Patents

Literature

61results about How to "Minimize amount of material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

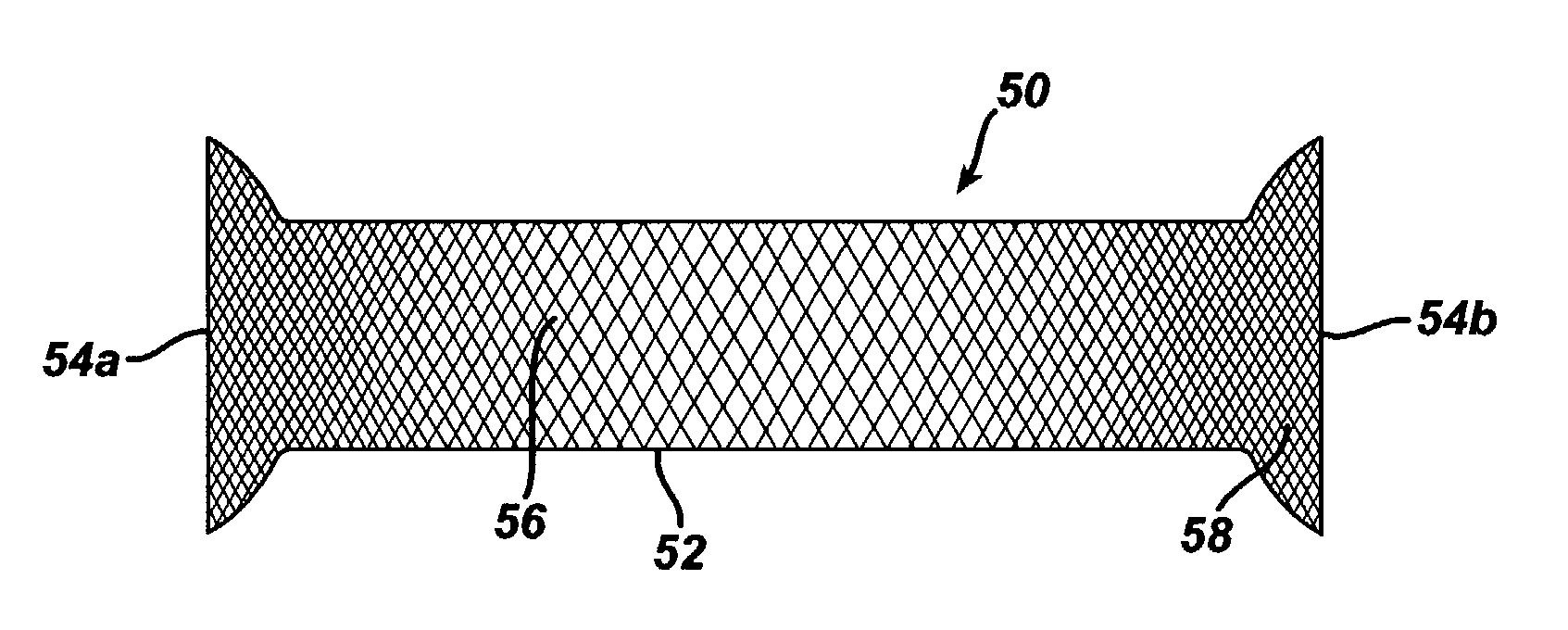

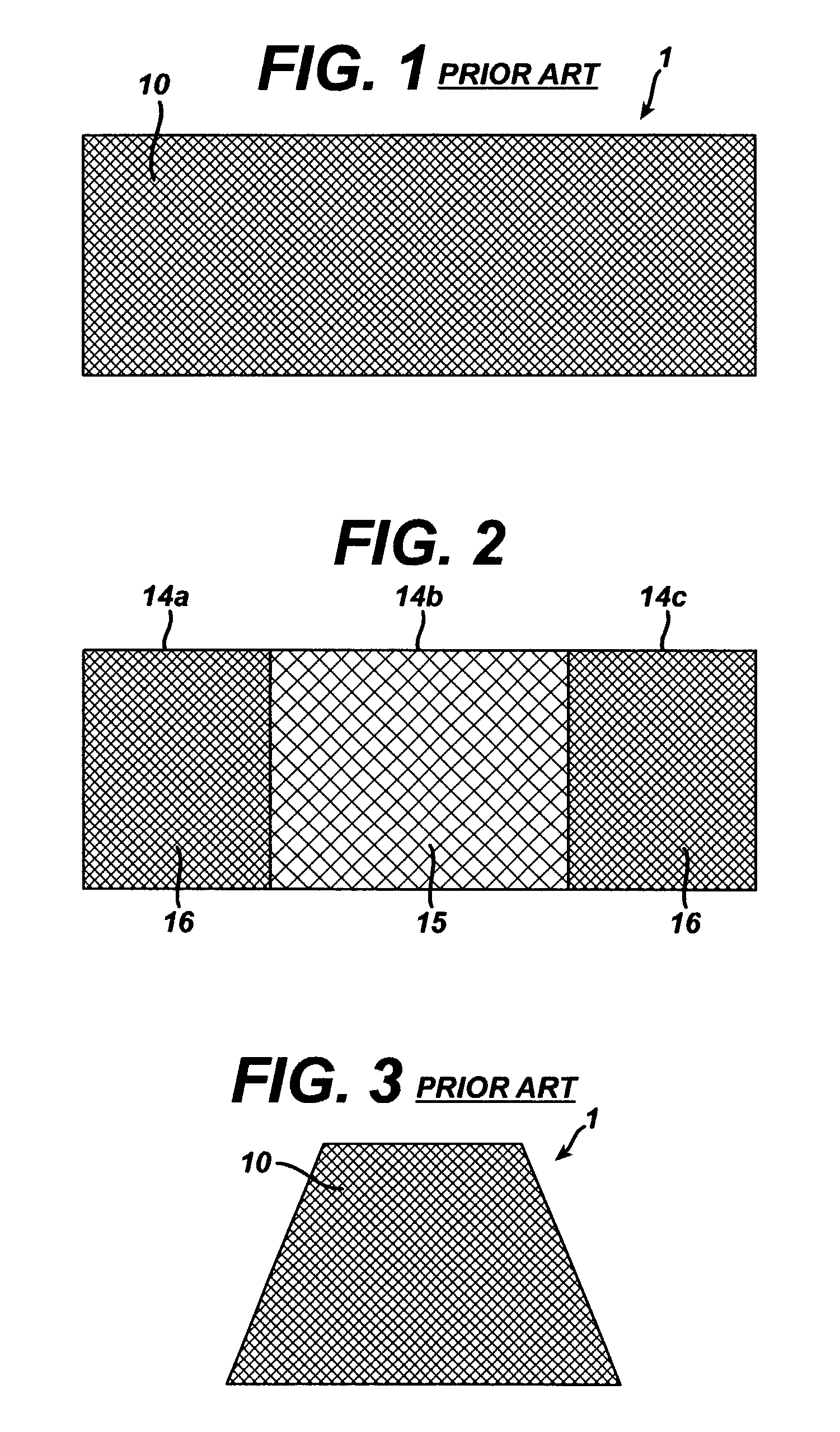

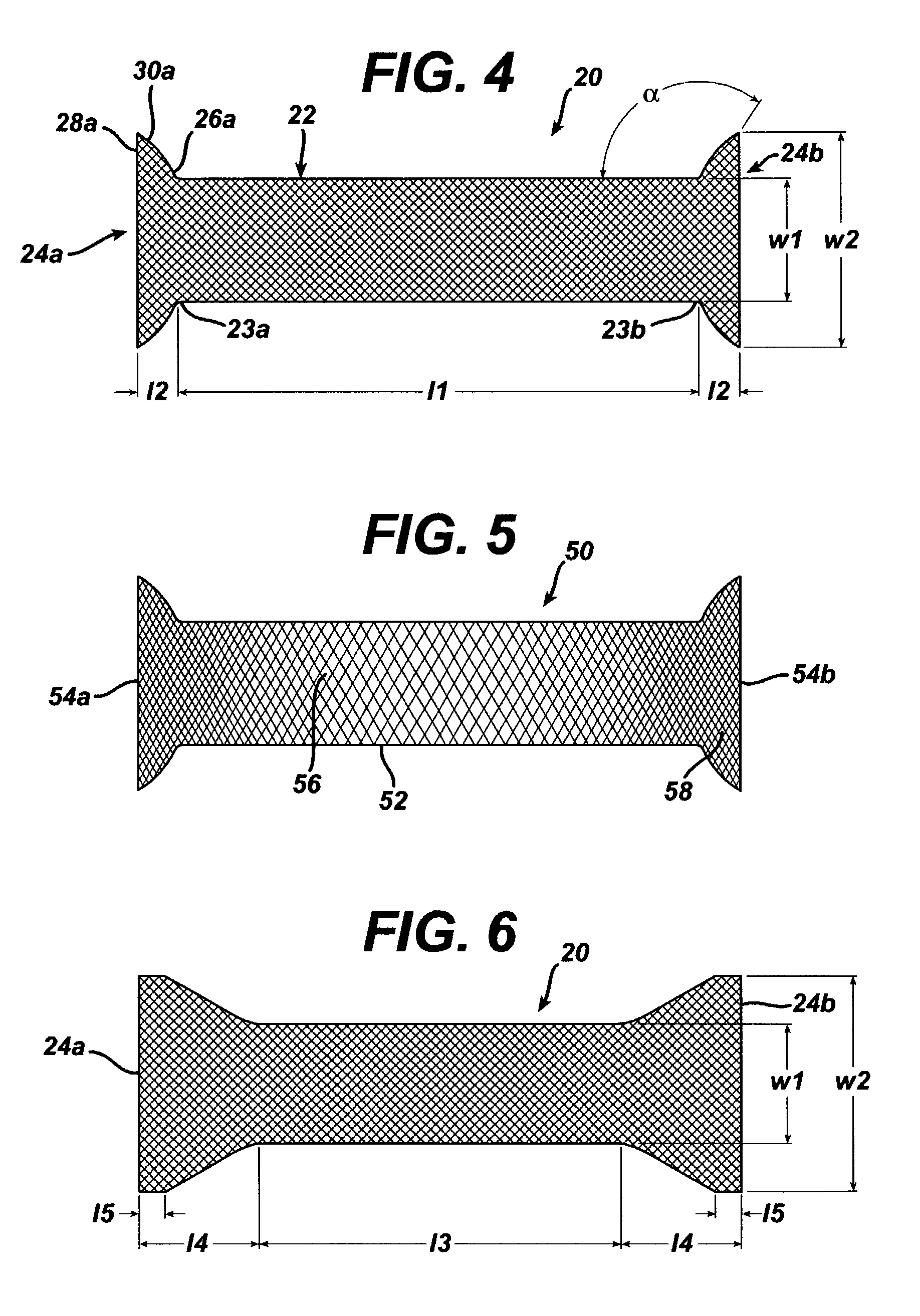

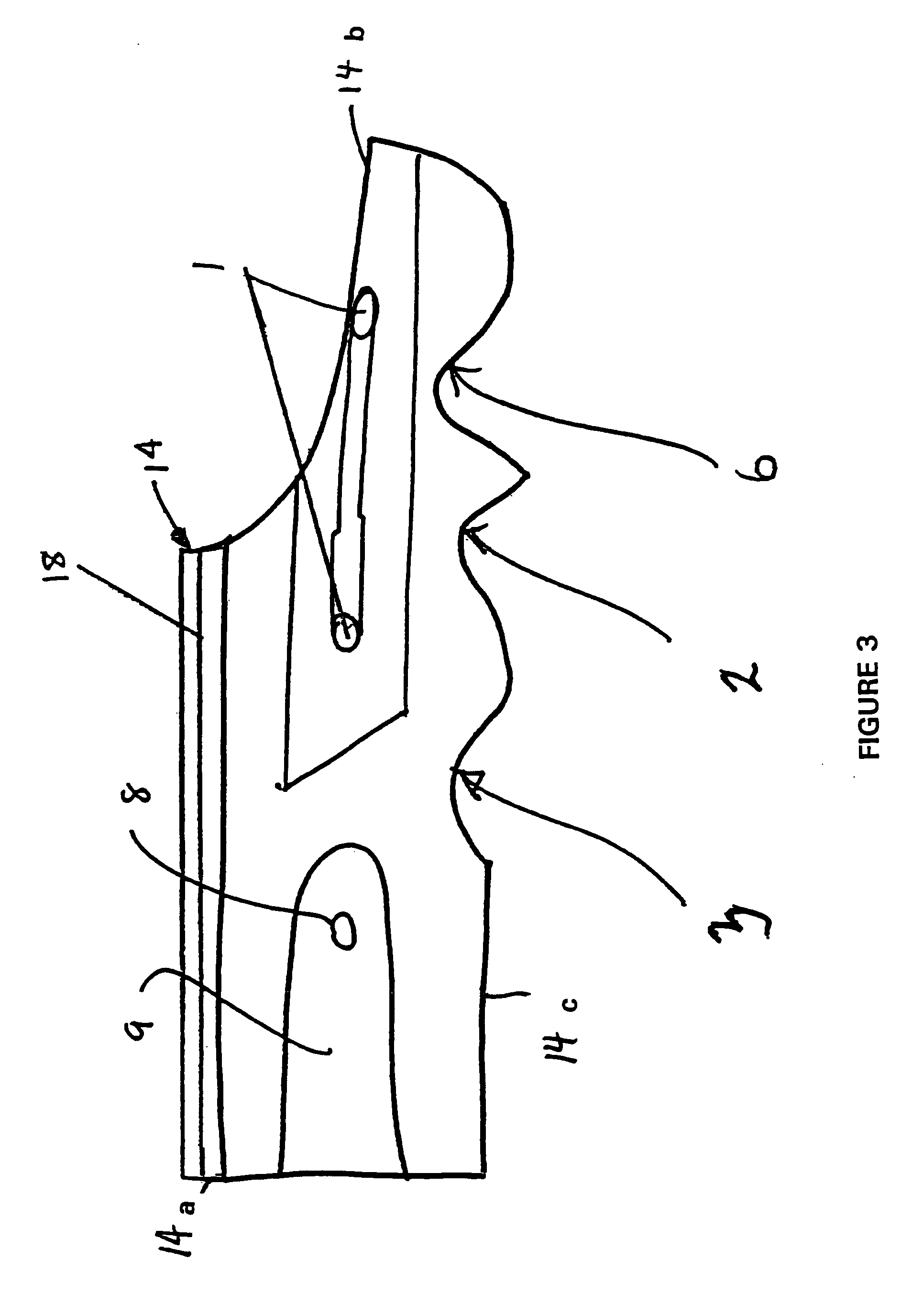

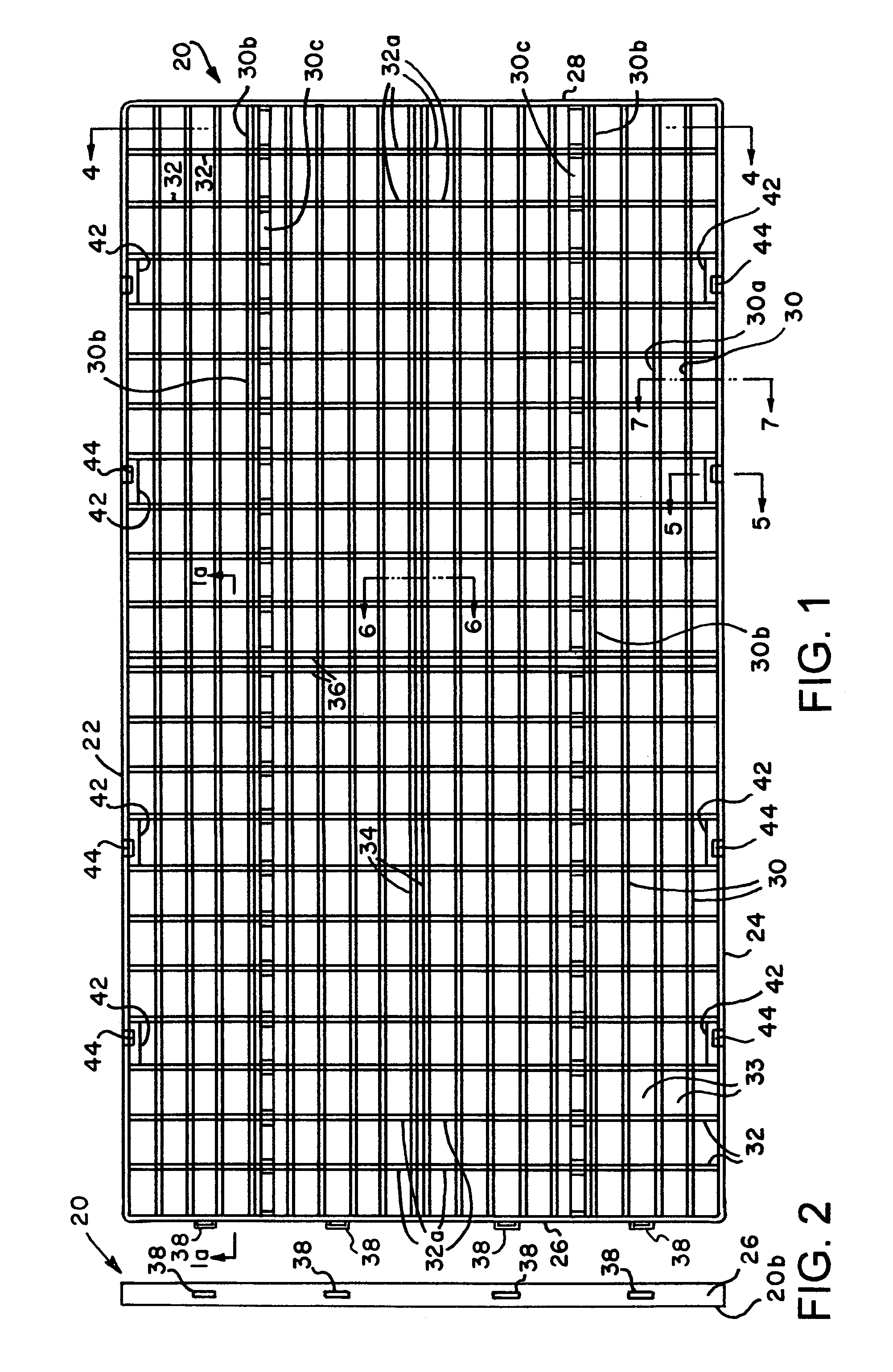

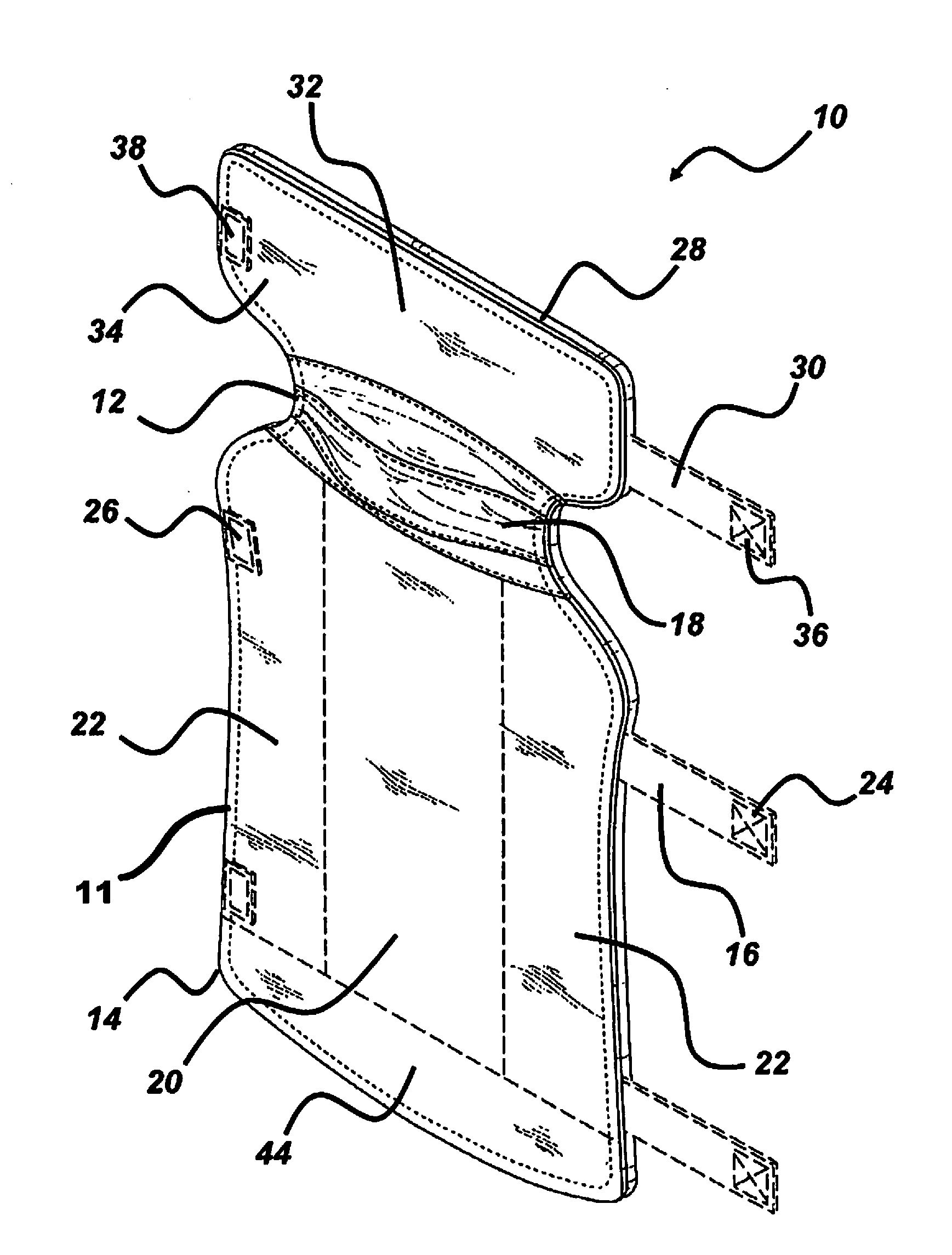

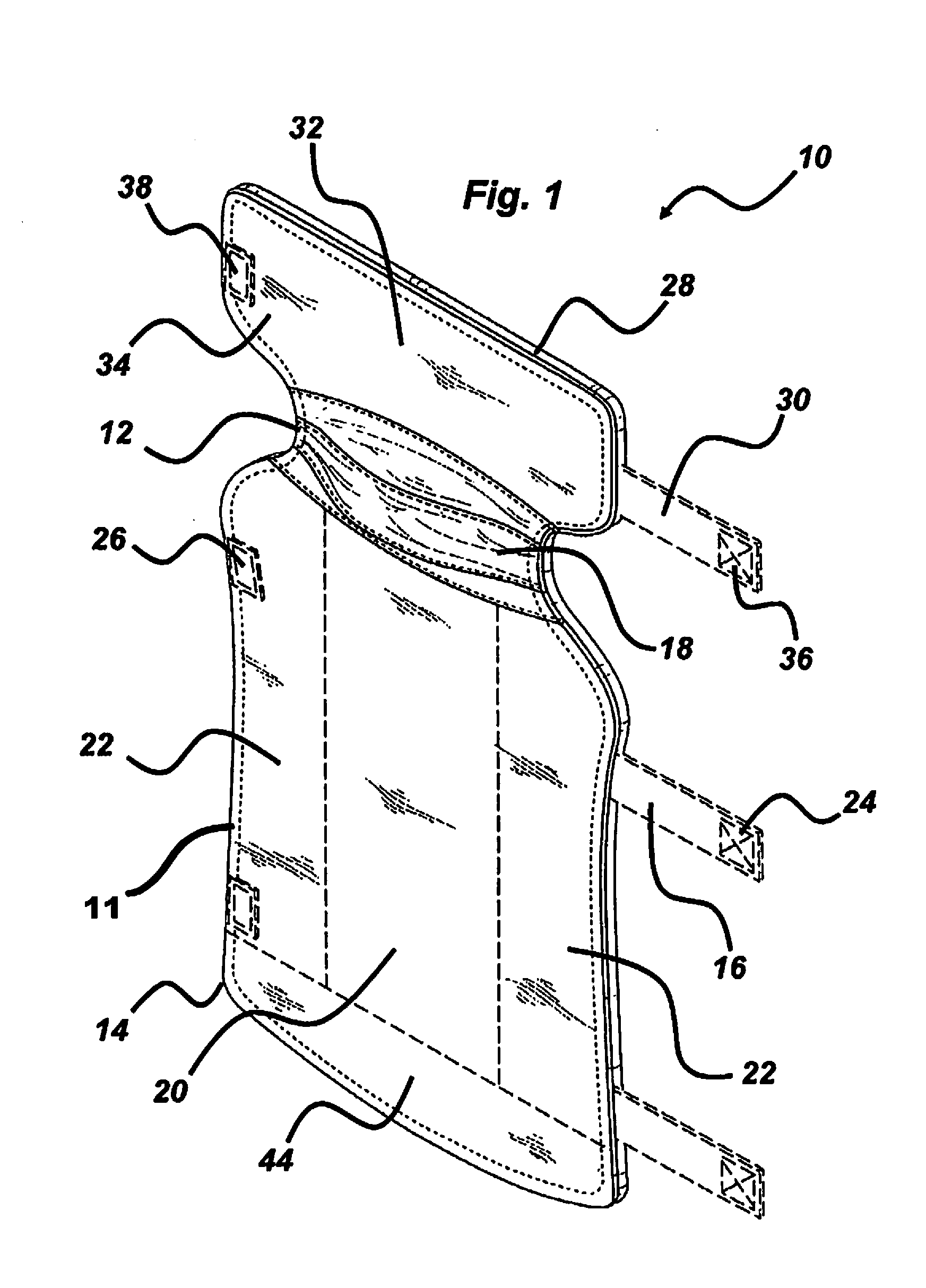

Mesh for pelvic floor repair

InactiveUS7087065B2Reduce vaginal prolapseIncrease heightSuture equipmentsAnti-incontinence devicesPelvisPelvic floor repair

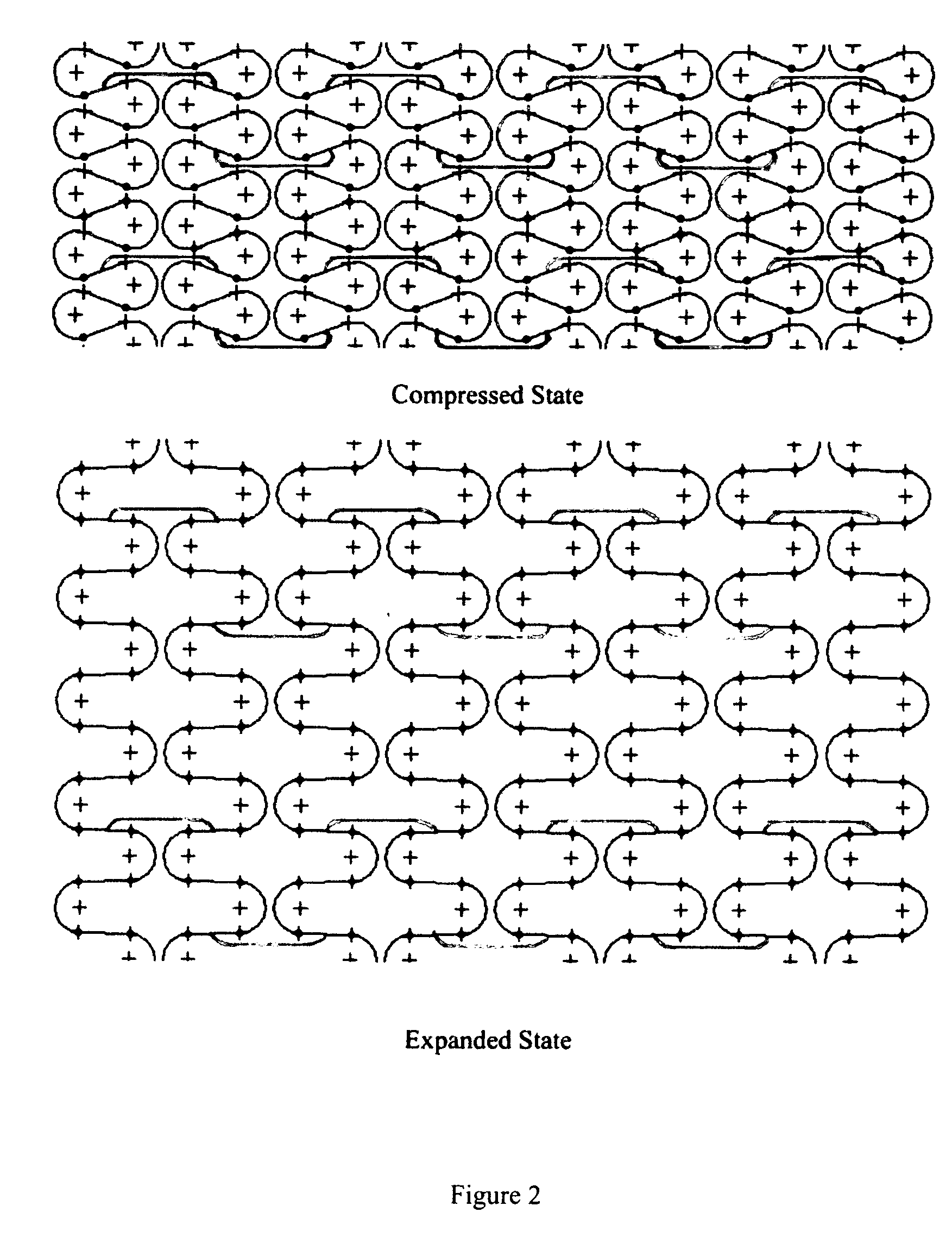

A woven mesh is provided for supporting tissue or an organ within a female patient's pelvis, and a method for using the same. The mesh includes a central portion having a width, a length, first and second ends, and first and second side edges, and first and second wing portions extending from the first and second ends of the central portion respectively. The first and second wing portions each have a width, a length, and first and second peripheral edges. The width of the wing portions are each greater than the width of the central portion, and when positioned within the female patient, the central portion is positioned below and supports the tissue or organ. A mesh is also provided having woven fibers with voids therebetween, and having a central portion and first and second ends. The average size of the voids at least in the central portion is at least 25–50 mm2, and when positioned within the patient, the central portion is positioned below and supports the tissue or organ.

Owner:ETHICON INC

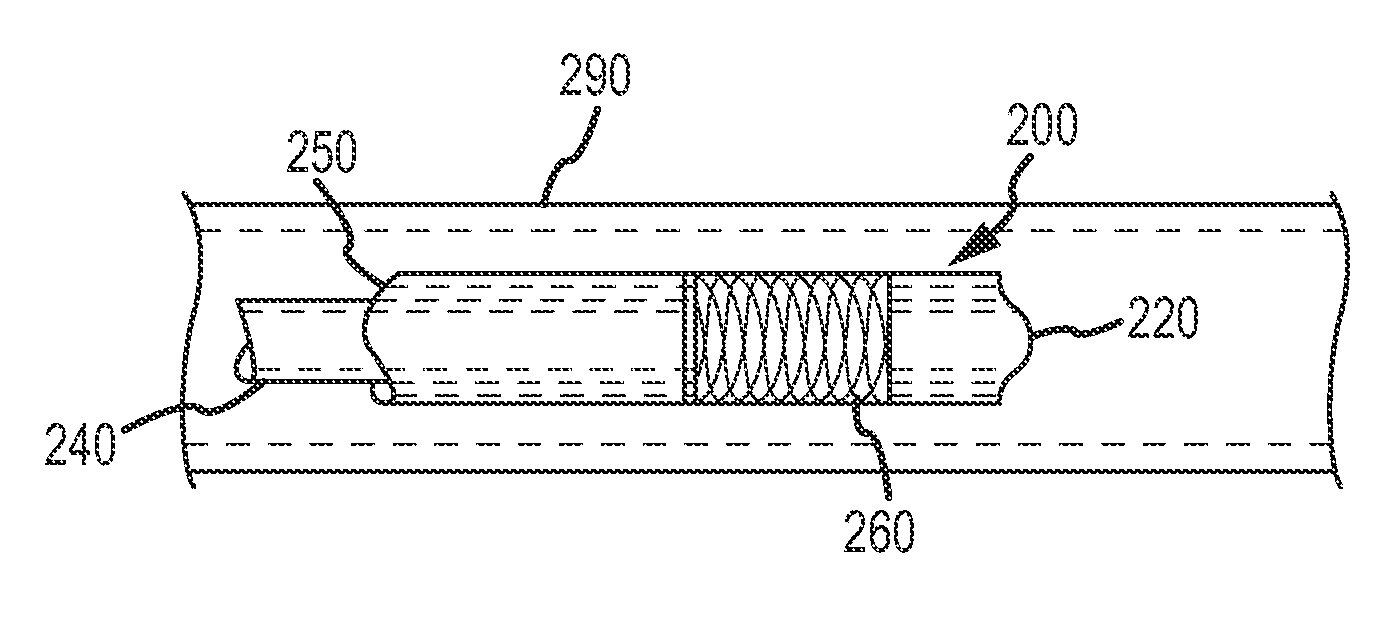

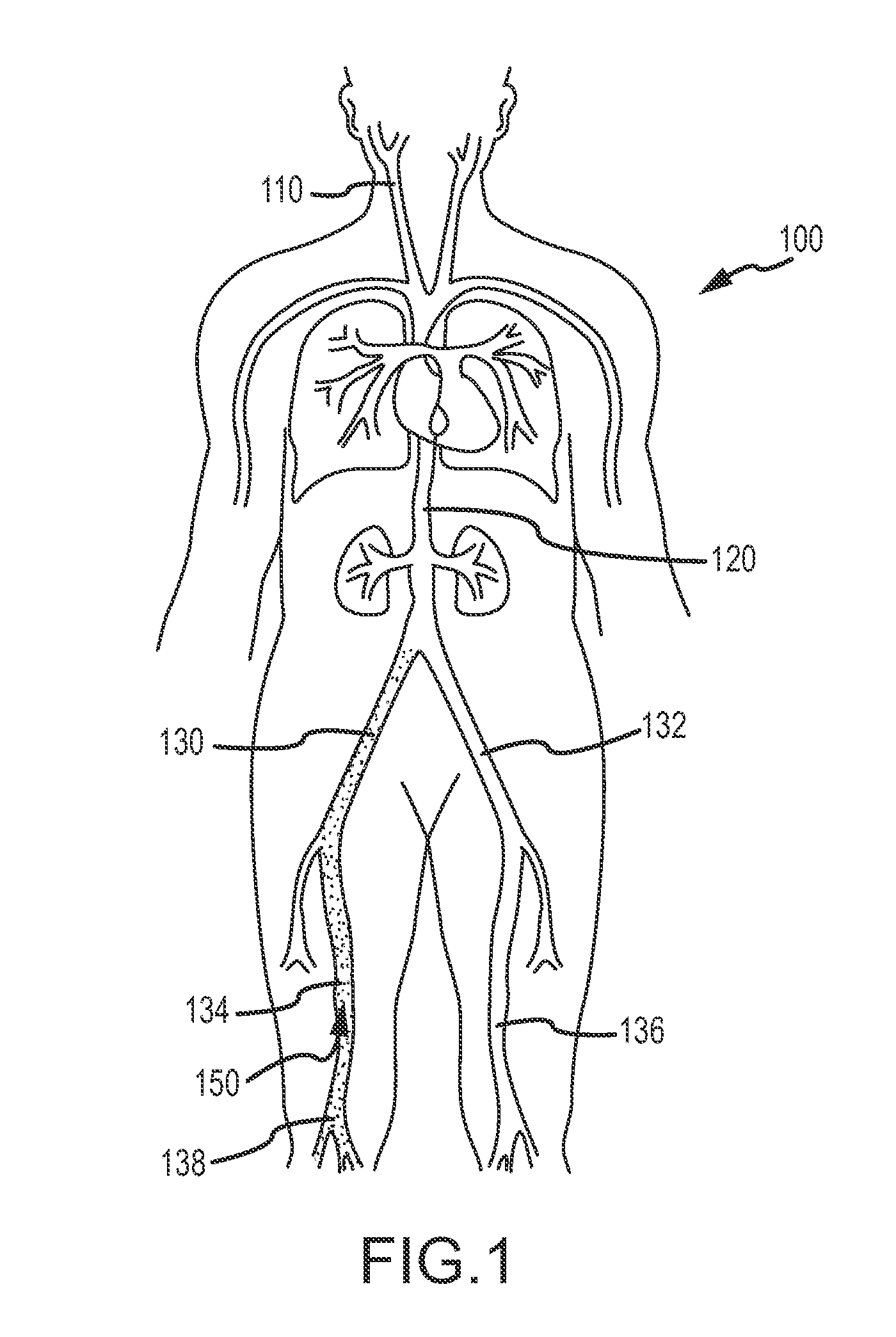

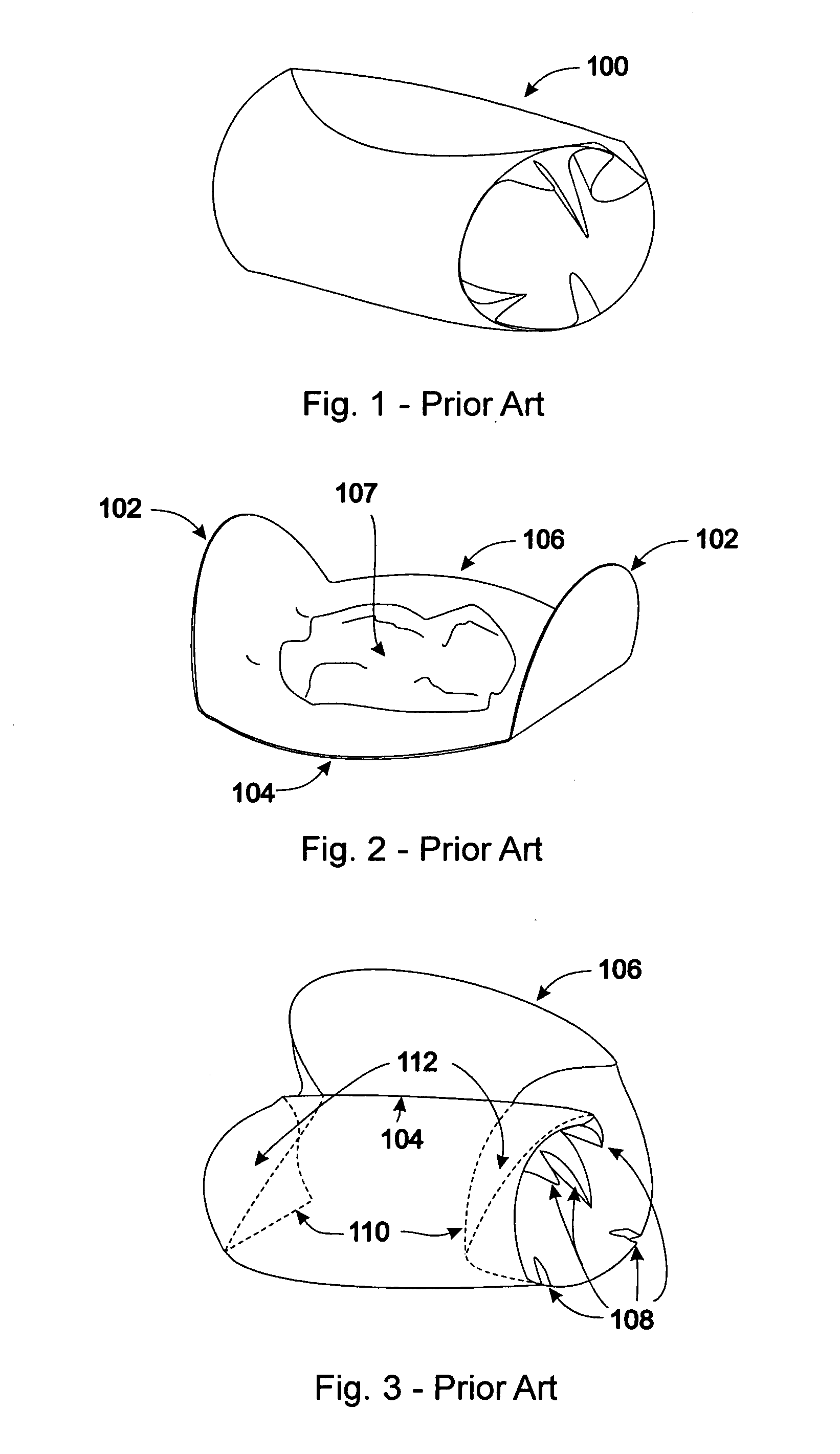

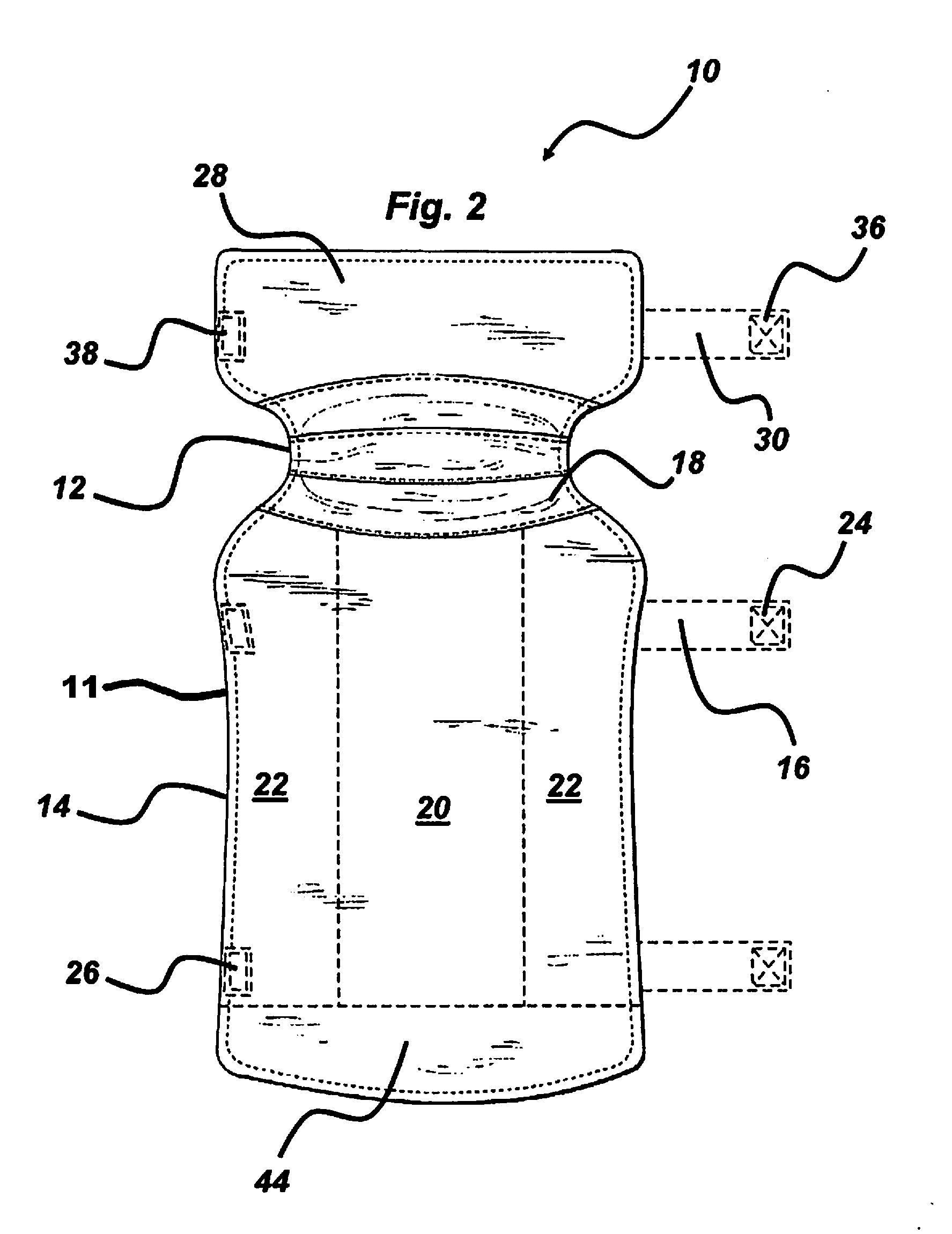

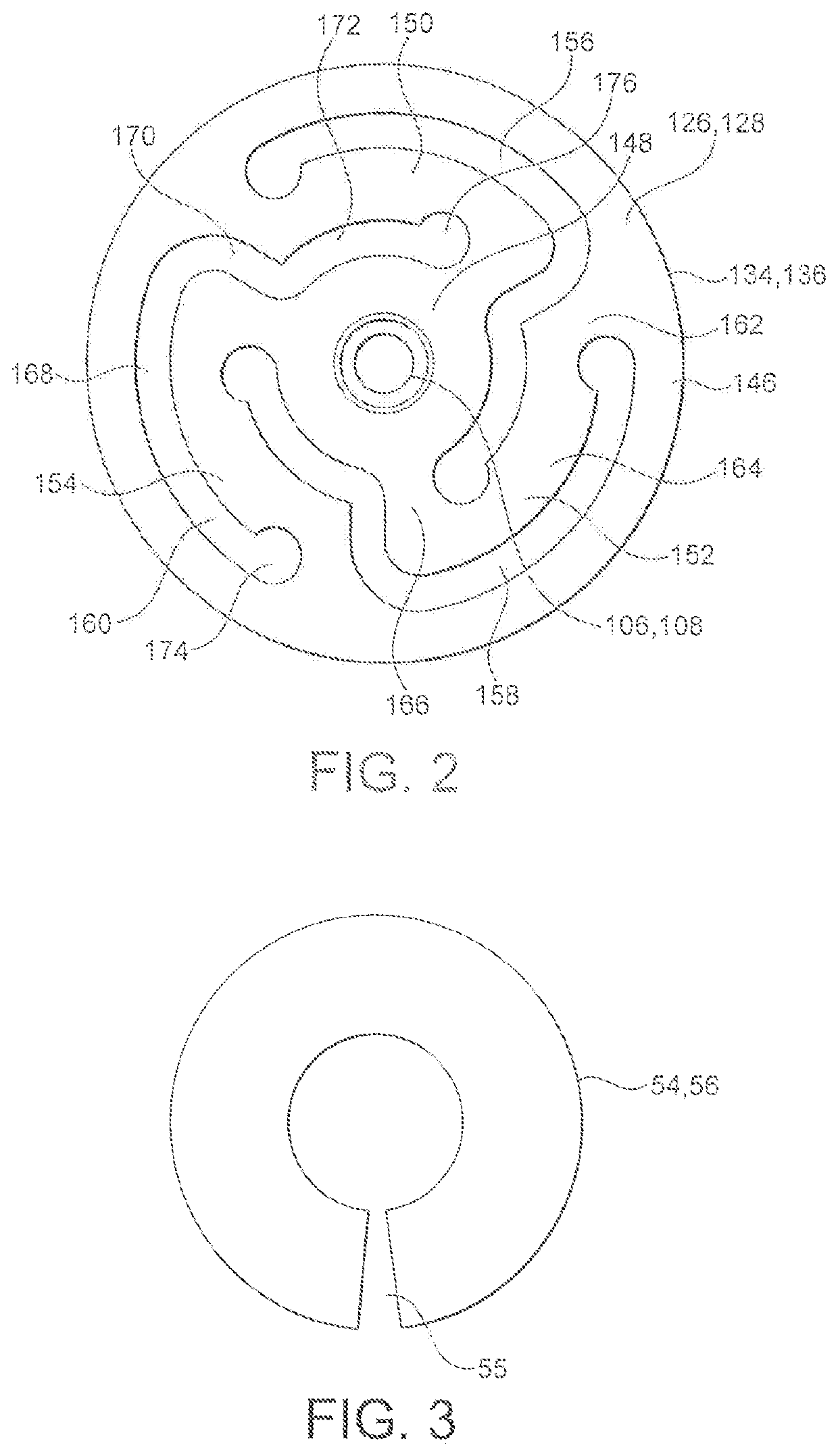

Devices and methods for treating venous diseases

ActiveUS20120022579A1Simple pliablePrevent backflowDilatorsExcision instrumentsDiseaseVenous disease

The present invention relates generally to a medical device and method of use, and more specifically to a method and apparatus with coaxial components used to treat venous diseases. The apparatus according to various embodiments operates as an inferior vena cava filter, a clot puller, a clot shredder, and as a prosthetic venous valve.

