Feeding control device and method and digital spray printing machine

A technology of feeding control and controller, applied in printing devices, printing and other directions, can solve the problems of inaccurate printing of cardboard, reduce the efficiency of users' work, and affect the printing effect of the first cardboard, so as to ensure the printing effect and improve the work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

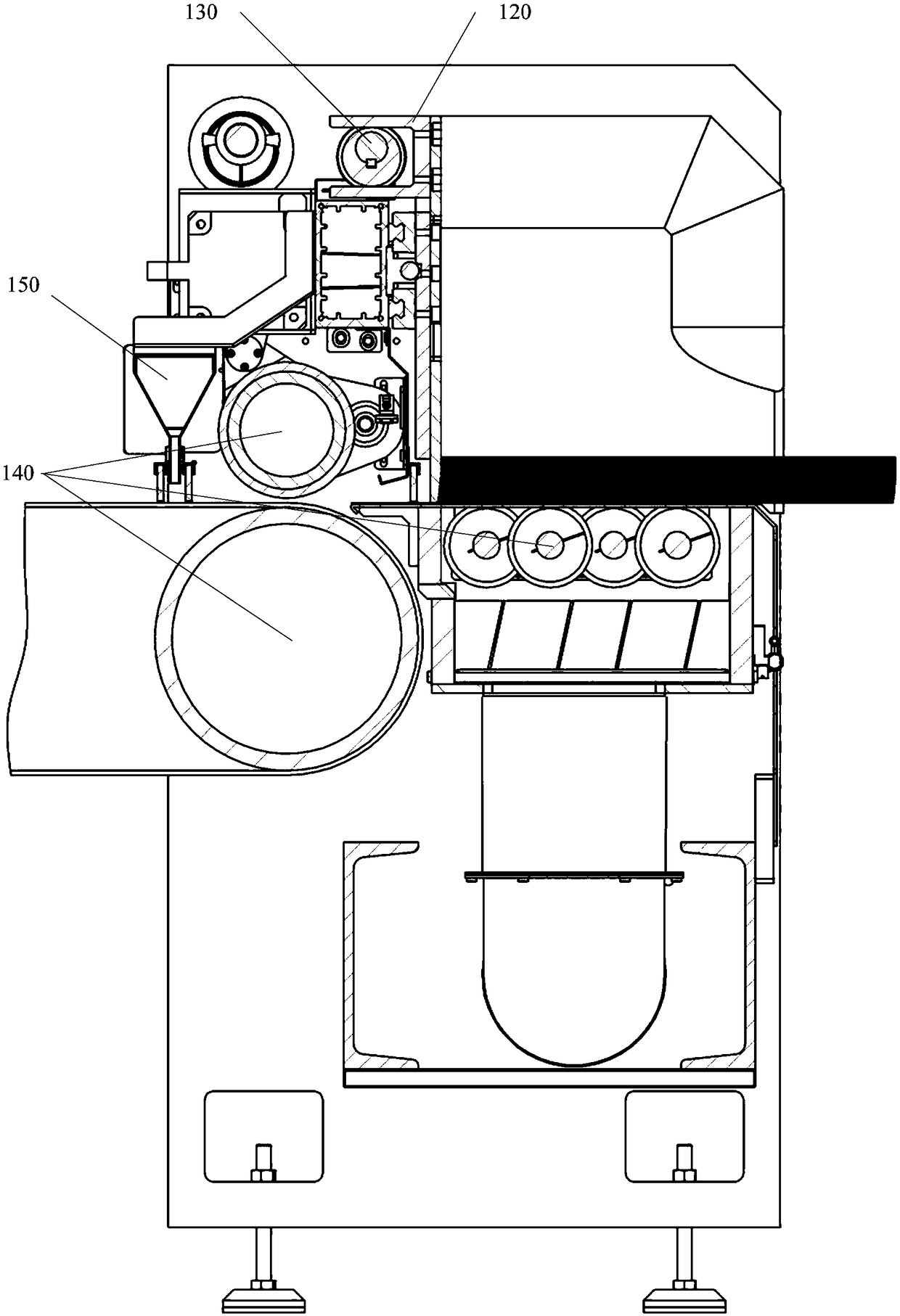

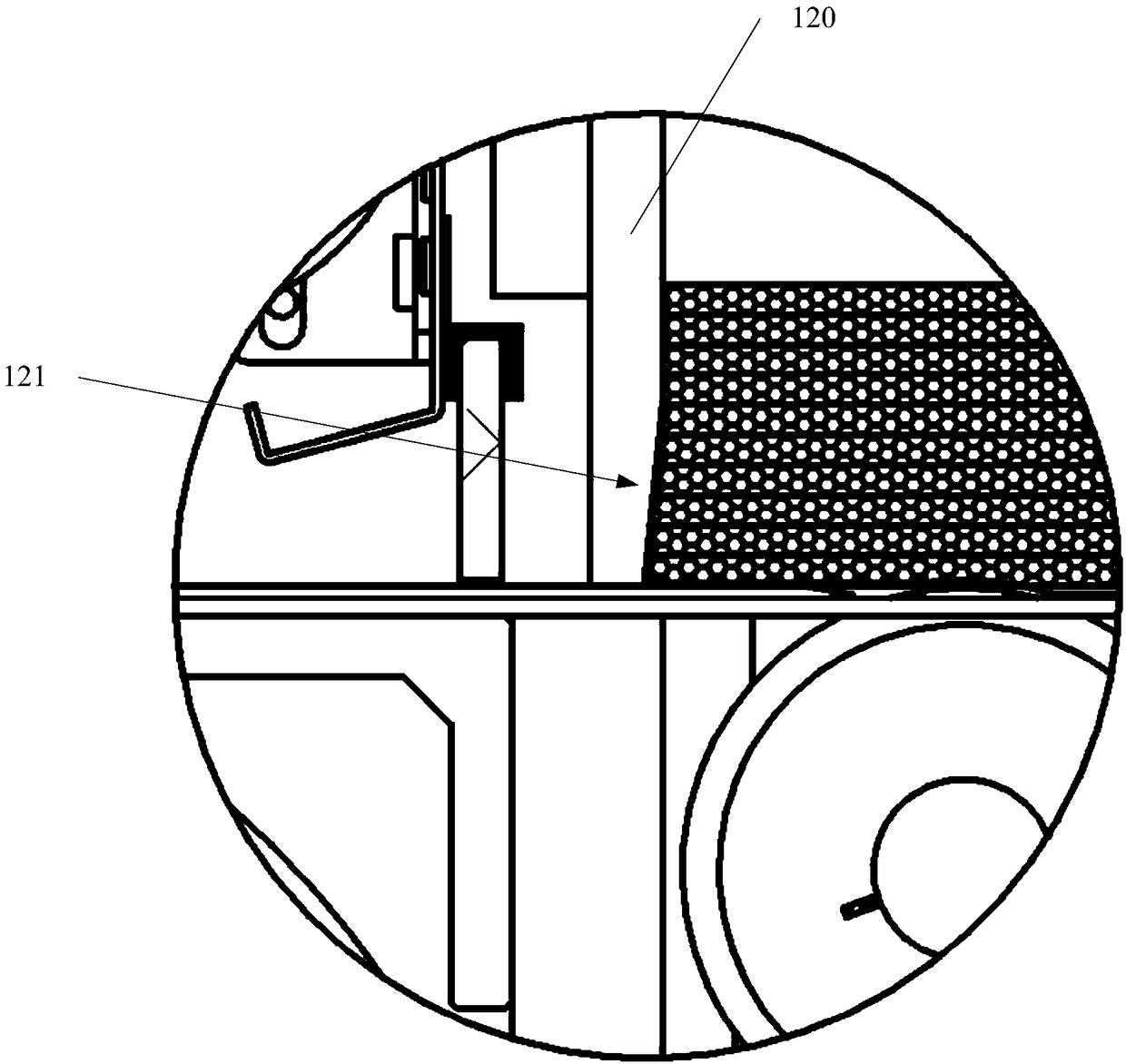

[0042] figure 1 A schematic structural view of the feed control device provided by the embodiment of the present invention is shown, and for the convenience of description, only the parts related to the present invention are shown.

[0043] controller (not shown in the figure).

[0044] In the embodiment of the present invention, the controller may be a microcontroller unit (Microcontroller Unit; MCU), to control the work of equipment such as the baffle drive mechanism, the printing mechanism, and the feeding mechanism in the printing system. As an optimized embodiment of the present invention, the work of the controller can be manually controlled by the user, or automatically controlled by programming.

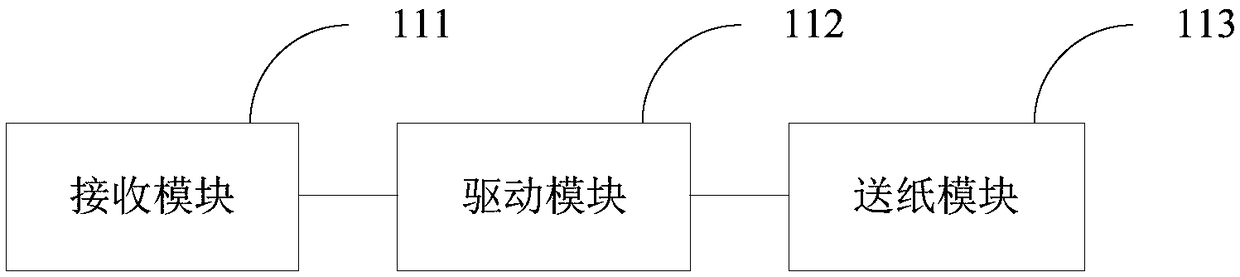

[0045] As another optimized embodiment of the present invention, such as figure 2 As shown, the controller also includes a receiving module 111 , a driving module 112 and a paper feeding module 113 .

[0046] A receiving module 111 for receiving orders.

[0047] In this ...

Embodiment 2

[0067] Figure 5 The flow chart of the implementation of the feed control method provided by the embodiment of the present invention is shown, and for the convenience of description, only the parts related to the present invention are shown.

