Liner container molding structure and molding method of dishwasher

A technology for a dishwasher liner and molding structure, which is applied to the washing machine/washing machine of tableware, the parts of the washing machine/rinsing machine for tableware, auxiliary devices, etc. Large and other problems, to achieve the effect of high molding dimensional accuracy, convenient and fast molding, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

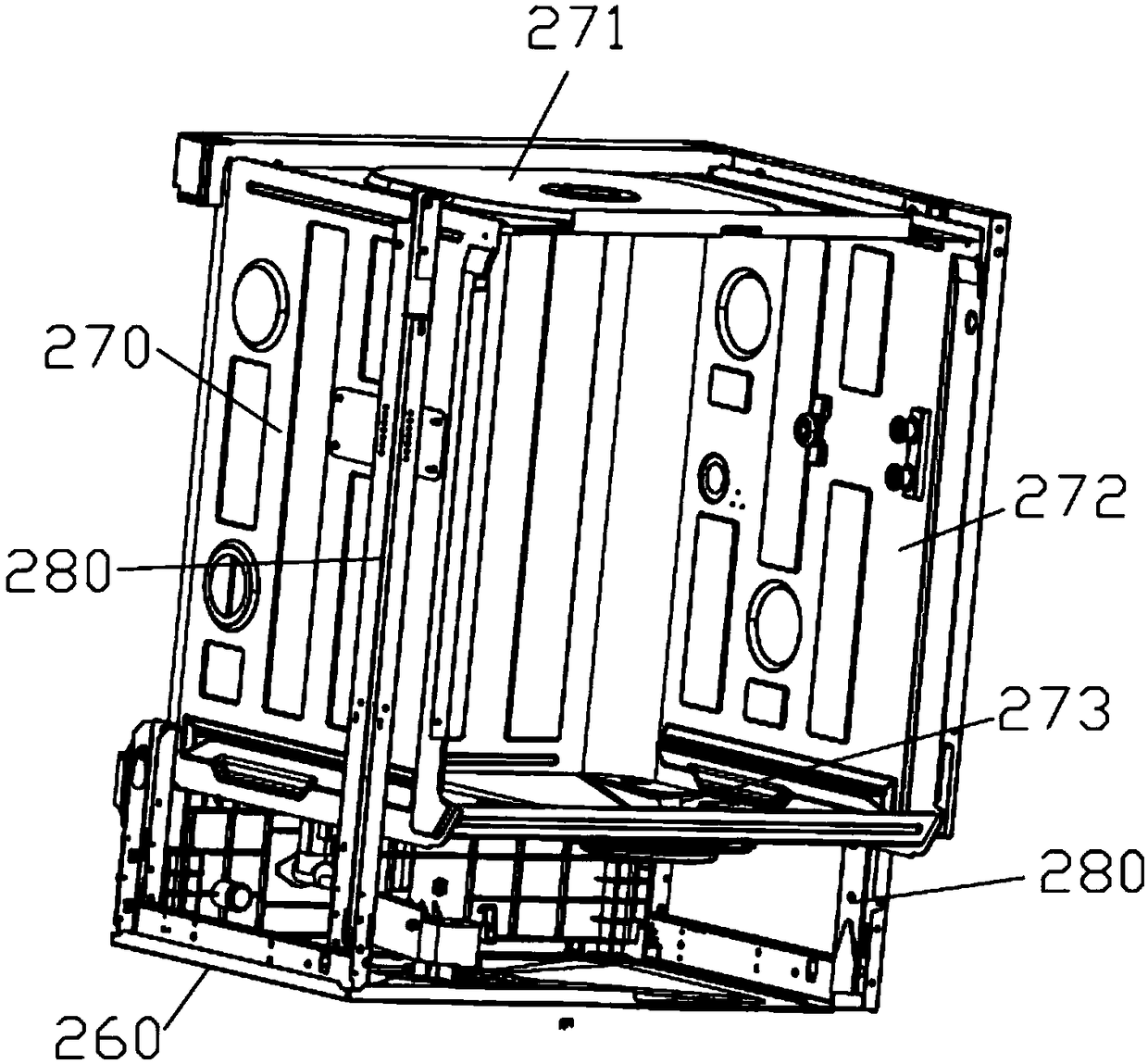

[0023] The cabinet assembly of the dishwasher includes an inner container 270, a top plate is provided on the top of the inner container 270, side panels are provided on both sides, a bottom plate 260 is arranged at a certain height below the inner container 270, and the dishwasher is arranged on the bottom plate 260. Motor pump, water cup, filter system assembly, water separator assembly, etc.