Owner:VASCULAR DEV CORP LLC

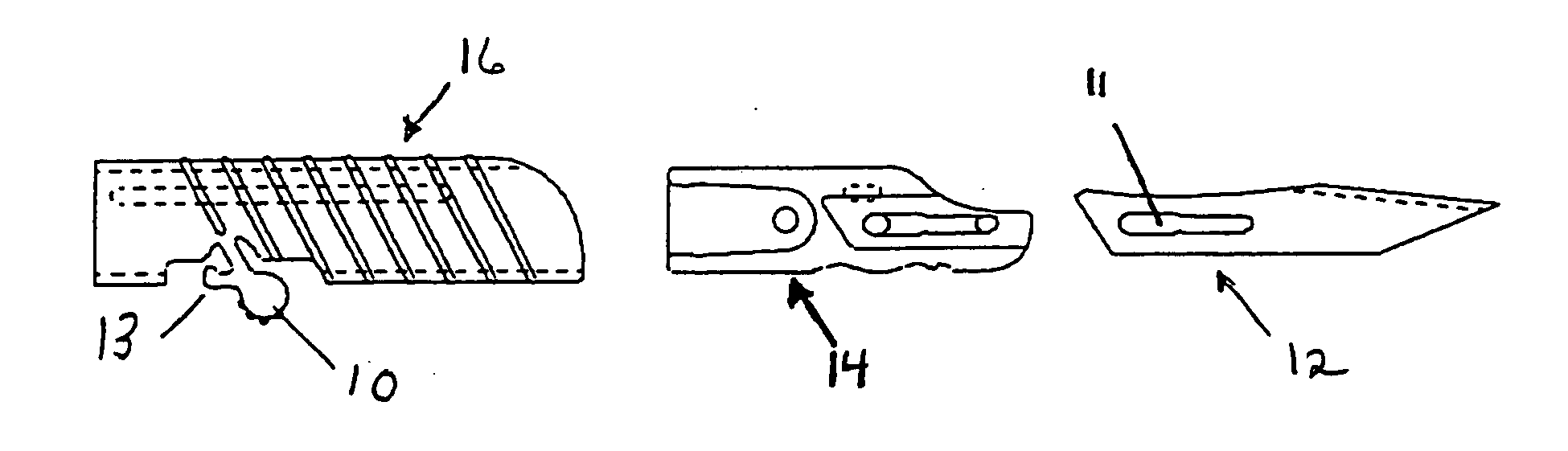

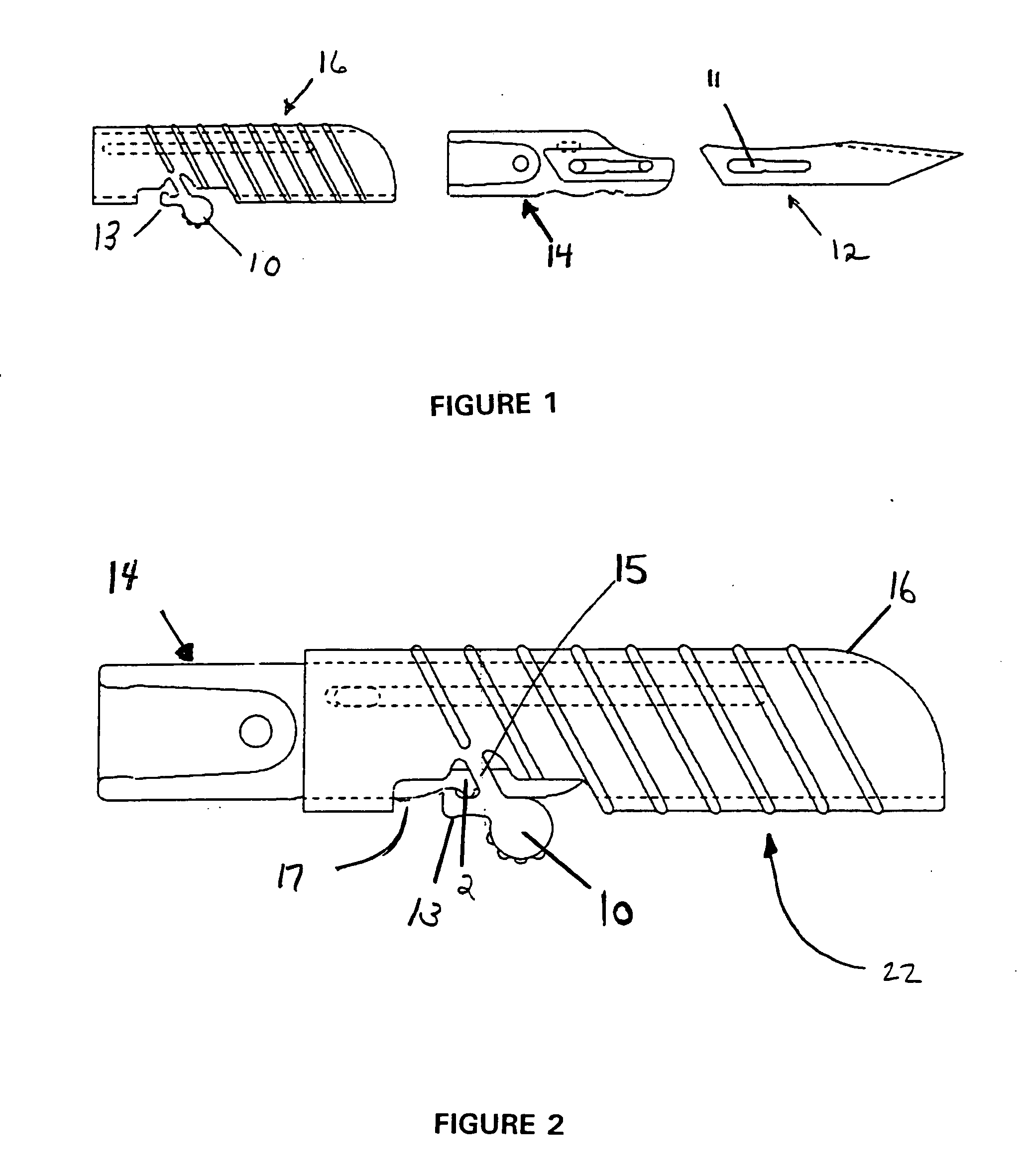

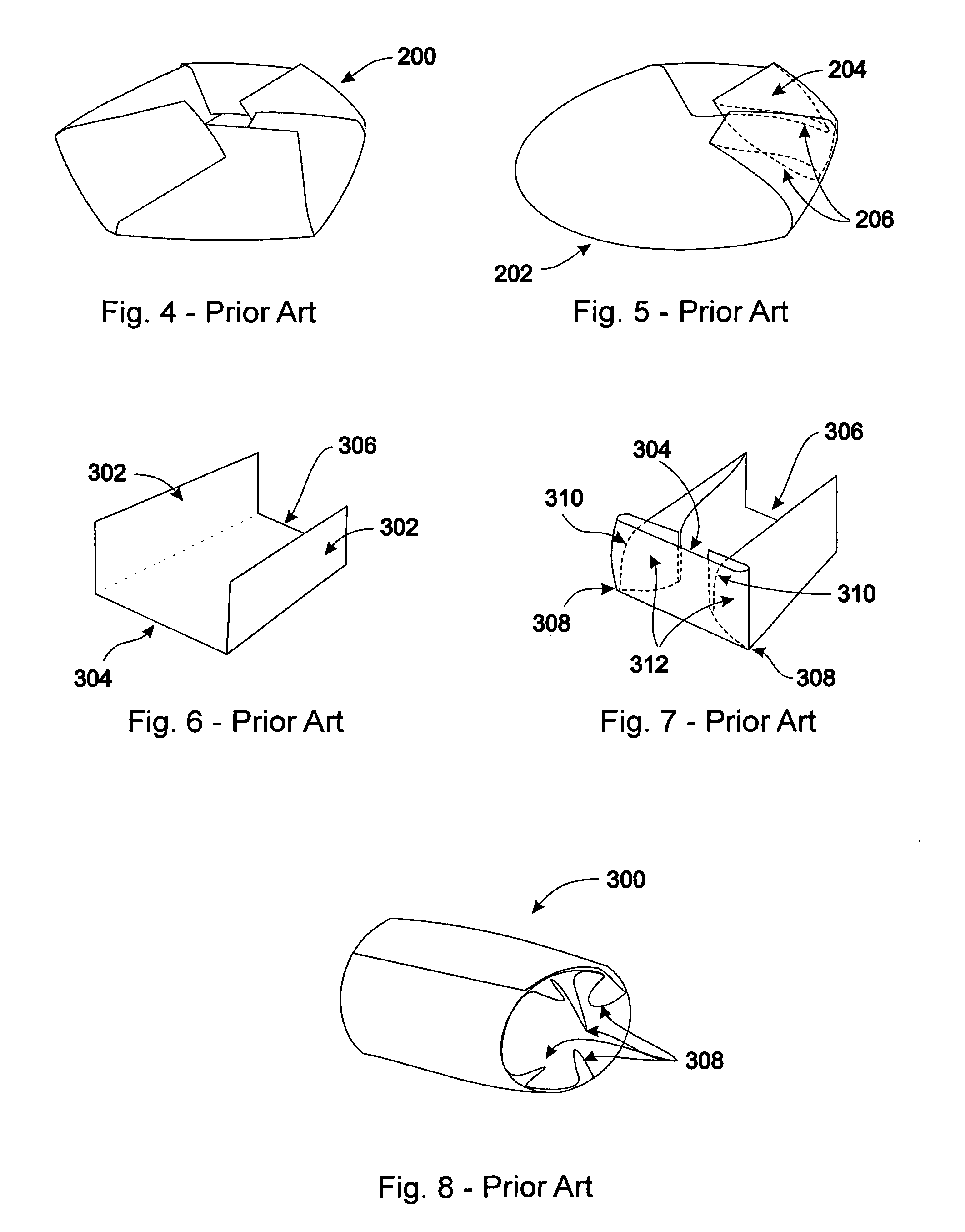

Disposable safety surgical blade

InactiveUS20060212058A1Minimize wasteLow tooling costIncision instrumentsSurgical knifeSurgical department

A surgical scalpel assembly includes a blade carrier, a blade, a protective sleeve and a handle. The blade carrier has a number of notches and the protective sleeve has a depending tooth. The user positions the sleeve relative to the blade carrier and / or the handle by positioning the tooth to engage the notches. The blade carrier, blade, and protective sleeve are pre-assembled as a cartridge. A high volume yet safe method of assembly is also described.

Owner:PL MEDICAL

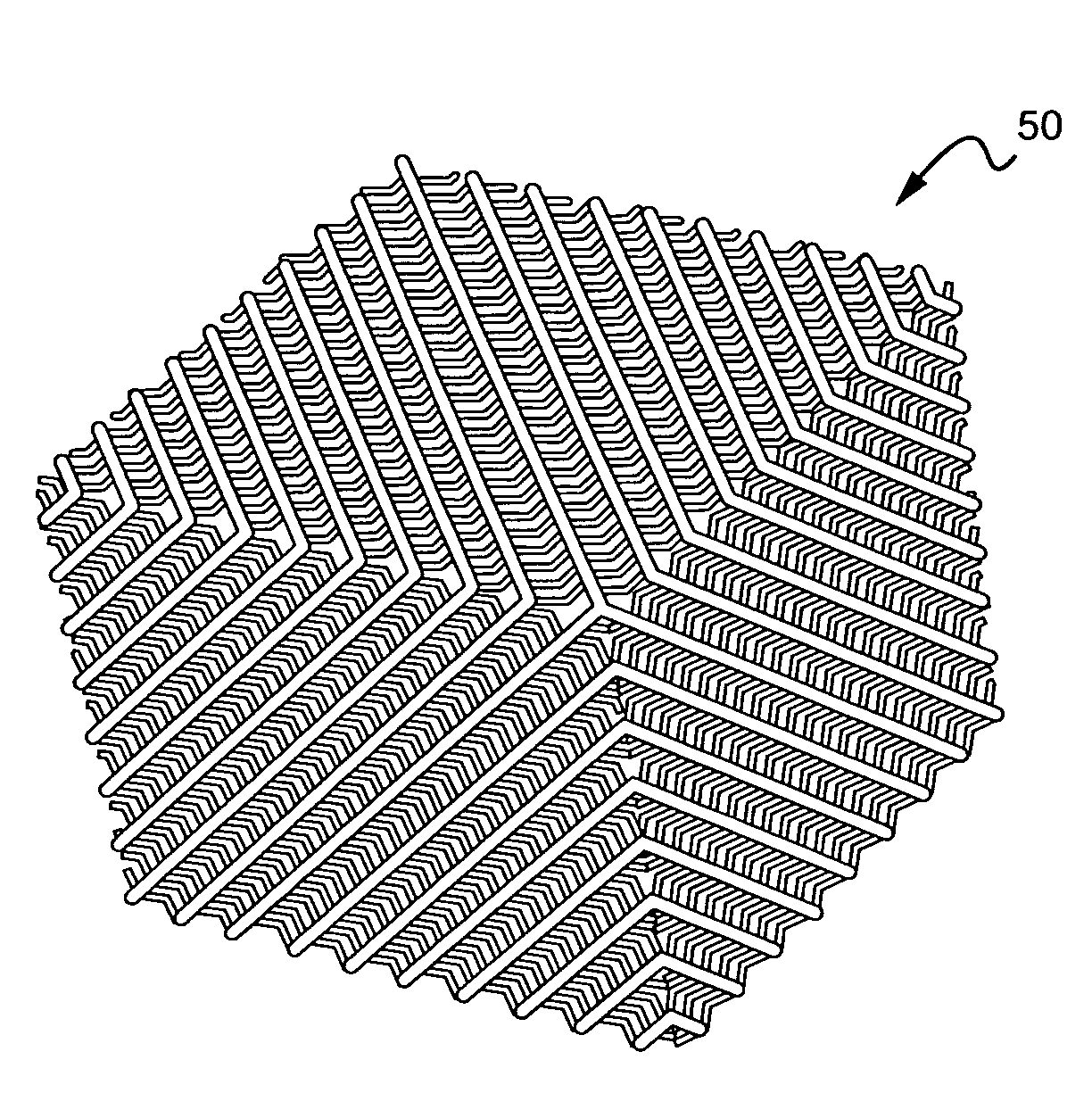

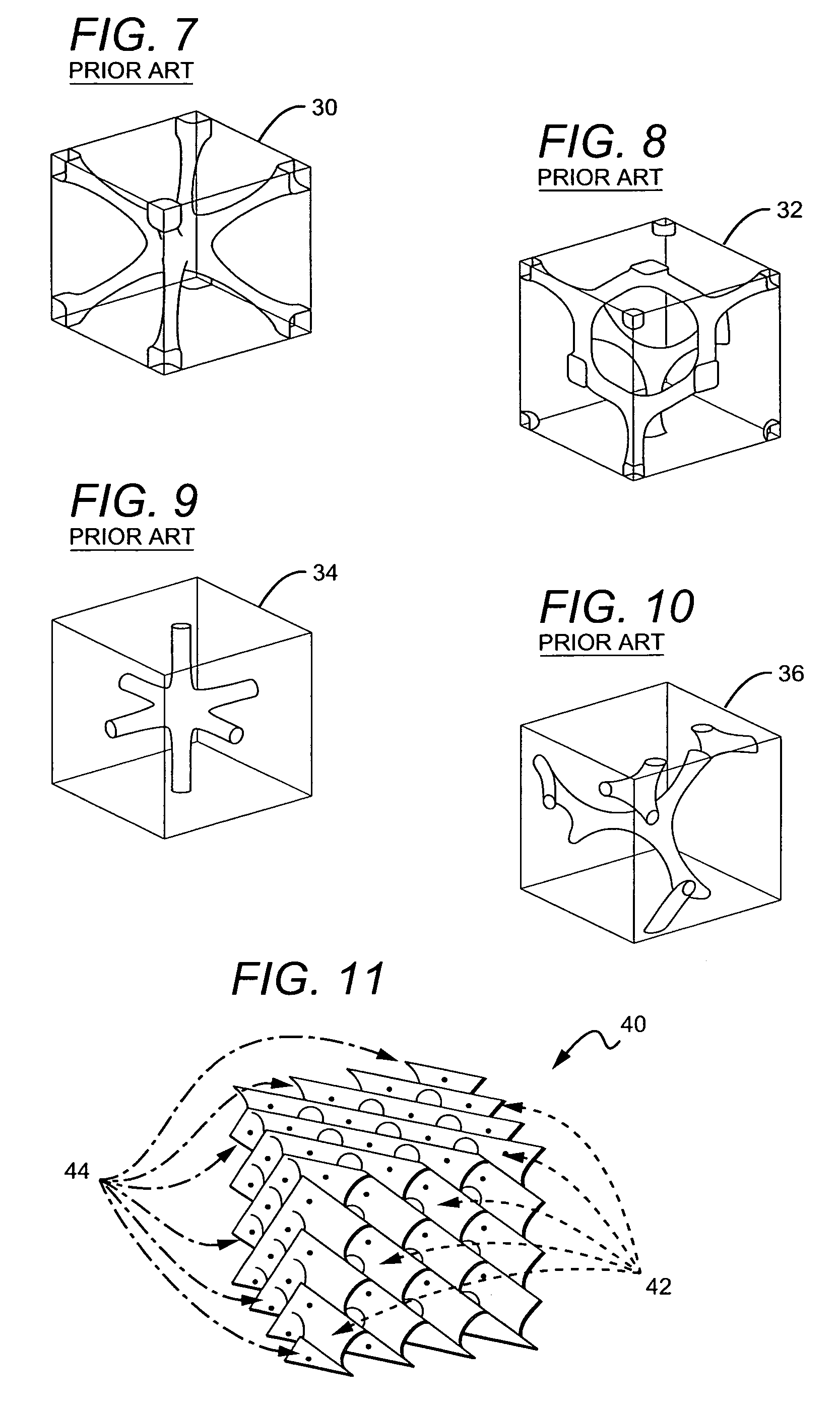

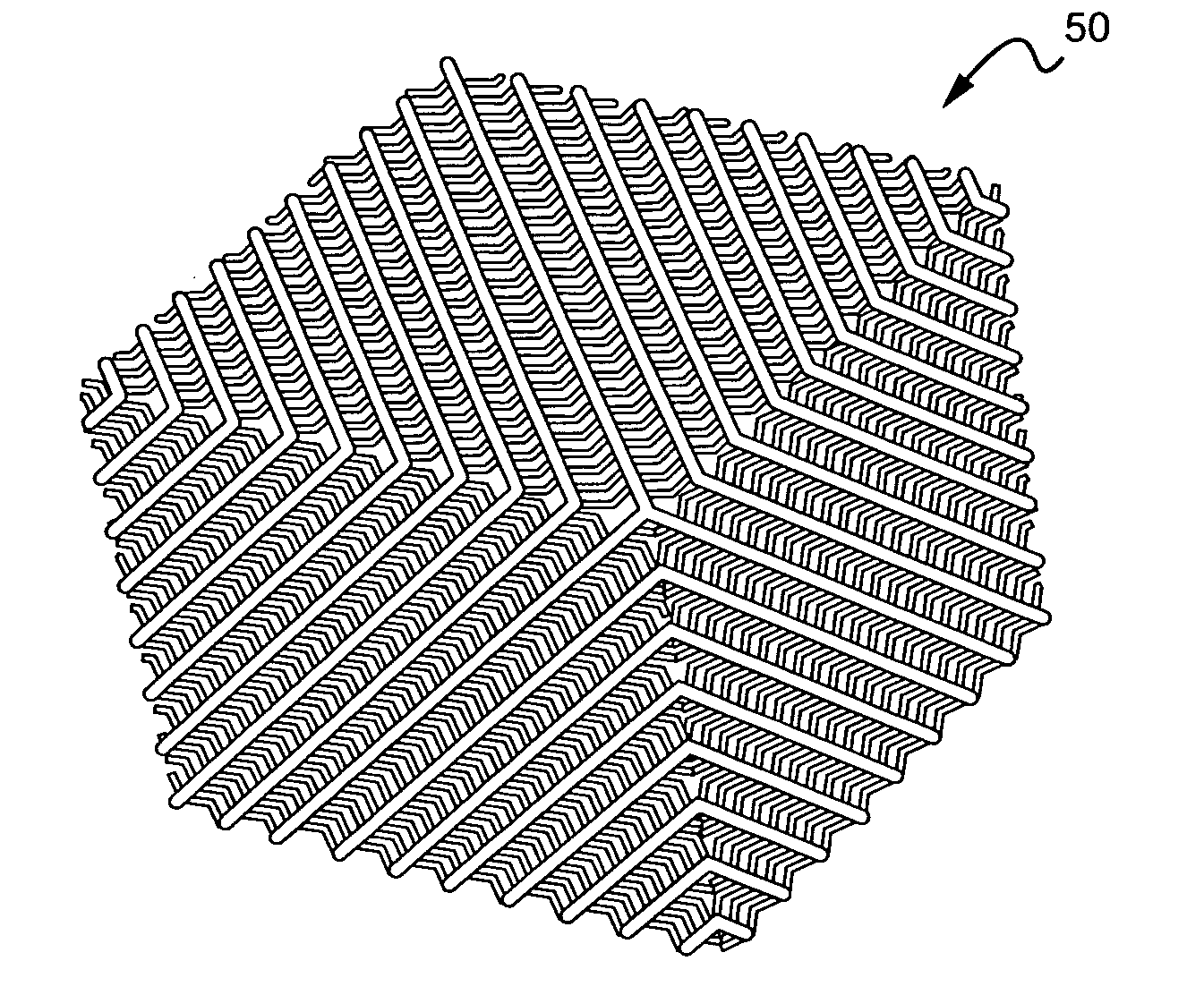

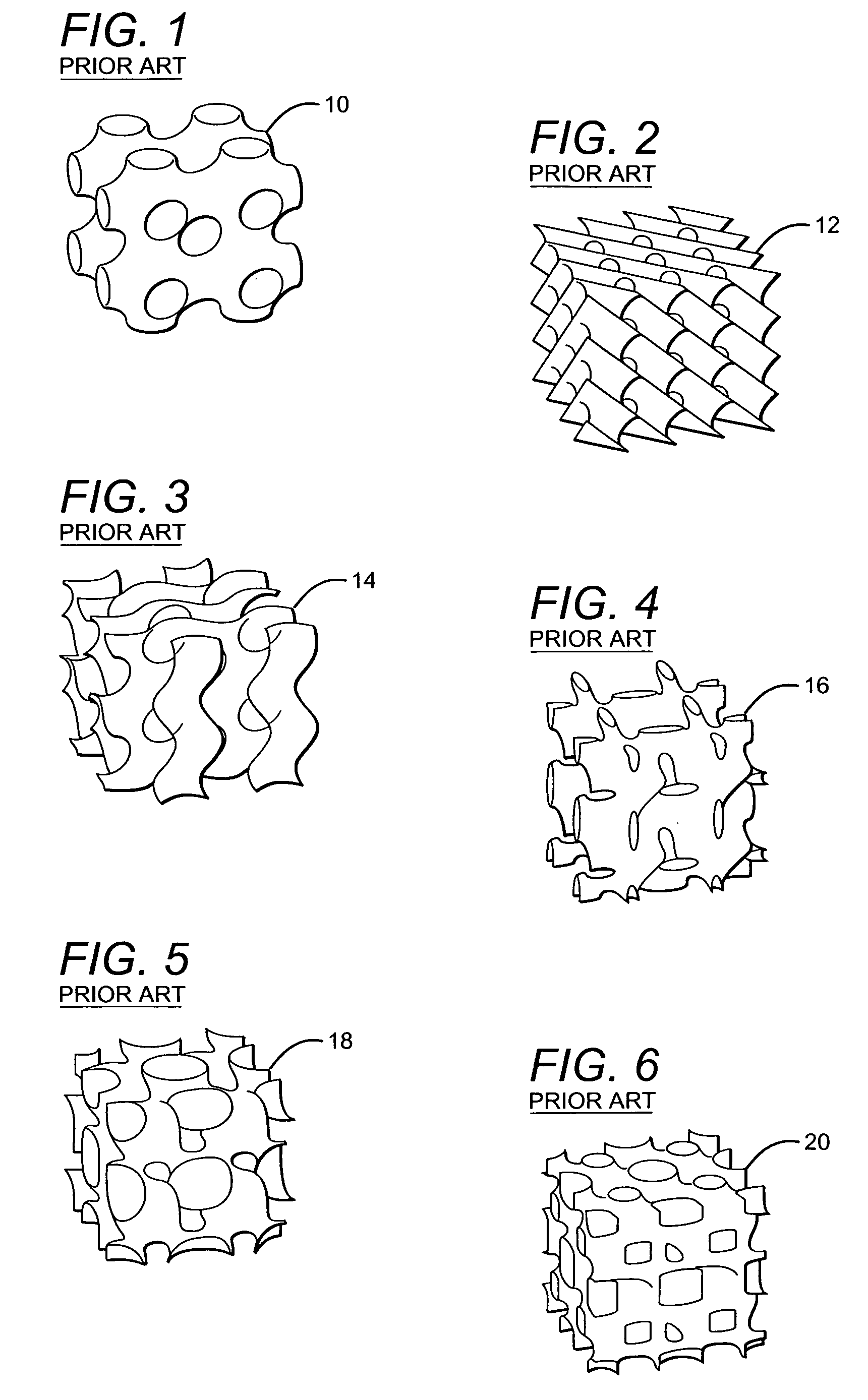

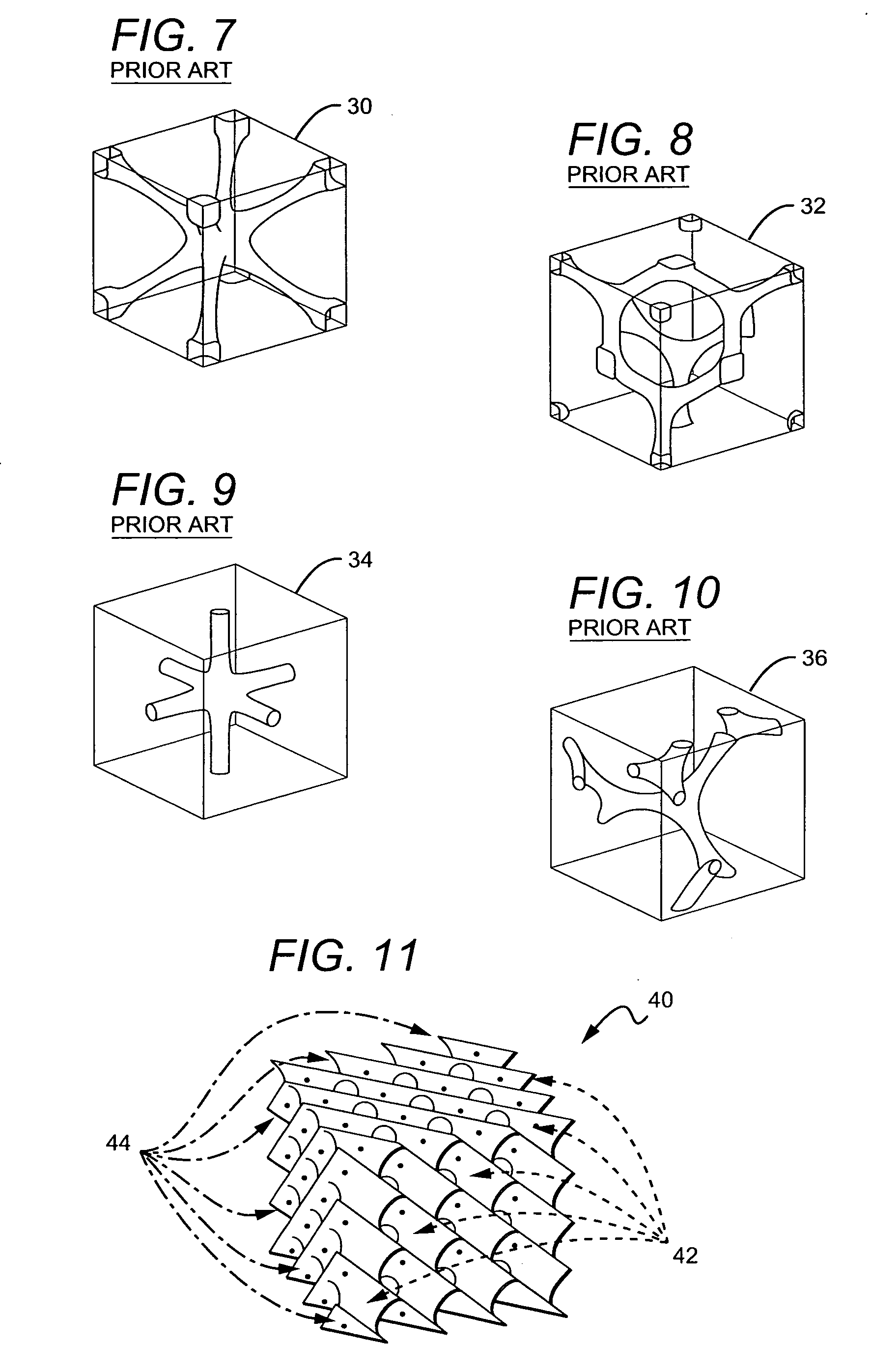

Method of using minimal surfaces and minimal skeletons to make heat exchanger components

ActiveUS7866377B2Minimize amount of materialReduce manufacturing costAdditive manufacturing apparatusIncreasing energy efficiencyComputer scienceThermal transmittance

A method of using a minimal surface or a minimal skeleton to make a heat exchanger component is provided. The method comprises the steps of generating a stereolithography file from design data, slicing the stereolithography file into two-dimensional patterns, repeating the two-dimensional patterns sequentially to produce a three-dimensional minimal surface component or minimal skeleton component, and depositing at least one layer of a material having a high thermal conductivity onto a top surface of a base, wherein the deposited material forms either a three-dimensional minimal surface component or a three-dimensional minimal skeleton component. Also provided are the heat exchanger components made by the embodiments of the method using either minimal surfaces or minimal skeletons.

