Apparatus and Method of Use for a PVC Composite Mattress Foundation

a technology of pvc and mattress support, which is applied in the direction of bedsofas, seating furniture, bedstands, etc., can solve the problems of insufficient strength of steel bedframes, waste of materials and increased costs, and inability to meet the needs of users, so as to reduce the amount of materials used and eliminate extra fastening hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In the descriptions that follow, like parts are marked throughout the specification and drawings with the same numerals, respectively. The drawing figures are not necessarily drawn to scale and certain figures may be shown in exaggerated or generalized form in the interest of clarity and conciseness.

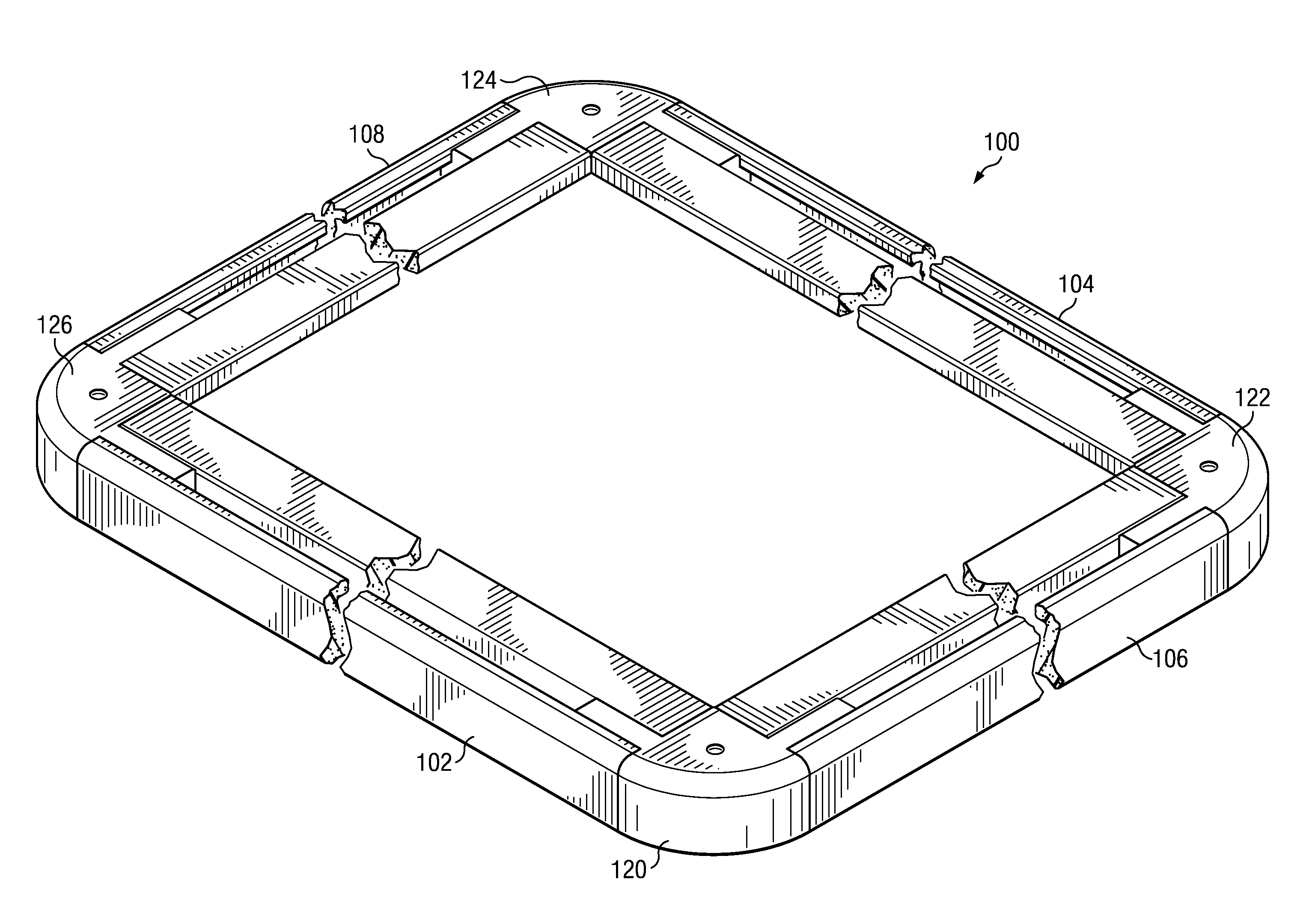

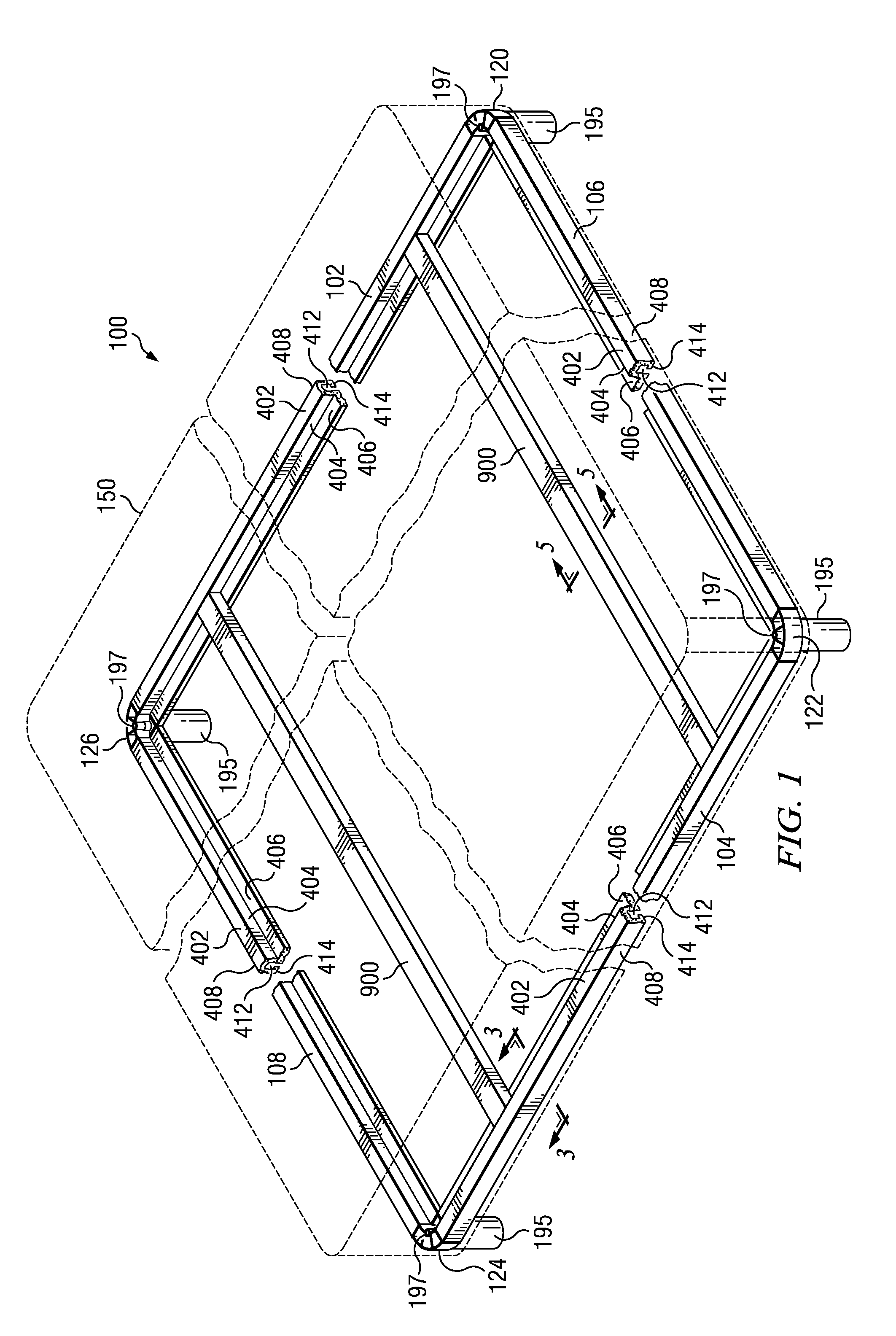

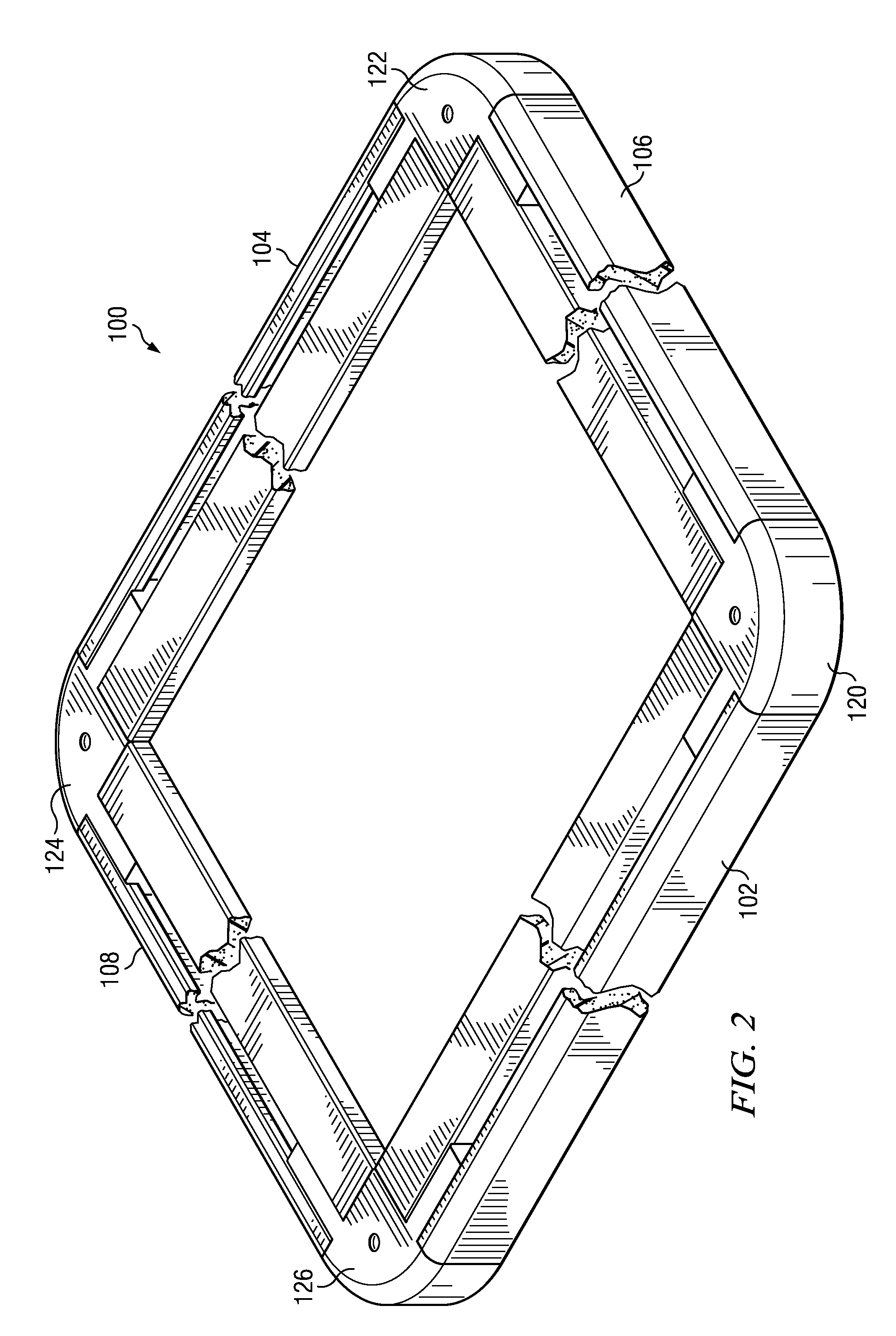

[0030]FIG. 1 shows mattress frame 100 as would be incorporated within box springs 150 (shown in shadow) where box springs 150 would include springs and fabric cover as is common in the art. A set of feet 195 is included to raise the mattress frame when in use.

[0031]Referring to FIGS. 1 and 2, mattress frame 100 is comprised of a pair of side rails 102 and 104 connected to a pair of end rails 106 and 108 via end caps 120, 122, 124, and 126. In the preferred embodiment, the side rails and end rails are made of an extruded polyvinyl chloride (PVC) plastic. Other lightweight, flexible plastics will suffice. In the preferred embodiment, the end caps are made of a fiber reinforced nylon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com