Pressure cooker having bayonet mount and related manufacturing method

a technology of manufacturing method and pressure cooker, which is applied in the field of pressure cookers with bayonet mounts and related manufacturing methods, can solve the problems of affecting the general aspect, limiting in particular the possibility of accessorizing the concerned pressure cookers, and limiting the possibility of accessorizing them, etc., and achieves good affordance properties, easy handling, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

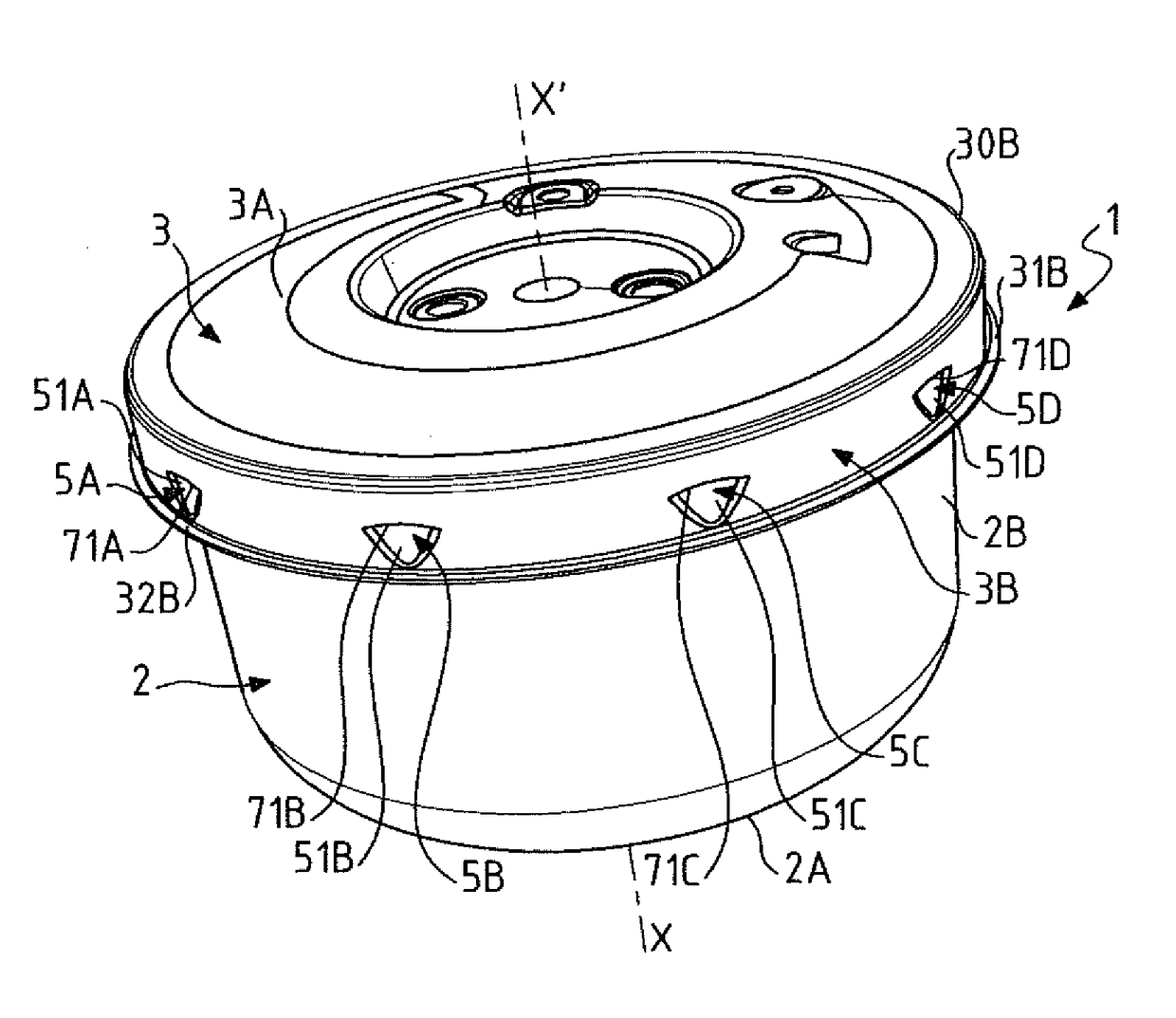