Owner:THE BOEING CO

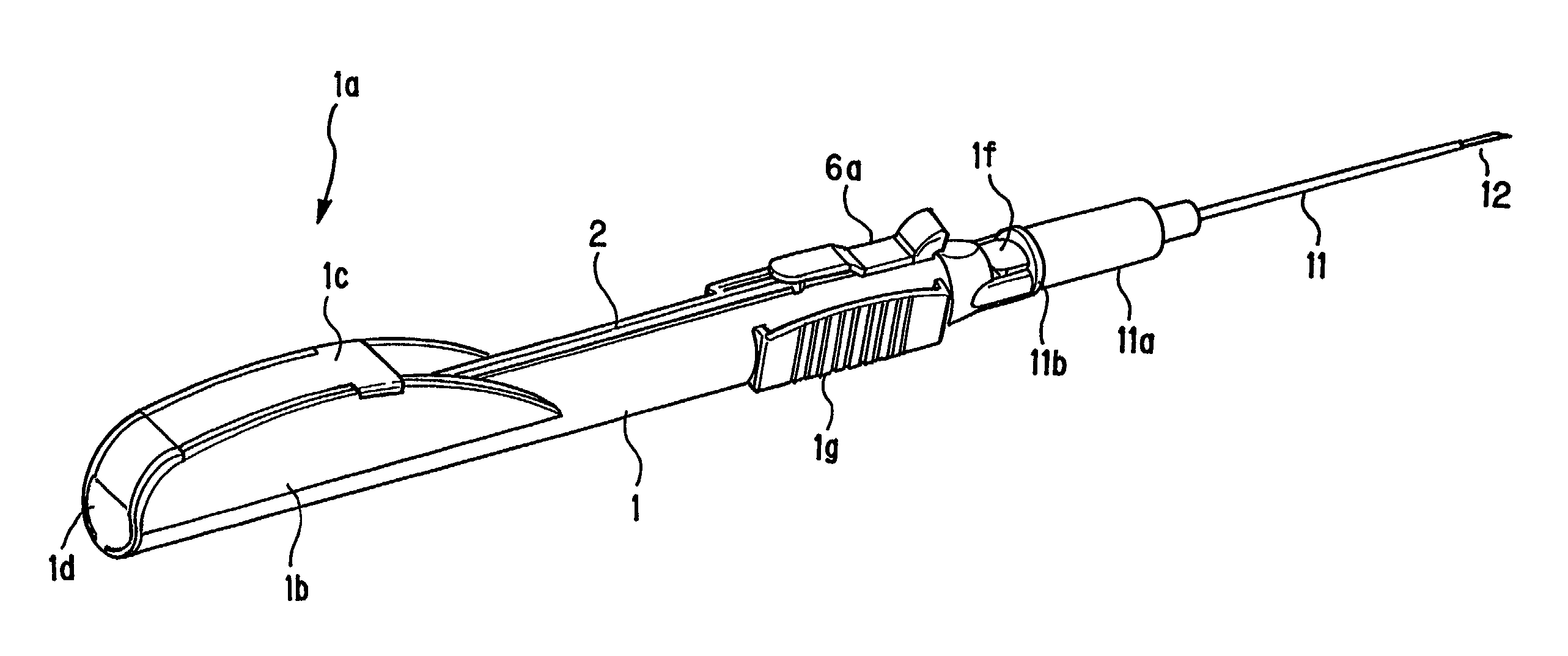

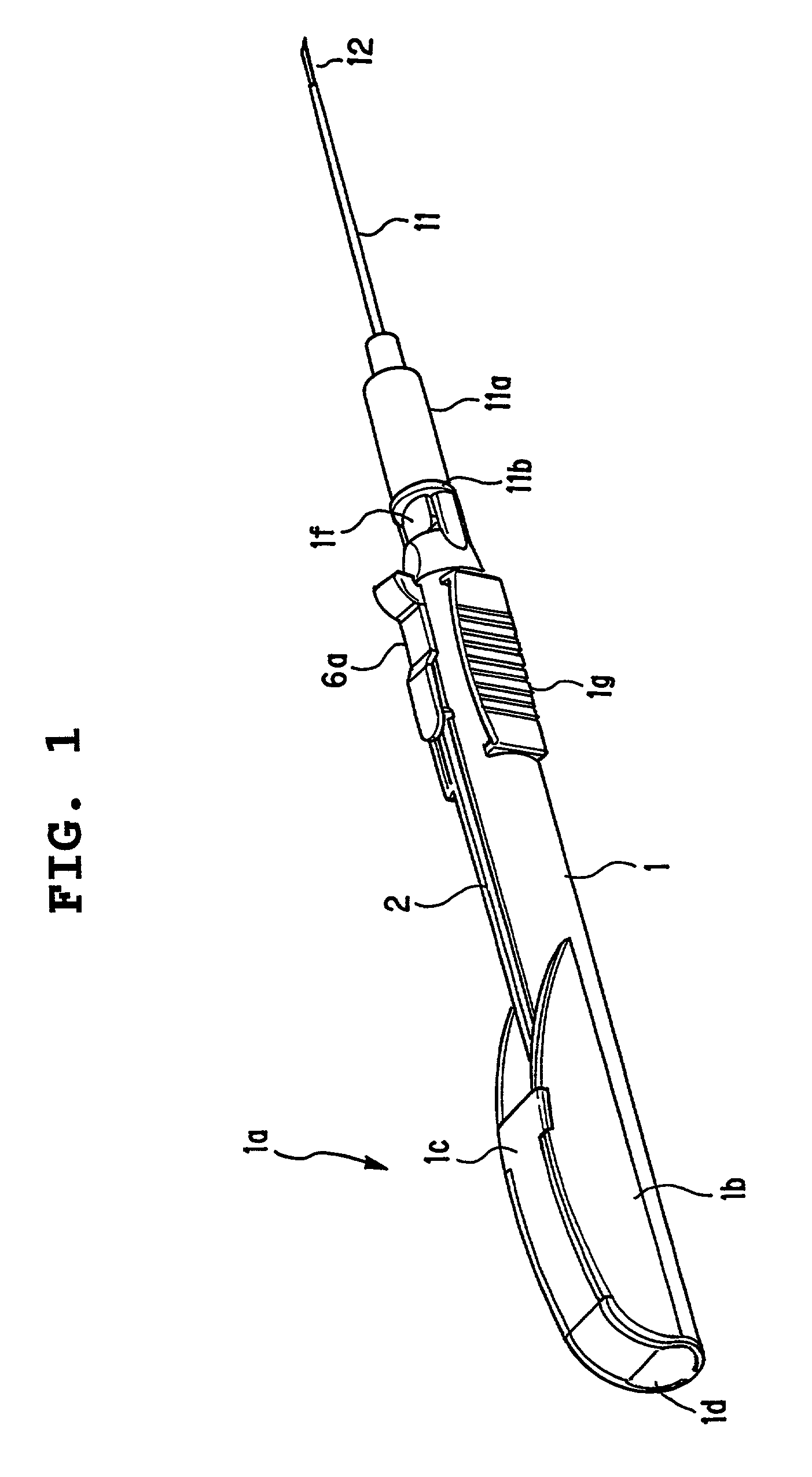

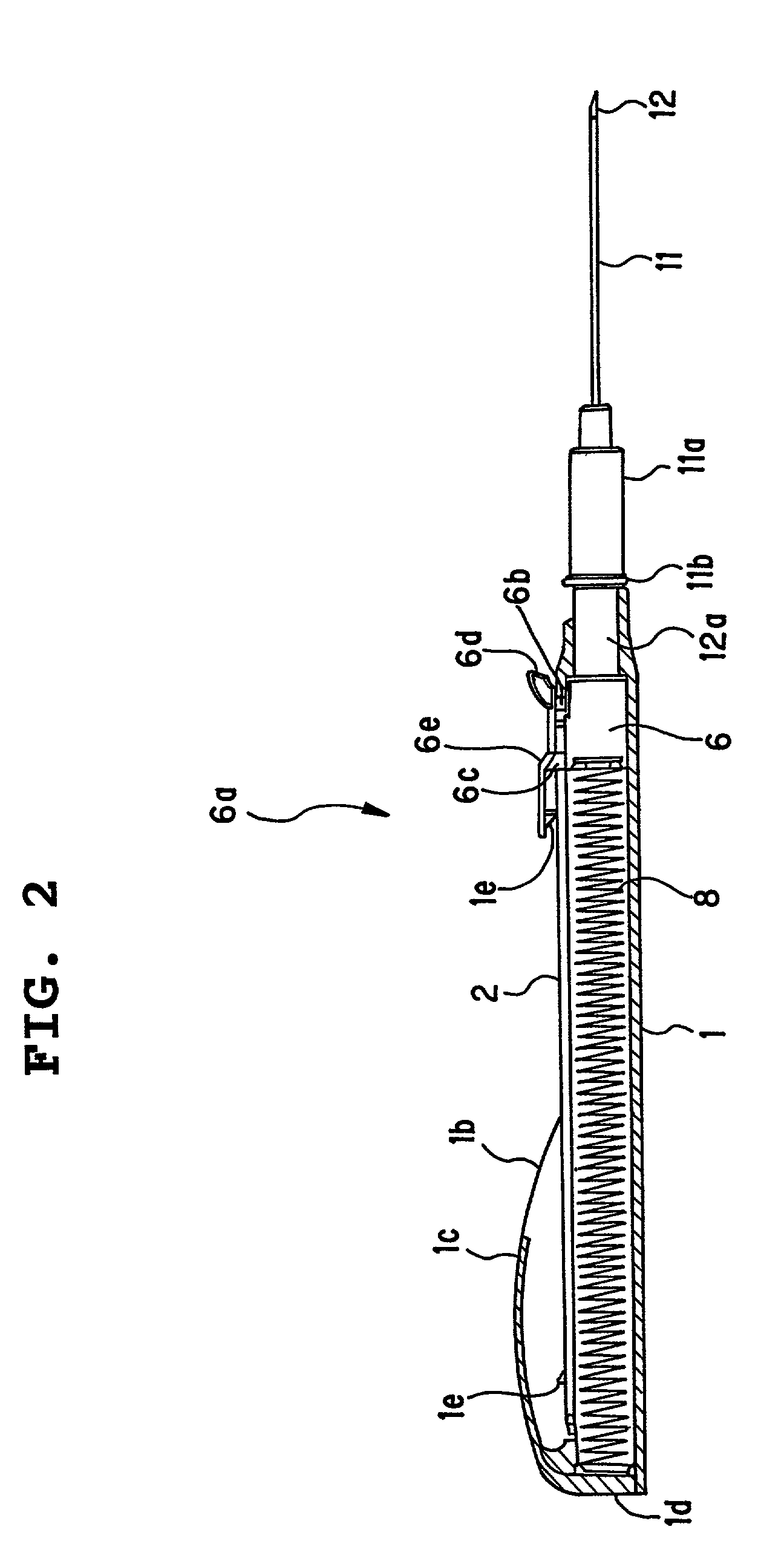

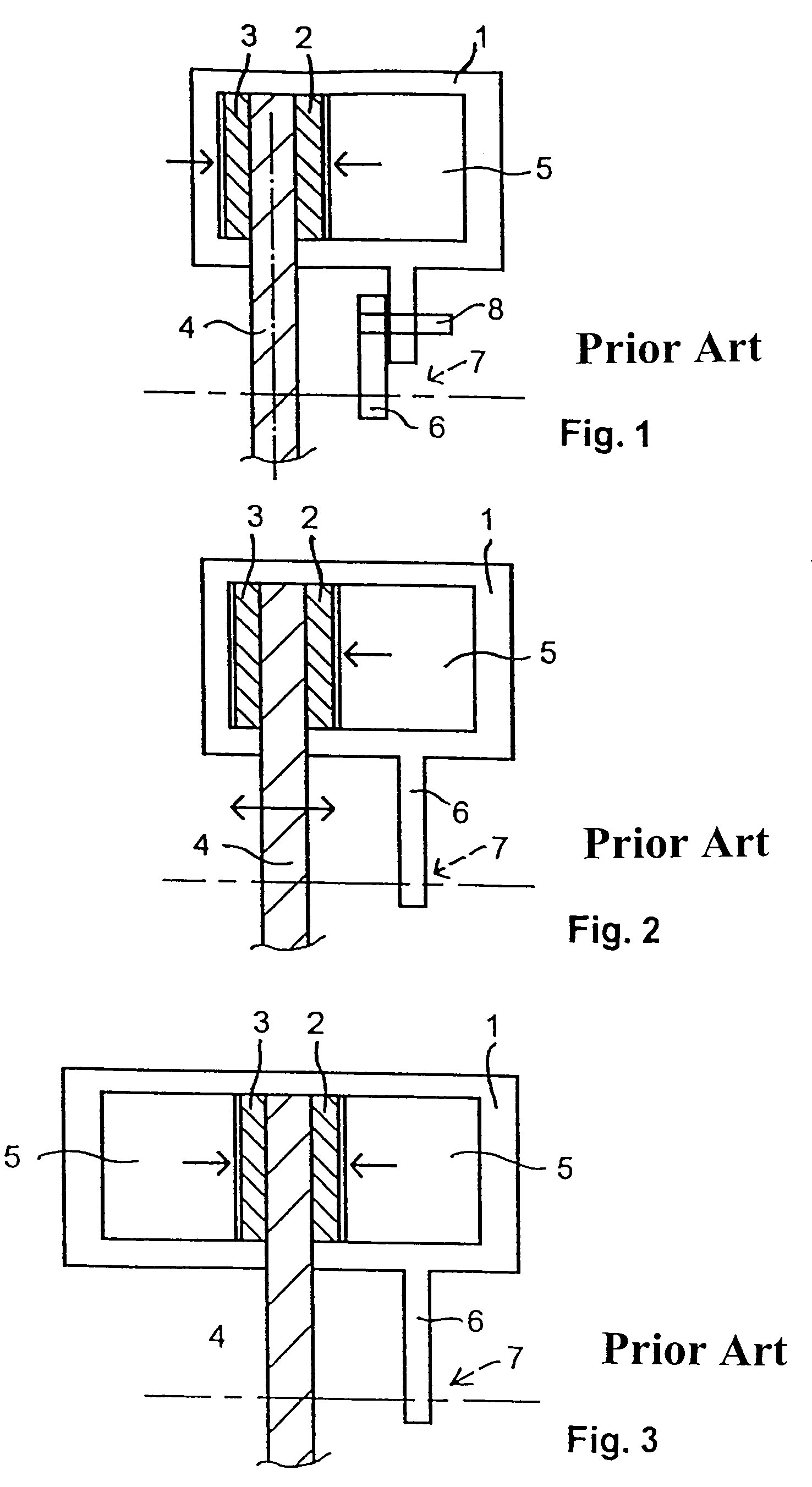

Safety indwelling needle

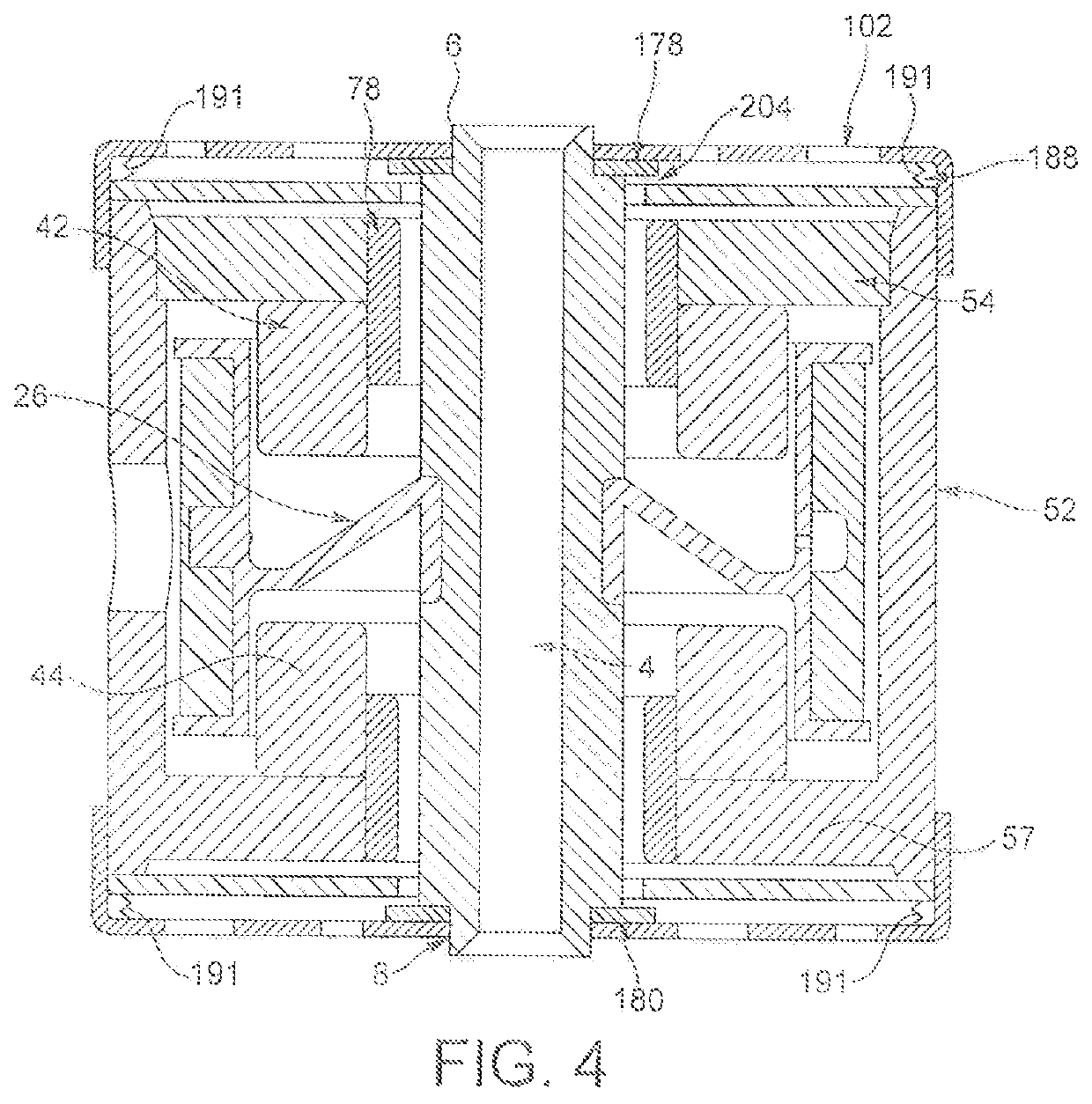

InactiveUS6969376B2Avoid exposureMinimize amount of materialGuide needlesInfusion syringesEngineeringActuator

The mechanism includes: an urging means for urging an inner needle (12) to the side opposite to an outer needle (11) with respect to the axial direction of a holder sleeve (1) for holding the inner needle (12); an actuator (6) which is positioned between the urging means (8) and inner needle (12), moves together with the inner needle (12) and has a puncture position retainer for keeping the inner needle (12) and outer needle (11) ready for puncture and an inner needle retraction actuating portion for allowing for the retraction actuation of the inner needle (12); and a slit (2) for assuring the path of movement of the actuator (6). The puncture position retainer has a puncture position engagement portion whereby the actuator (6) is engaged with the holder sleeve (1) at a position on the outer needle side (11). The inner needle retraction actuating portion includes: an actuating portion (6a) for releasing the actuator (6) from the engaged state of the puncture position engagement portion into the urged state by the urging means (8) and an actuator housing for enclosing the actuator after retraction of the inner needle.

Owner:MITSUBISHI PENCIL CO LTD

Method of using minimal surfaces and minimal skeletons to make heat exchanger components

ActiveUS20080149299A1Reduce manufacturing costImprove efficiencyAdditive manufacturing apparatusPhotomechanical apparatusComputer scienceDesign data

A method of using a minimal surface or a minimal skeleton to make a heat exchanger component is provided. The method comprises the steps of generating a stereolithography file from design data, slicing the stereolithography file into two-dimensional patterns, repeating the two-dimensional patterns sequentially to produce a three-dimensional minimal surface component or minimal skeleton component, and depositing at least one layer of a material having a high thermal conductivity onto a top surface of a base, wherein the deposited material forms either a three-dimensional minimal surface component or a three-dimensional minimal skeleton component. Also provided are the heat exchanger components made by the embodiments of the method using either minimal surfaces or minimal skeletons.

Owner:THE BOEING CO

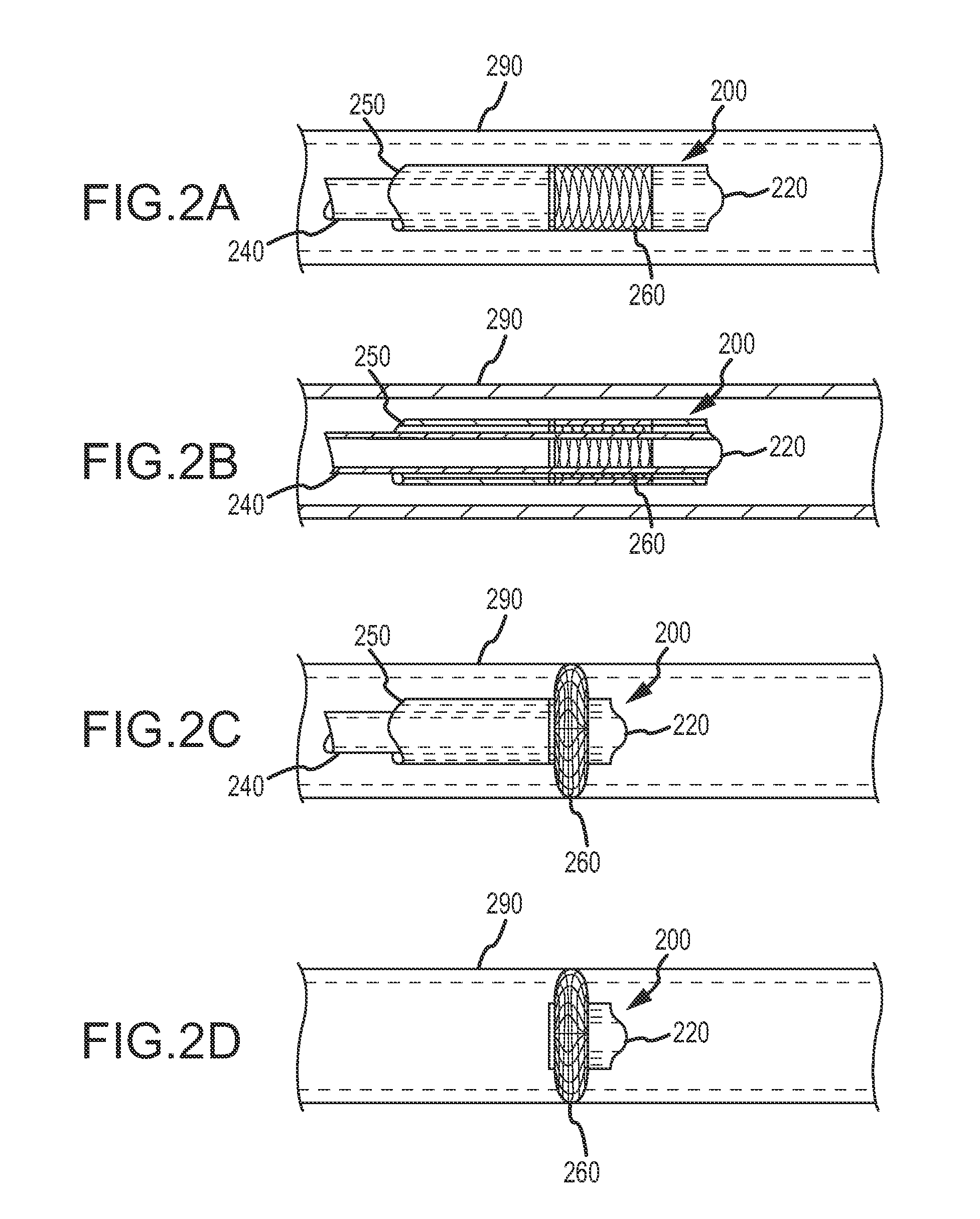

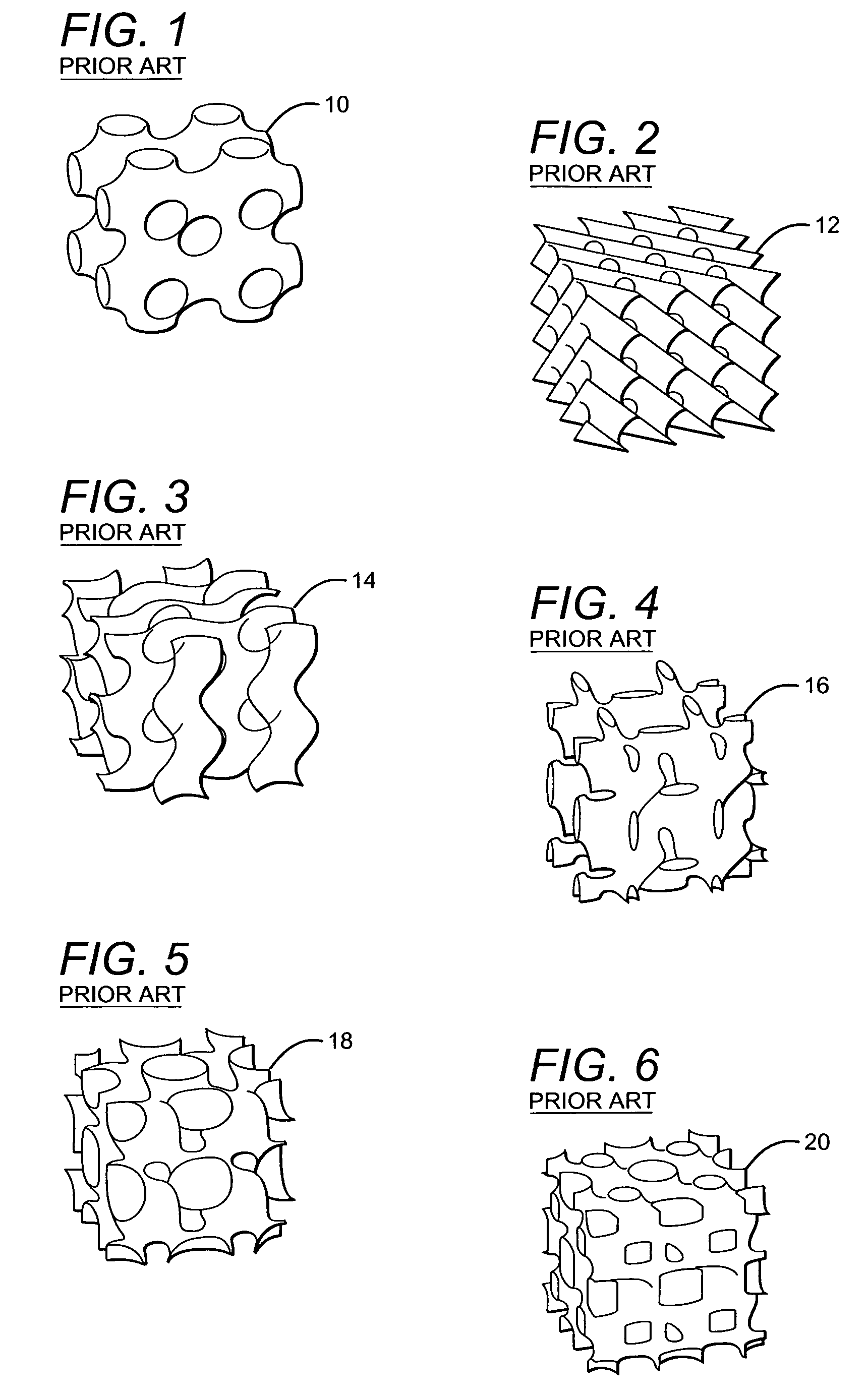

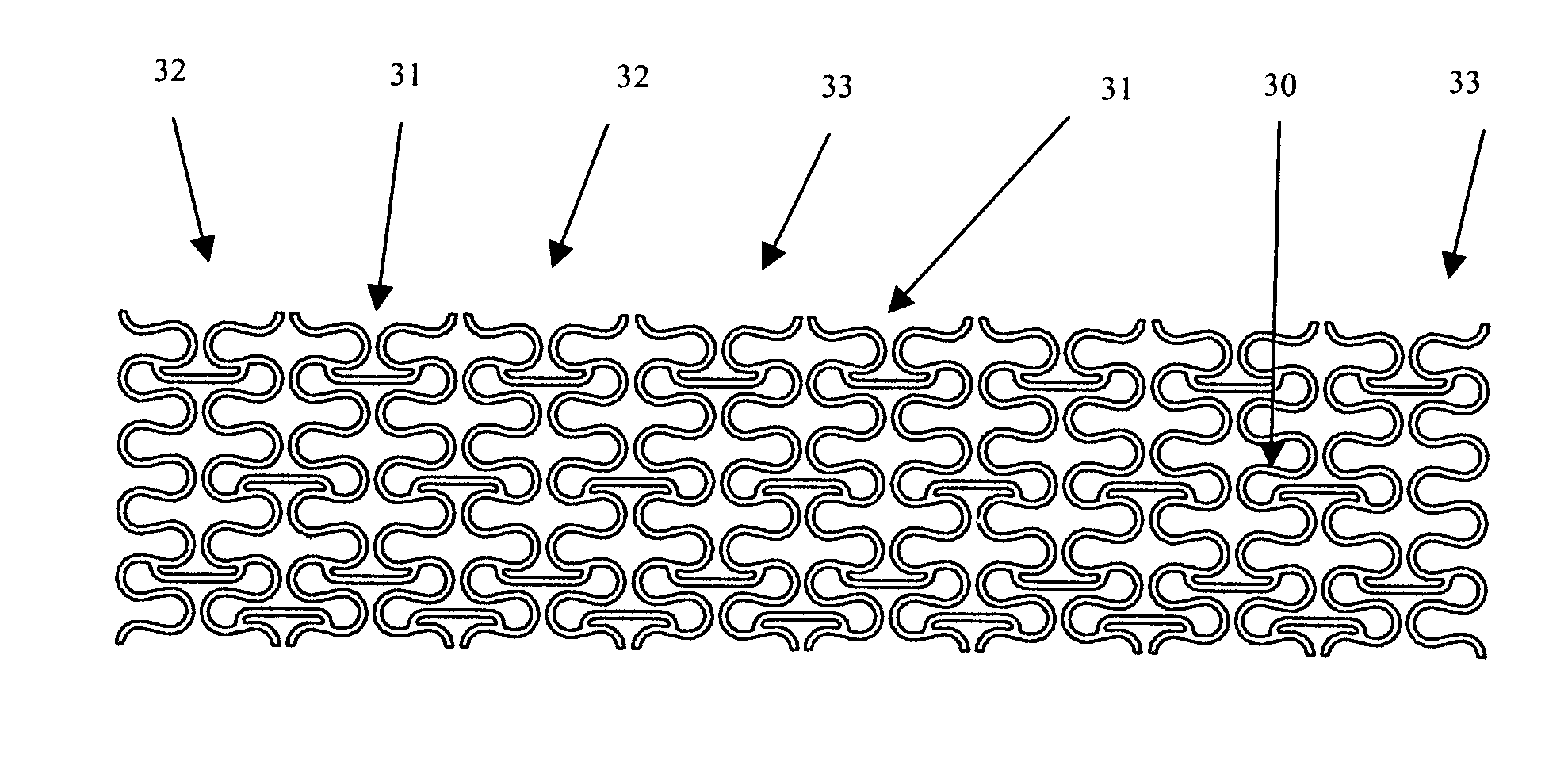

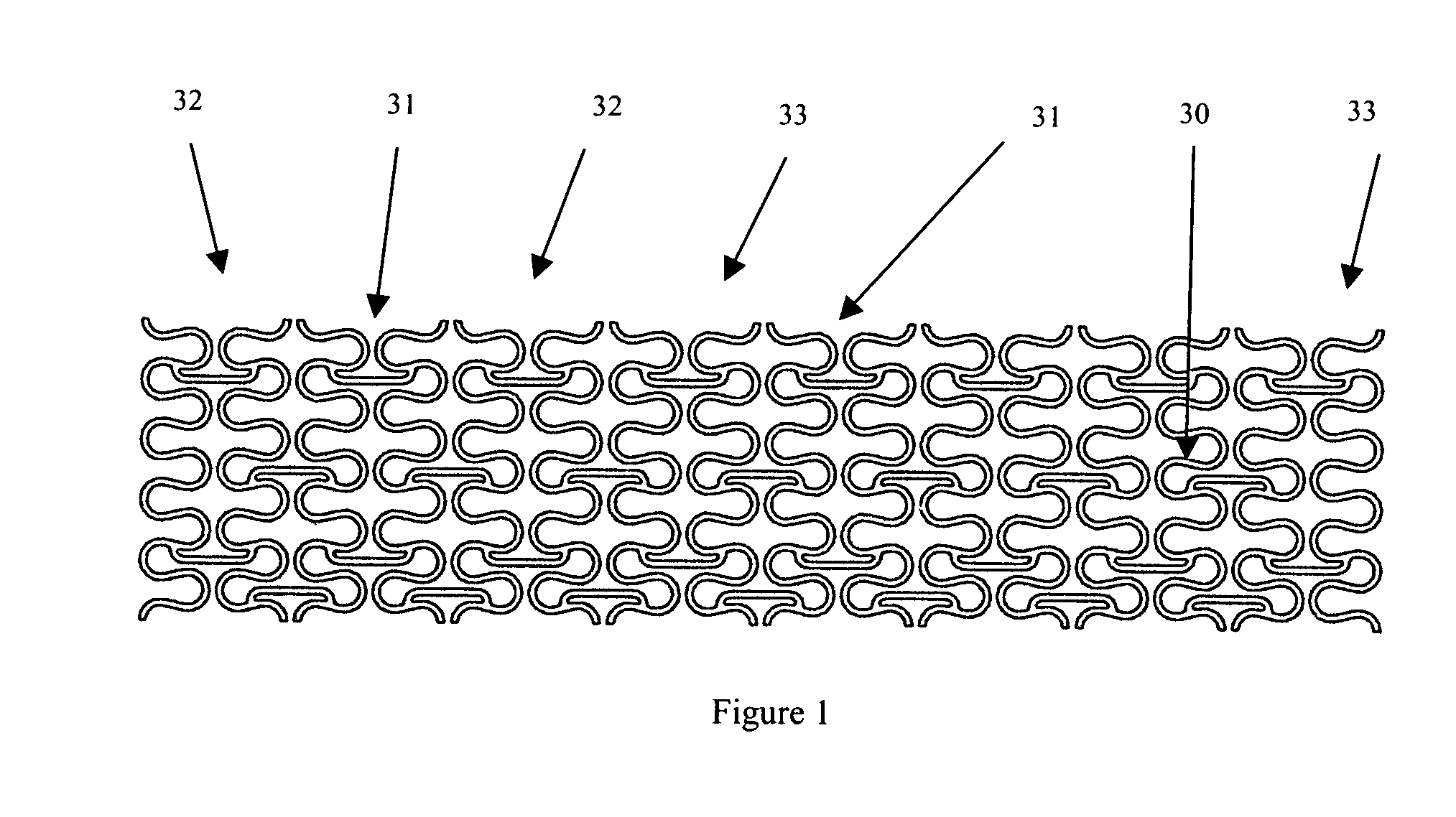

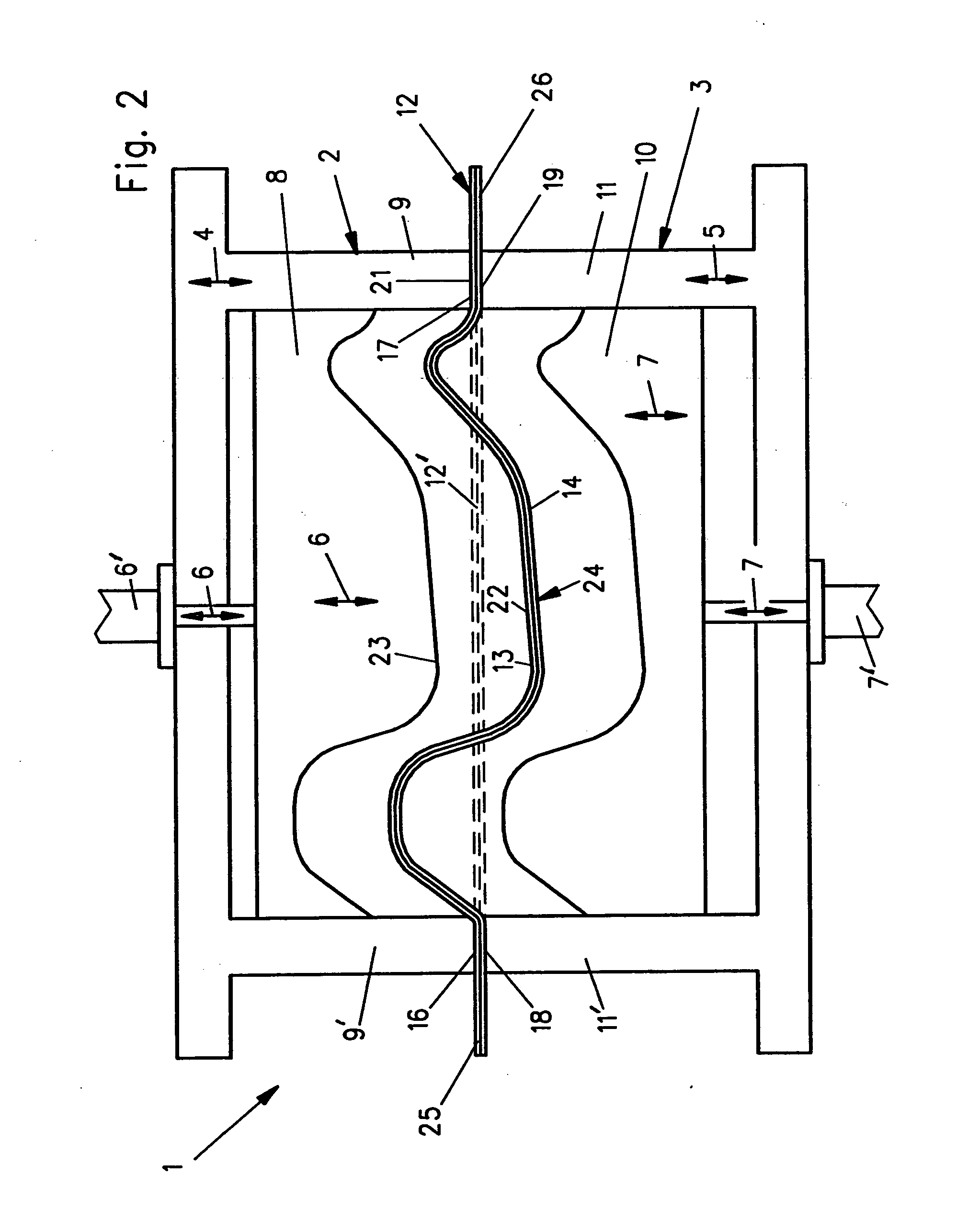

Expandable endovascular stent

InactiveUS20050080479A1Minimize amount of materialSubstantial longitudinal flexibility longitudinalStentsBlood vesselsStress concentrationPercent Diameter Stenosis

Disclosed herein is a tubular endovascular stent comprising a plurality of annular segments connected by one or more bridging elements. Each annular segment takes forms of periodic wavelets with a plurality of alternating symmetric peaks and valleys, preferably consisting of circular arc segments of large radii connected tangentially with straight segments to minimize stress concentration when the stent undergoes radial deformation, transverse to the longitudinal axis of the stent. The points of connection between the bridging elements and adjacent annular segments are so designed that deformations of the bridging elements remain negligible as the stent deforms radially, namely, the longitudinal dimension of the stent does not vary during the radial expansion or contraction of the stent. Hence, the radial strength and the longitudinal flexibility of the stent made according to the principles disclosed by the present invention can be independently controlled by the design parameters for the annular segments and bridging elements, without compromising the longitudinal dimensional stability of the stent. Since stress concentration and deformation in the stent can lead to restenosis, stent made from the invention disclosed here can reduce the probability of restenosis.

Owner:FENG JAMES Q +1

Power converter permitted to be reduced in size and manufactured at decreased cost

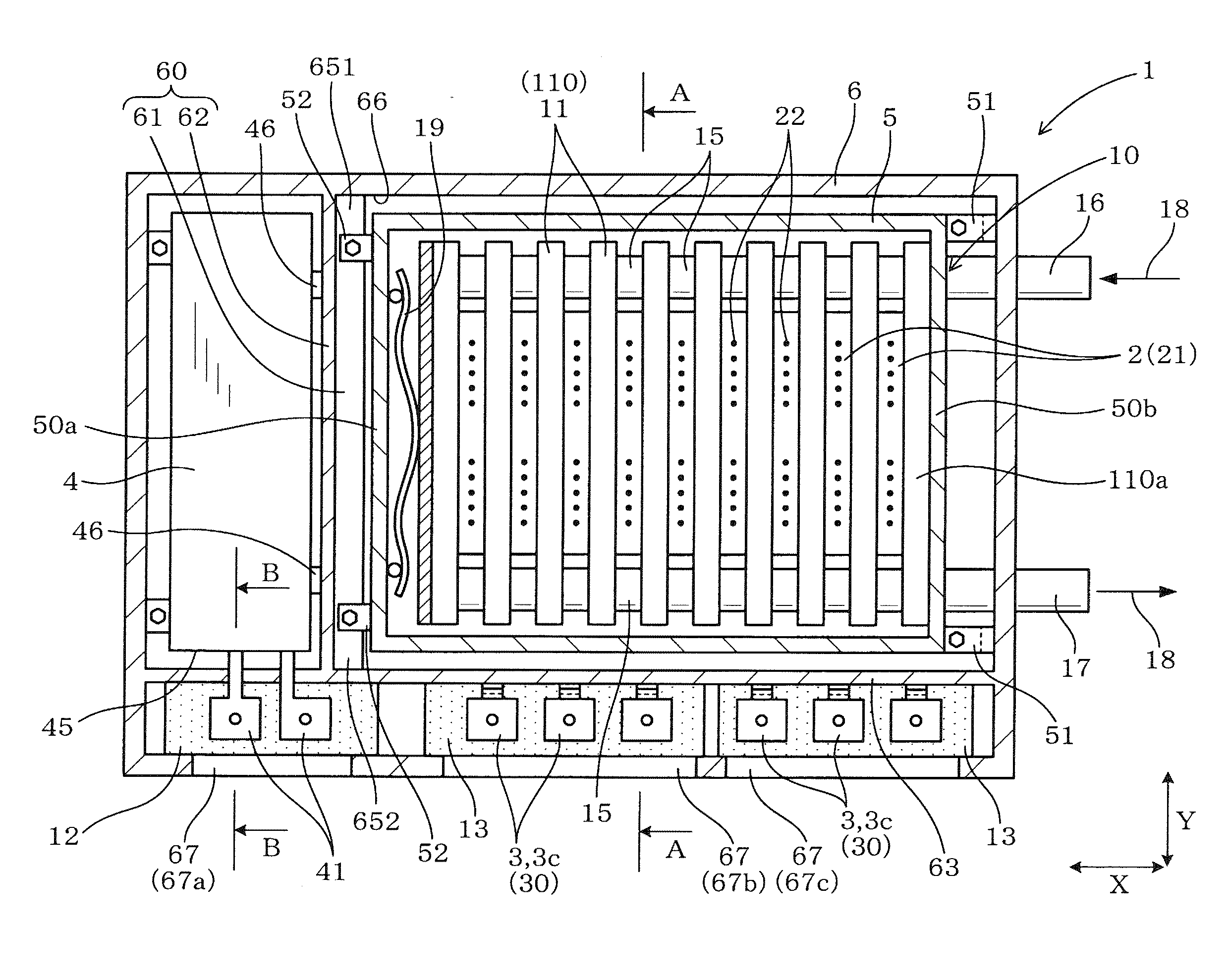

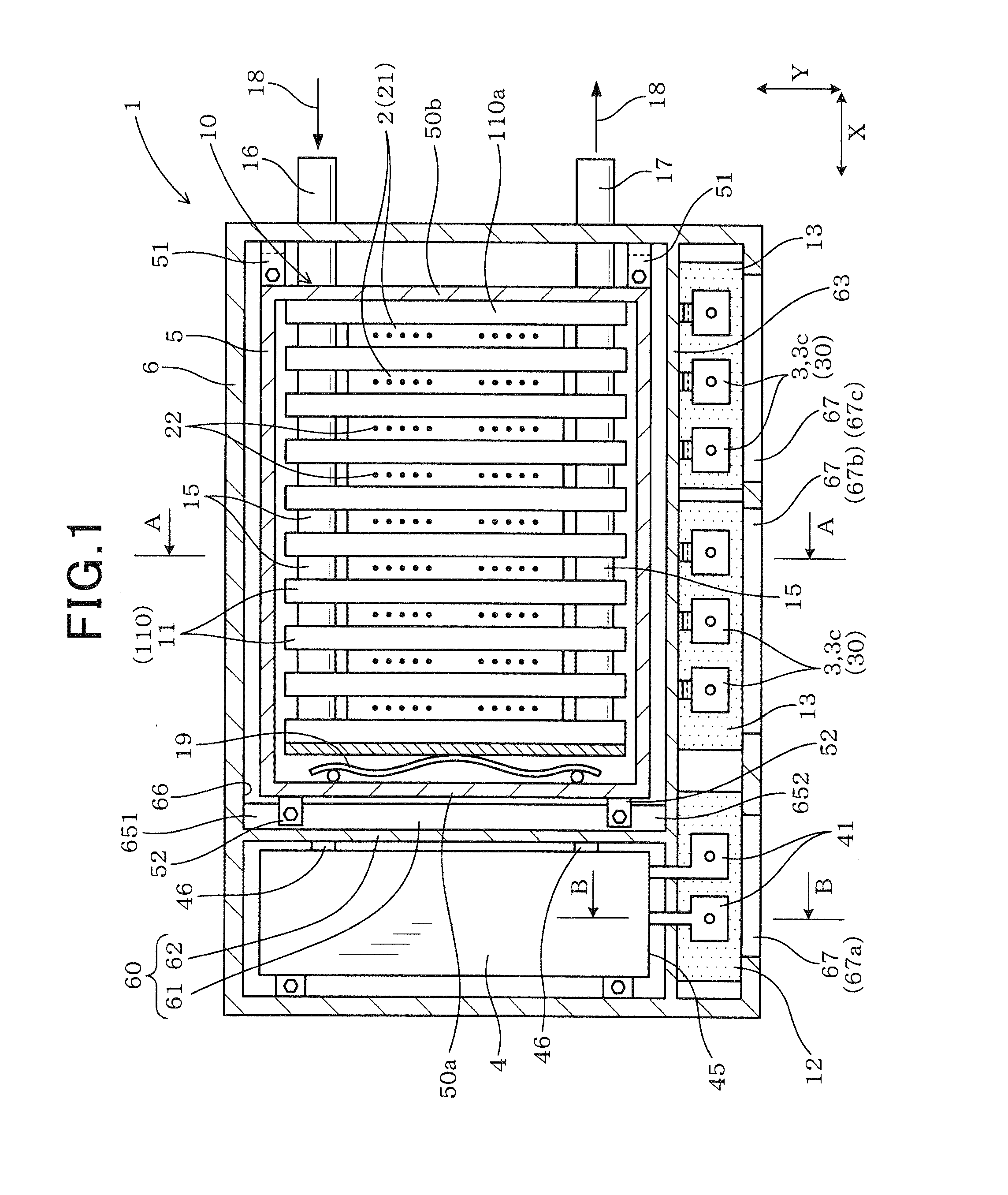

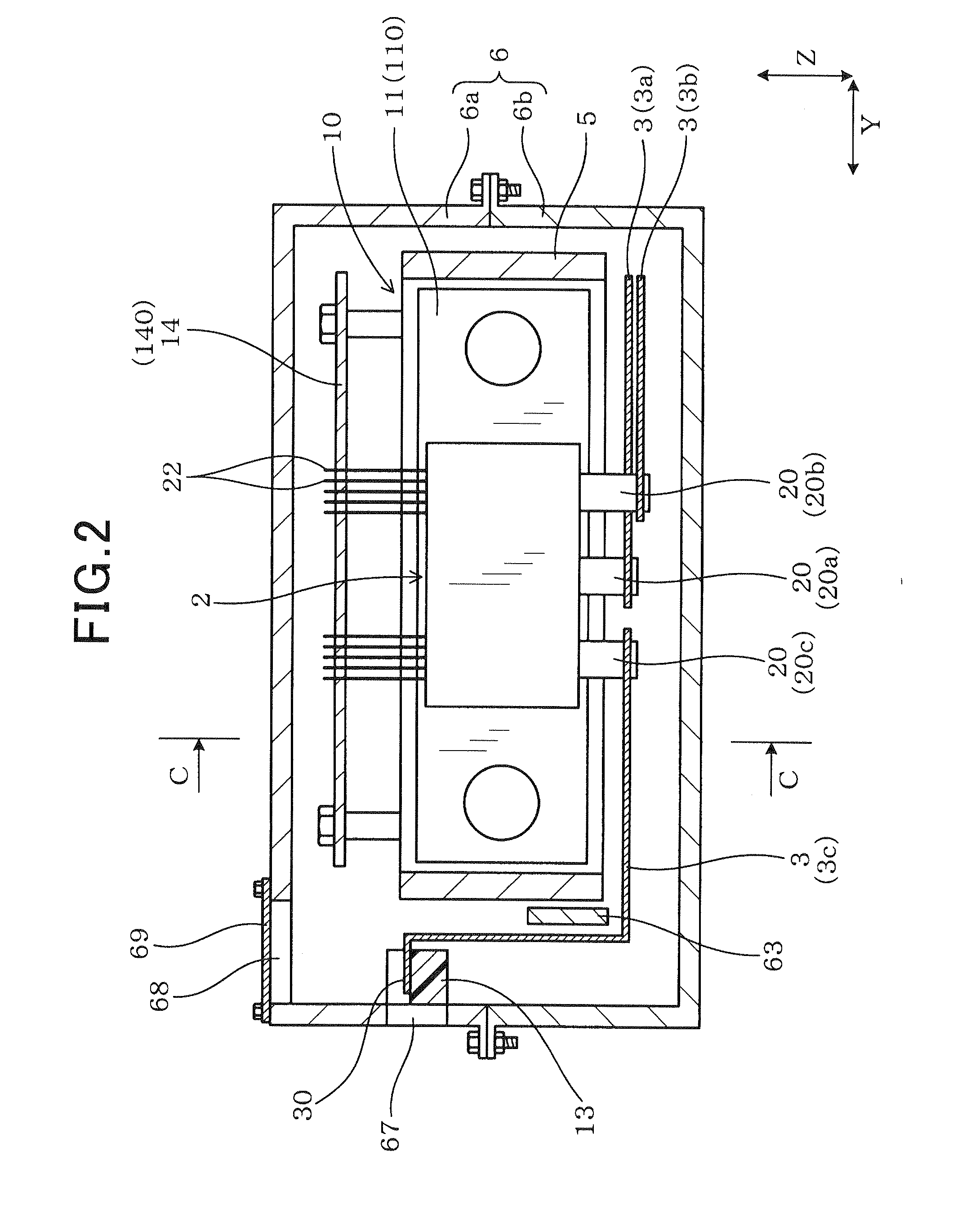

ActiveUS20130058068A1Ensures stability in installationImprove vibration resistanceCircuit arrangements on support structuresManufacturing cost reductionCapacitor

A power converter equipped with a semiconductor stack made up of semiconductor modules, bus bars coupled to power terminals of the semiconductor modules, a capacitor, and an input terminal table. The capacitor is disposed in alignment with a first direction in which the semiconductor modules are stacked. The capacitor has a first end and a second end opposed to the first end in a second direction in which the power terminals extend from the semiconductor modules. The first end faces in the second direction. The input terminal table is located near the second end of the capacitor. This structure permits the power converter to be reduced in size and produced at a decreased cost.

Owner:DENSO CORP

Rotor balancing method

ActiveUS20130340521A1Reducing of methodShorten the timePump componentsBlade accessoriesEngineeringDeposition process

A method of balancing a physical rotor includes: determining a first balance state of the physical rotor at one or more rotational frequencies; identifying one or more balance zones on a surface of the rotor; providing a computerised simulation of the rotor having the first balance state; providing a first test mass in a first test location within one of the balance zones on the rotor simulation; determining a second balance state of the rotor simulation; providing at least one subsequent test mass in at least one subsequent test location within a balance zone on the rotor simulation and determining at least one subsequent balance state of the rotor simulation; selecting a mass and location from one of the first and subsequent test masses and test locations; and performing a material deposition process to add the selected mass of material to the selected location on the physical rotor.

