Rotary Shaft Double-head Central Hole Vertical Grinder

A center hole and rotary shaft technology, used in the field of center hole grinding equipment, can solve the problems of difficulty in ensuring the center hole grinding quality, incomplete grinding of the center hole oxide layer, unreliable grinding quality, etc. The effect of labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

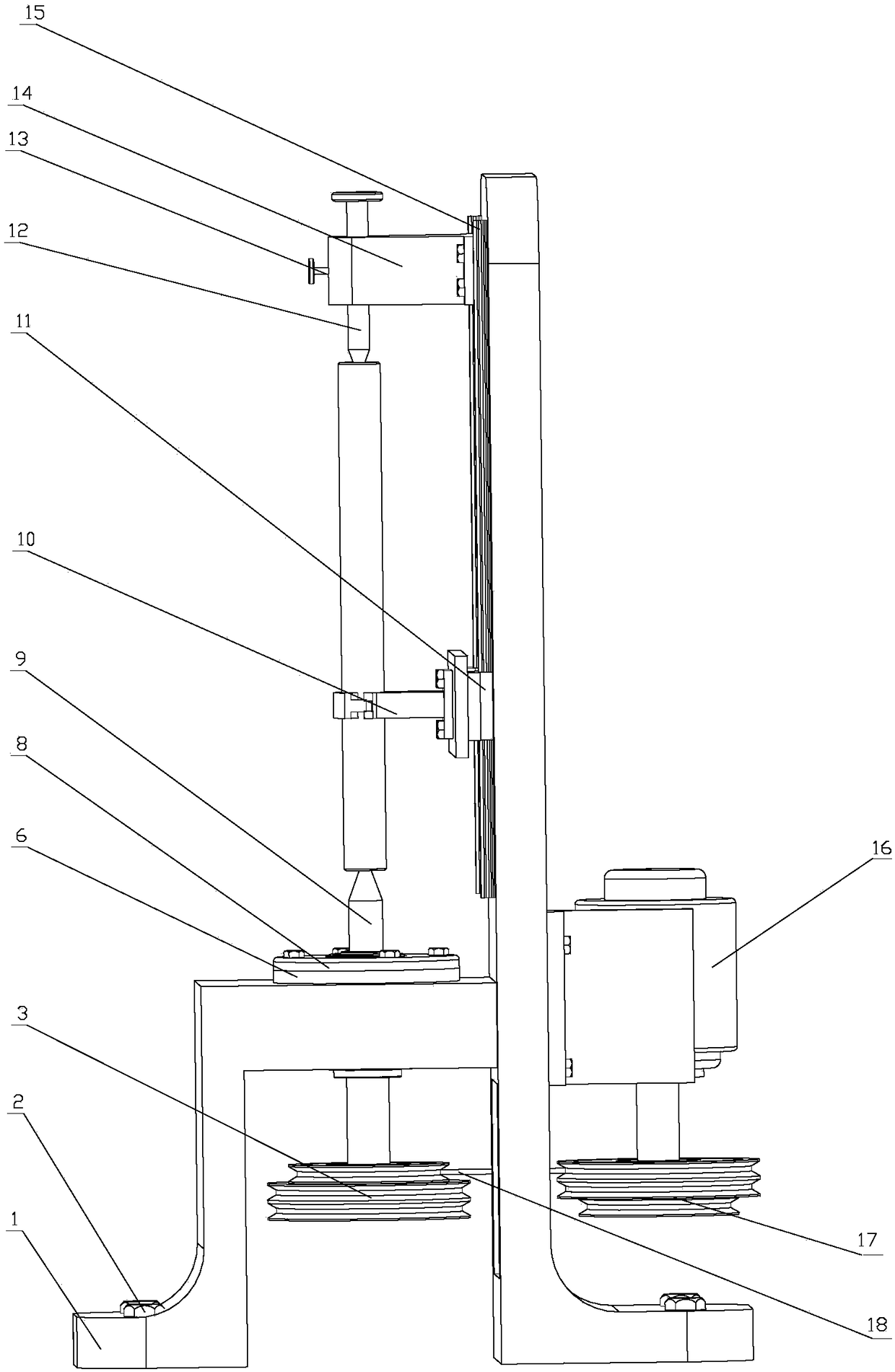

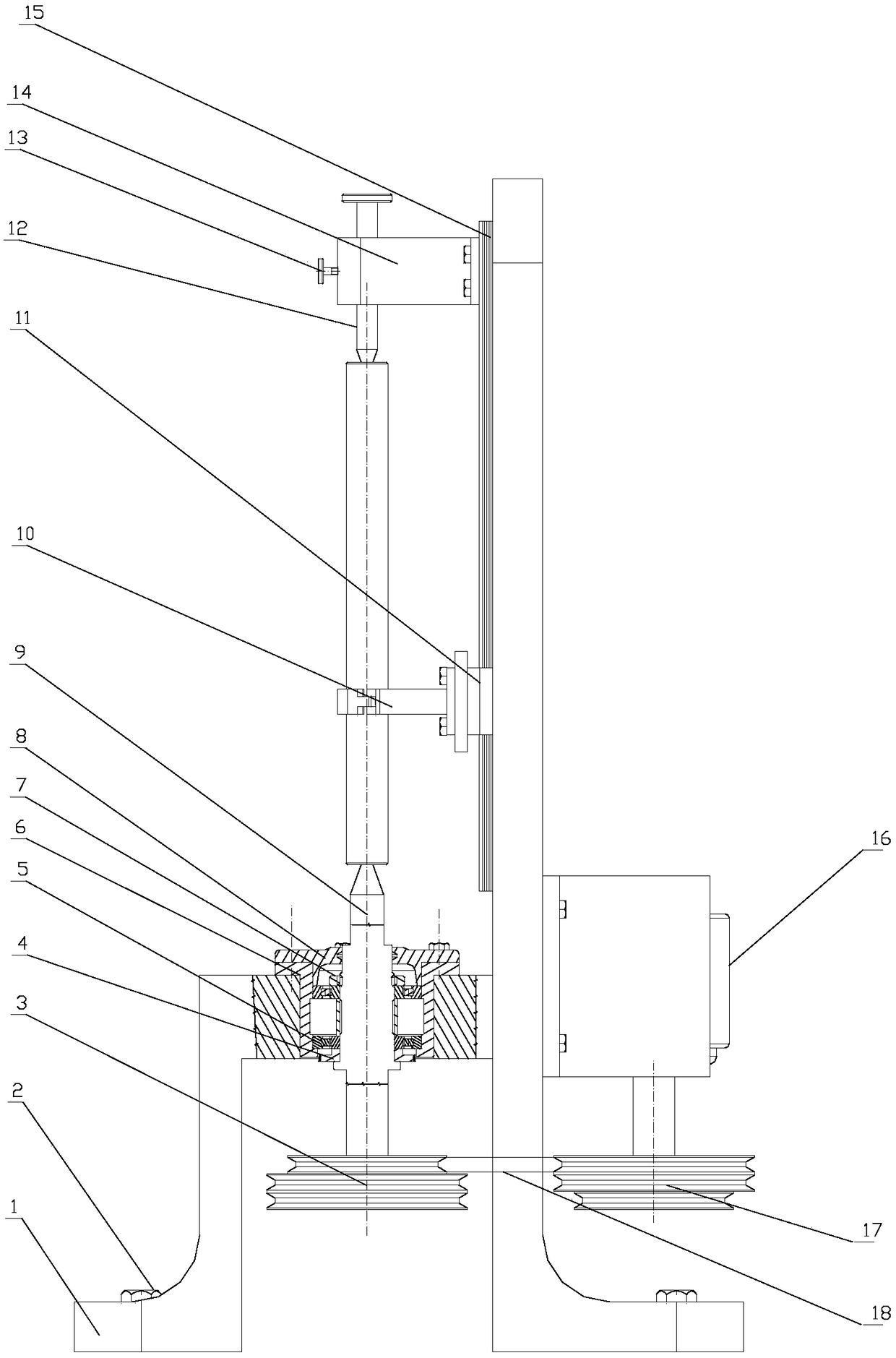

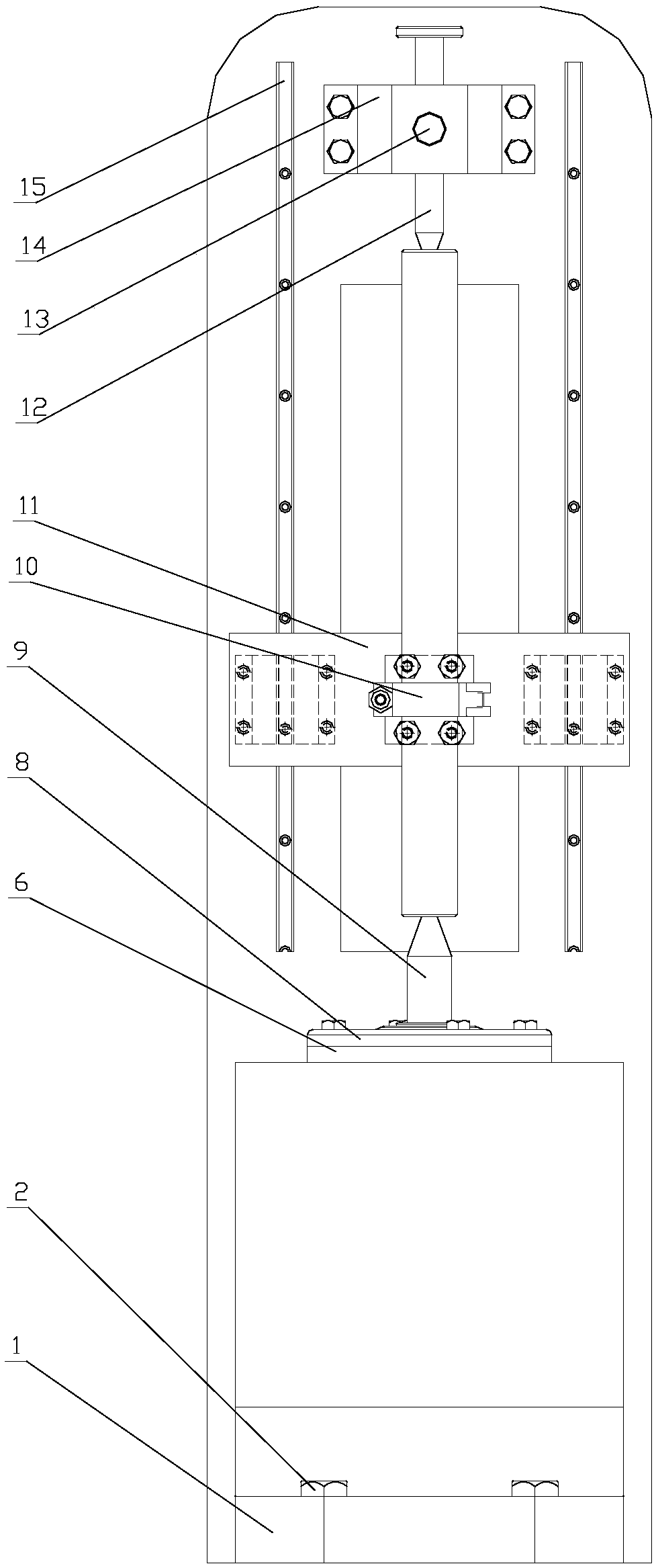

[0016] refer to Figure 1-Figure 3 . In the embodiment described below, a rotary shaft double-headed center hole vertical grinding machine has a π-shaped base 1 and a column plate vertical to the π-shaped base 1 in space, and the π-shaped The base 1 is fixed on the working ground, and the motor gearbox 16 fixed on the non-working surface of the column plate, the pulley 17 assembled on the main shaft of the motor gearbox 16 passes through the hollow of the lower part of the column plate through the transmission belt 18 Holes are connected to the pulley 3 located below the rectangular frame of the π-shaped base 1. The connecting shaft of the belt pulley 3 is provided with an active top 9, and the active top 9 passes through the rolling bearing assembled on the platform of the π-shaped base 1 and the bushing end cover 8 vertically upwards, the bushing 6 is assembled in the transmission hole of the π-shaped base, and the rolling bearing The outer circle of 5 fits in the inner ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com