[0068] In step S501, an order is received.

[0069] In this embodiment of the present invention, an order refers to a print task instruction when a printer performs printing.

[0070] In step S502, drive the driving mechanism of the material baffle to lower the material baffle to the lowest point.

[0071] In the embodiment of the present invention, the drive can be driven by a mechanical motor, connected with the driving mechanism of the material blocking plate through a conveyor belt or a rotating shaft, and the driving mechanism of the material blocking plate is driven to work by controlling the rotation of the motor, and then the rising or falling of the material blocking plate is controlled. .

[0072] In step S503, the cardboard...

Embodiment 3

[0080] Figure 6 A schematic structural diagram of a digital jet printer provided by an embodiment of the present invention is shown, and for convenience of description, only parts related to the present invention are shown.

[0081] The digital jet printing machine includes the above-mentioned feeding control device.

[0082] To sum up, in the embodiment of the present invention, since the printer has its own feed roller 140 and printing device 150, before printing, the user controls the driving mechanism of the material stopper through the controller, and then controls the material stopper of the printer inlet. 110 down to the lowest point of the feed inlet, so that the first corrugated cardboard is close to the feed inlet side 160 against the bottom of the baffle plate, so as to position the first corrugated cardboard; when printing, it is controlled by the controller The driving mechanism of the baffle plate, and then controls the material baffle plate of the printer feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com