Owner:ROLLS ROYCE PLC

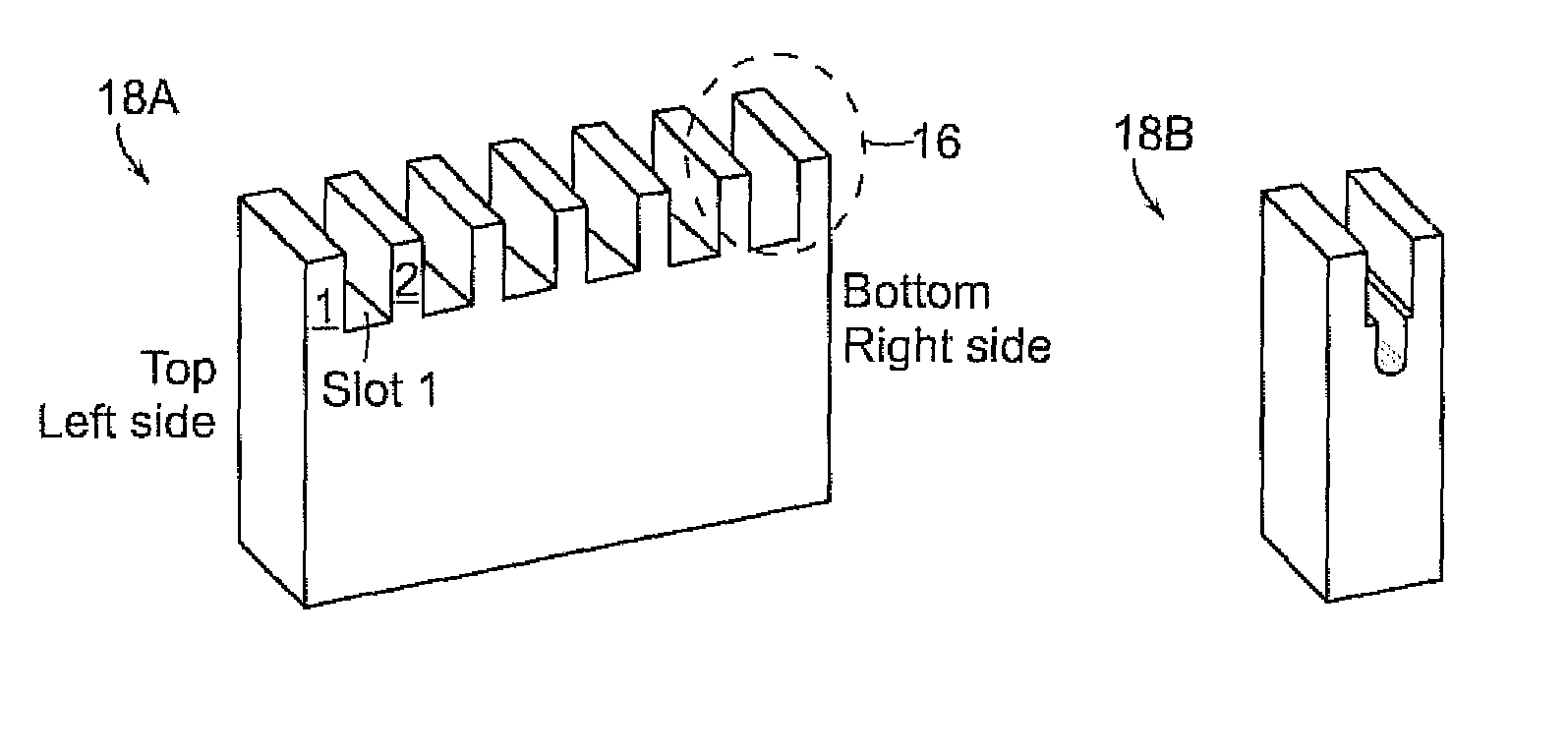

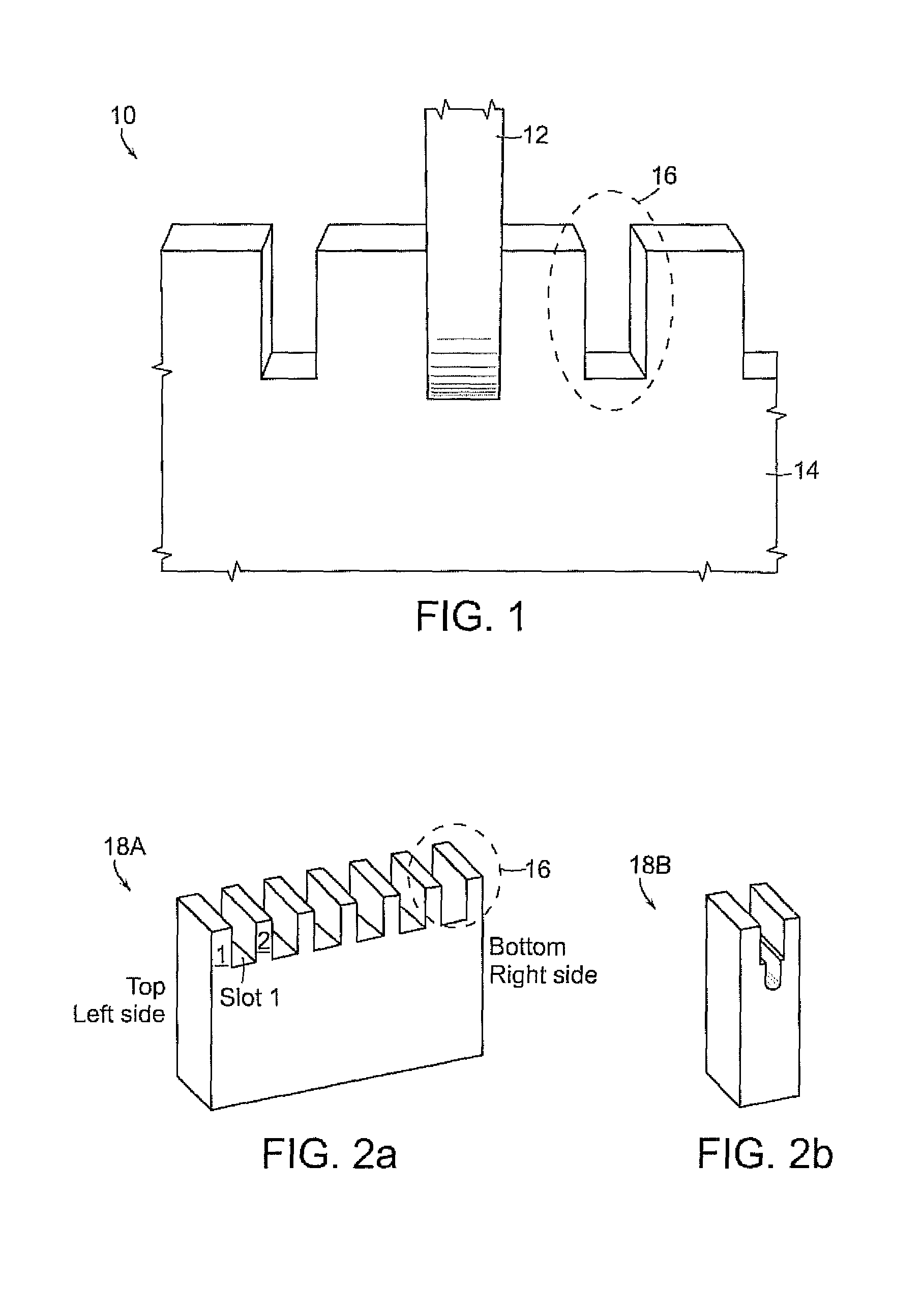

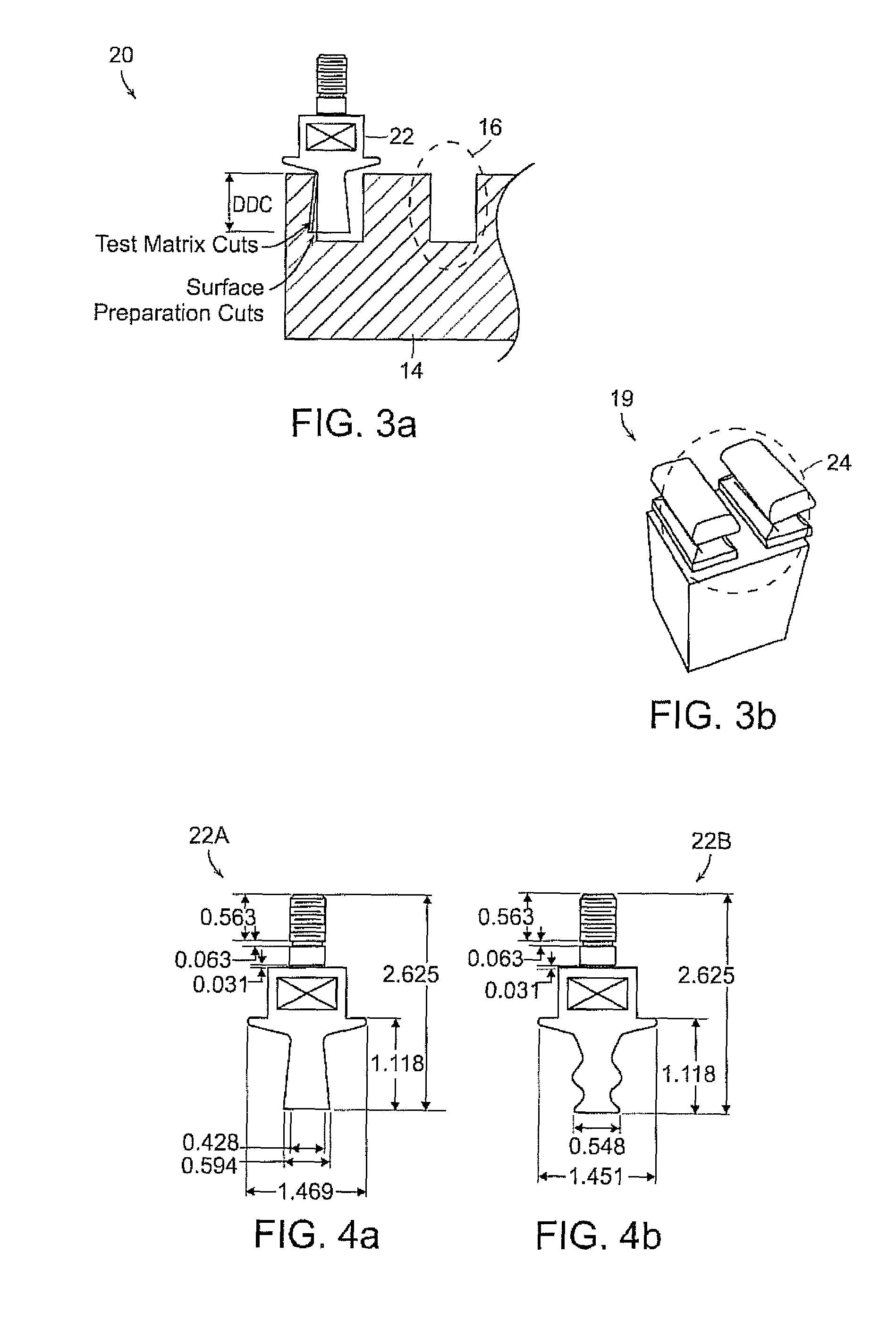

Method for grinding complex shapes

ActiveUS7708619B2Improve metal removal rateHigh surface finishAbrasion apparatusGrinding feed controlMaterial removalHardness

A method of producing a complex shape in a workpiece includes the steps of: i) grinding a workpiece at a maximum specific cutting energy of about 10 Hp / in3·min with at least one bonded abrasive tool, thereby forming a slot in the workpiece; and ii) grinding the slot with at least one mounted point tool, thereby producing the complex shape in the slot. The bonded abrasive tool includes at least about 3 volume % of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1 or an agglomerate thereof. A method of producing a slot in a metallic workpiece having a maximum hardness value of equal to, or less than, about 65 Rc includes the step of grinding the workpiece with a bonded abrasive tool at a material removal rate in a range of between about 0.25 in3 / min·in and about 60 in3 / min·in and at a maximum specific cutting energy of about 10 Hp / in3·min.

Owner:SAINT GOBAIN ABRASIVES INC +1

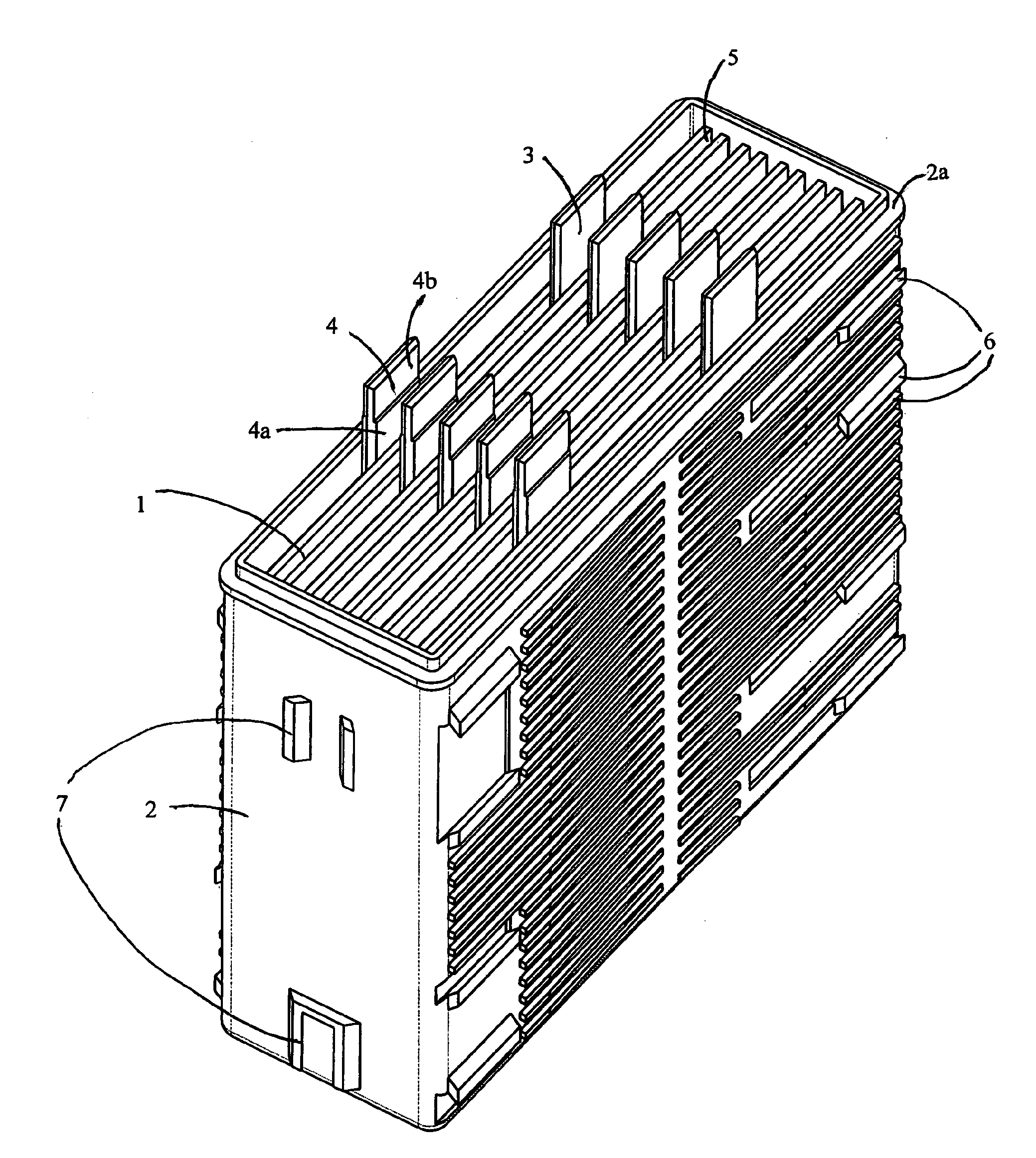

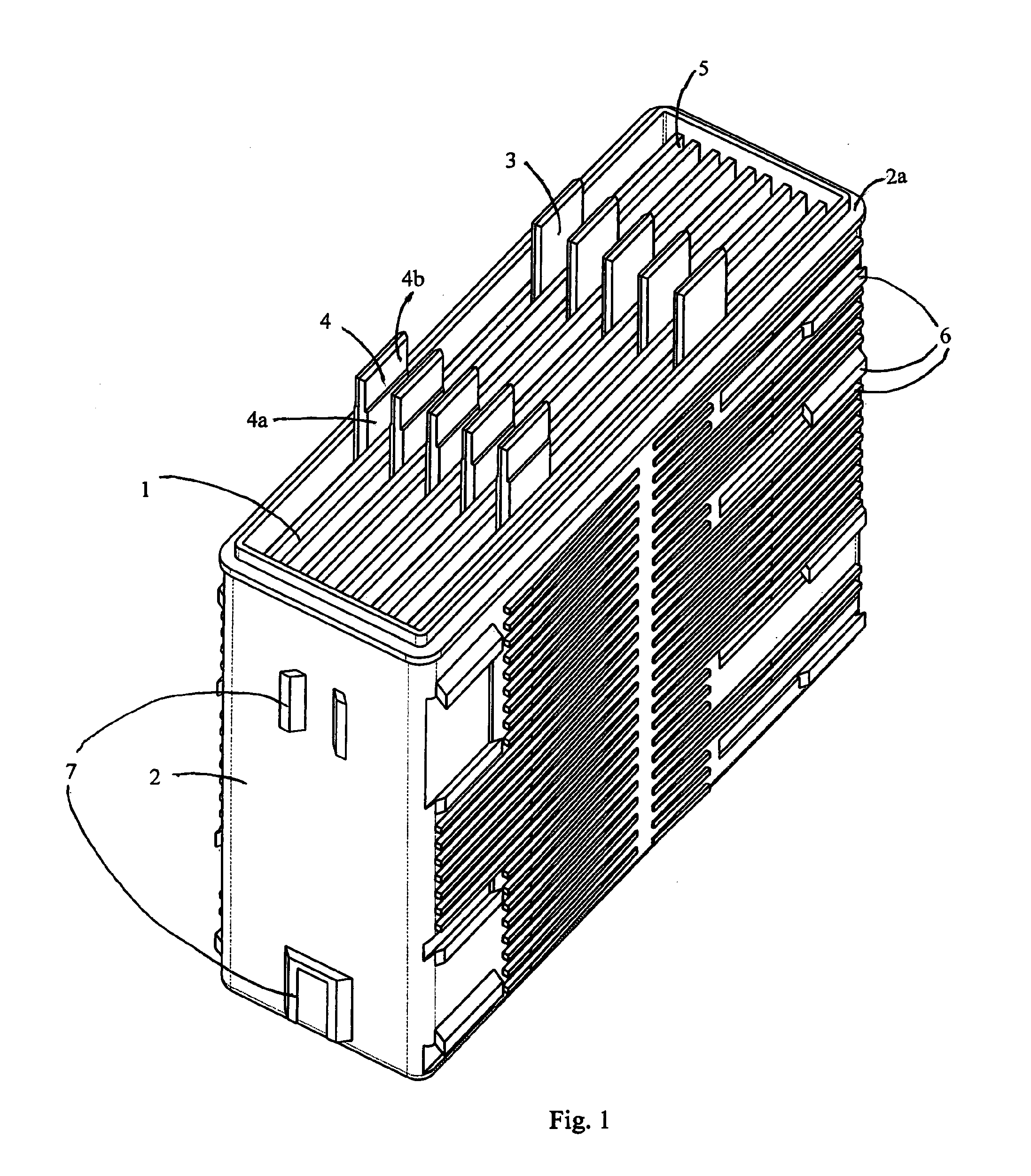

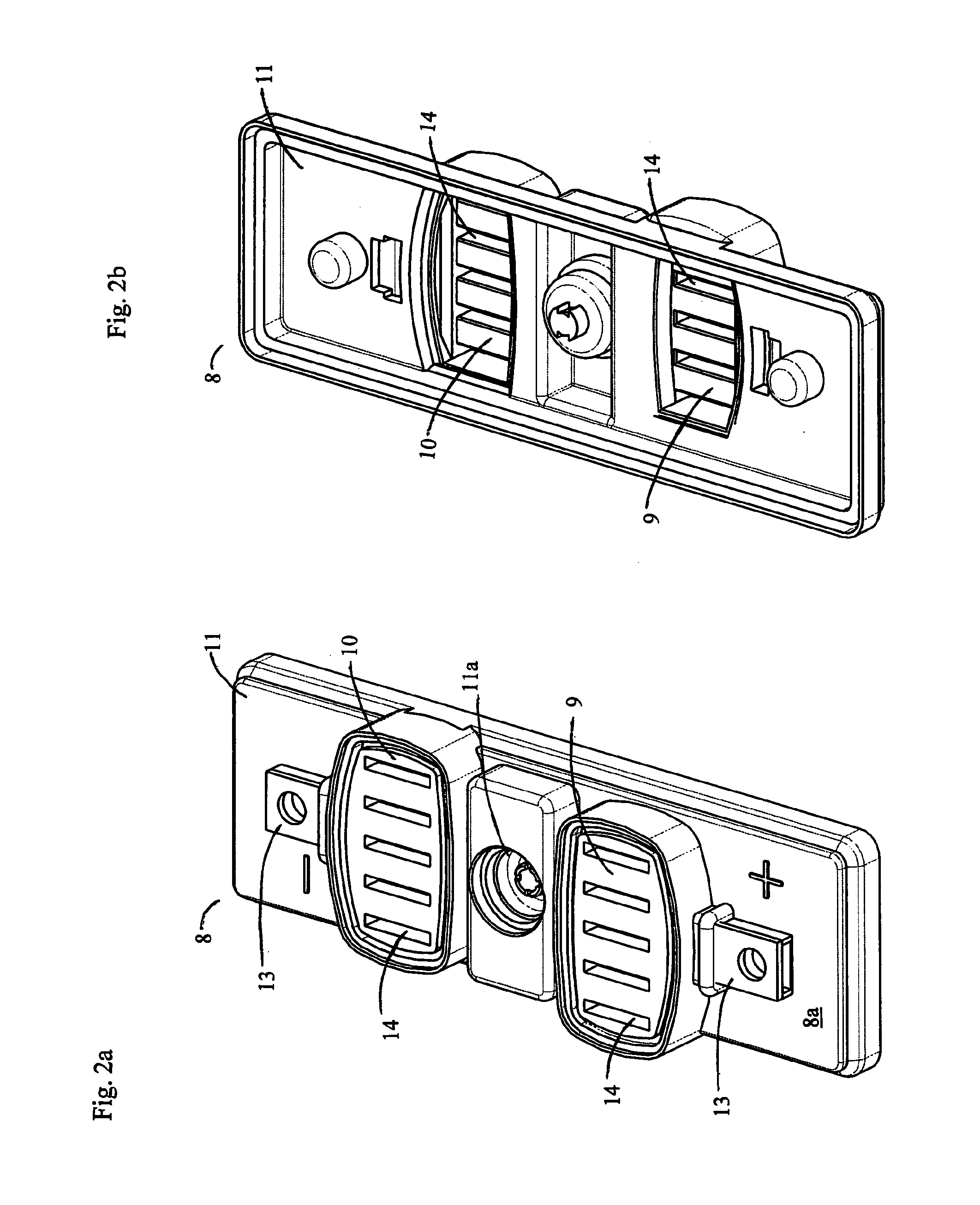

Battery and a Process for Making a Battery

InactiveUS20100143795A1Minimize amount of materialMinimize heightLarge-sized flat cells/batteriesFinal product manufactureMetal insertMetal

A process for making a battery includes providing a lid (31) having a least one metal insert (22) containing an aperture or apertures (26) for the plate lugs. During assembly of the battery the lid (31) is placed over the plate stack such that the plate lugs of the battery plates extend into the aperture or apertures (26). Heat is then applied to the outer surface of the metal insert (22) to weld the plate lugs to the insert (22).

Owner:EH EURO GMBH

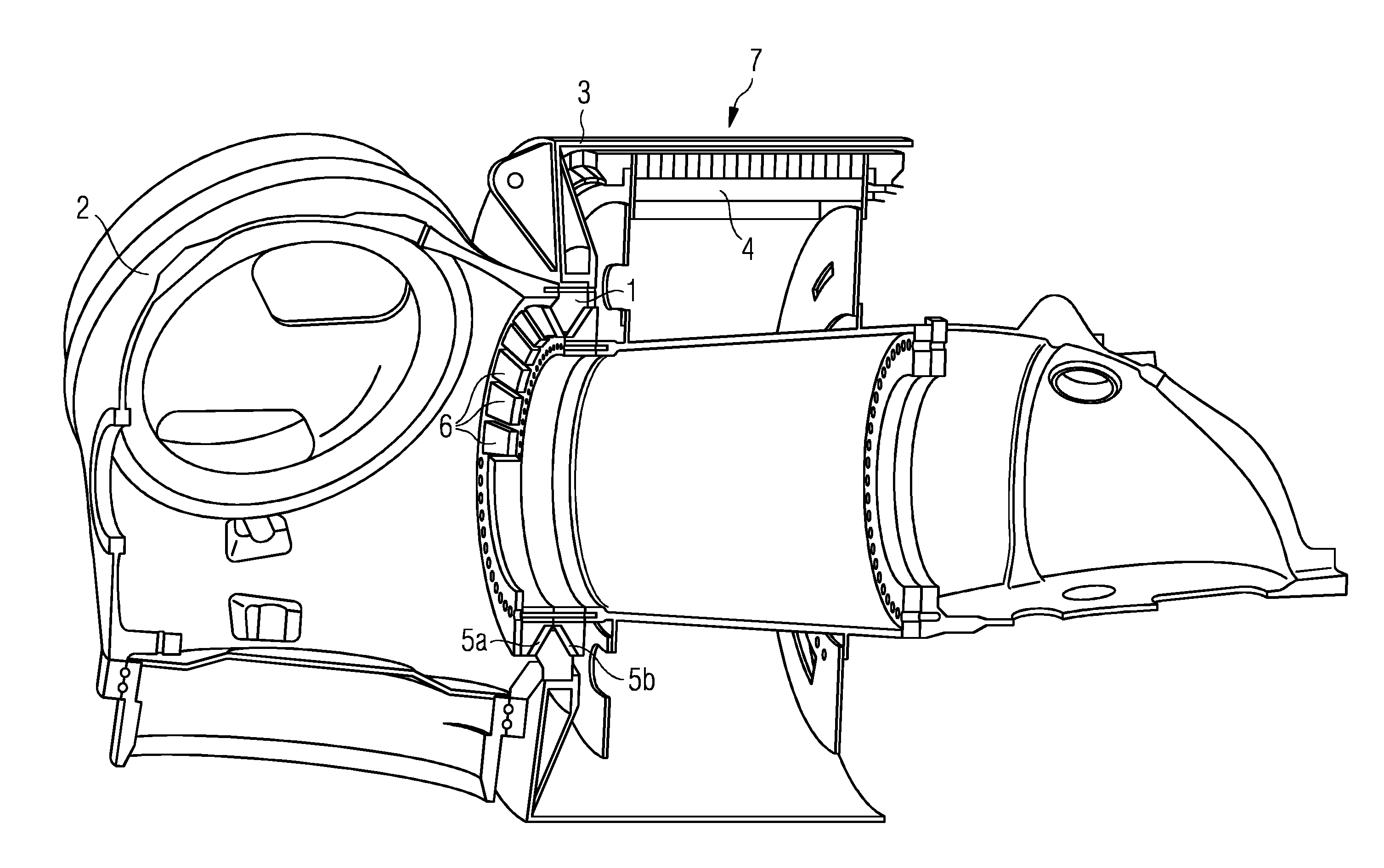

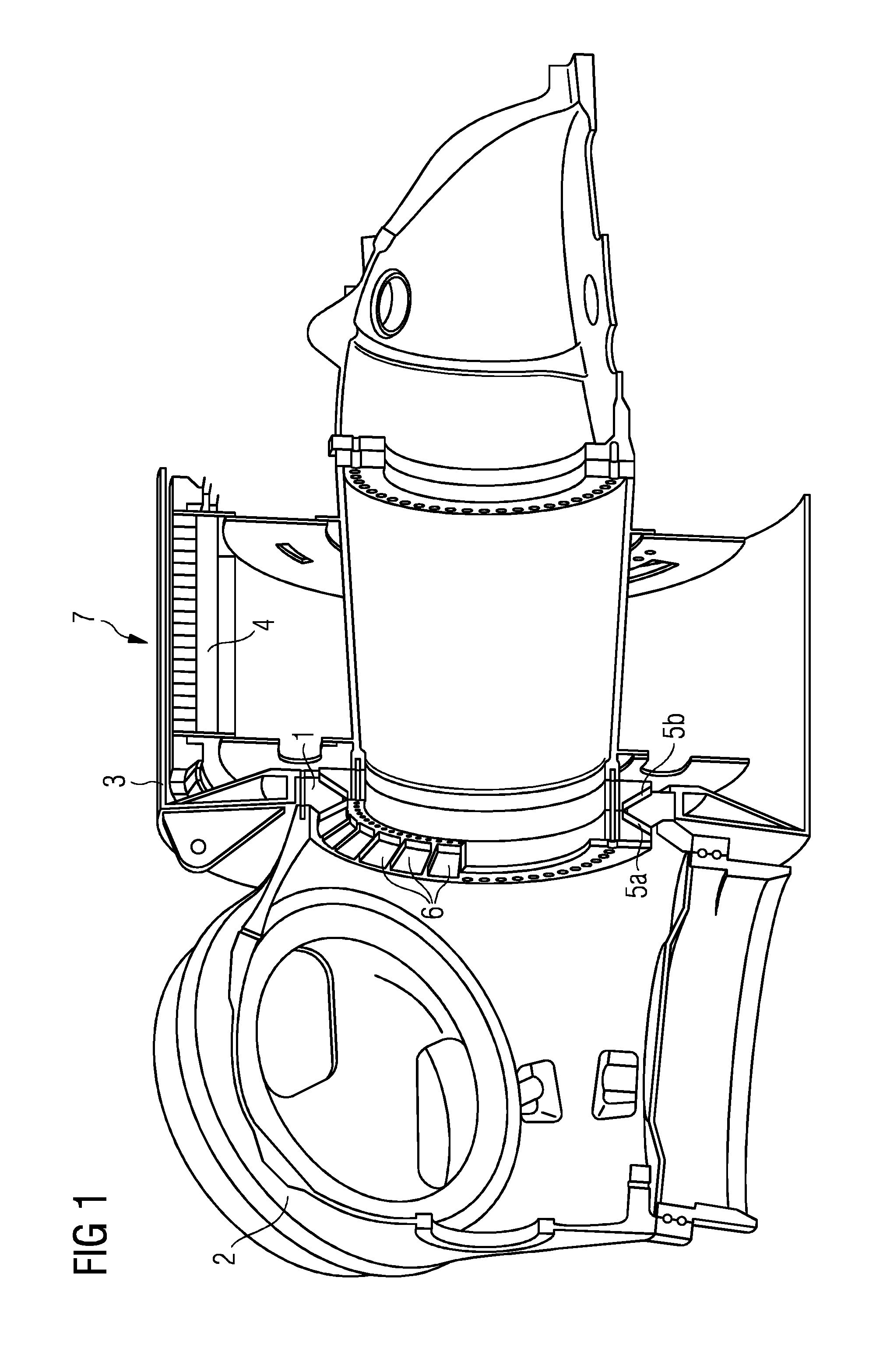

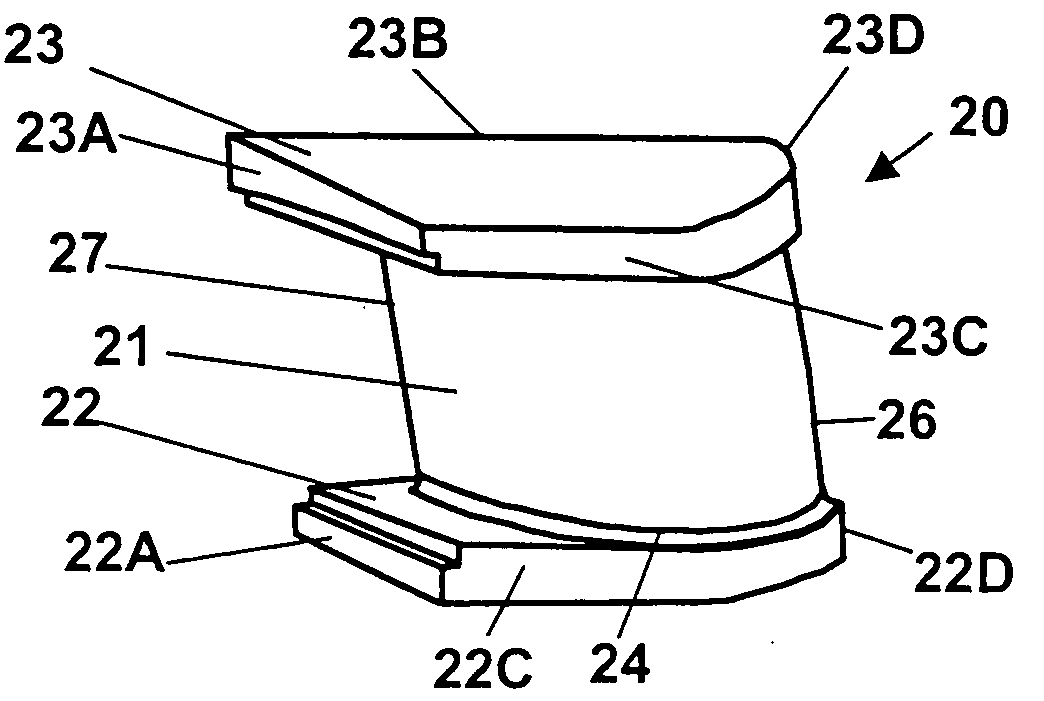

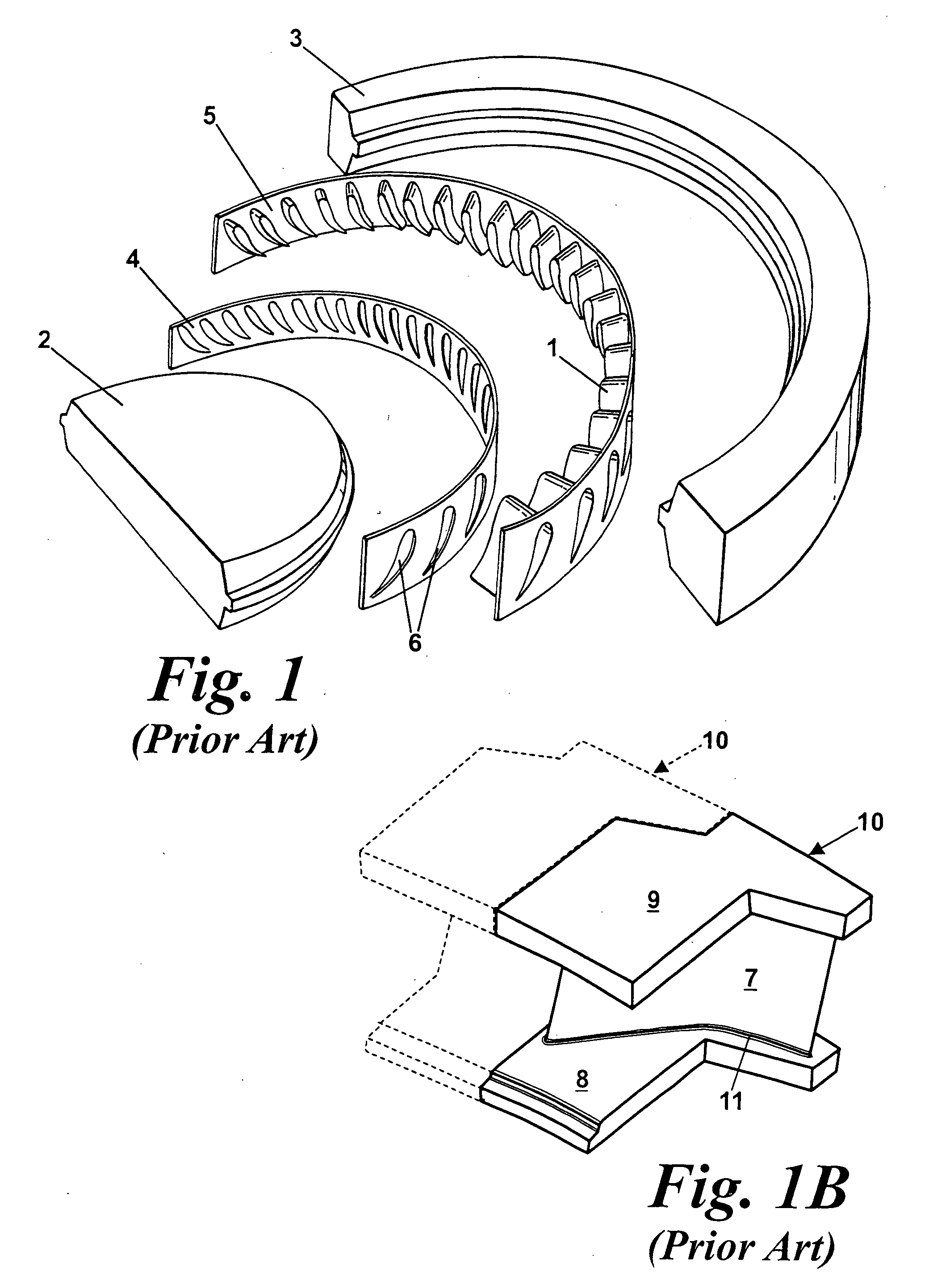

Direct-drive wind turbine

ActiveUS20140169952A1Reduce energy useImprove the lubrication effectPump componentsEngine fuctionsTurbineWind force

A direct driven wind turbine and a main bearing used in such a wind turbine is provided. A rotor of the wind turbine is directly connected with a rotating drive train of the wind turbine, the rotating drive train is directly connected with a rotor of an electrical generator of the wind turbine. The rotating drive train is connected with a stationary part of the wind turbine via at least one bearing, which allows the rotation of the drive train in relation to the stationary part. The at least one bearing is a plain bearing and the bearing is a tapered bearing, which comprises at least one conical shaped sliding surface.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

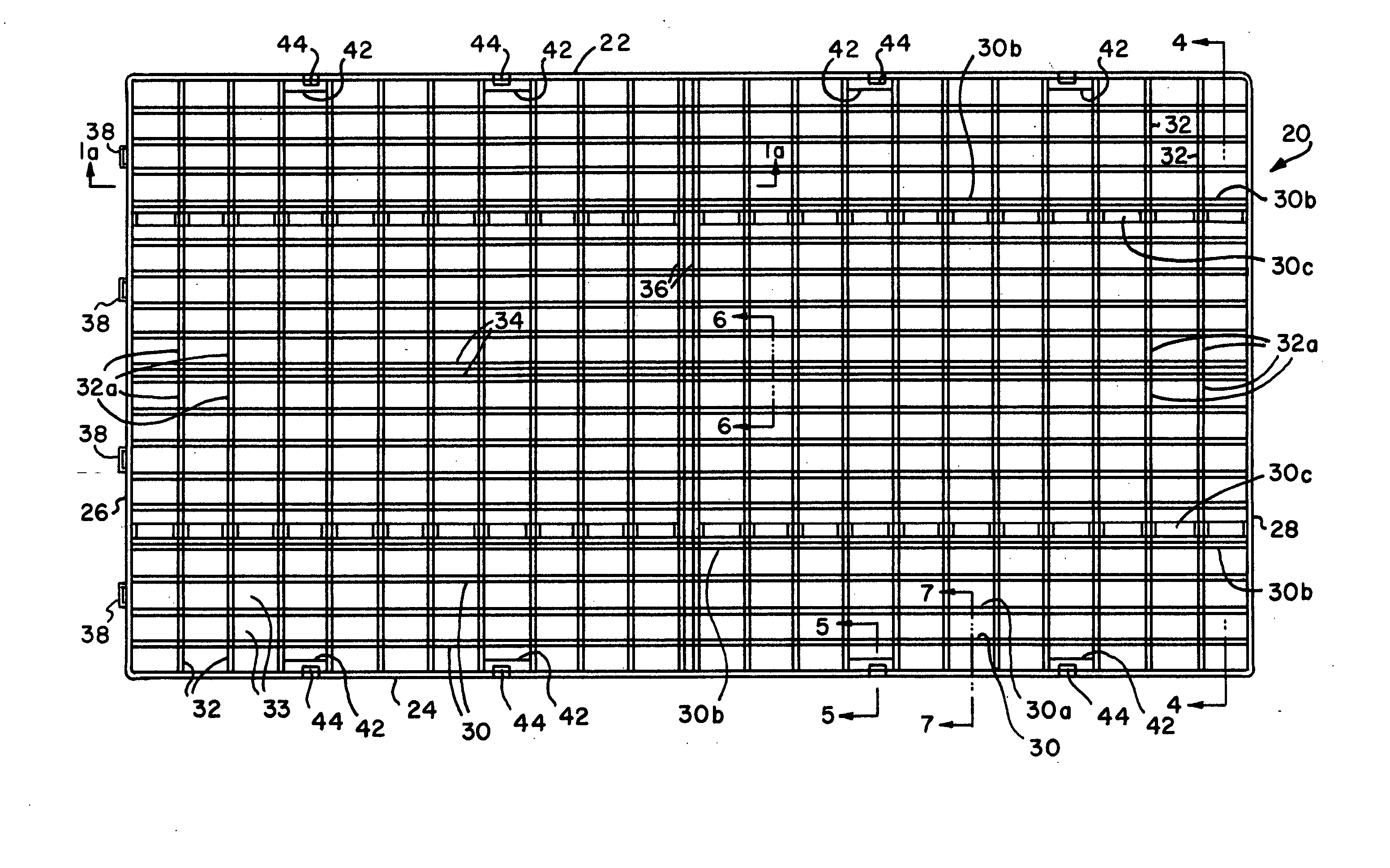

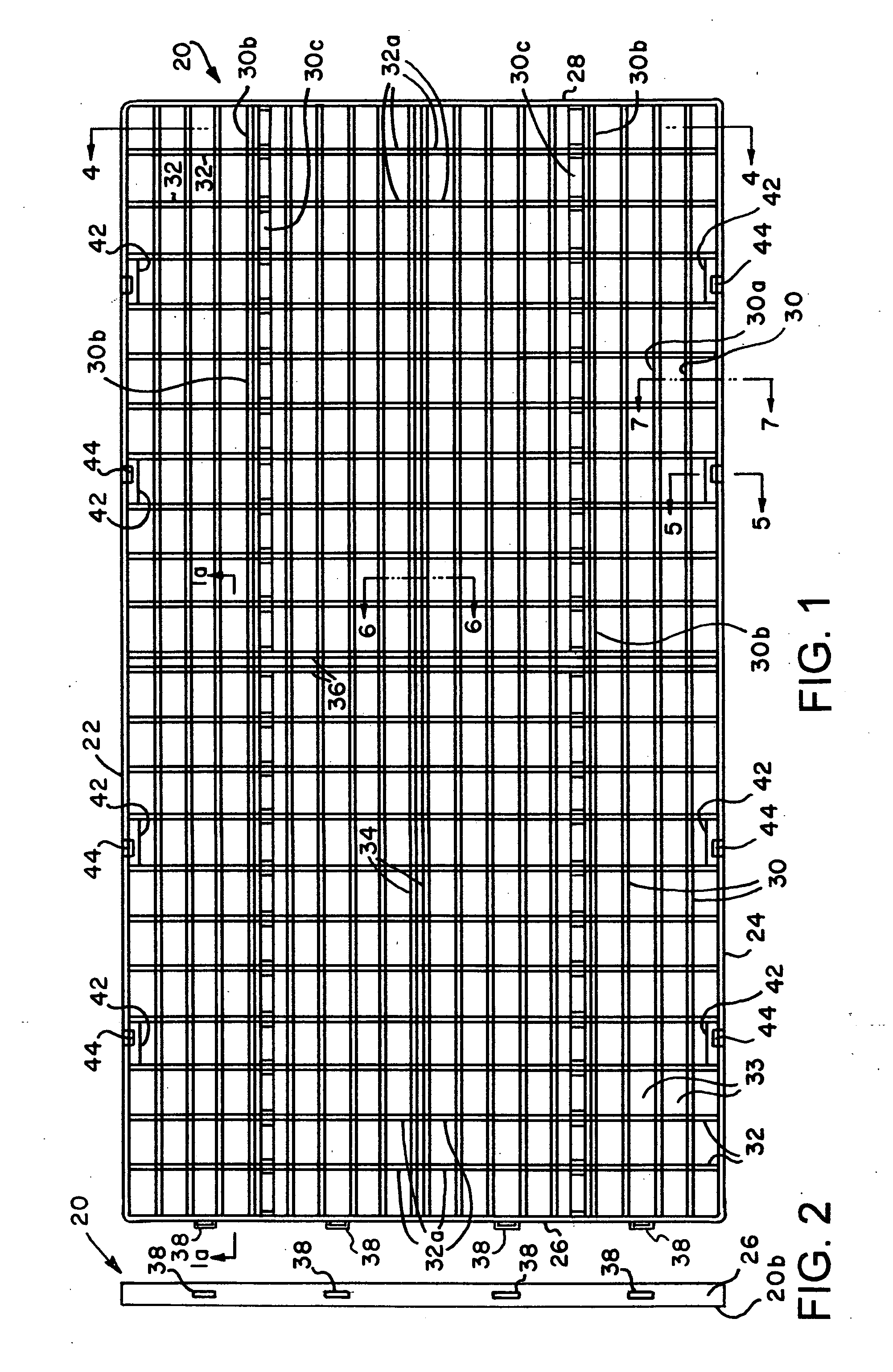

Apparatus and Method of Use for a PVC Composite Mattress Foundation

InactiveUS20130025051A1Minimize amount of materialEliminates extra fastening hardwareSofasBedsEngineering

A lightweight and durable mattress foundation. The apparatus includes a first tier of side rails connected to a first tier of end rails via four end caps and a second tier of side rails connected to a second tier of end rails where the first tier is connected to the second tier via a plurality of standoffs. The side rails and the end rails can vary in length and include strengthening ribs. The first tier side and end rails have a unique cross-section made up of five sections surrounding a slot. The second tier side and end rails have a different unique cross-section. The end caps each include tabs for insertion into the slots of the side and end rails. Slats having a U-shaped cross-section and including strengthening ribs extend from side rail to side rail and / or from end rail to end rail. An alternate embodiment includes feet.

