Pile foundation combined grouting reinforcement construction method combining waterproof curtain

A water-stop curtain and composite grouting technology, which is applied in the repair of foundation structure, foundation structure engineering, sheet pile wall, etc., can solve the problem of large consolidation shrinkage, affecting the bearing capacity of pile foundation, affecting the engineering quantity and progress of reinforcement engineering And the reinforcement effect and other issues, to achieve the effect of expanding the diameter of the pile body or the bottom of the pile, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

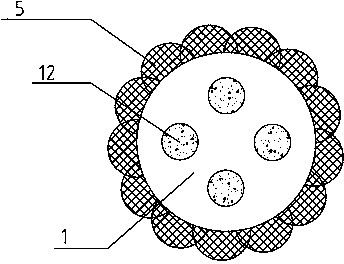

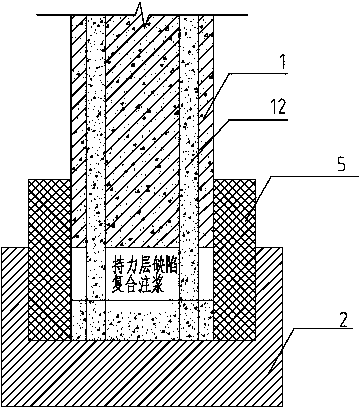

[0042] like Figure 1~3 As shown, the embodiment of the present invention provides a construction method for pile foundation composite grouting combined with water-stop curtain to strengthen the pile bottom bearing layer defect, including the following steps:

[0043](1) Drilling construction of rotary grouting piles: When reinforcing the defects of the bearing layer at the bottom of the pile foundation, according to the lap width of the rotary grouting piles and the pile foundation, a high-pressure rotary grouting drilling rig is used to carry out rotary grouting pile holes at the design position around the pile Construction, and then drill the high-pressure rotary grouting drilling rig to the designed bottom position of the rotary grouting pile according to the defect position of the pile foundation. For the position of the bearing layer at the bottom of the pile, the rotary grouting pile is constructed upwards from the position 3 times the pile diameter below the bearing la...

Embodiment 2

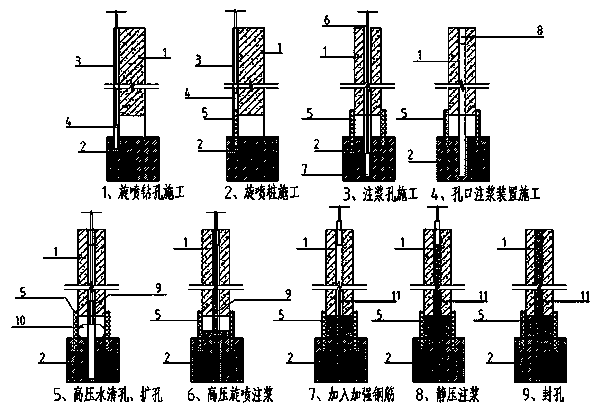

[0053] like Figure 4~5 As shown, the embodiment of the present invention provides a construction method for pile foundation composite grouting combined with water-stop curtain to strengthen pile body defects, including the following steps:

[0054] (1) Drilling construction of rotary grouting pile: When reinforcing the pile body defects of the pile foundation, according to the lap width of the rotary grouting pile and the pile foundation, use a high-pressure rotary grouting drilling rig to carry out rotary grouting pile hole construction at the designed position around the pile. Then, according to the defect position of the pile foundation, the high-pressure rotary grouting drilling rig is drilled to the designed bottom position of the rotary grouting pile. For the pile body defect, the rotary grouting pile shall be constructed upwards from 1 meter below the defect position. When the soil layer or strongly weathered rock layer is used as the bearing layer at the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com