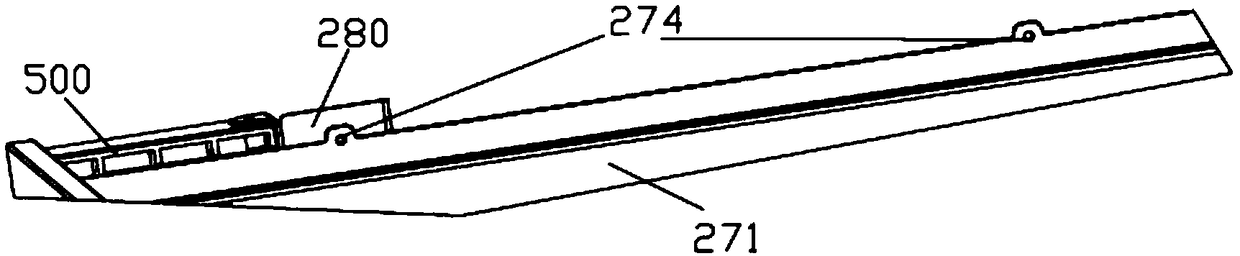

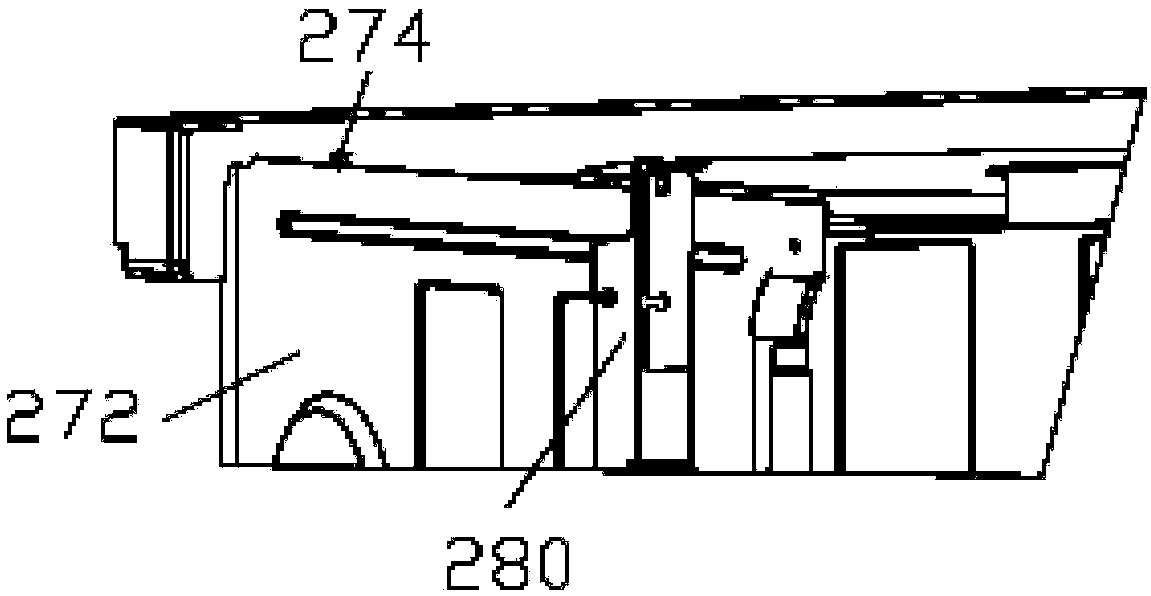

[0024] Inner tank molding structure of the present invention, as figure 1 As shown, the liner 270 includes a middle cover 272 and a top cover 271 and a bottom cover 273 connected to the upper and lower ends of the middle cover 272 respectively. The lower flange structure formed by extending downwards, the upper flange structure and the lower flange structure are respectively provided with pre-position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com