Owner:WESTECH BUILDING PRODS

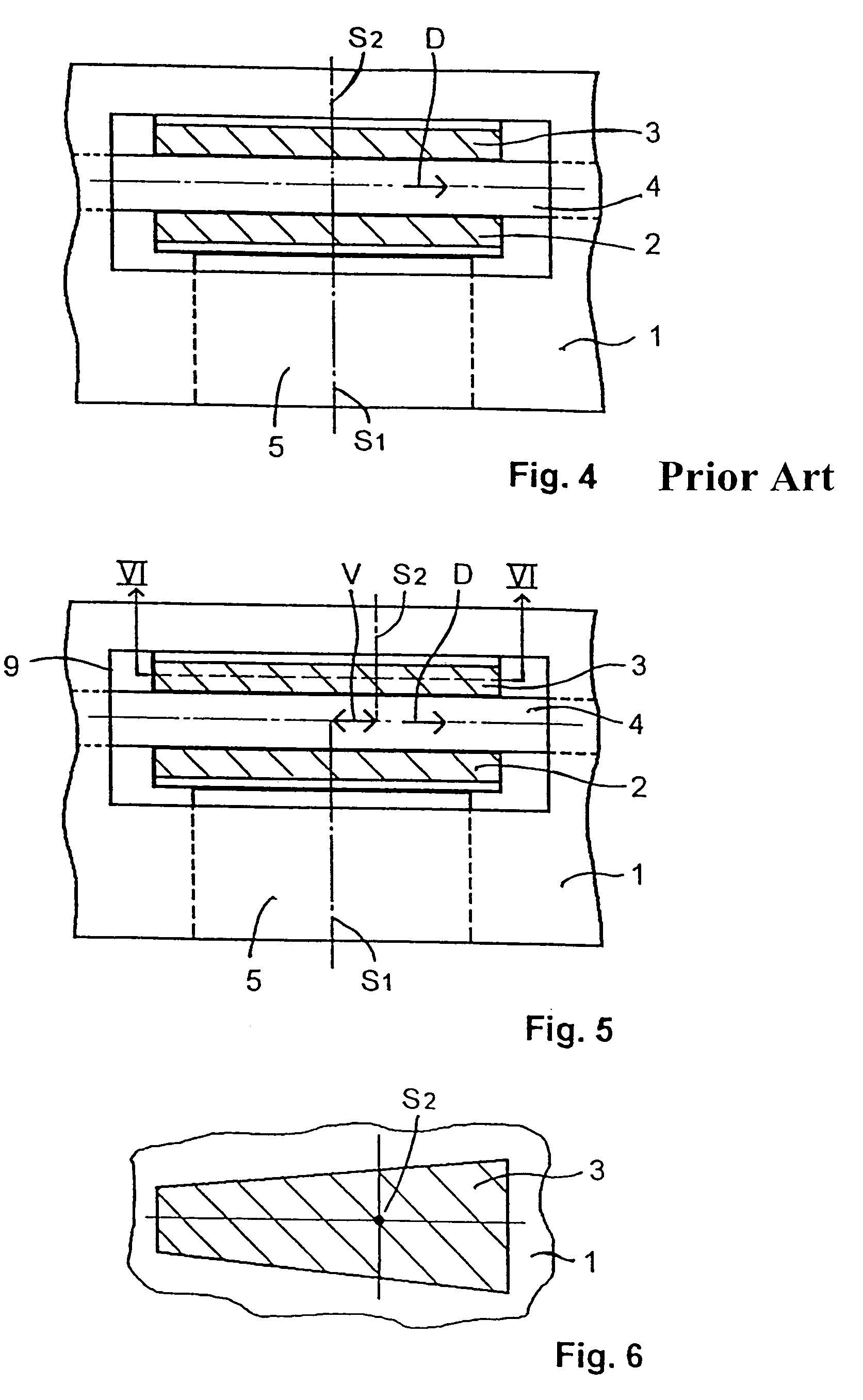

Disk brake

InactiveUS7461725B2Reduce weightReliable functionAxially engaging brakesBrake actuating mechanismsCalipersBrake pad

A disk brake includes a brake disk with a preferred rotational direction, with a first brake pad with a first center of gravity on a first side of the brake disk, a second brake pad with a second center of gravity on a second side of the brake disk, and a caliper for transmitting the braking forces produced by the second brake pad to the first side of the brake disk. The second center of gravity is offset from the first center of gravity by a predetermined distance in the direction toward the side of the brake disk that trails when the disk is rotating in its preferred direction.

Owner:WABCO EURO BVBA SPRL

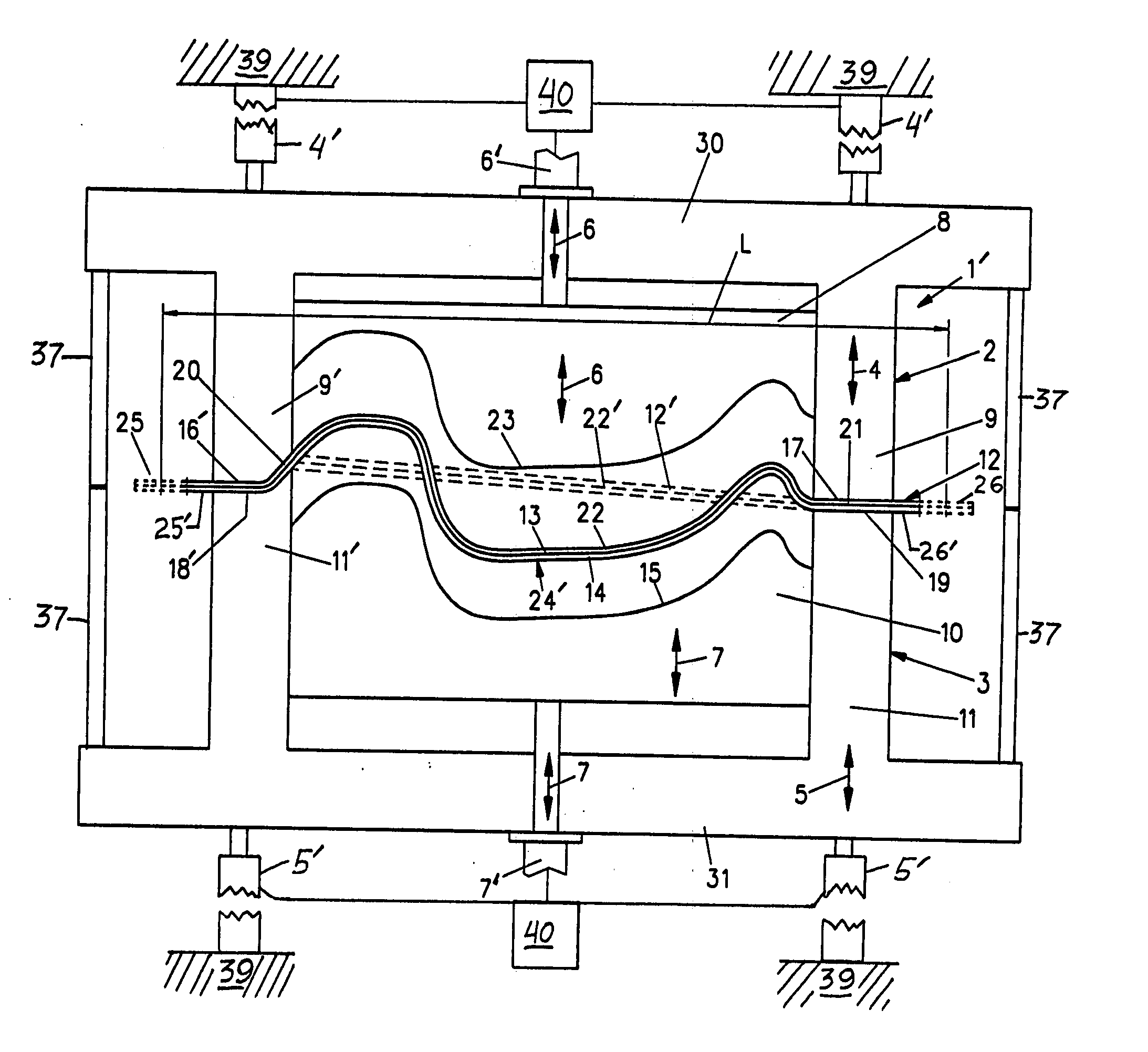

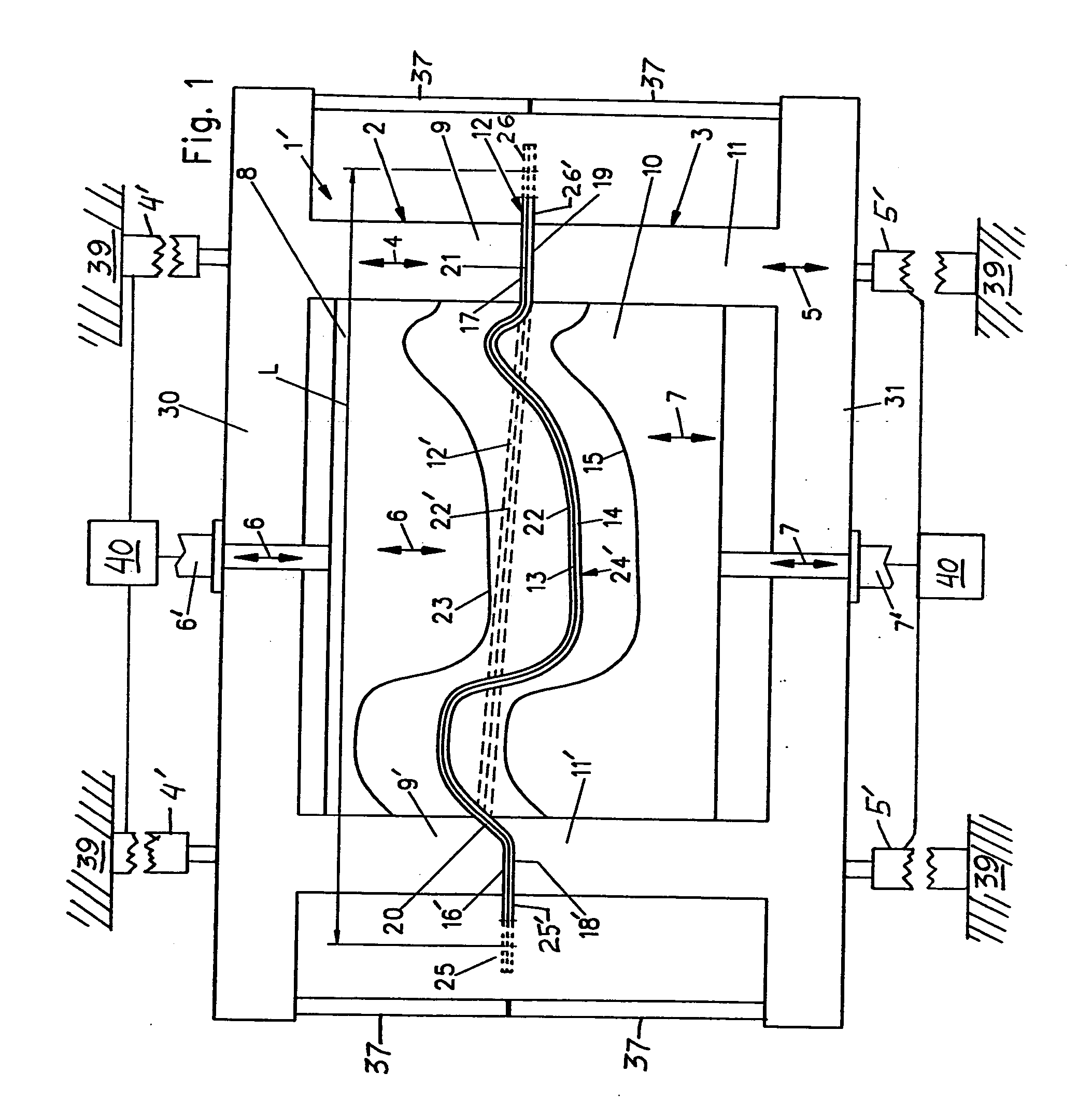

Method and apparatus for molding a laminated trim component without use of slip frame

ActiveUS20060012075A1Minimize amount of materialQuantity minimizationConfectionerySweetmeatsDriven elementPermanent Mount

An apparatus for producing a molded product from a sheet-form raw material blank has first and second mold tools that each respectively include a respective inner core mold and a respective outer edge mold laterally adjacent thereto. Drive elements drive the outer edge molds relative to a machine frame, and drive the inner core molds relative to the outer edge molds. A molding process involves closing the outer edge molds to hold an edge rim of the material blank while allowing slippage thereof, and then closing the inner core molds to three-dimensionally deform and mold a central portion of the material blank while pulling required additional material by slippage through the outer edge molds. A separate slip frame is not used. The edge rim held by the outer edge molds remains as a permanent mounting rim or flange of the finished molded product. Edge waste is minimized.

Owner:HERBERT OLBRICH

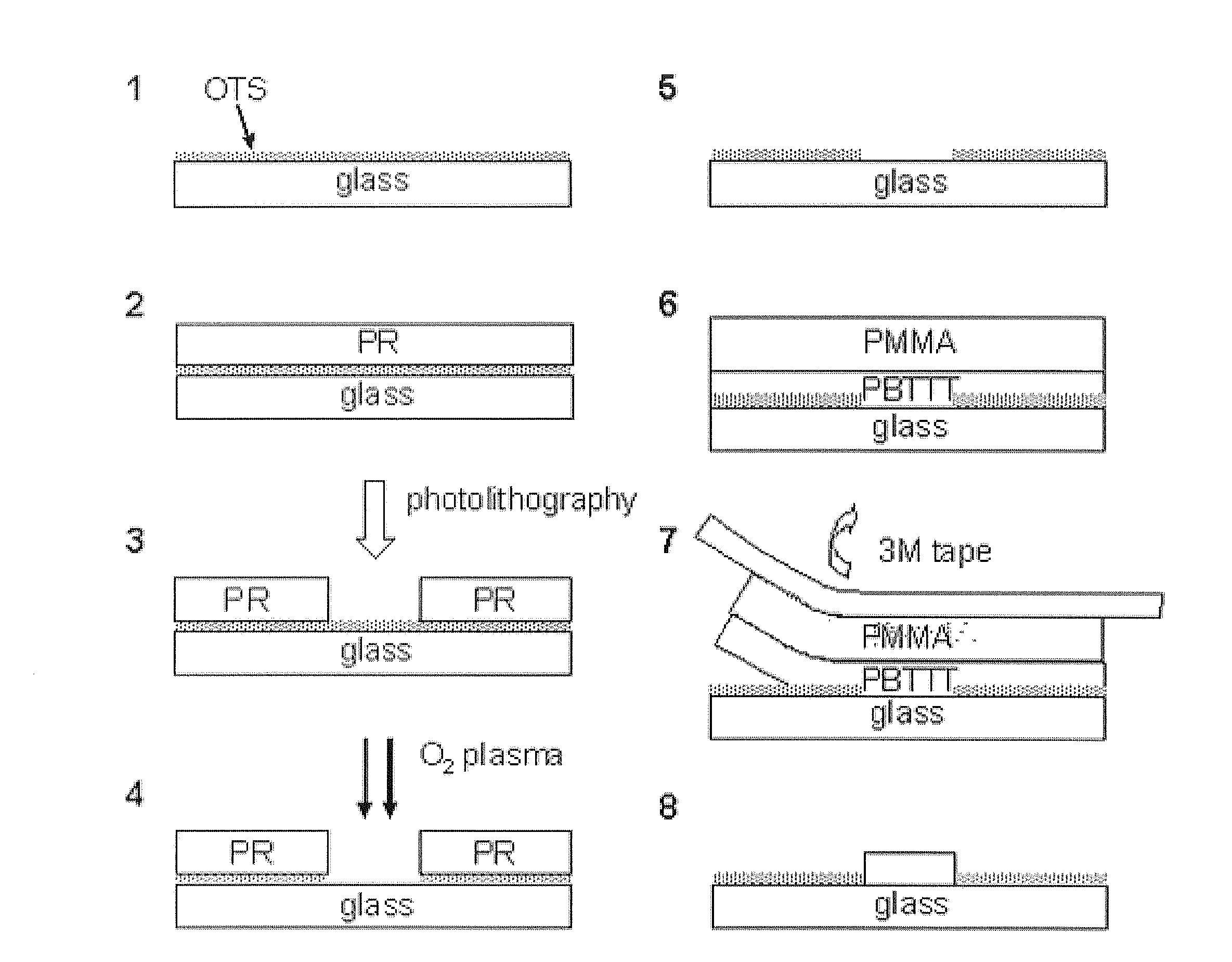

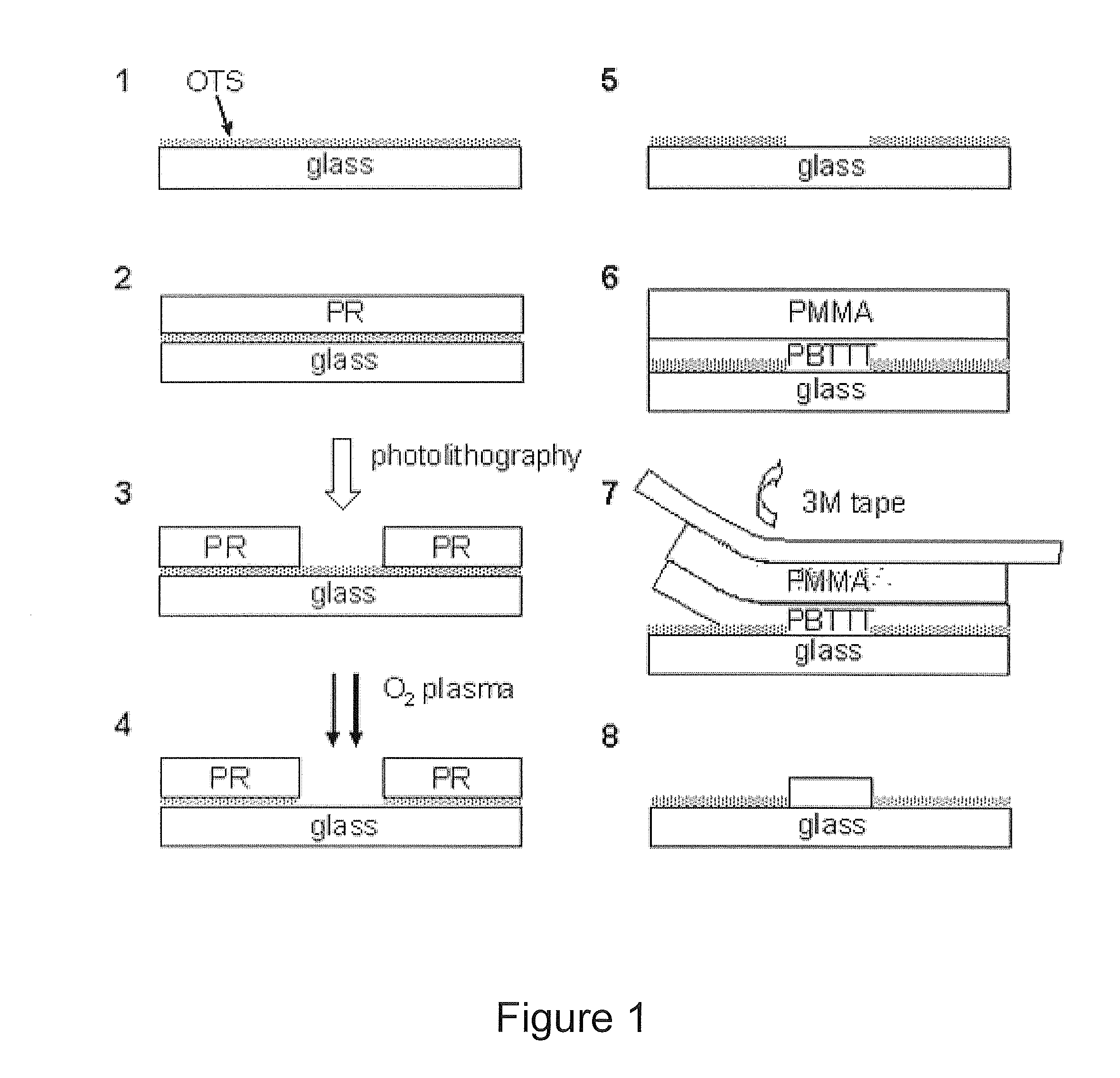

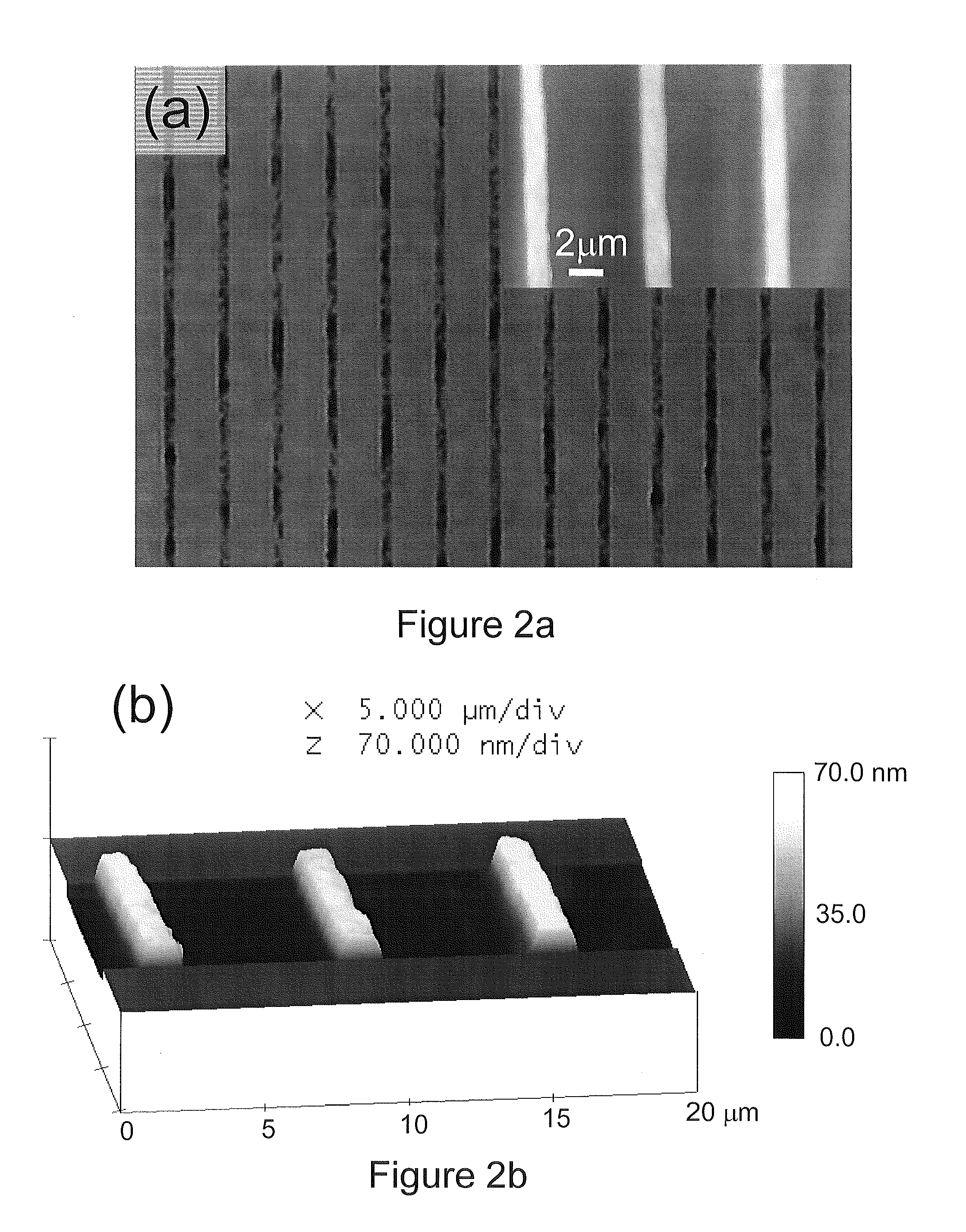

Method of Patterning an Electronig of Photonic Material

ActiveUS20110232954A1Reduce disruptionUniform thicknessPrinted electric component incorporationSolid-state devicesAdhesivePhotonics

Owner:CAMBRIDGE ENTERPRISE LTD

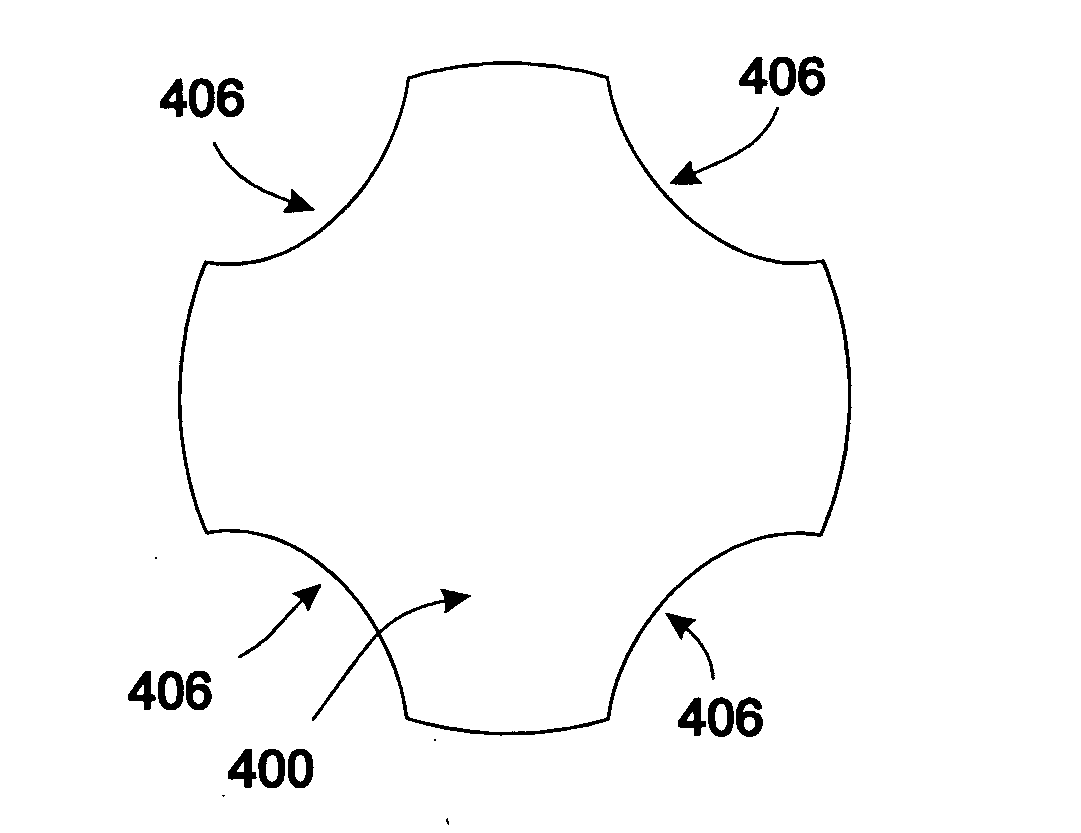

Efficient food wraps

A more-efficient edible food wrap eliminates the excess material of conventional wrap food products, providing effective containment while reducing the amount of raw materials used in production. Unused materials are thus available for additional production, extending quantities and thereby lowering producer costs. Easily fabricated on an automated or manual, multiple or individual basis, these improved structures provide easier assembly by hand or machine and selectable control of contained fluids. Further, these wrapper structures reduce collections of unconsumed food waster by including less of the often-discarded overlapped portions of wrap food products. These wrap designs are also applicable to egg rolls, pizza-like products, and other dough-based comestibles.

