Profile steel reinforced light steel keel partition wall and construction method

A light steel keel and reinforced technology, which is applied to walls, building components, buildings, etc., can solve the problems of hollowing out in the middle of the installation structure and low strength of the partition wall structure, and achieve the effect of improving the compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

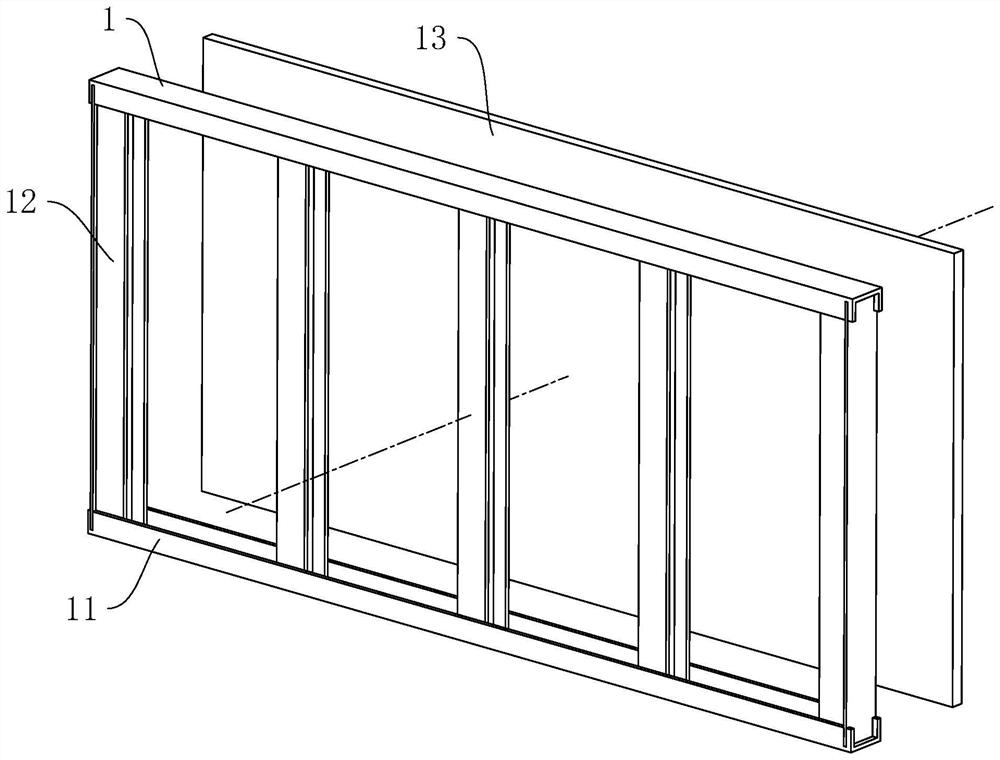

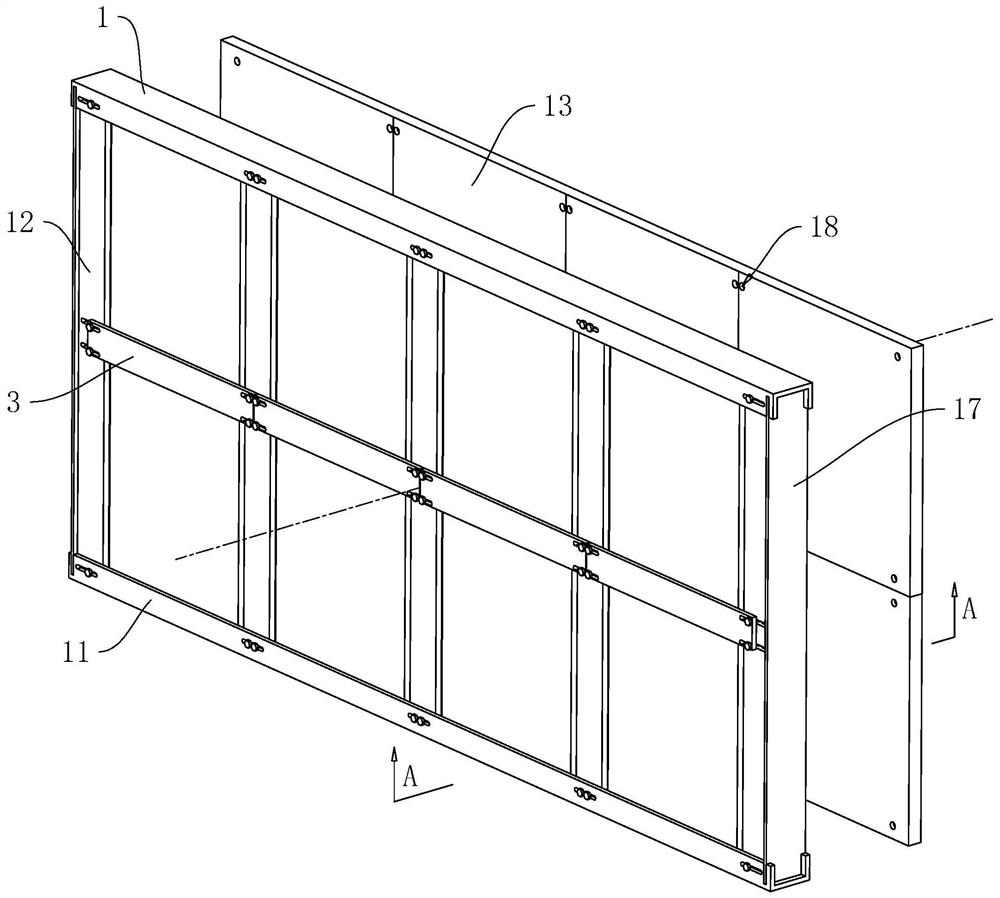

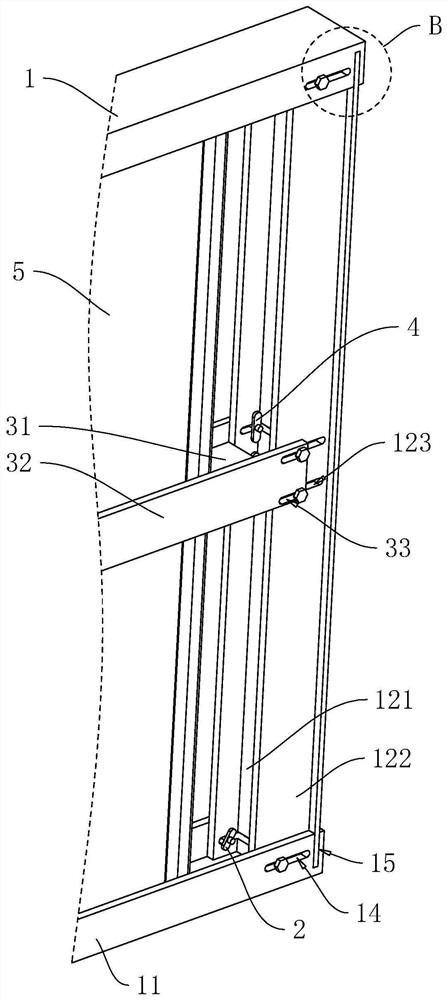

[0046] refer to figure 2 as well as image 3 A steel-reinforced light steel keel partition wall includes a sky keel 1, a ground keel 11, five vertical keels 12 and several wall surfaces 13, the sky keel 1 is fixedly connected to the ceiling, and the ground keel 11 is fixedly connected to the ground. A vertical keel 12 is installed between the sky keel 1 and the ground keel 11 through the second fixing member 2, and two vertically distributed support layers 5 are arranged between two adjacent vertical keels 12, and two adjacent support layers A supporting piece 3 is arranged between the layers 5, and the supporting piece 3 and the vertical keel 12 are connected to each other through the first fixing piece 4. Several walls 13 are arranged on the vertical wall formed by the sky keel 1, the ground keel 11, and the five vertical keels 12. to the plane.

[0047] refer to image 3 as well as Figure 4 The sky keel 1 and the ground keel 11 are both C-shaped steel beams. The verti...

Embodiment 2

[0059] A construction method for a section steel reinforced light steel keel partition wall, comprising the following steps:

[0060] S1: Positioning and setting out;

[0061] S2: Install the sky keel 1 and the ground keel 11;

[0062] S3: Place the first vertical keel 12 between the sky keel 1 and the ground keel 11 and pass the second fixing member 2 through the first waist hole 123 and the third waist hole 14 on the first vertical keel 12, Place several support members 3 on the vertical keel 12, then pass the first fixing member 4 through the first waist-shaped hole 123 and the second waist-shaped hole 33 on the first vertical keel 12, so that the support member 3 is pre-positioned at On the vertical keel 12, put the support plate into several frames formed by the support member 3, the vertical keel 12, the sky keel 1 and the ground keel 11;

[0063] S4: Place the second vertical keel 12 between the sky keel 1 and the ground keel 11 and pass the second fixing member 2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com