High-temperature pipe fitting radial deformation sensing device

A technology of radial deformation and sensing device, applied in measurement devices, mechanical solid deformation measurement, instruments, etc., can solve the problems that measurement technology is difficult to meet long-term online monitoring, material requirements are very strict, installation is difficult, etc., to achieve high engineering applications Value, high linearity and resolution, easy installation and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

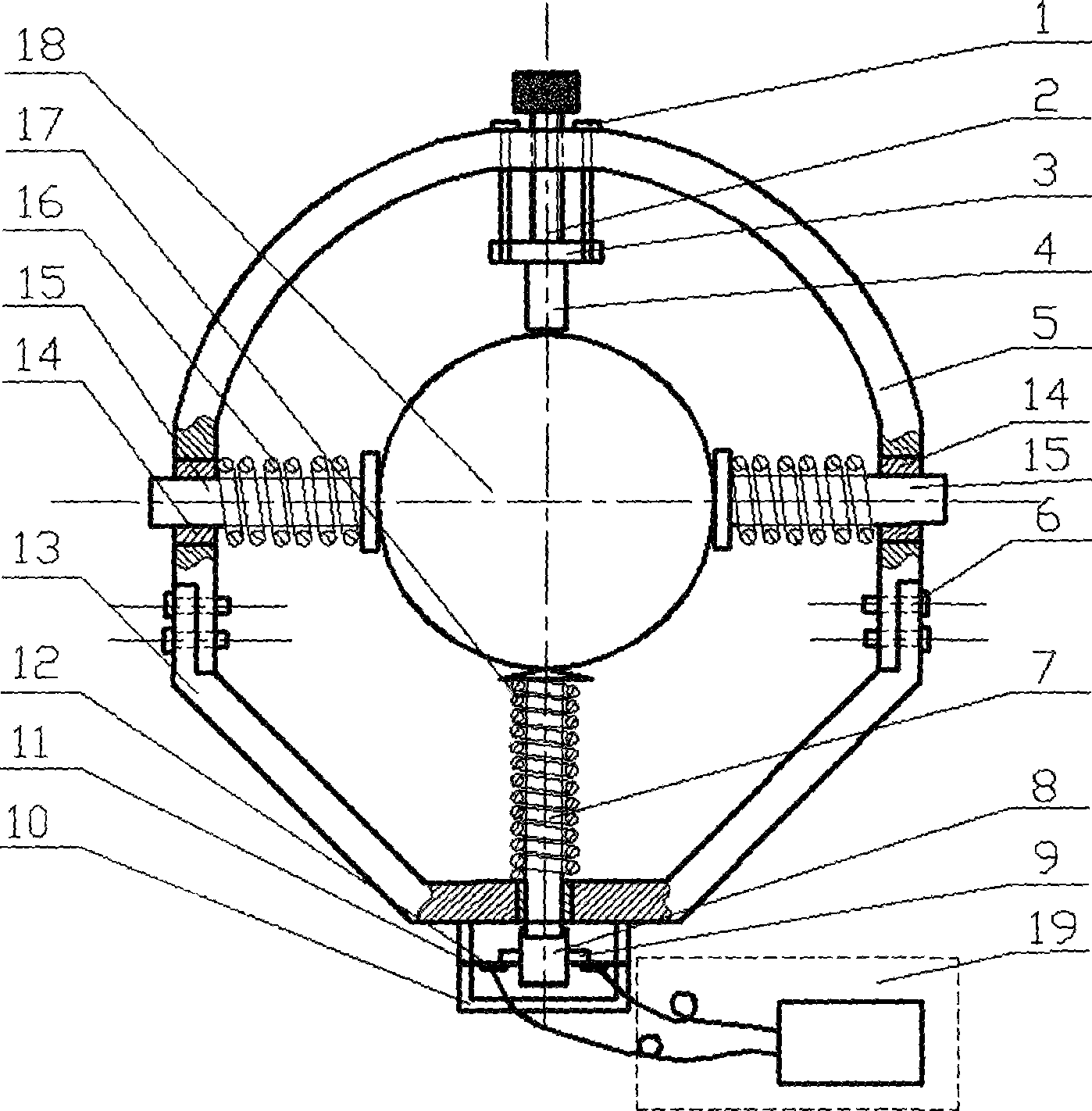

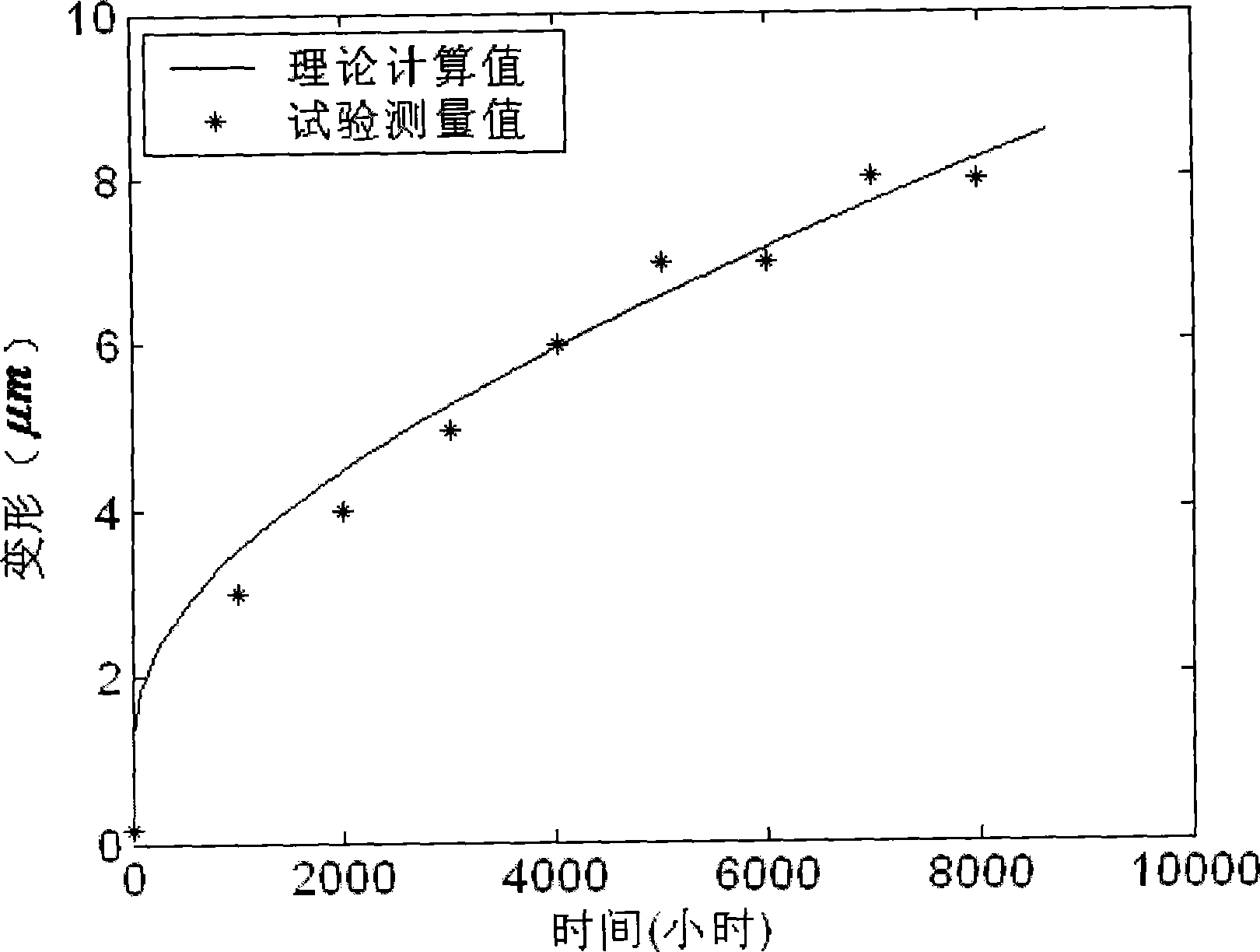

[0029] Simulating the process conditions of the main steam pipeline of a petrochemical plant, the experiment was carried out using the radial deformation sensing device of high temperature pipe fittings. The main parameters of the tested main steam pipeline are: the material is 10CrMo910, the pressure is 10Mpa, the temperature is 540°C, the specification is Φ273mm×28mm, and the thickness of the insulation layer is 200mm. The main structural dimensions of the prototype used in the test are: the fixture width is 26mm and the thickness is 10mm, the measuring probe 7 is 250mm long, the stabilizing rod 15 is 230mm long; the bearing 14 is made of polytetrafluoroethylene, the length is 20mm, the inner diameter is 10mm, 16mm in diameter.

[0030] Assemble the radial deformation sensing device of high-temperature pipe fittings according to the above parameters, open the insulation layer of the pipe, and fix it on the pipe. Connect the signal output wire of the strain gauge test termin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com