Owner:BAKER ROBERT G

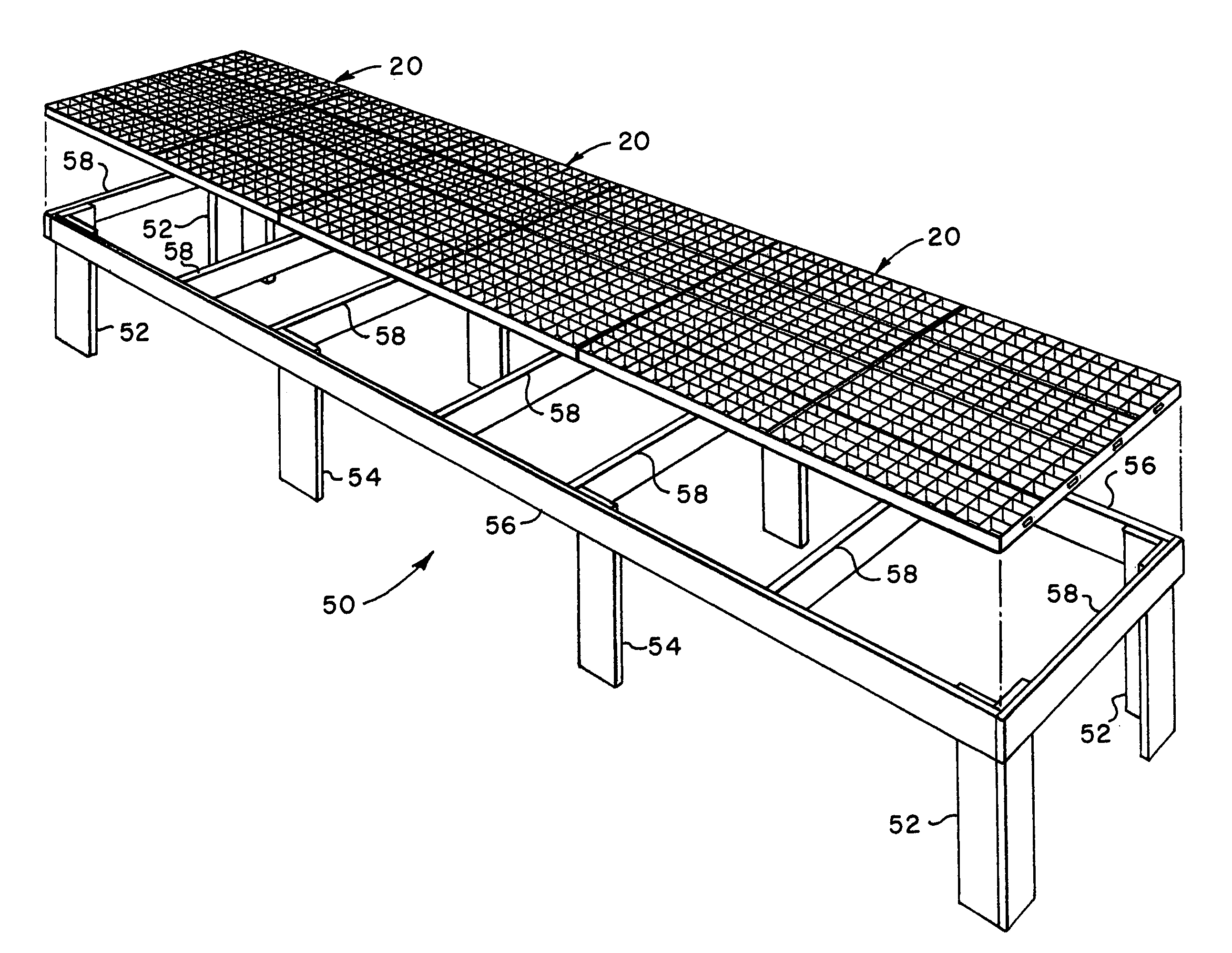

Benchtop panels

Owner:DURAPLAS LP

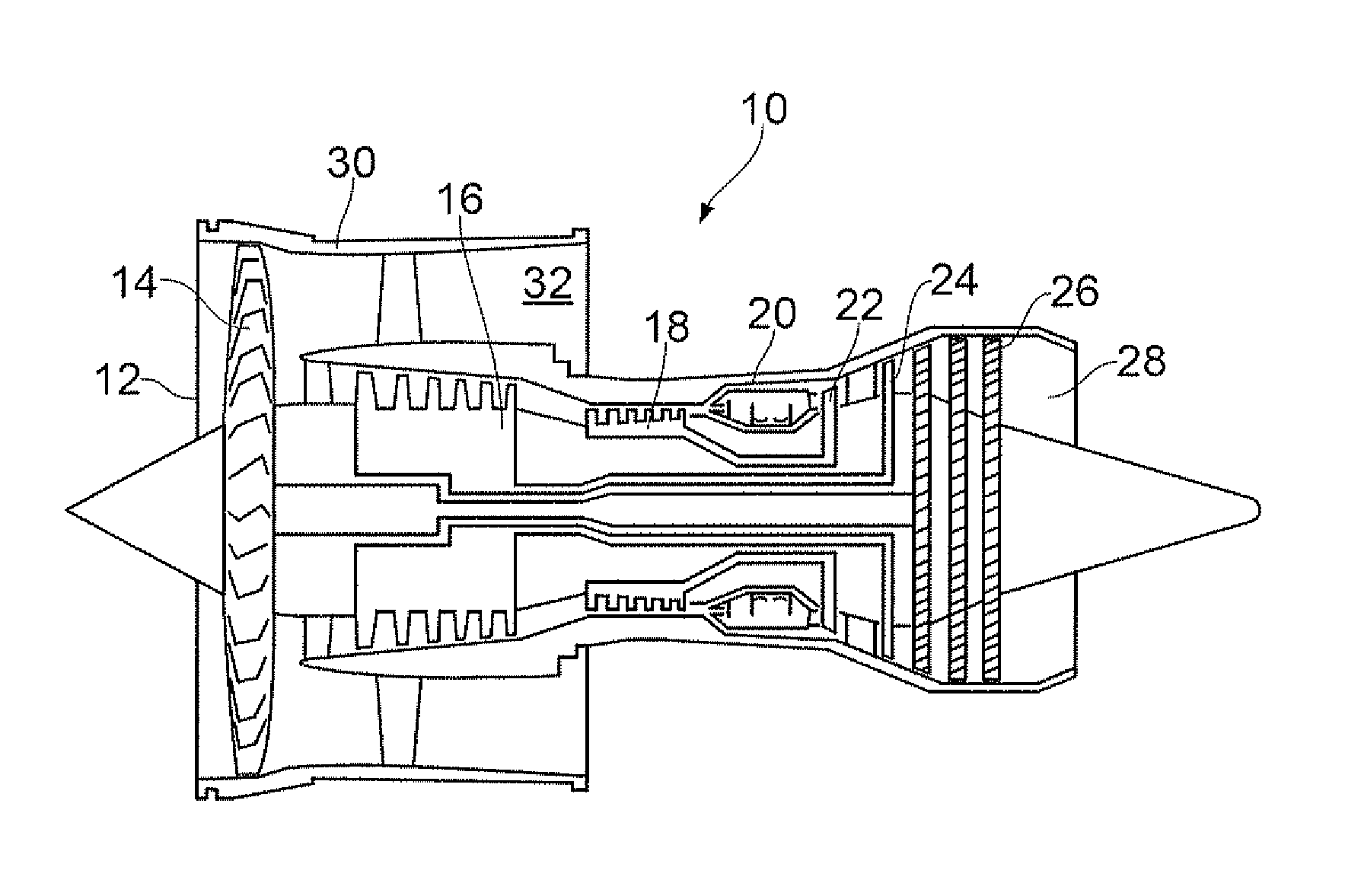

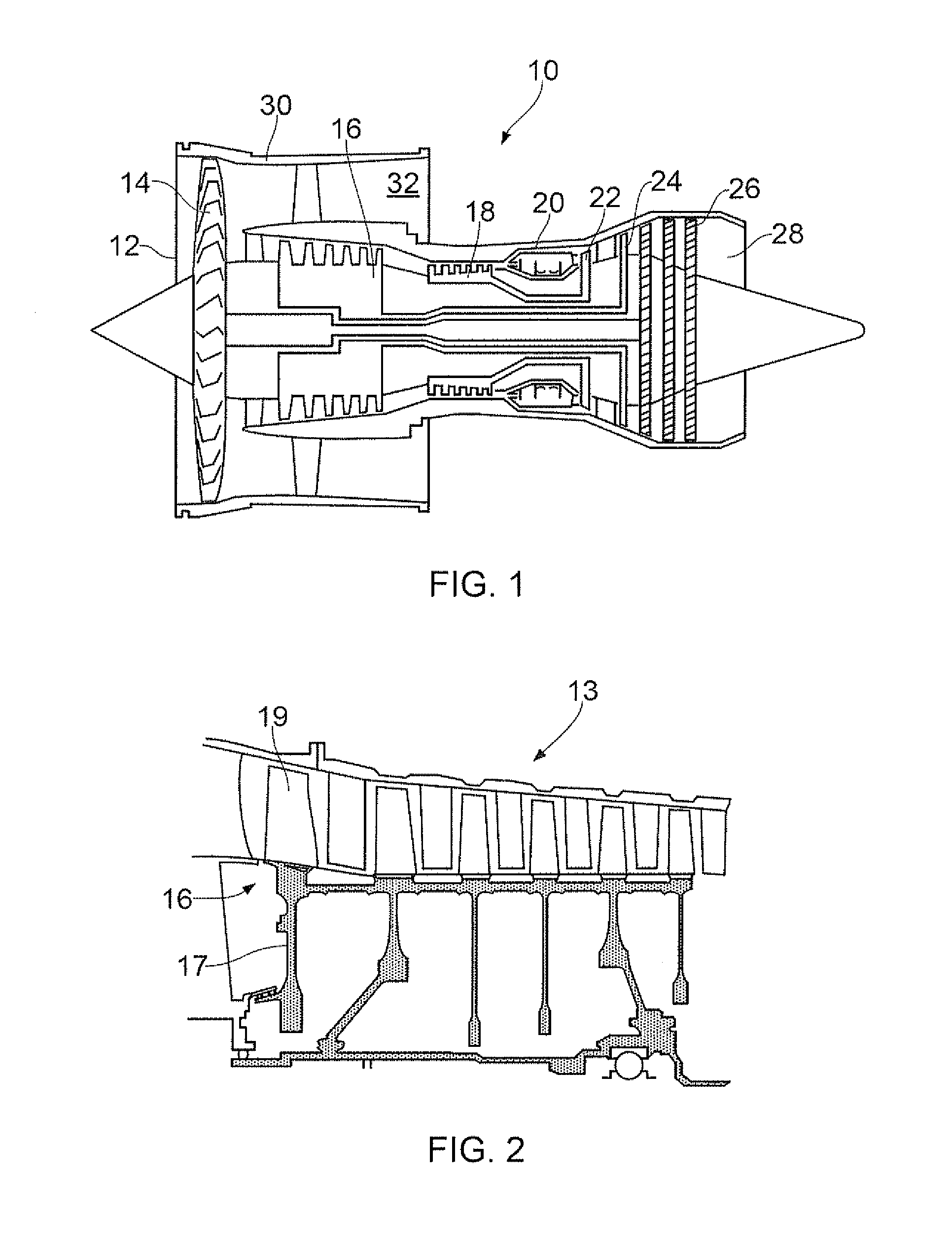

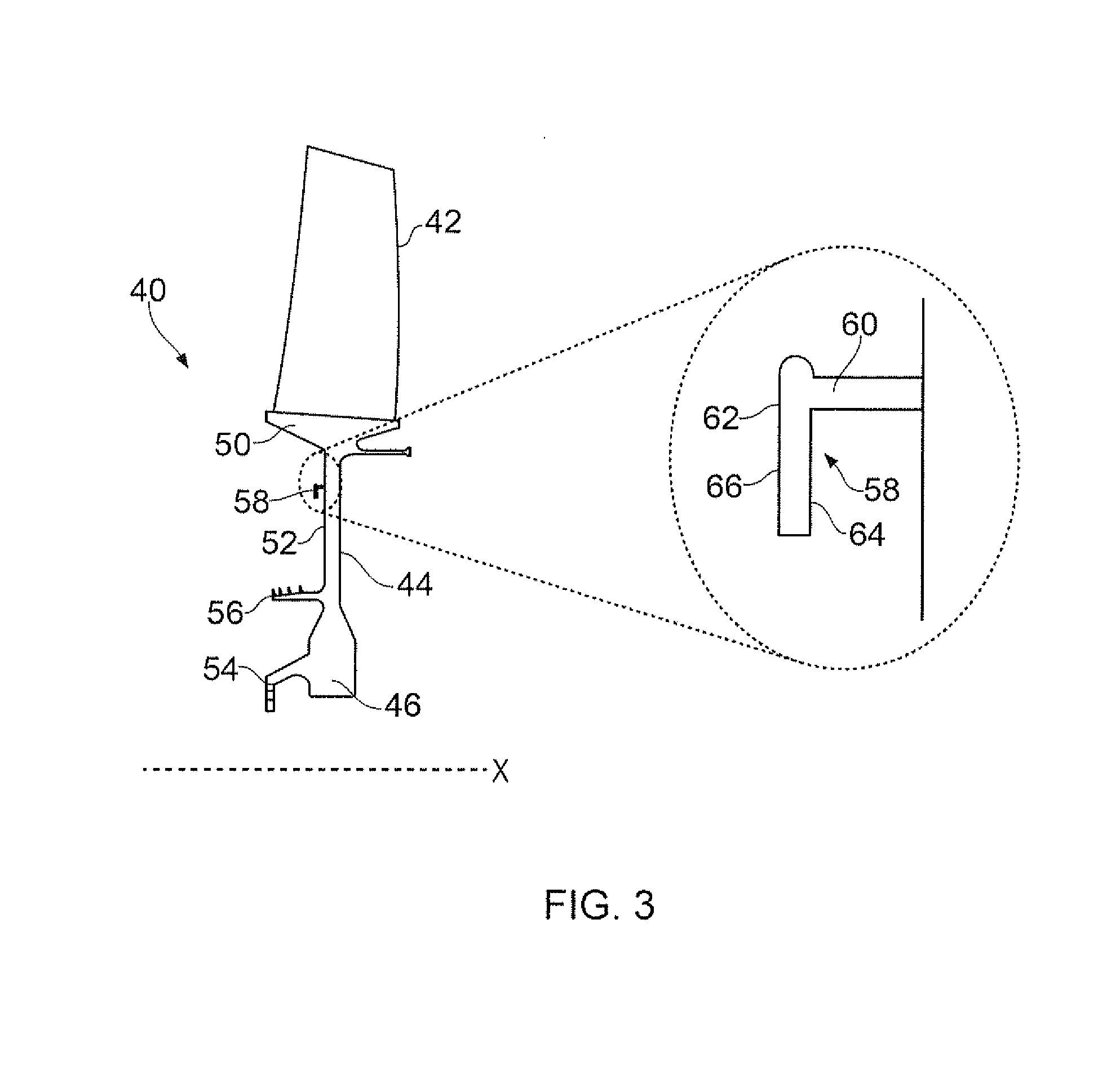

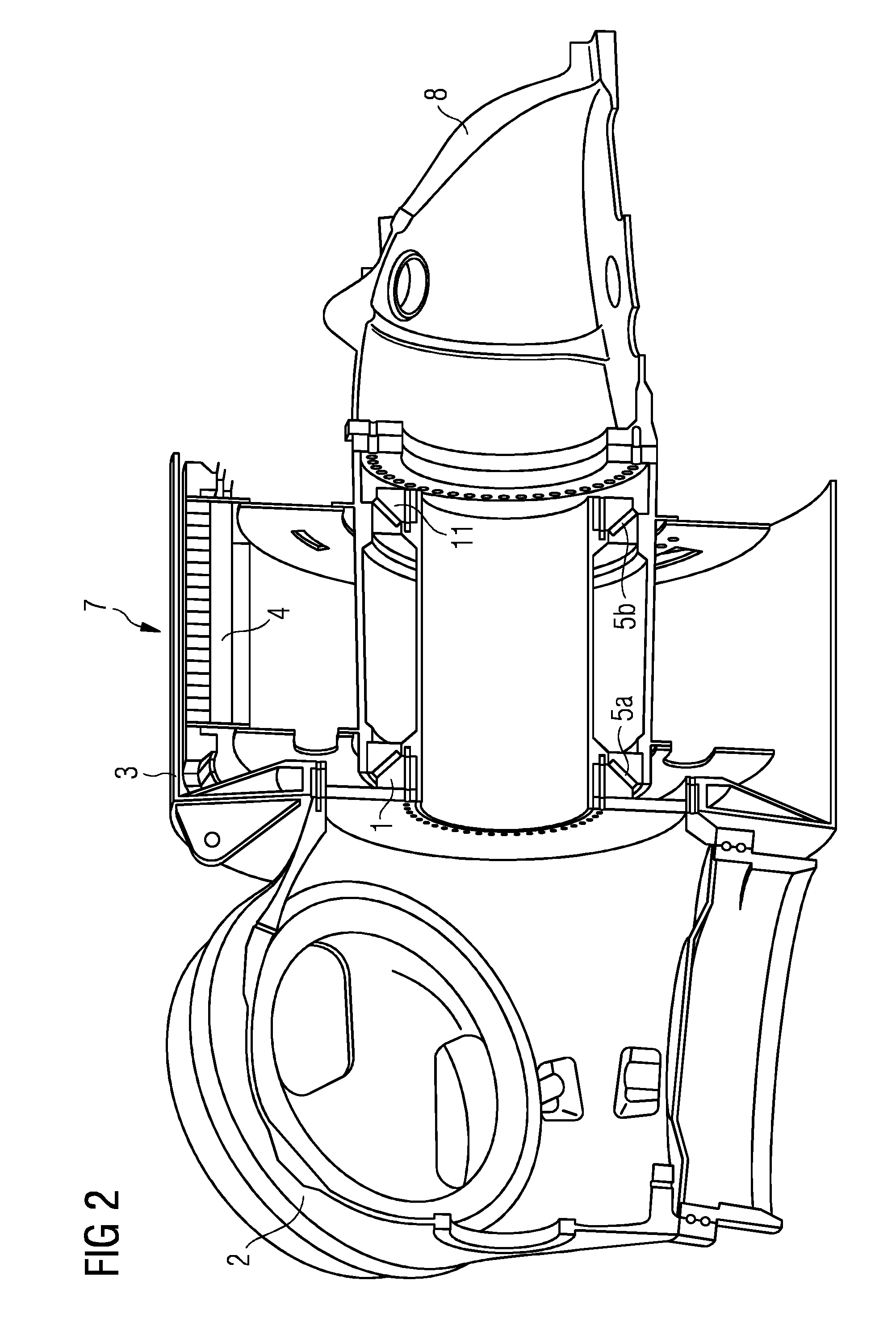

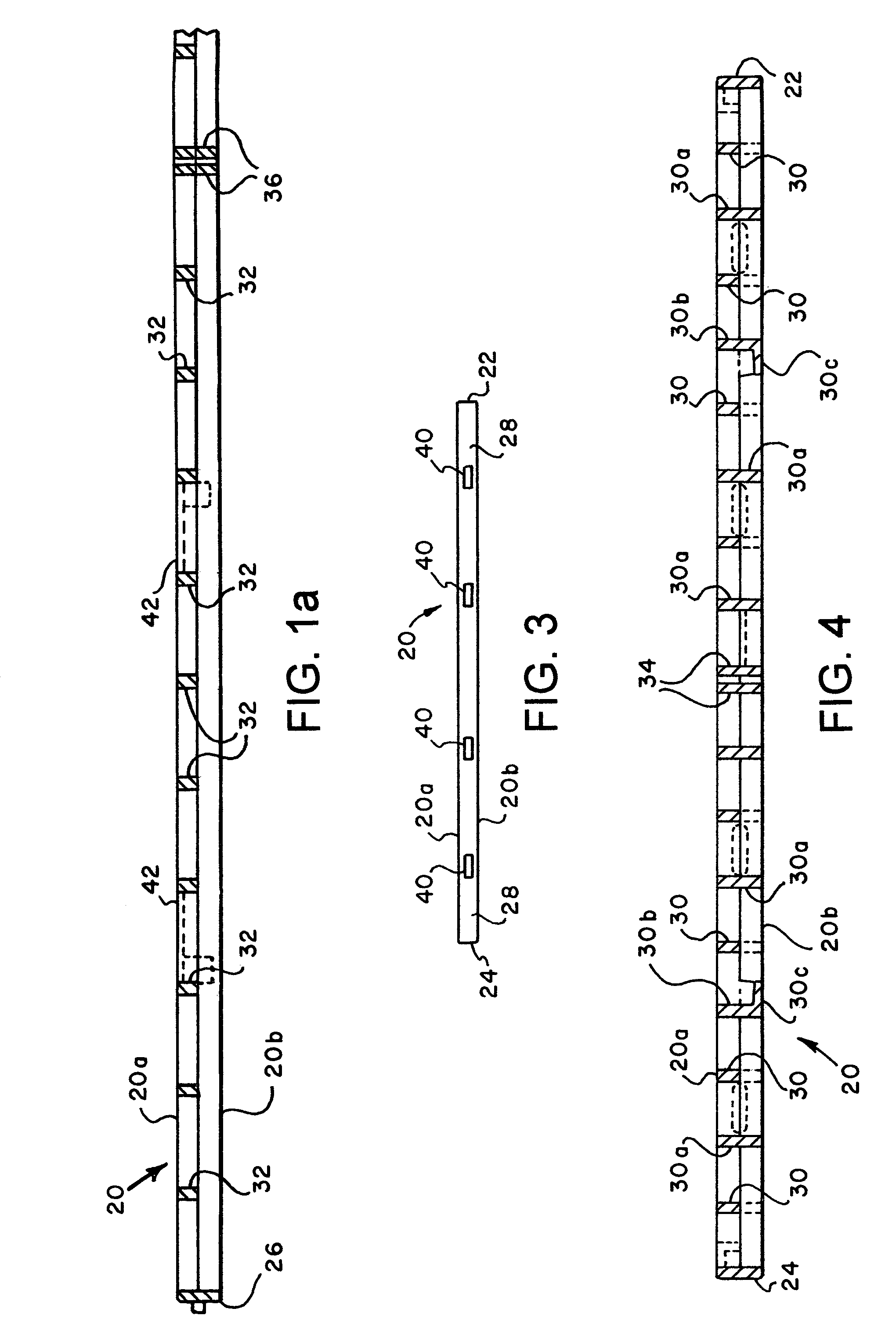

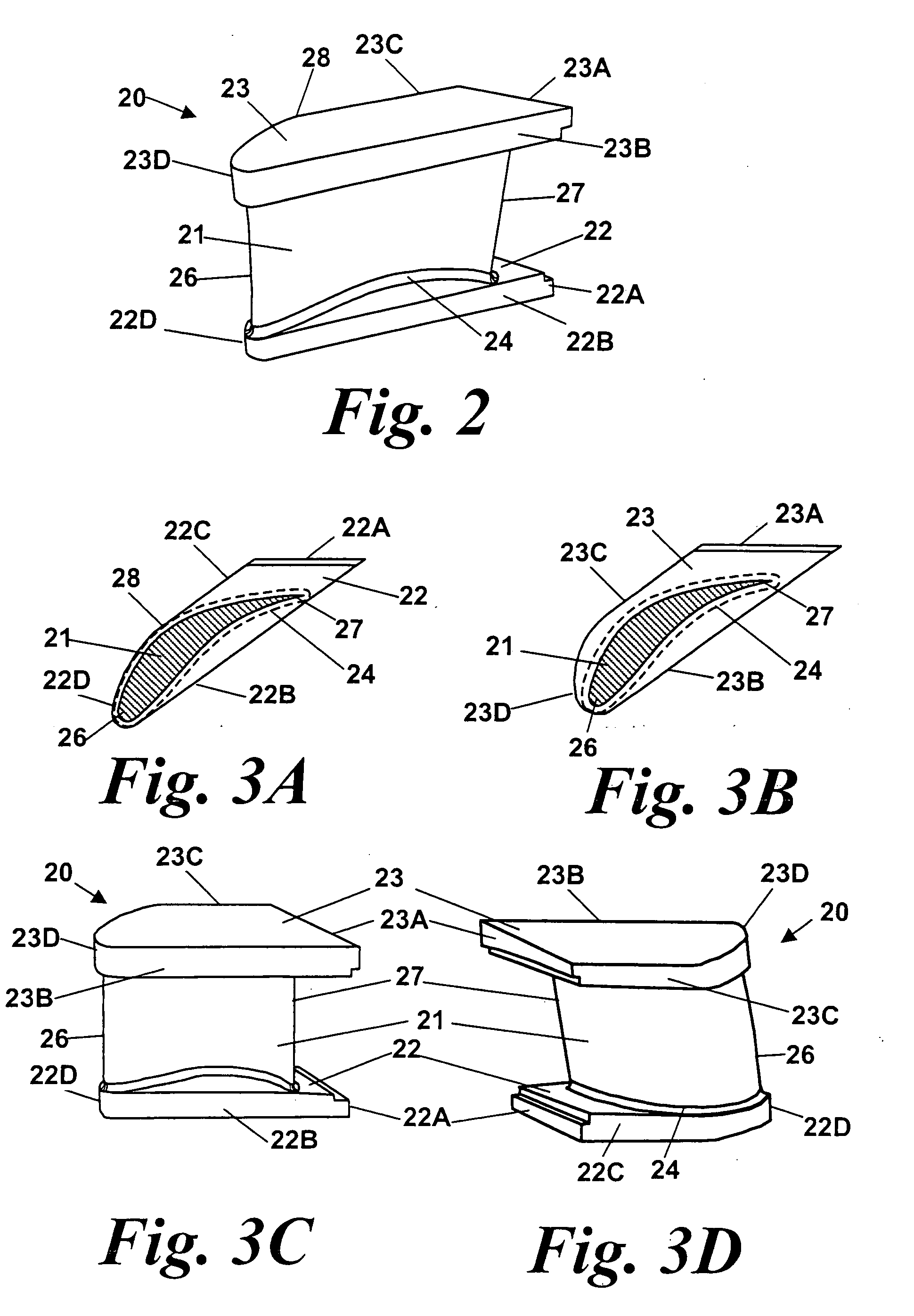

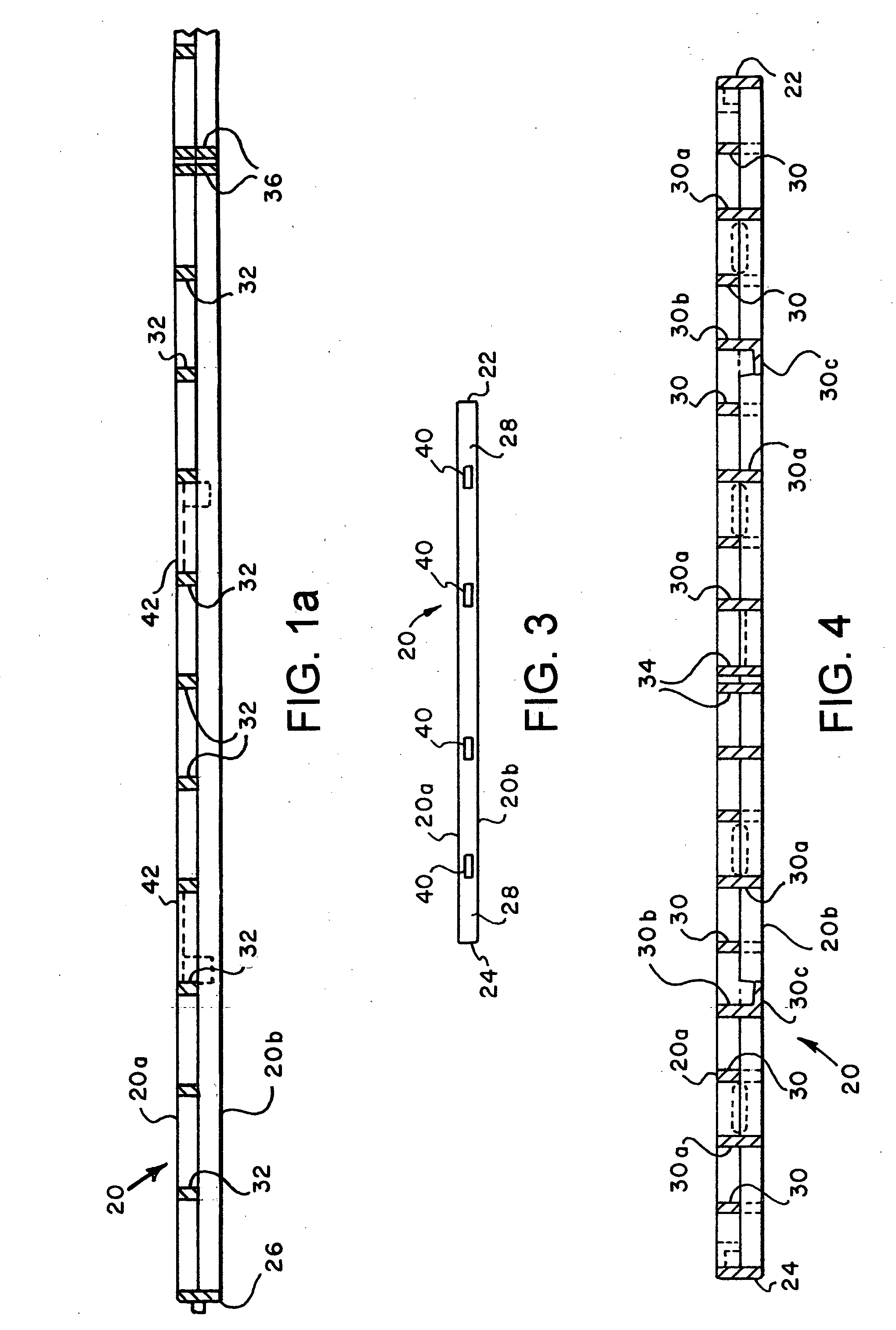

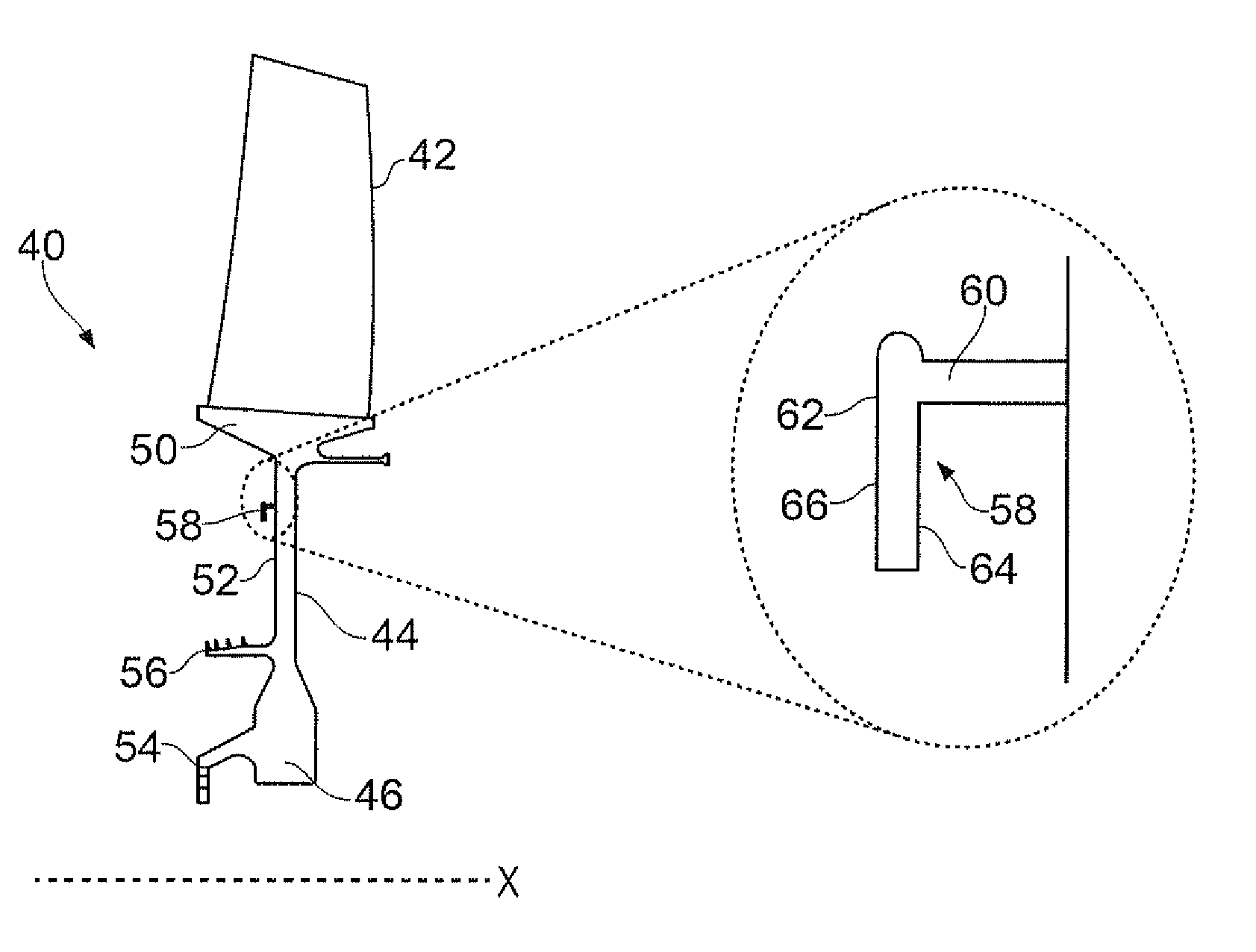

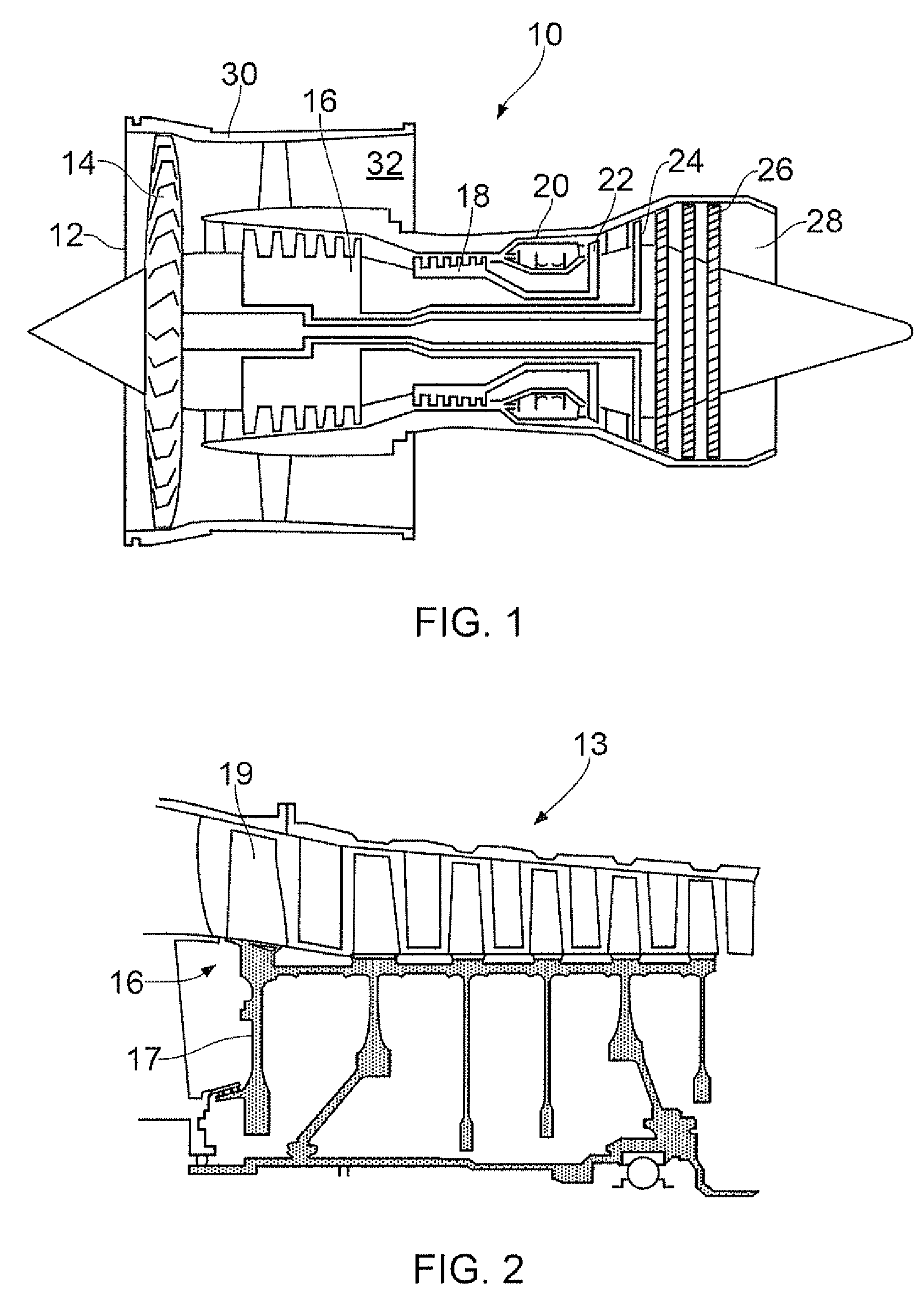

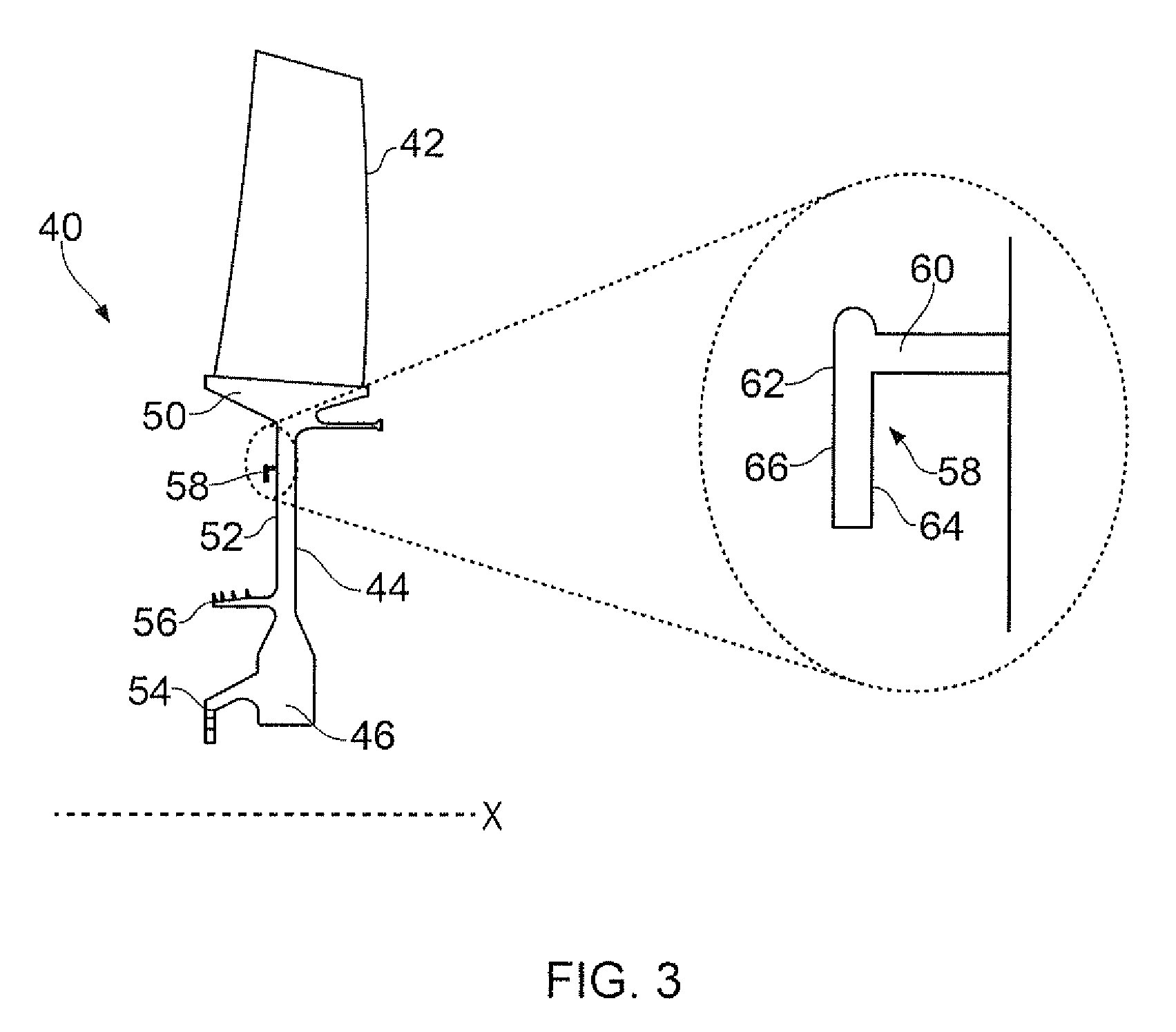

Turbine blade and diaphragm construction

InactiveUS20070224043A1Minimise amountSmooth transitionEngine manufacturePump componentsTurbine bladeLeading edge

An axial flow turbine blade and diaphragm construction comprises an annulus of static turbine blades 20 and inner and outer spacer rings 40, 42 having apertures 41, 43 shaped to accommodate inner and outer platform portions 22, 23 of the blades, whereby the platform portions and the spacer rings together form inner and outer port walls of the turbine diaphragm. A particular feature of the blades is that the inner and outer platform portions 22 and 23 have straight side edges 22B, 22C and 23B, 23C, which are joined to each other by curved leading edges 22D and 23D that in plan view have a shape that follows the edge of the corner fillet 24 in the region of the leading edge 26 of the aerofoil 21.

Owner:ALSTOM TECH LTD

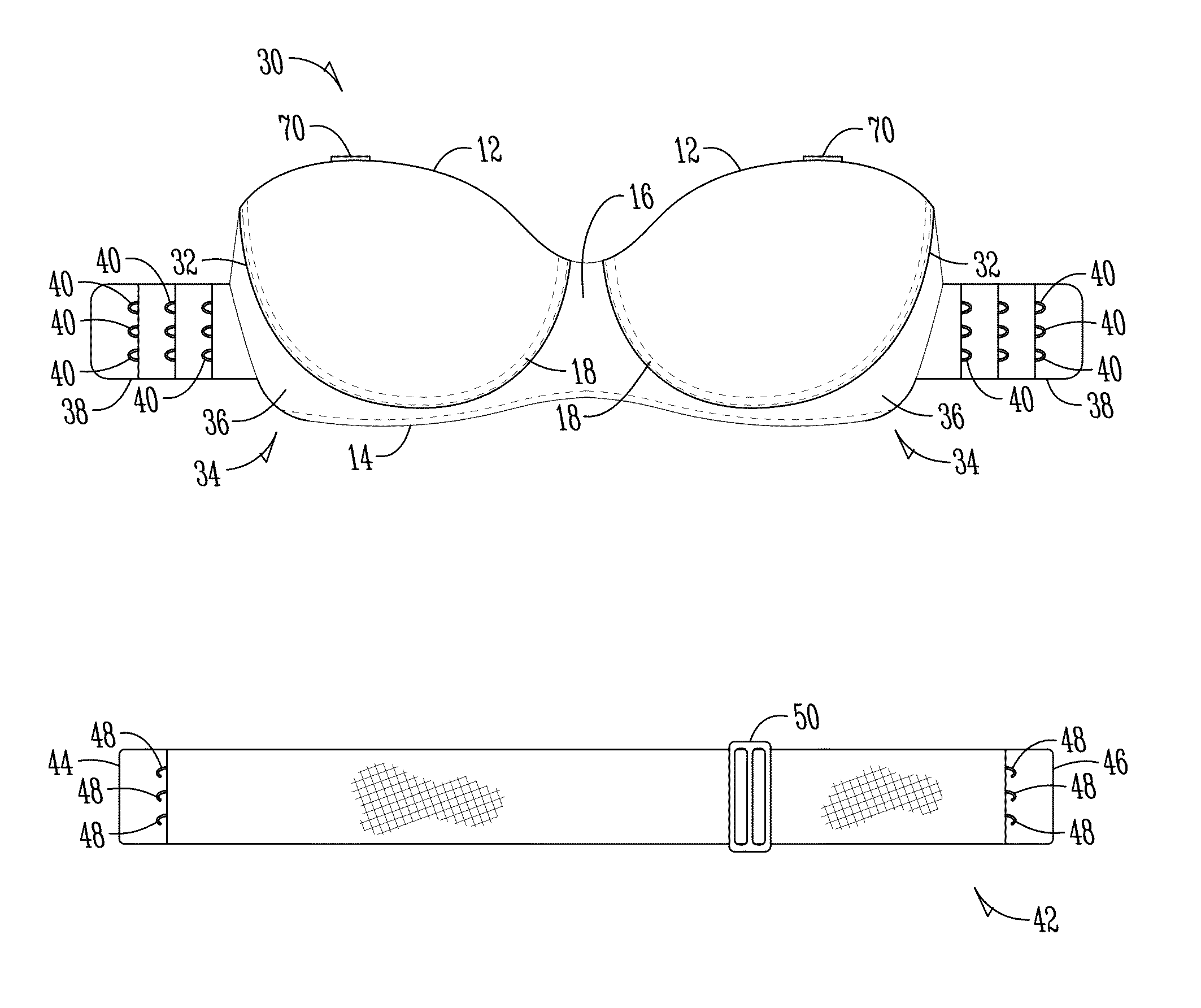

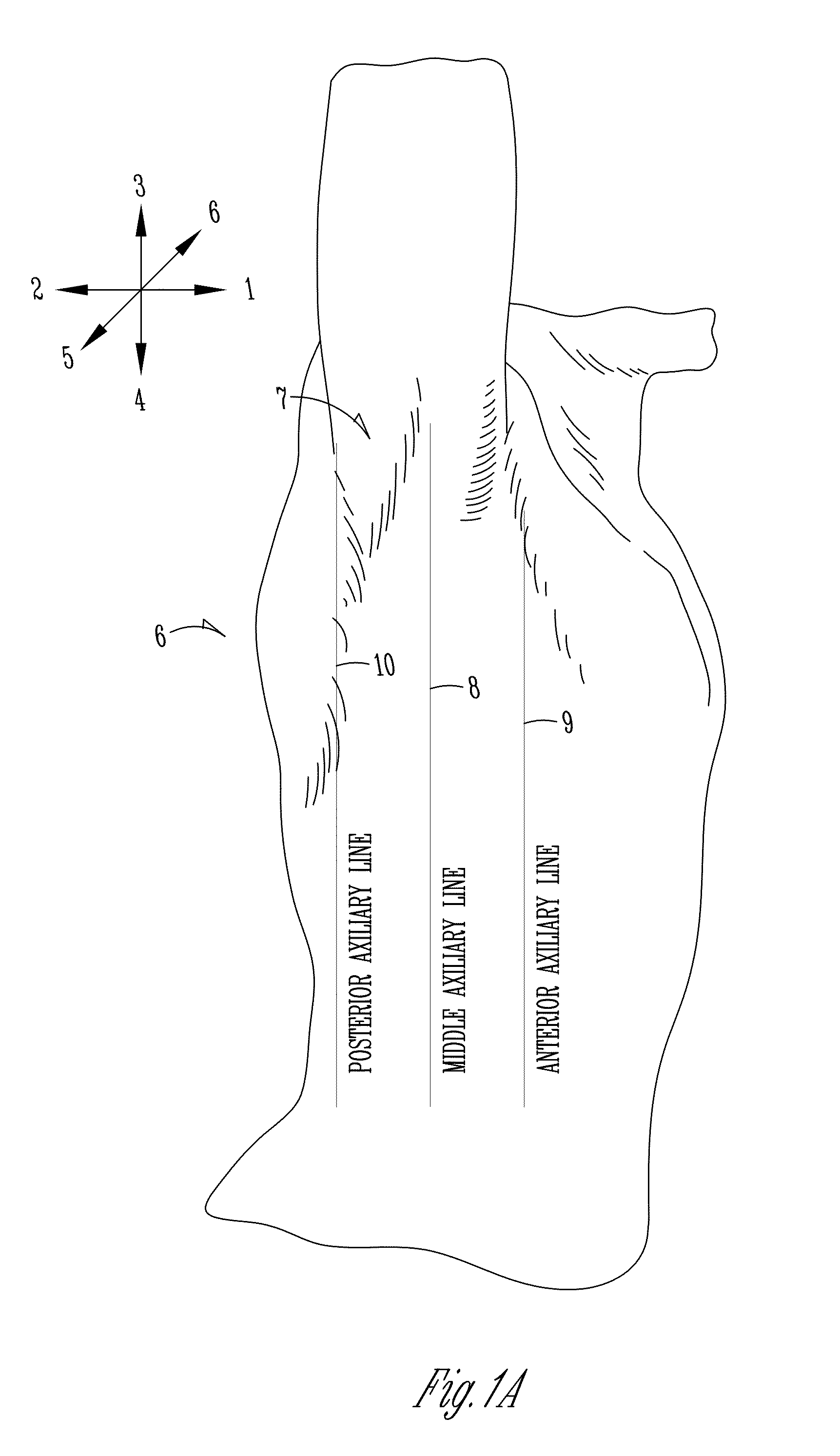

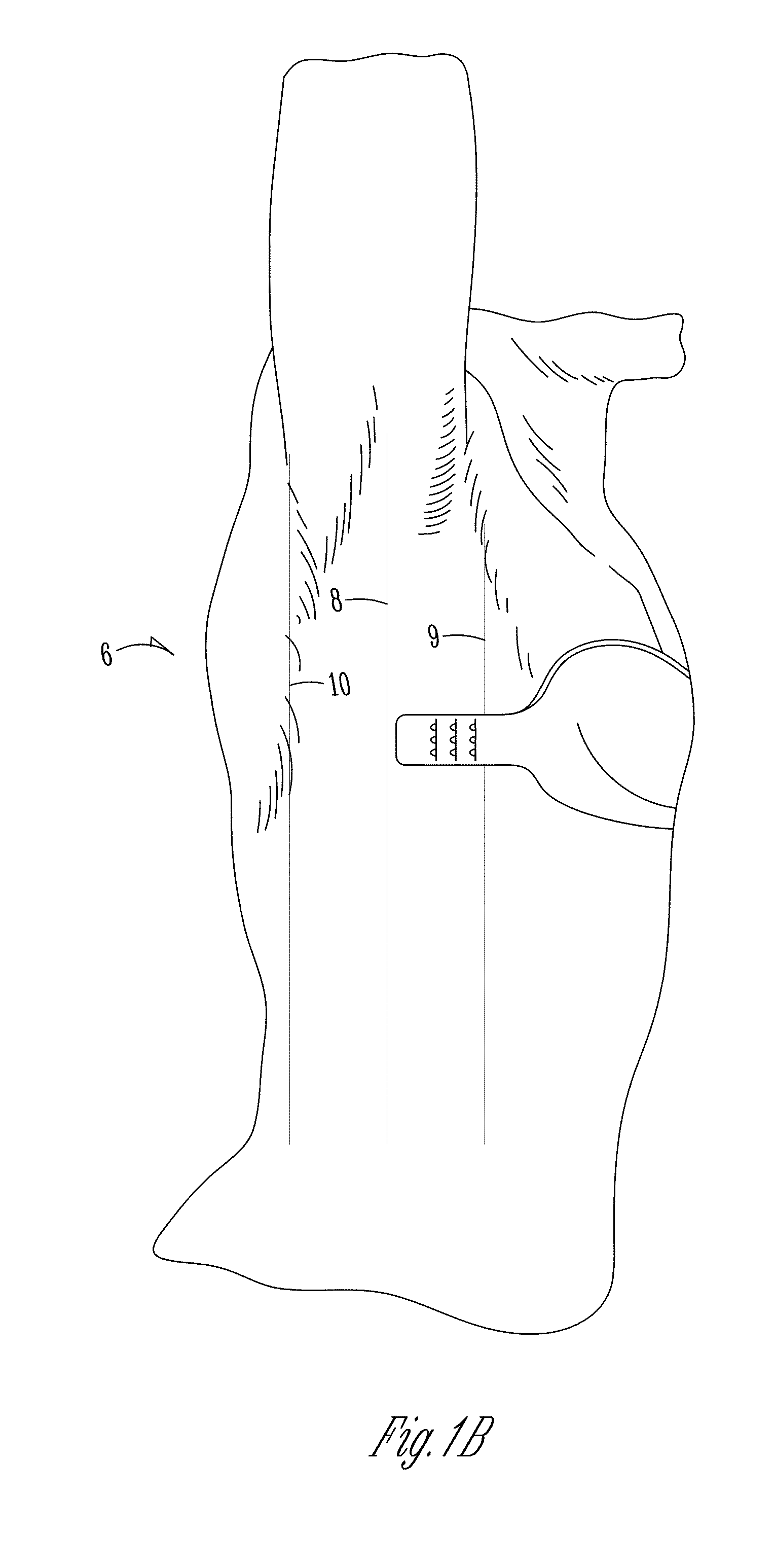

Detachable bra and bra strap assembly and system

InactiveUS20160150833A1Improve any deficiencyMinimized footprintShoulder strapBrassieresPosterior axillaryEngineering

An improved bra assembly includes a pair of cups each having a cup boundary. An outer gore is associated with each of the cups at the cup boundary. The outer gores are configured to extend around the torso to a position anterior to the posterior axillary line, and / or anterior to the midaxillary line. A back strap is configured to removably connect with the outer gores and is preferably transparent. To attach removable shoulder straps, the bra can further include cup connection members and strap connection members, each configured to removably connect to the shoulder straps. An improved bra system includes a first back strap without strap connection members and a second back strap with strap connection members. The first back strap and the second back strap are selectively interchangeable. The first back strap, the second back strap, and / or the shoulder straps can be at least partially transparent.

