5 into the fork-shaped wheel groove 4, slide the middle blade 5 so that several ...

Embodiment 2

[0055] A method for installing a steam turbine rotor fork-shaped blade, comprising the following steps,

[0056] S1, insert the blade roots of the middle sheets through the wheel groove 6 in turn, and then slide inward along the fork-shaped wheel groove 4, so that the blade roots of several middle sheets are arranged closely, and the fork-shaped wheel grooves are arranged in 4 rows through the middle sheets Full;

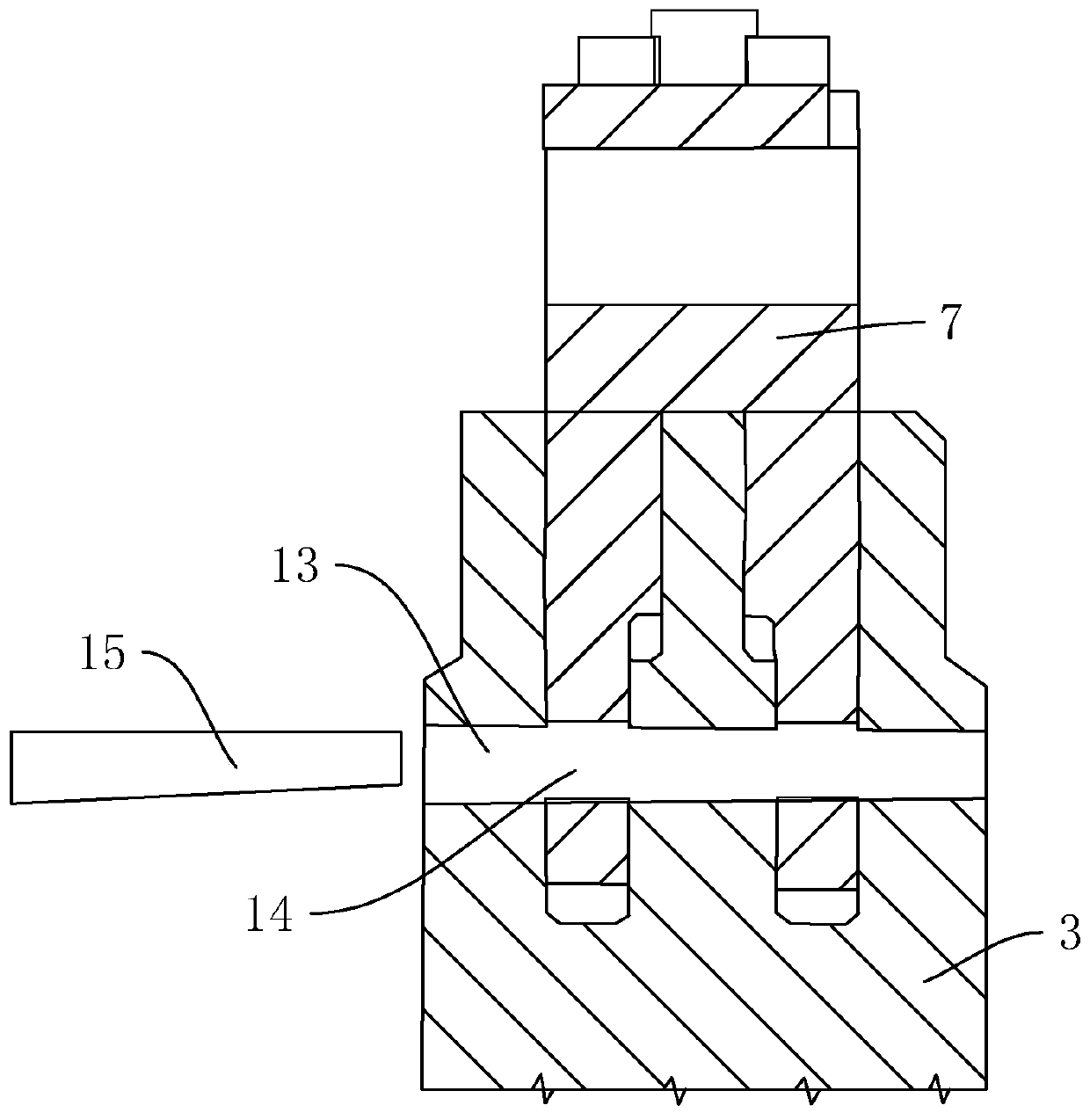

[0057] S2, such as image 3 As shown, a first prefabricated hole 13 is provided on the side wall of the wheel groove 6 on the mounting seat 3, and a second prefabricated hole 14 corresponding to the first prefabricated hole 13 is provided at the root of the last blade 7. The aperture of the second prefabricated hole 14 is greater than or equal to the diameter of the first prefabricated hole 13;

[0058] S3, insert the blade root of the last blade 7 into the wheel groove 6, at this time there is a gap between the lower surface of the blade root of the last blade 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com