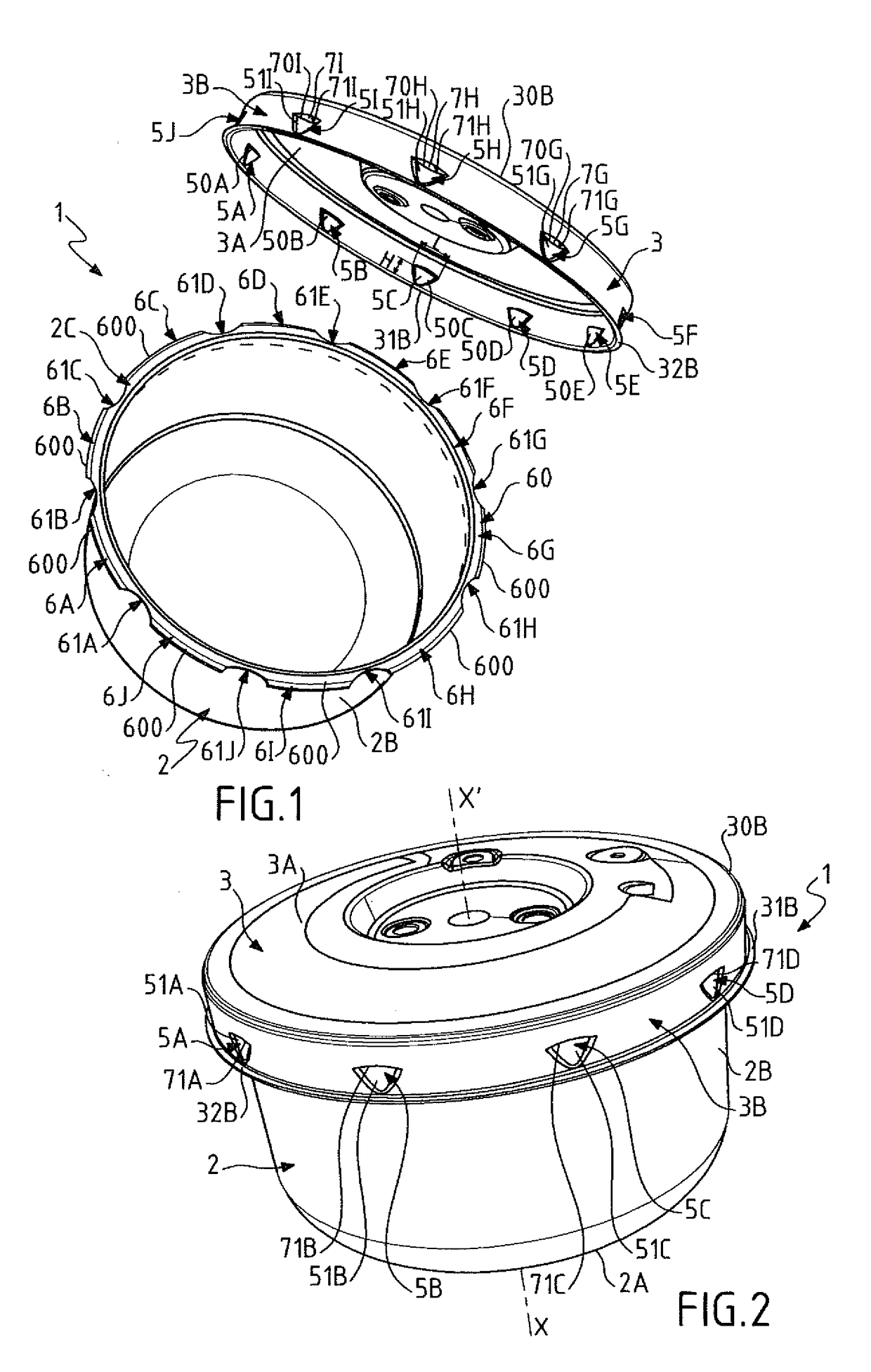

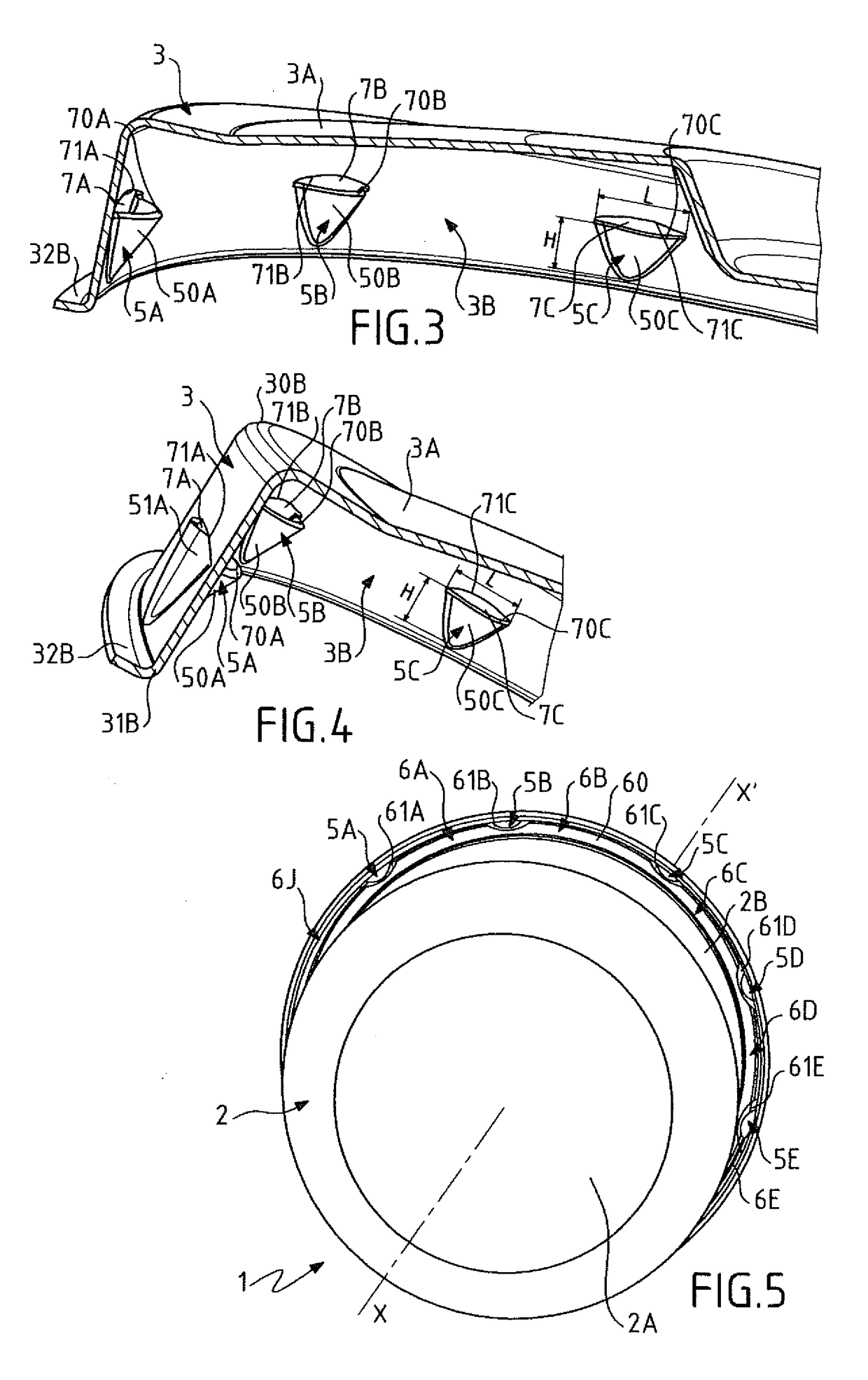

[0045]As illustrated in the Figures, the invention relates to a food pressure cooking appliance 1, intended to ensure the cooking of various foodstuffs at a level of pressure higher than the atmospheric pressure, in the presence of steam, and for example water steam. Said steam is generated by the heating, with the appliance 1 and in the presence of food, of a cooking liquid, for example an aqueous liquid. The appliance 1 according to the invention is preferentially intended to a household use, it being however understood that the invention may also relates to professional or semi-professional appliances.

[0046]The appliance 1 according to the invention is designed to rise in pressure exclusively under the effect of a heating source (integrated or external), without addition of external pressure. The food pressure cooking appliance 1 hence constitutes a pressure cooker, preferentially intended to be placed on an independent cooking plate to heat the content thereof.

[0047]The cooking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com