Owner:SPICER TARRITA

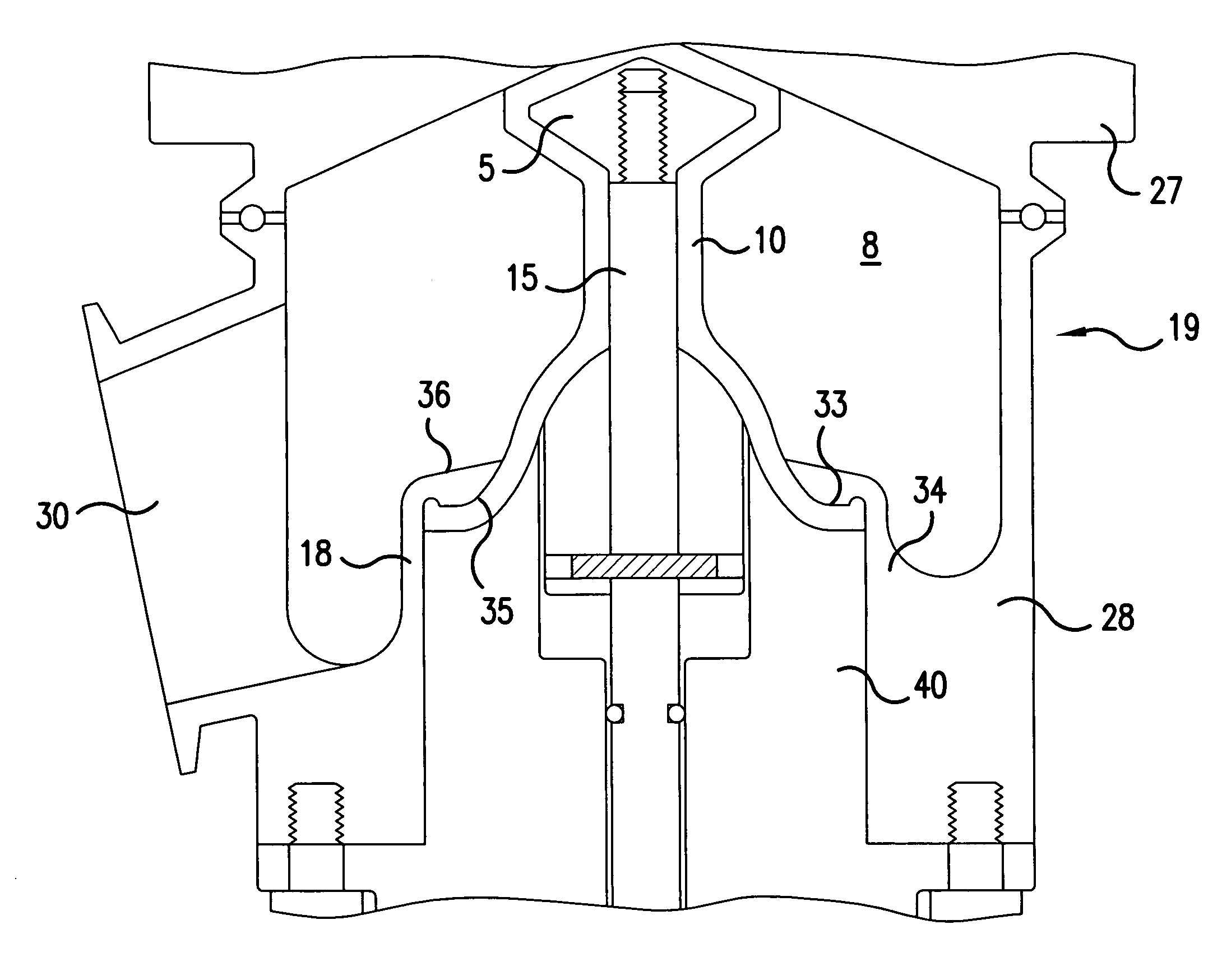

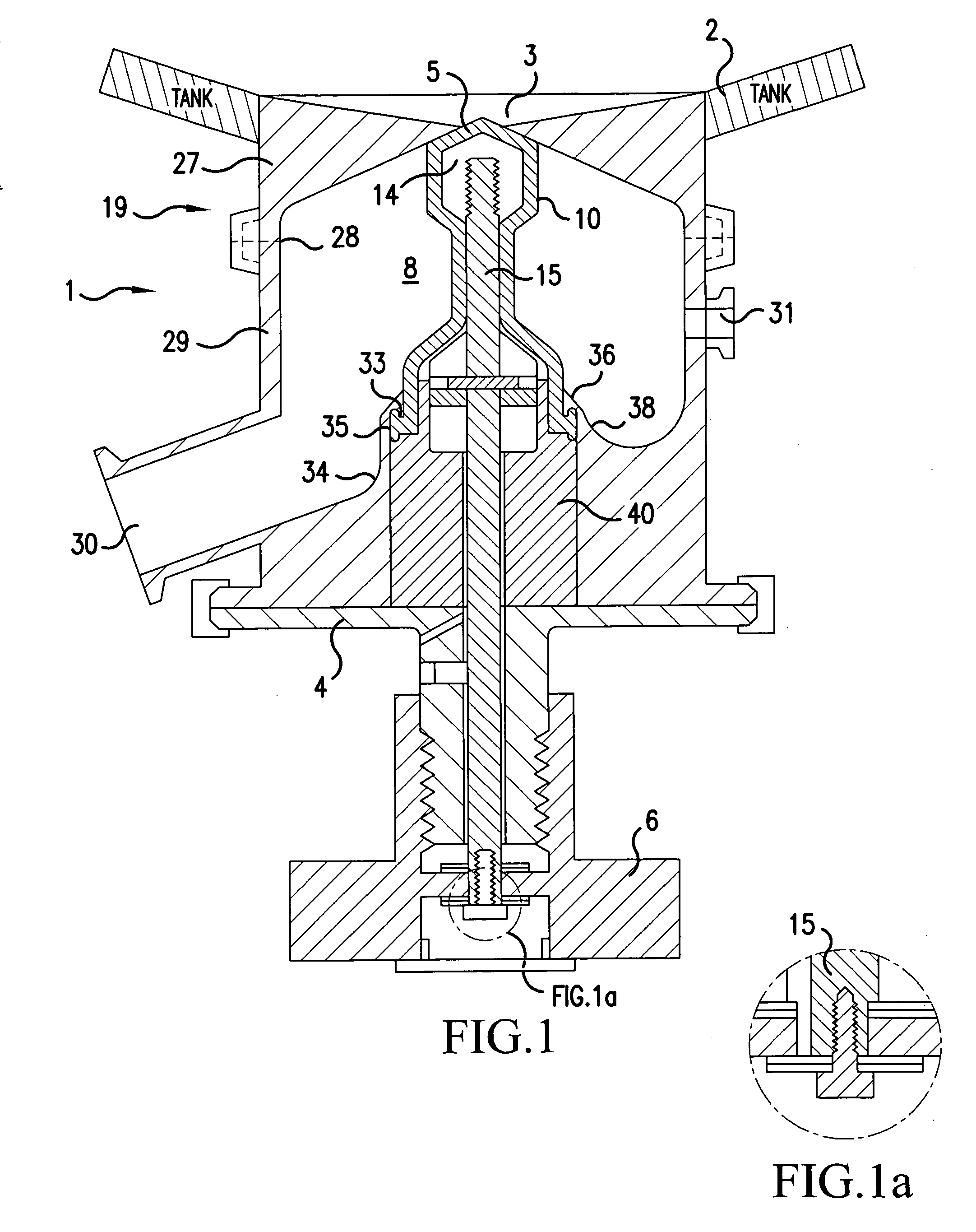

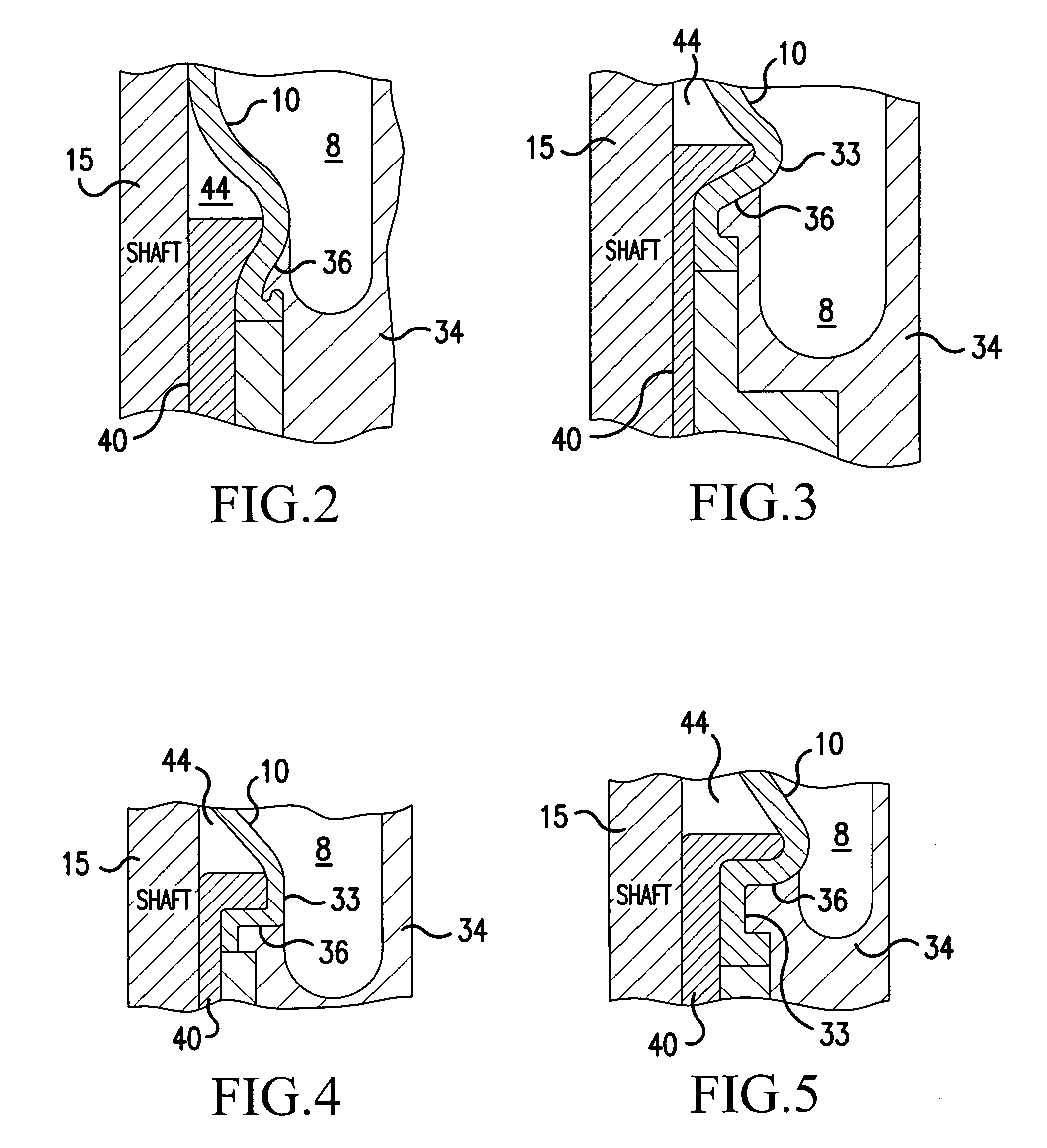

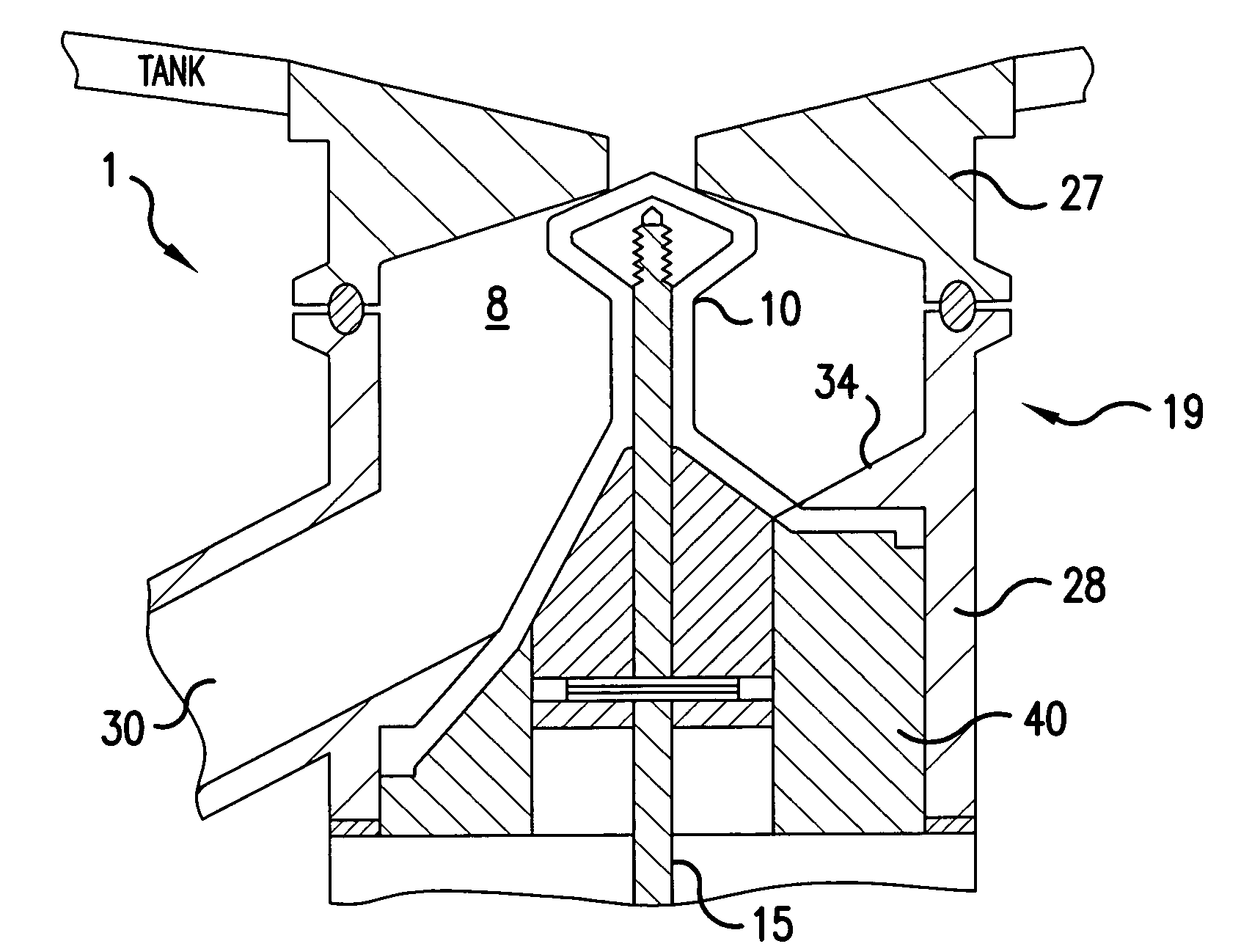

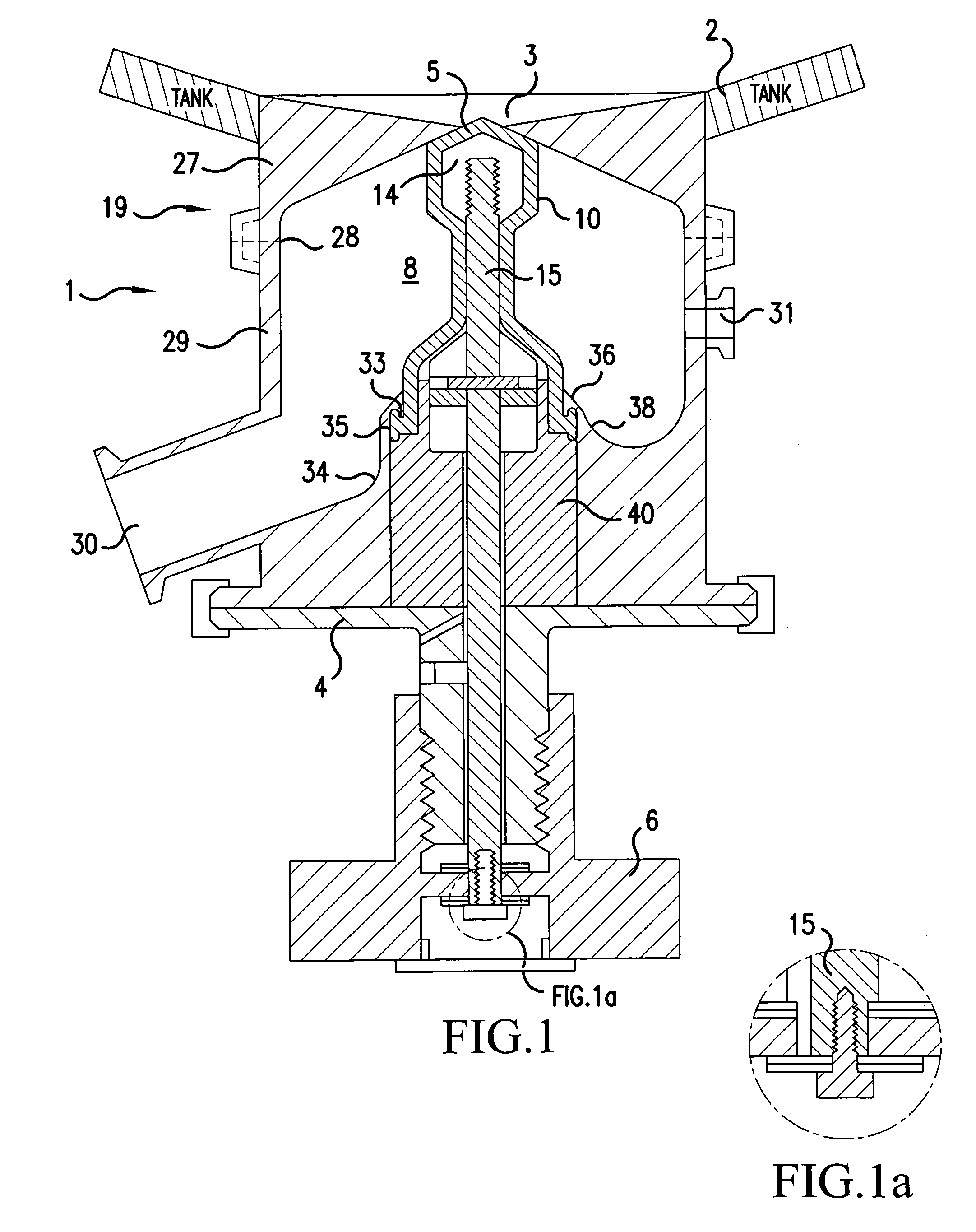

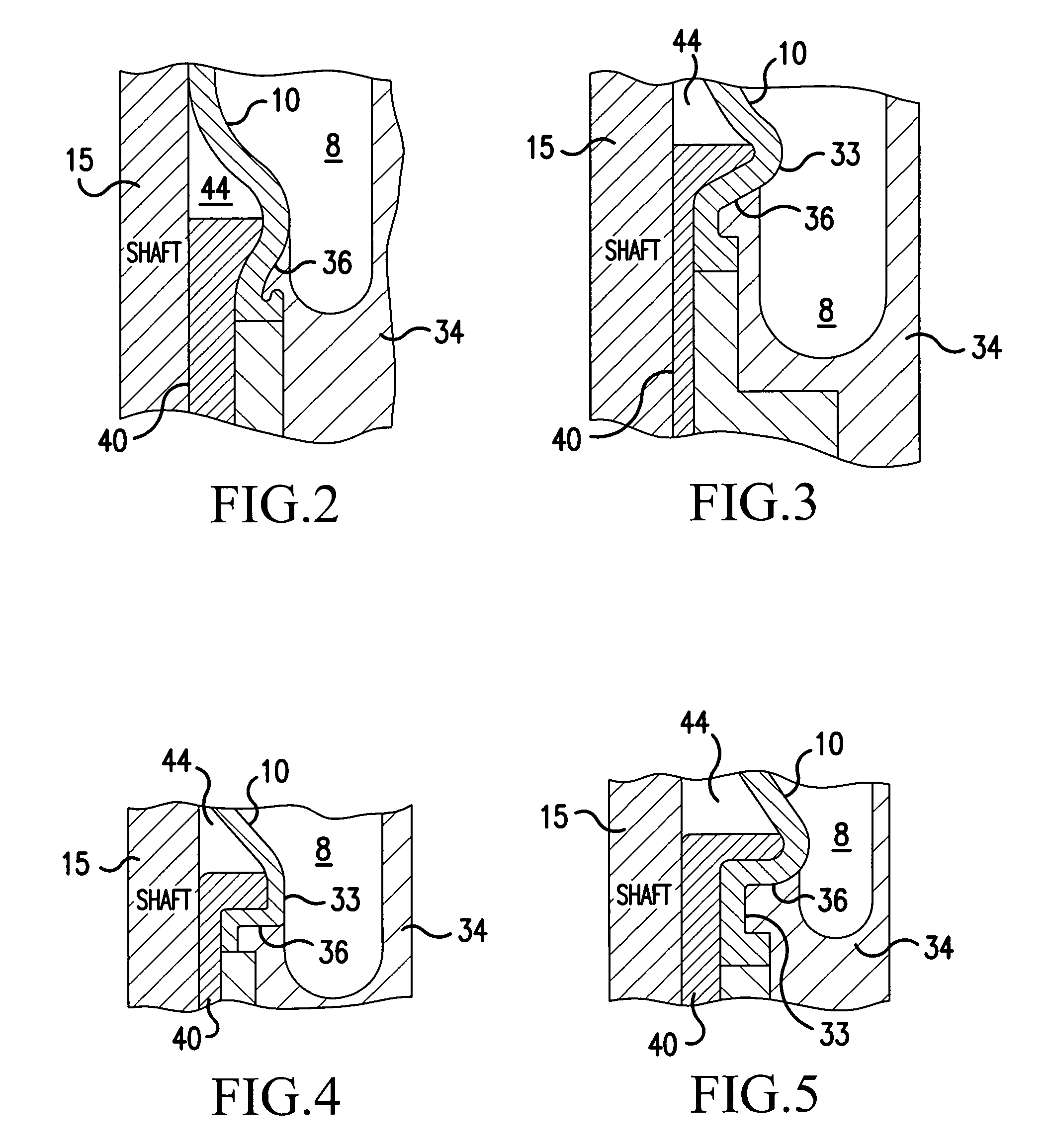

Sanitary drain valve

ActiveUS20060151737A1Simplifying valve maintenanceMinimal clearanceSpindle sealingsOperating means/releasing devices for valvesValve actuatorEngineering

A valve assembly includes a valve body having an internal cavity, an orifice in communication with the internal cavity for communicating with a process in a tank or conduit and an outlet through which process material entering the internal cavity through the orifice can be drained from the internal cavity. A valve actuator body includes an actuating shaft having a sealing tip and is mounted for movement in the valve actuator body to seal and unseal the orifice. A diaphragm is mounted to the sealing tip and includes a base that seals with a bottom wall of the valve body. The bottom of the valve body has an aperture that receives the actuating shaft therethrough. The diaphragm is mountable to and removable from the bottom wall of the valve body through the aperture.

Owner:PHARMENTA

Leg protector

InactiveUS20150047090A1Quickly putIncrease awarenessSport apparatusProtective garmentEngineeringChaps

A leg protector sized to fold over the wearer's leg to cover the front side of the wearer's leg while leaving the backside of the wearer's leg exposed for easily placement and removal of the leg protector. Unlike conventional gaiters and half chaps that effectively operate as a second pant leg positioned over the pants, the adjustable strap of the insulated leg protector extends across the rear side of the wearer's leg to retain the leg protector without fully covering the backside of the wearer's leg. The arrangement allows the leg protector to be quickly put on by the wearer by draping the leg protector over the wearer's leg and secured with the adjustable strap. Similarly, the leg protector can also be removed by simply undoing the adjustable strap.

Owner:COOK ROBERT A

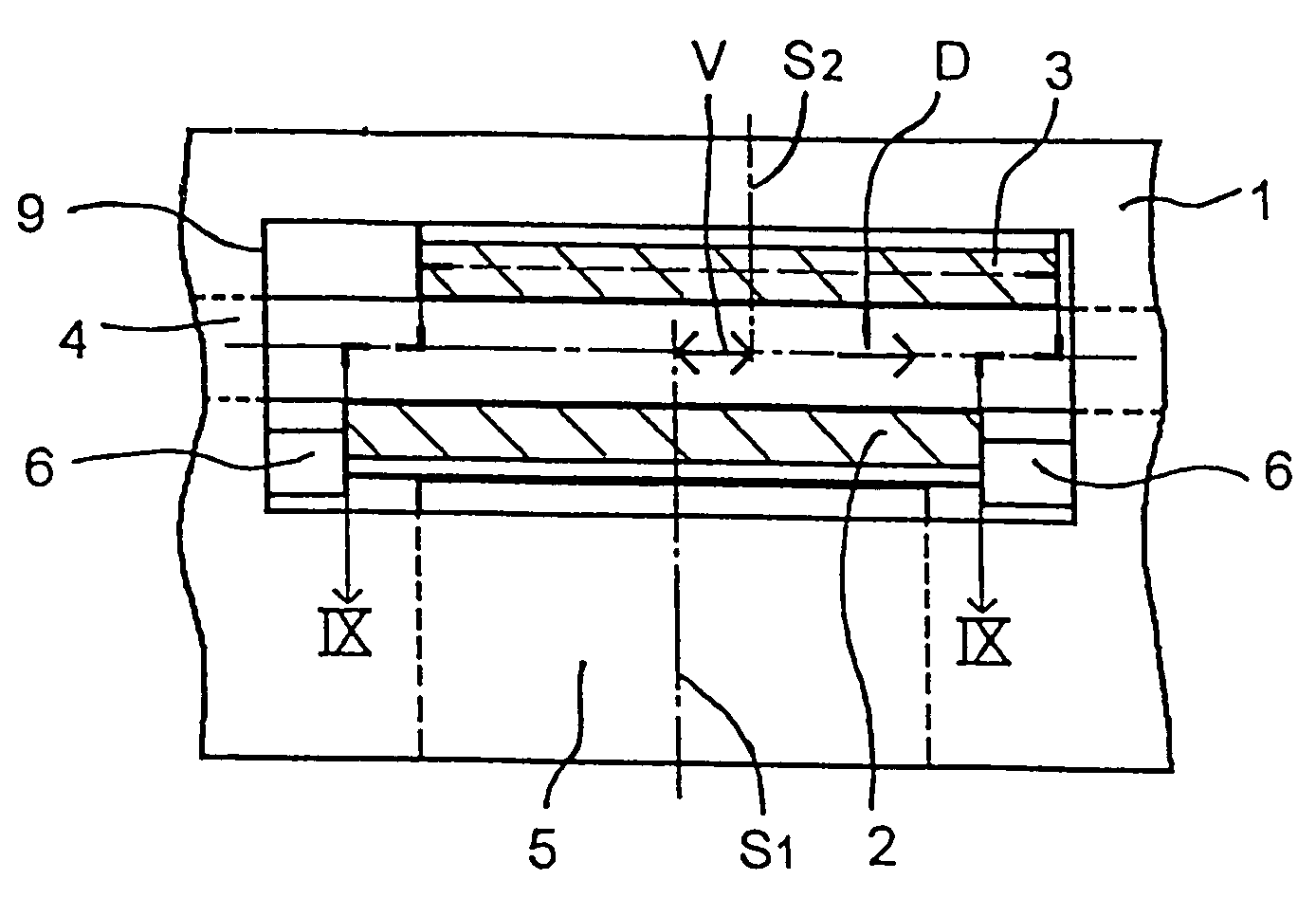

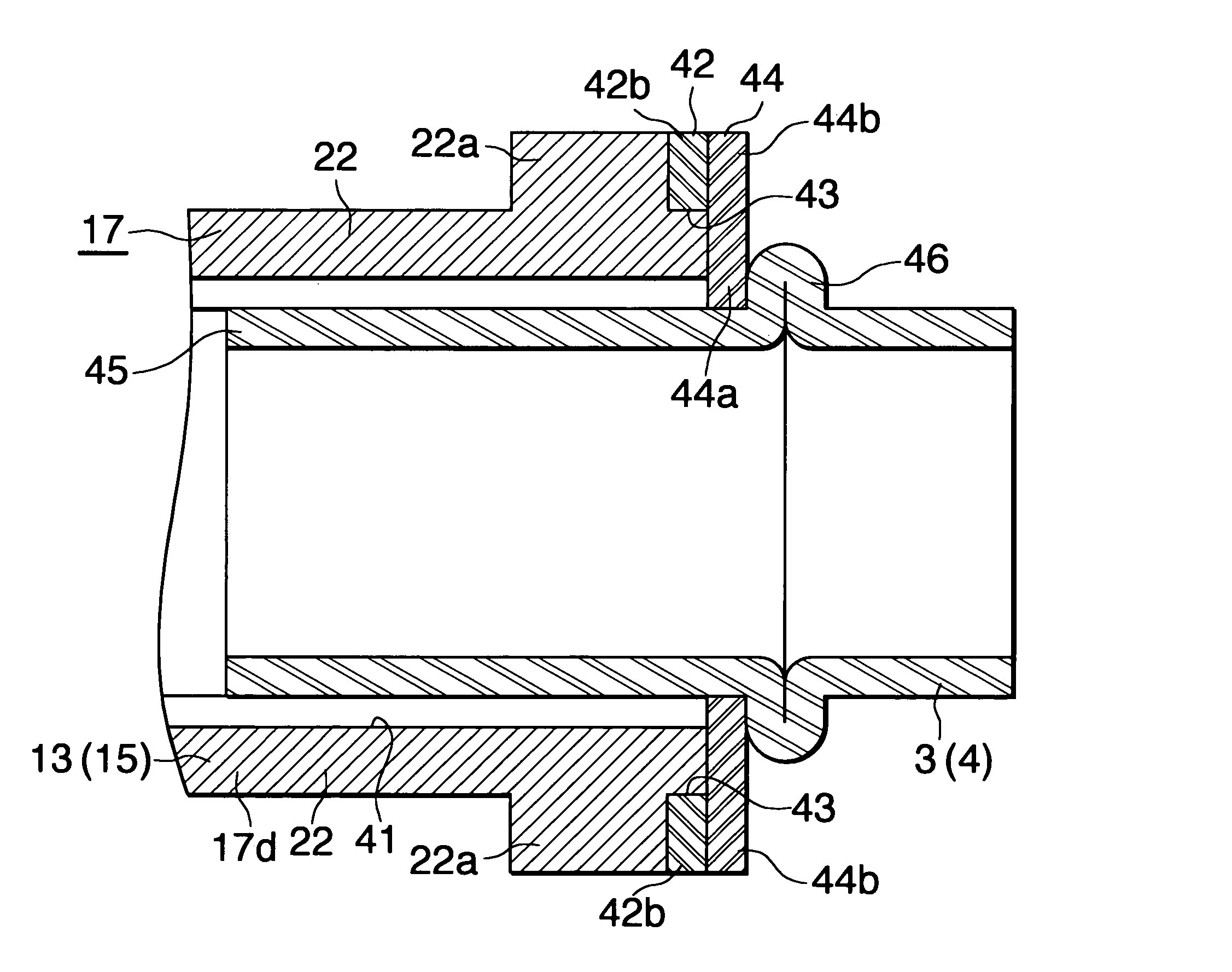

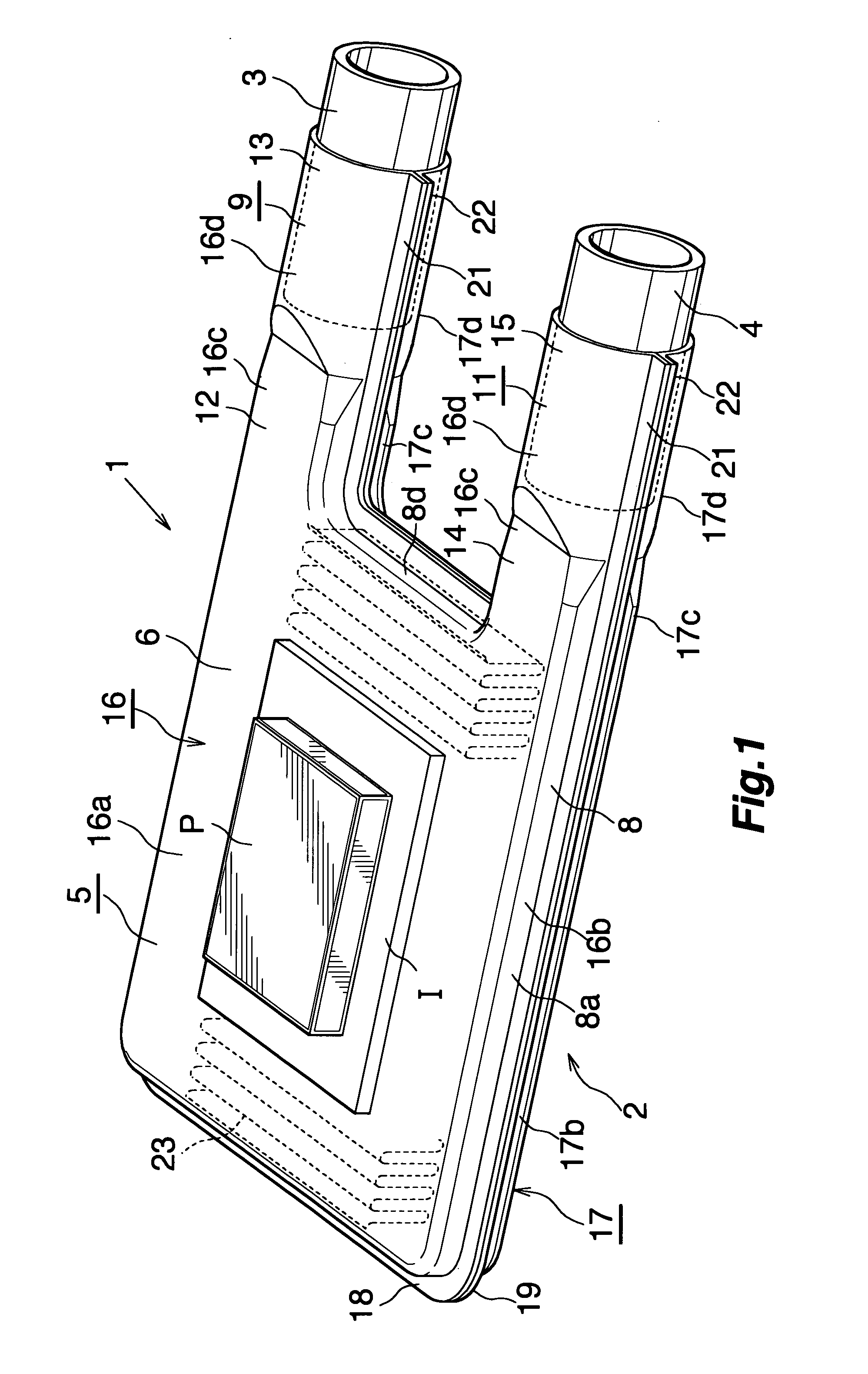

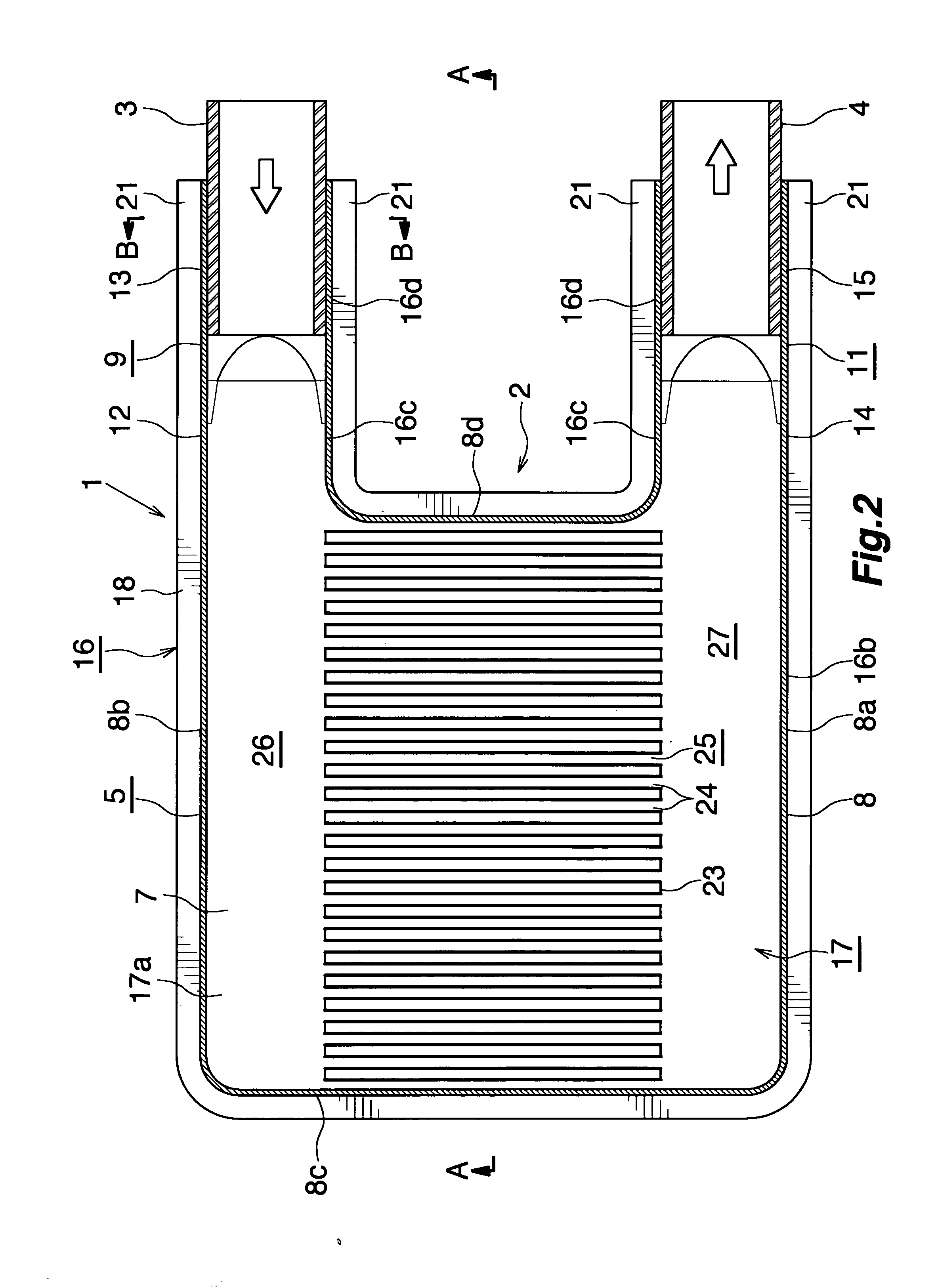

Method of manufacturing a pipe coupling component, method of manufacutring a casing structural member, and pipe coupling sturcture for a hollow part

InactiveUS20100320753A1Avoid formingPrevent liquid leakageSemiconductor/solid-state device detailsSolid-state devicesCouplingEngineering

In a first step of this method, a first intermediate product 42 having a coupling portion forming portion 16d and flat portions 21 is produced. In a second step, there is produced a second intermediate product 44 which is larger in the bending depth of the coupling portion forming portion 16d and is smaller in width of the flat portions 21 than the first intermediate product 42. In a third step, a third intermediate product 36 having the coupling portion forming portion 16d, sloping flat portions 34, and narrow flat portions 35 is produced. In a fourth step, the sloping flat portions 34 of the third intermediate product 36 are pressed obliquely upward so as to cause the material to move to the boundaries between the sloping flat portions 35 and the side walls of the coupling portion forming portion 16d, to thereby produce a fourth intermediate product 37. In a fifth step, the side walls of the coupling portion forming portion 16d, the sloping flat portions 34 and the narrow flat portions 35 of the fourth intermediate product 37 are pressed from the upper and lower sides, to thereby form a fifth intermediate product 39 in which burrs 38 are formed at the opening-side end portions of the side walls of the coupling portion forming portion 16d. In a sixth step, the burrs 38 are removed, whereby a casing structural member 16 produced. This method enables manufacture of casing structural members which can prevent leakage of fluid.

Owner:SHOWA DENKO KK

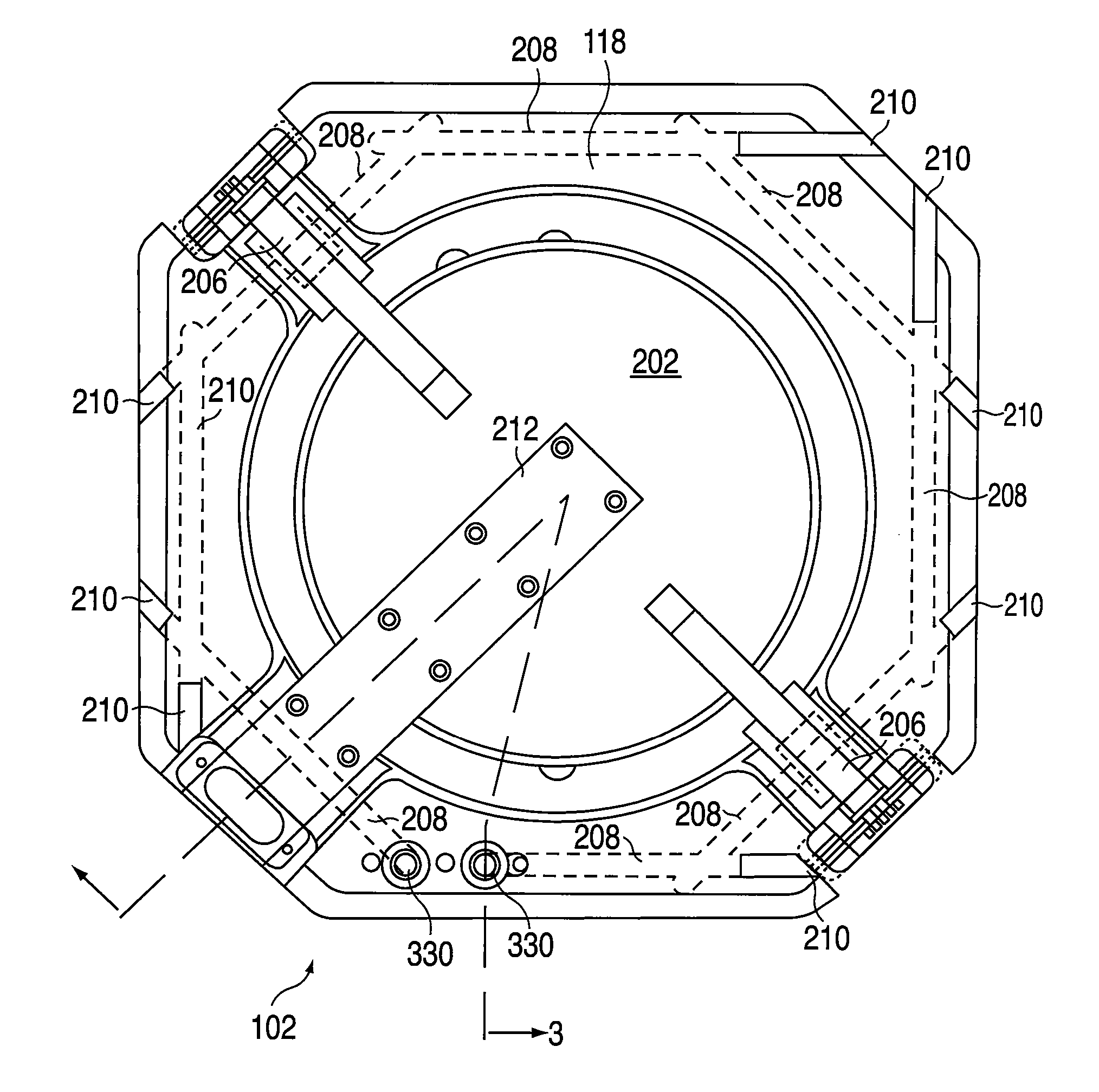

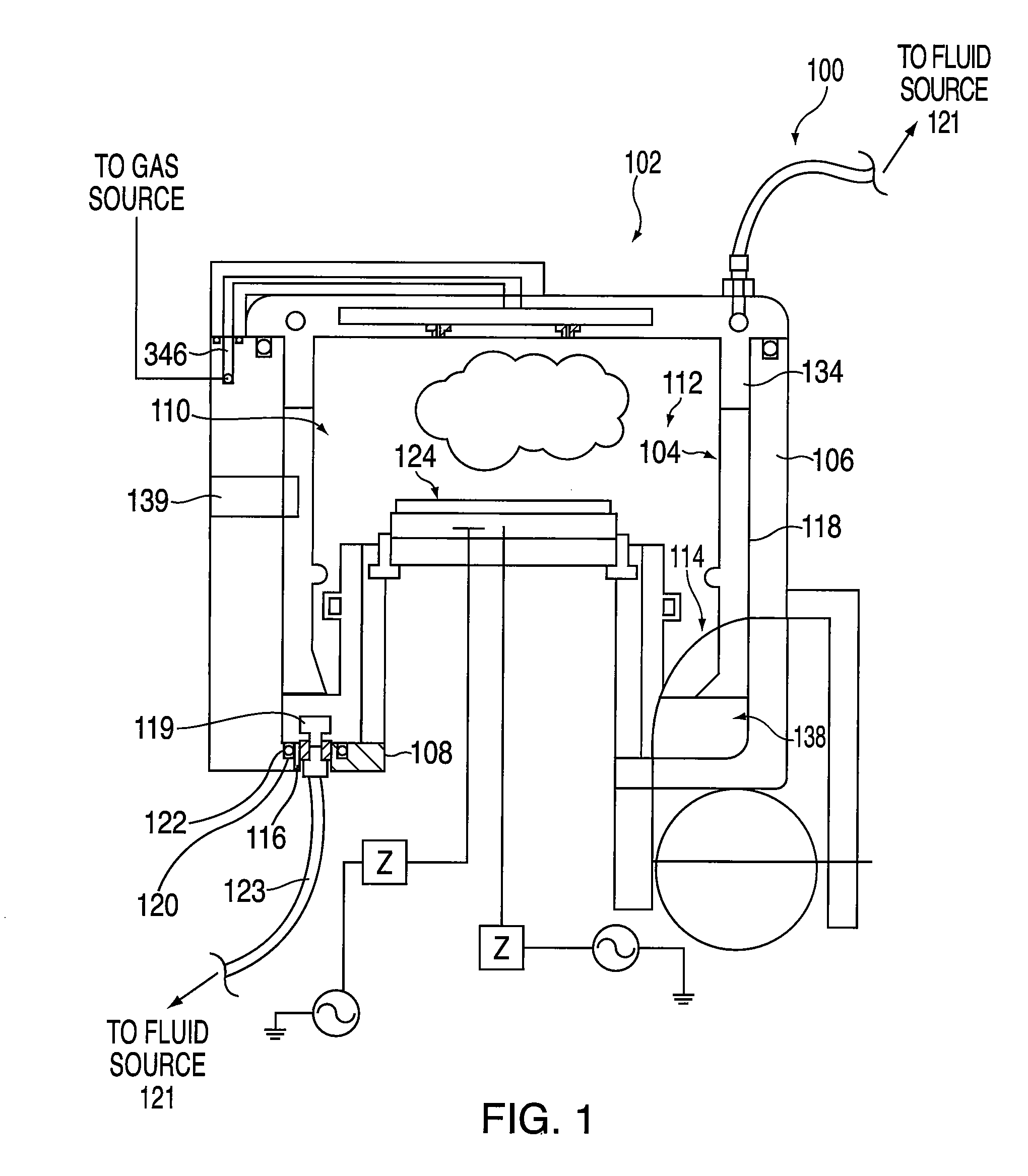

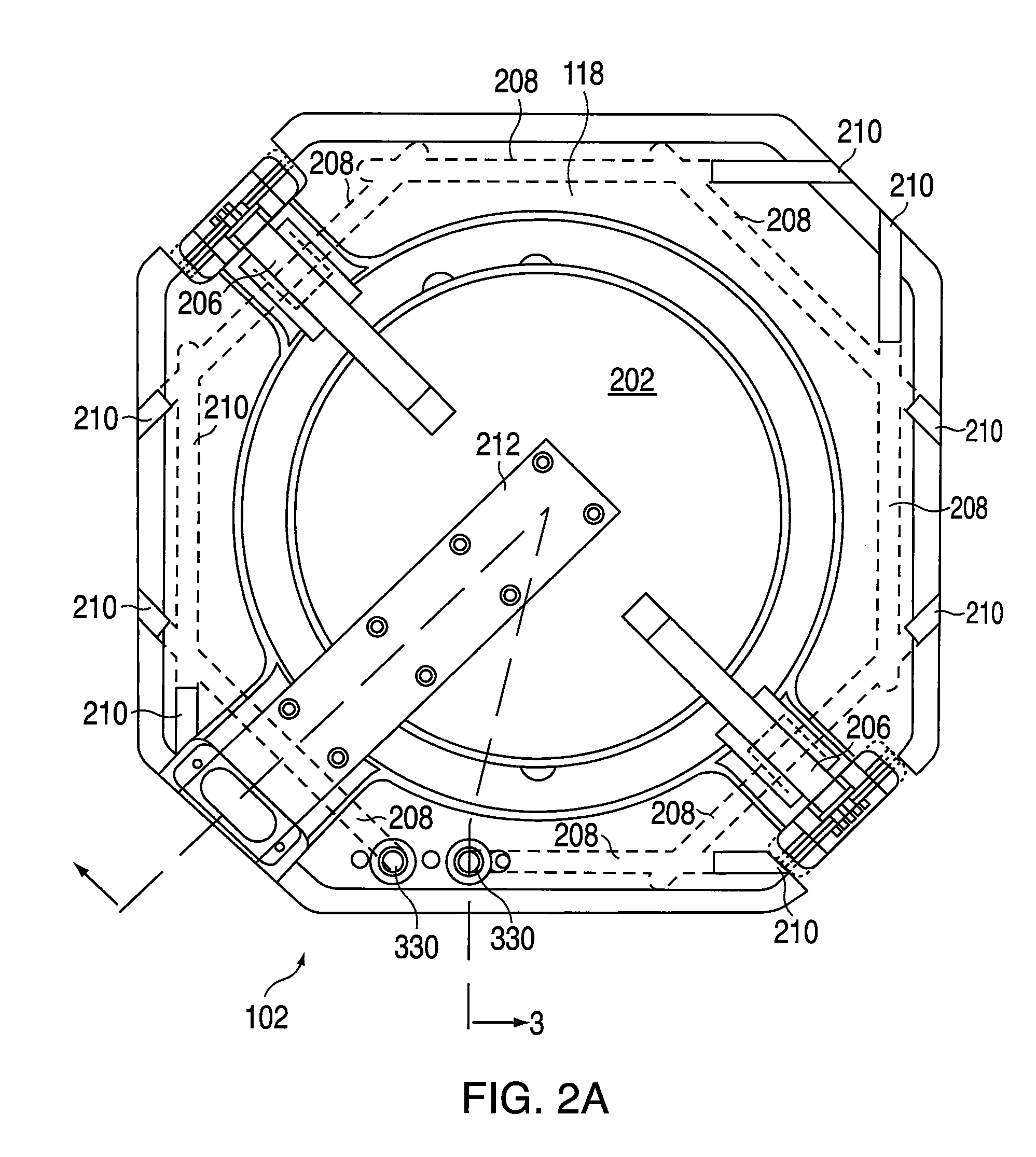

Temperature controlled semiconductor processing chamber liner

InactiveUS20070091535A1Minimize amount of materialReduce formationElectric discharge tubesElectromagnetic relay detailsTemperature controlEngineering

A thermally controlled chamber liner comprising a passage having an inlet and outlet adapted to flow a fluid through the one or more fluid passages formed at least partially therein. The chamber liner may comprise a first liner, a second liner or both a first liner and a second liner. The thermally controlled chamber liner maintains a predetermined temperature by running fluid from a temperature controlled, fluid source through the fluid passages. By maintaining a predetermined temperature, deposition of films on the chamber liner is discouraged and particulate generation due to stress cracking of deposited films is minimized.

Owner:APPLIED MATERIALS INC

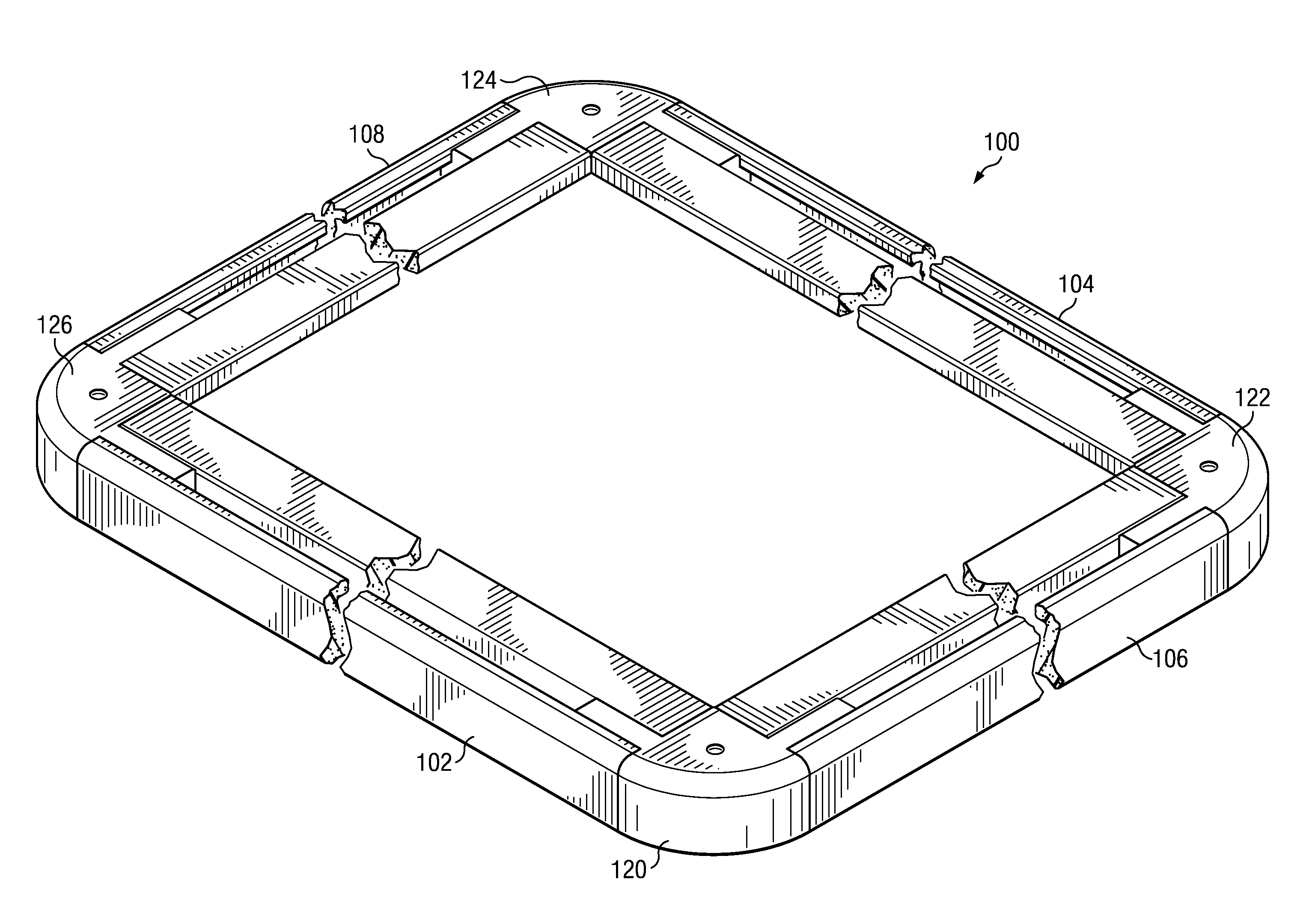

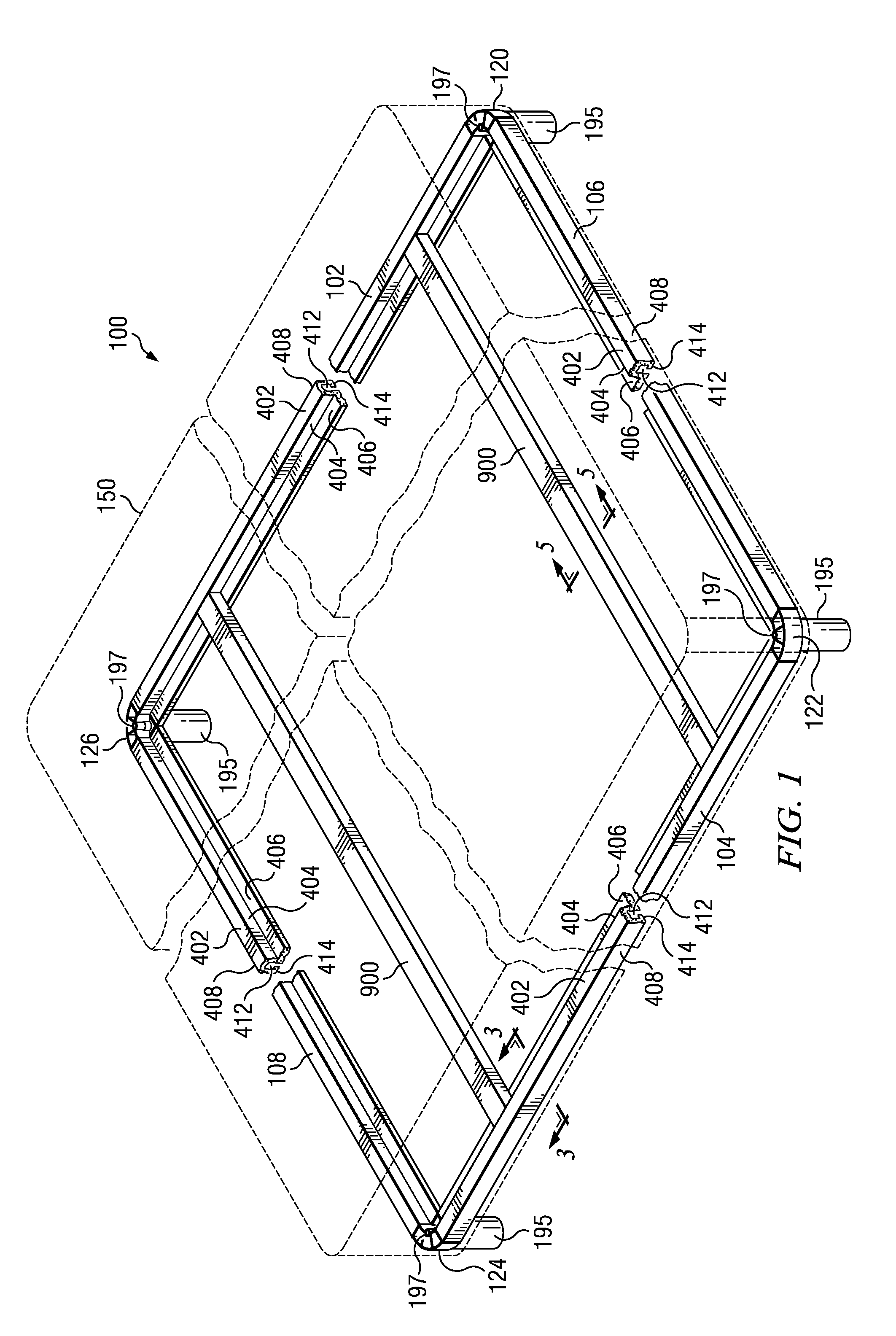

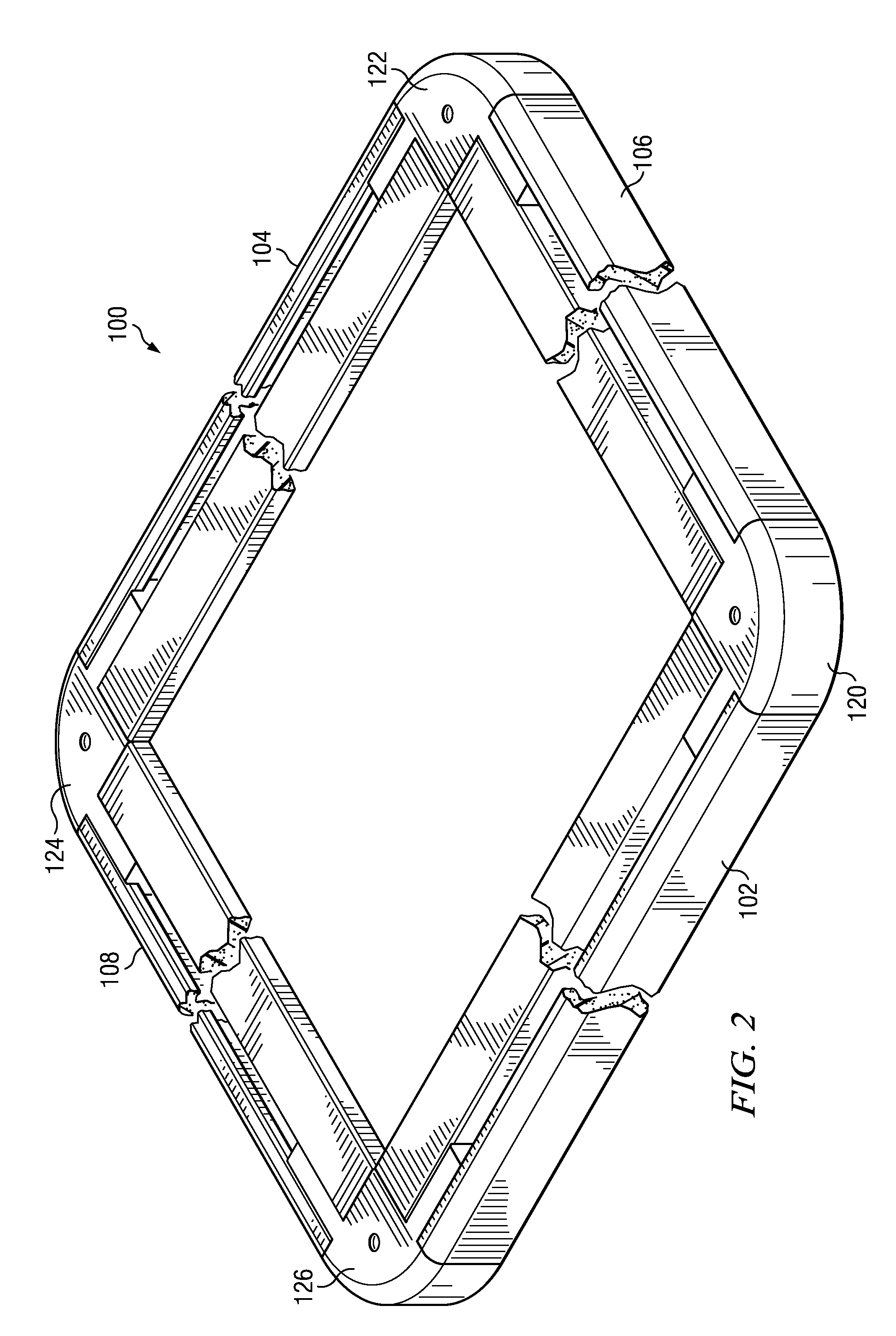

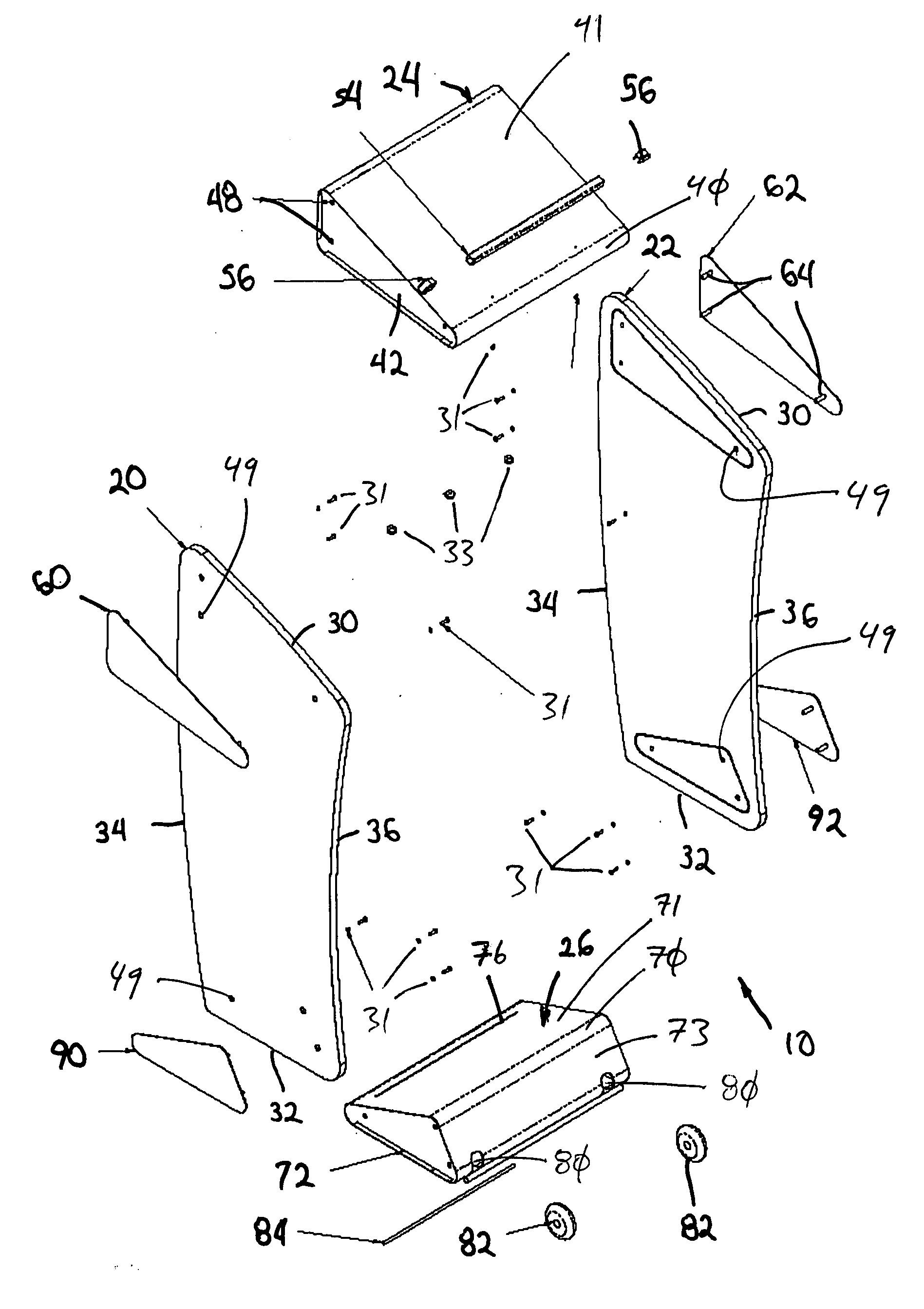

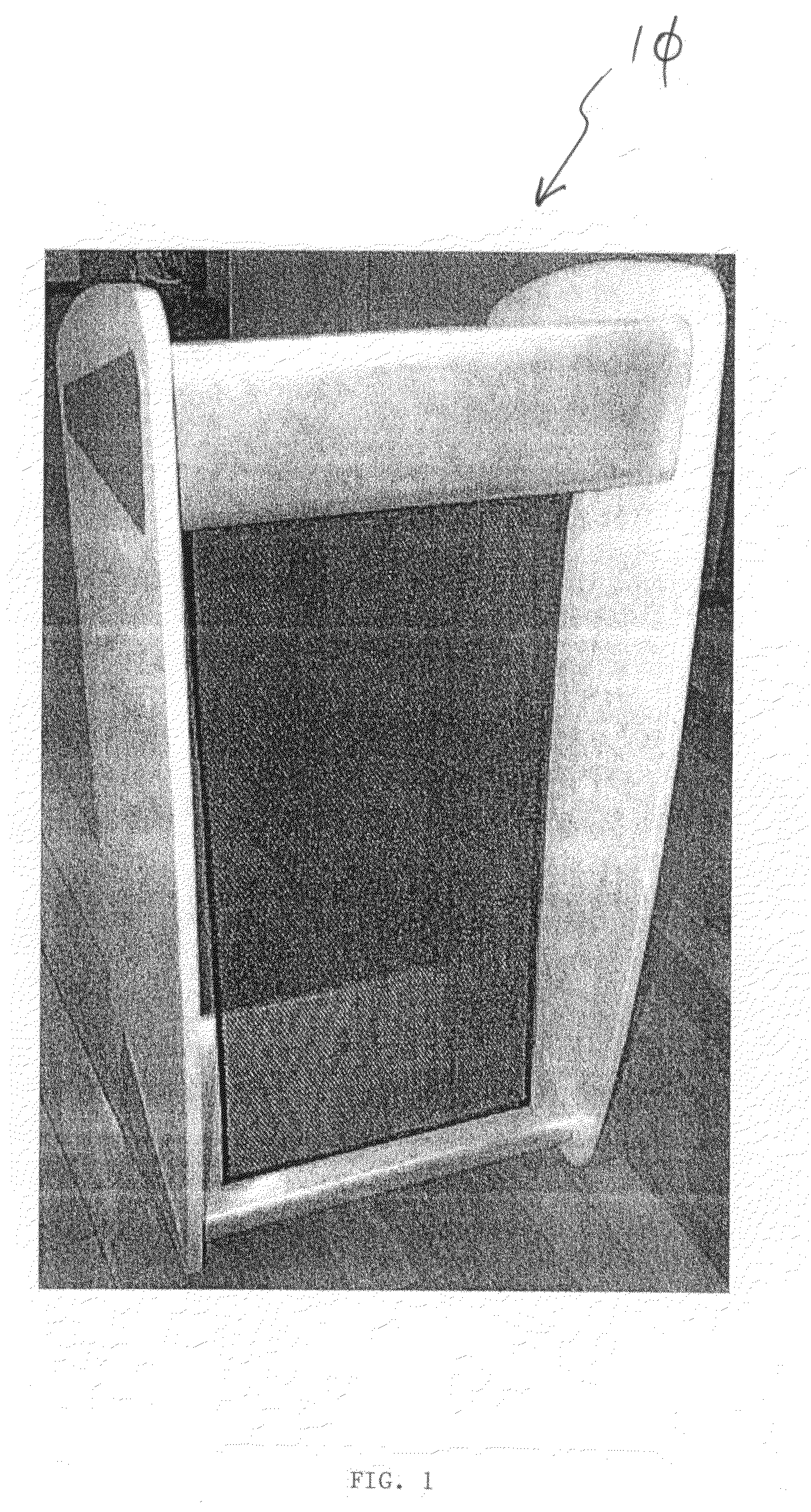

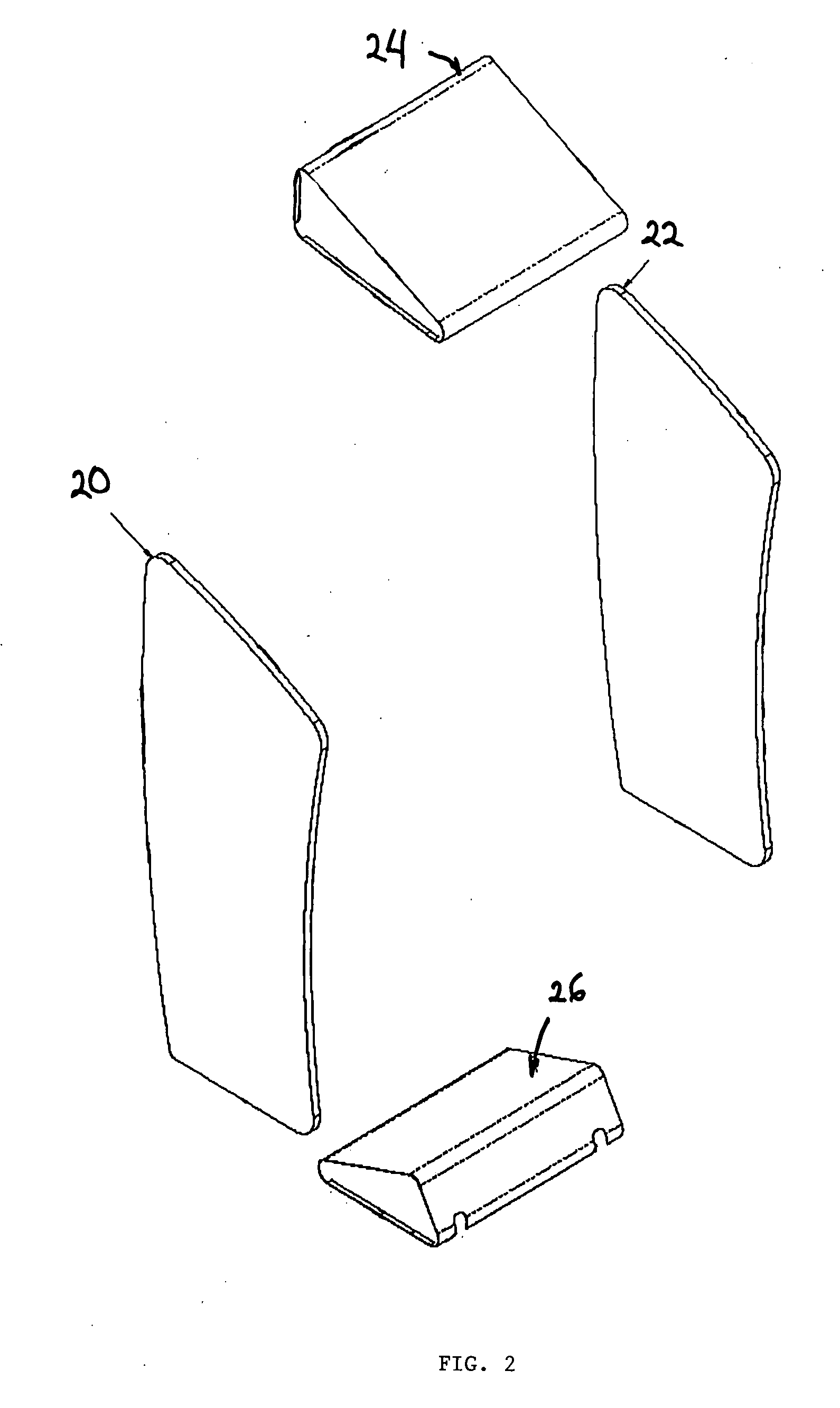

Loop-frame lectern with removable front panel

A lectern enhances the ability of a speaker to deliver a presentation to an audience. This invention is a lectern with support, base, and two side components assembled in a loop-frame construction. The loop-frame construction of the lectern minimizes the use of material, provides a functional and aesthetic design, and resists shear stress. A removable front panel can be attached to or removed from the loop frame without disassembling or reassembling the lectern.

Owner:SAFCO PRODS

Electromechanical generator for converting mechanical vibrational energy into electrical energy

ActiveUS11031857B2Minimize amount of materialHigh strengthReciprocating/oscillating/vibrating magnetic circuit partsPiezoelectric/electrostriction/magnetostriction machinesLinear vibrationVibrational energy

An electromechanical generator for converting mechanical vibrational energy into electrical energy, the electromechanical generator comprising: a central mast, an electrically conductive coil assembly fixedly mounted to the mast, the coil assembly at least partly surrounding the mast, a mount for the coil assembly extending radially inwardly of the coil assembly and fixing the coil assembly to the mast, wherein the mount comprises a conical wall extending between the coil assembly and the mast, a magnetic core assembly movably mounted to the mast for linear vibrational motion along an axis about an equilibrium position on the axis, the magnetic core assembly at least partly surrounding the coil assembly and the mast, and a biasing device mounted between the mast and the magnetic core assembly to bias the magnetic core assembly in opposed directions along the axis towards the equilibrium position.

Owner:PERPETUUM +1

Benchtop panels

ActiveUS20060162272A1Easy to makeFirmly connectedAnimal housingCultivating equipmentsGusset plateEngineering

Owner:DURAPLAS LP

Rotor balancing method

ActiveUS9182311B2Reduce the total massMinimize amount of materialPump componentsBlade accessoriesEngineeringDeposition process

Owner:ROLLS ROYCE PLC

Sanitary drain valve

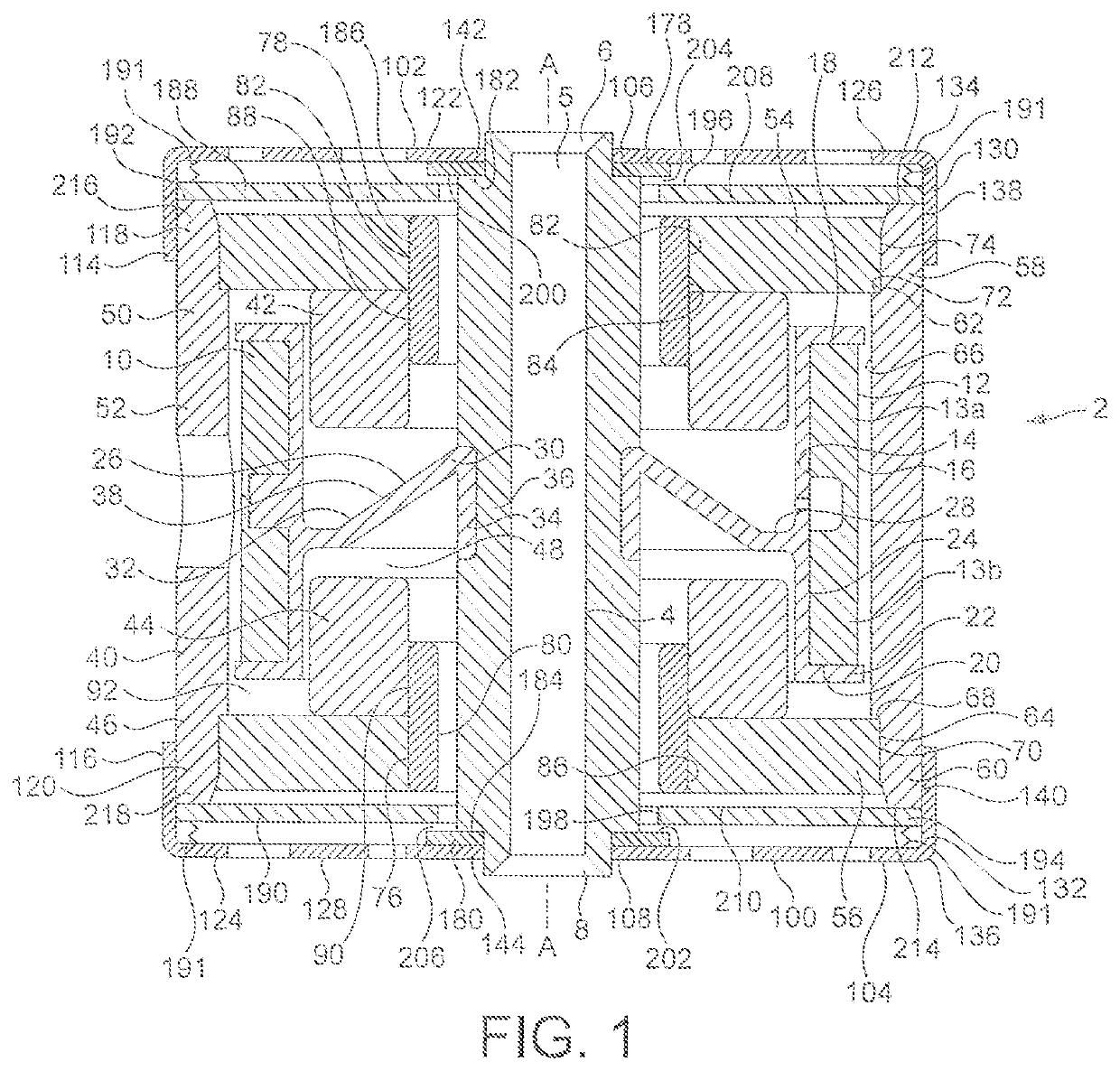

ActiveUS7571892B2Avoid defectsMinimize amount of materialSpindle sealingsOperating means/releasing devices for valvesValve actuatorVALVE PORT

A valve assembly includes a valve body having an internal cavity, an orifice in communication with the internal cavity for communicating with a process in a tank or conduit and an outlet through which process material entering the internal cavity through the orifice can be drained from the internal cavity. A valve actuator body includes an actuating shaft having a sealing tip and is mounted for movement in the valve actuator body to seal and unseal the orifice. A diaphragm is mounted to the sealing tip and includes a base that seals with a bottom wall of the valve body. The bottom of the valve body has an aperture that receives the actuating shaft therethrough. The diaphragm is mountable to and removable from the bottom wall of the valve body through the aperture.

Owner:PHARMENTA

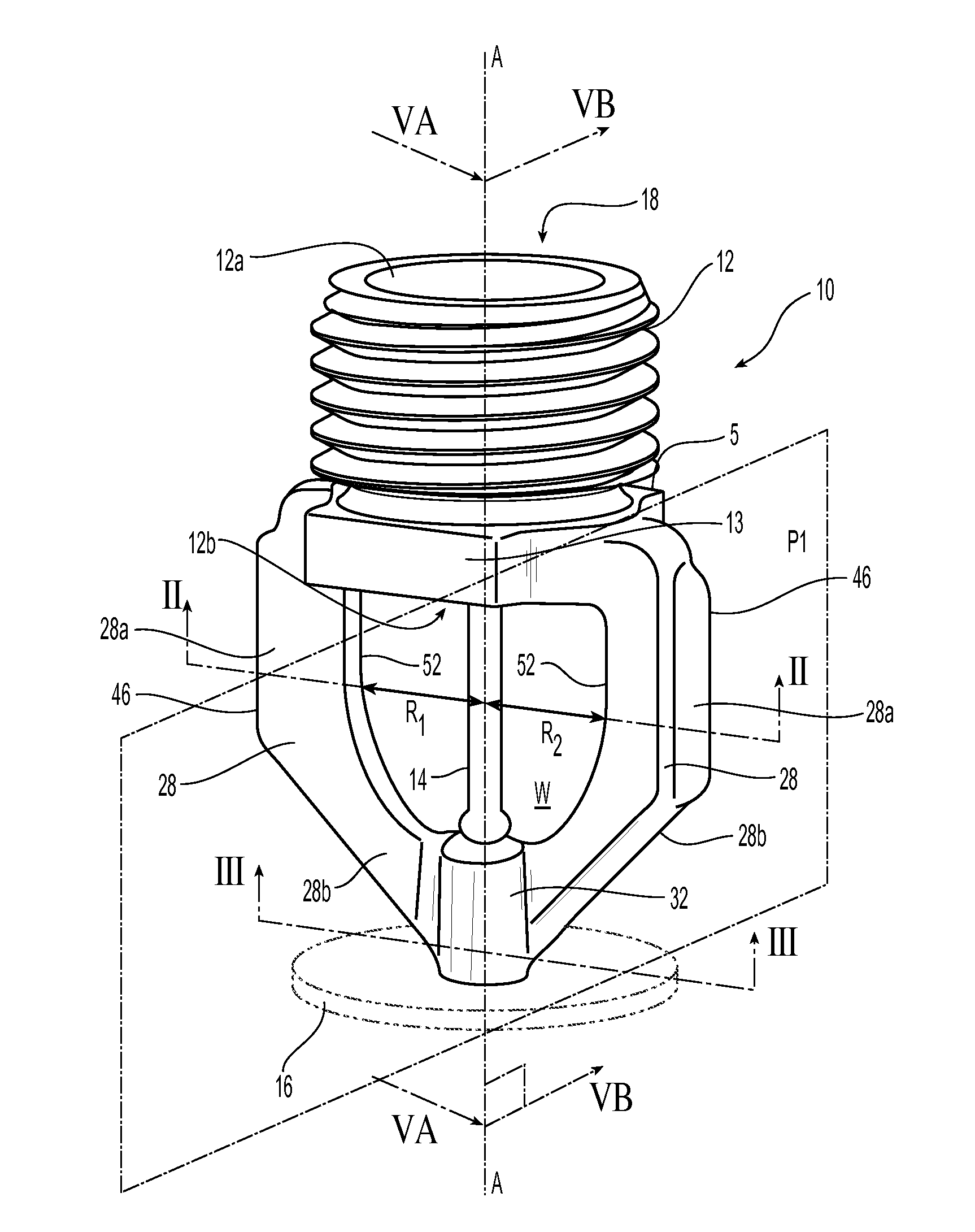

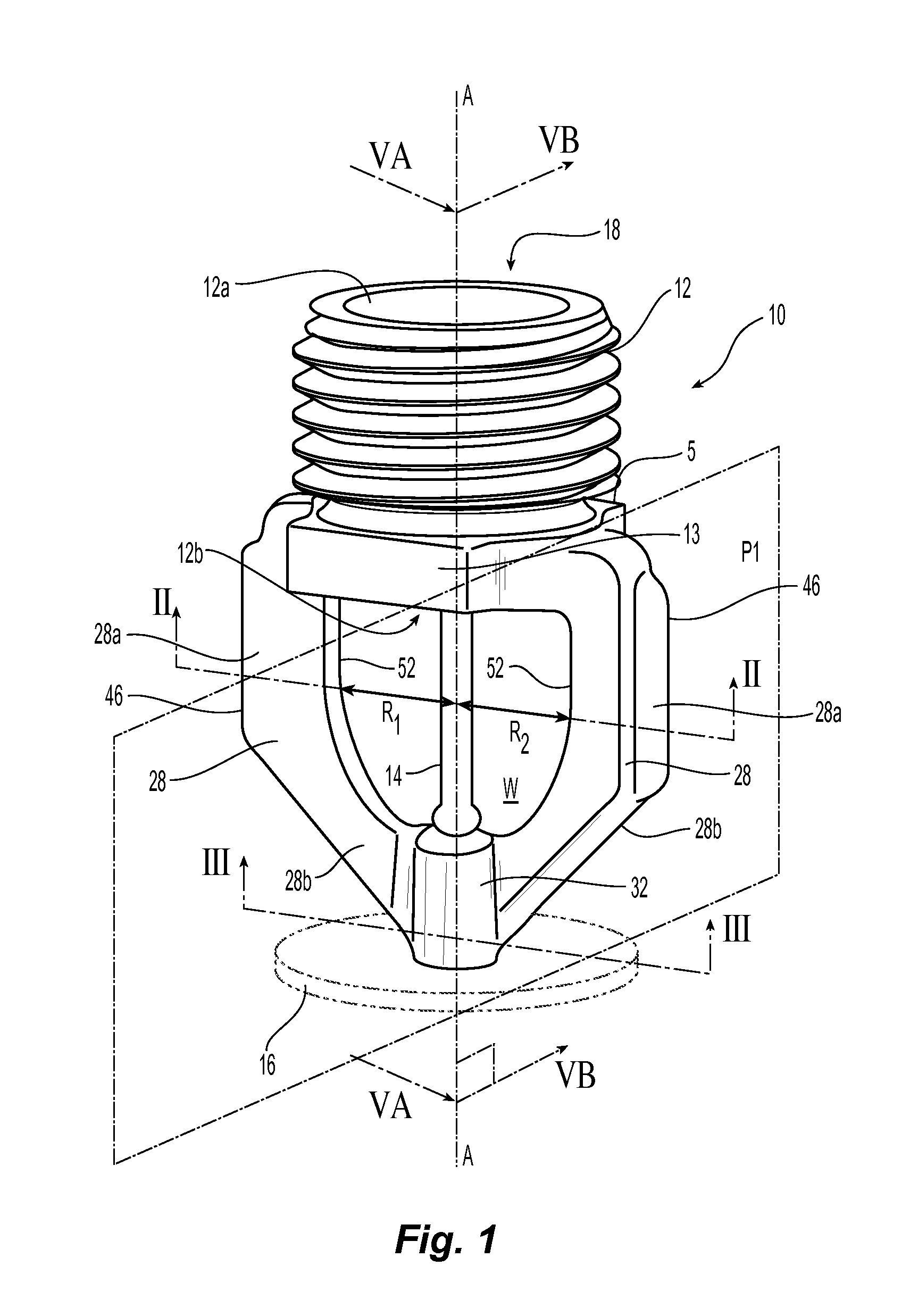

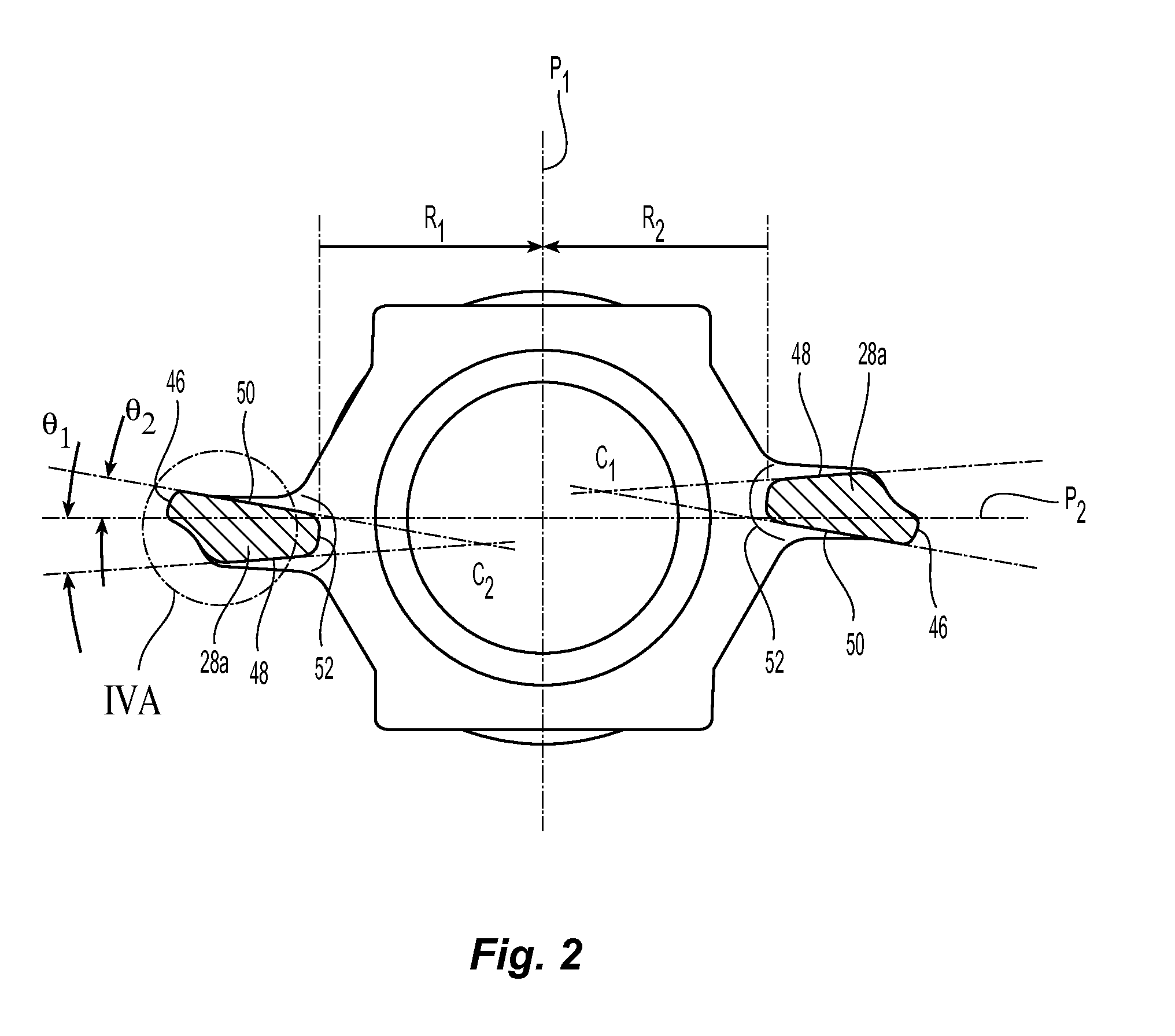

Sprinkler assembly

ActiveUS20150246252A1Easy to useMinimize amount of materialSpray nozzlesFire rescueSprinkler systemEngineering

A sprinkler assembly that includes a frame having a body including an inlet, an outlet and an internal passageway extending between the inlet and the outlet to define a longitudinal sprinkler axis. Two frame arms extend distally from the body, and each arm has a portion defining a cross-sectional area with a lateral surface and a medial surface spaced about a first plane bisecting the body with the sprinkler axis disposed in the first plane. An axially aligned thermally responsive glass-bulb type trigger is disposed along the sprinkler axis. The cross-sectional areas of the frame arms are asymmetrical with respect to one another about the first plane and each cross-sectional area is asymmetric about a second plane perpendicular to the first plane. The lateral surface of each arm includes an undulation to provide the sprinkler assembly with substantially consistent thermal sensitivity about the sprinkler axis.

Owner:TYCO FIRE PRODS LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com