Pressure-grouting construction method for structure consolidation

A technology of pressure grouting and construction method, which is applied in the direction of building structure, building maintenance, construction, etc., can solve the problems of not being able to meet the compactness and affect the effective force transmission of the vertical structure, and achieve the effect of ensuring the construction quality and the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

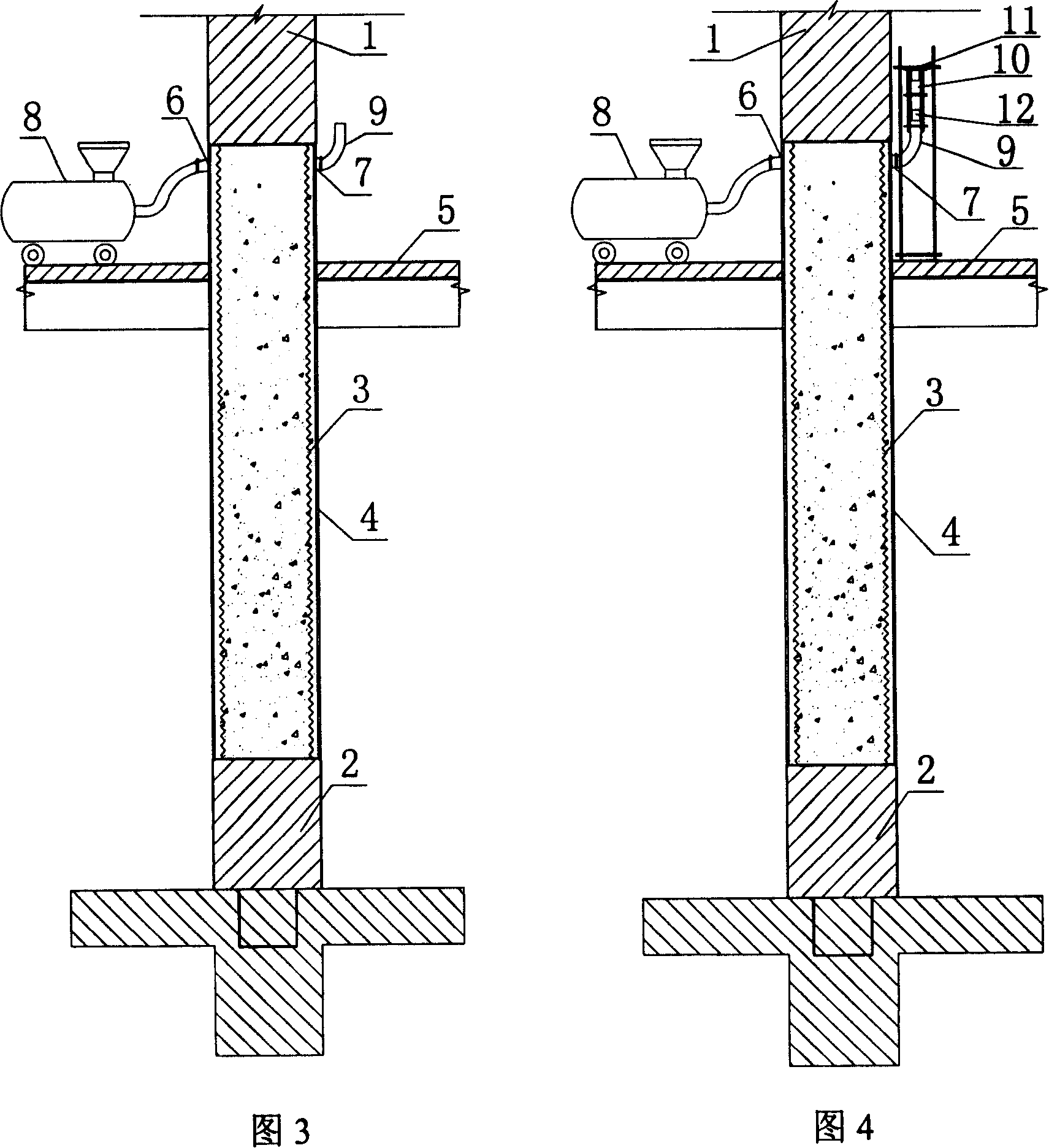

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The present invention is used for the pressure grouting construction method of structural reinforcement, comprises the following steps:

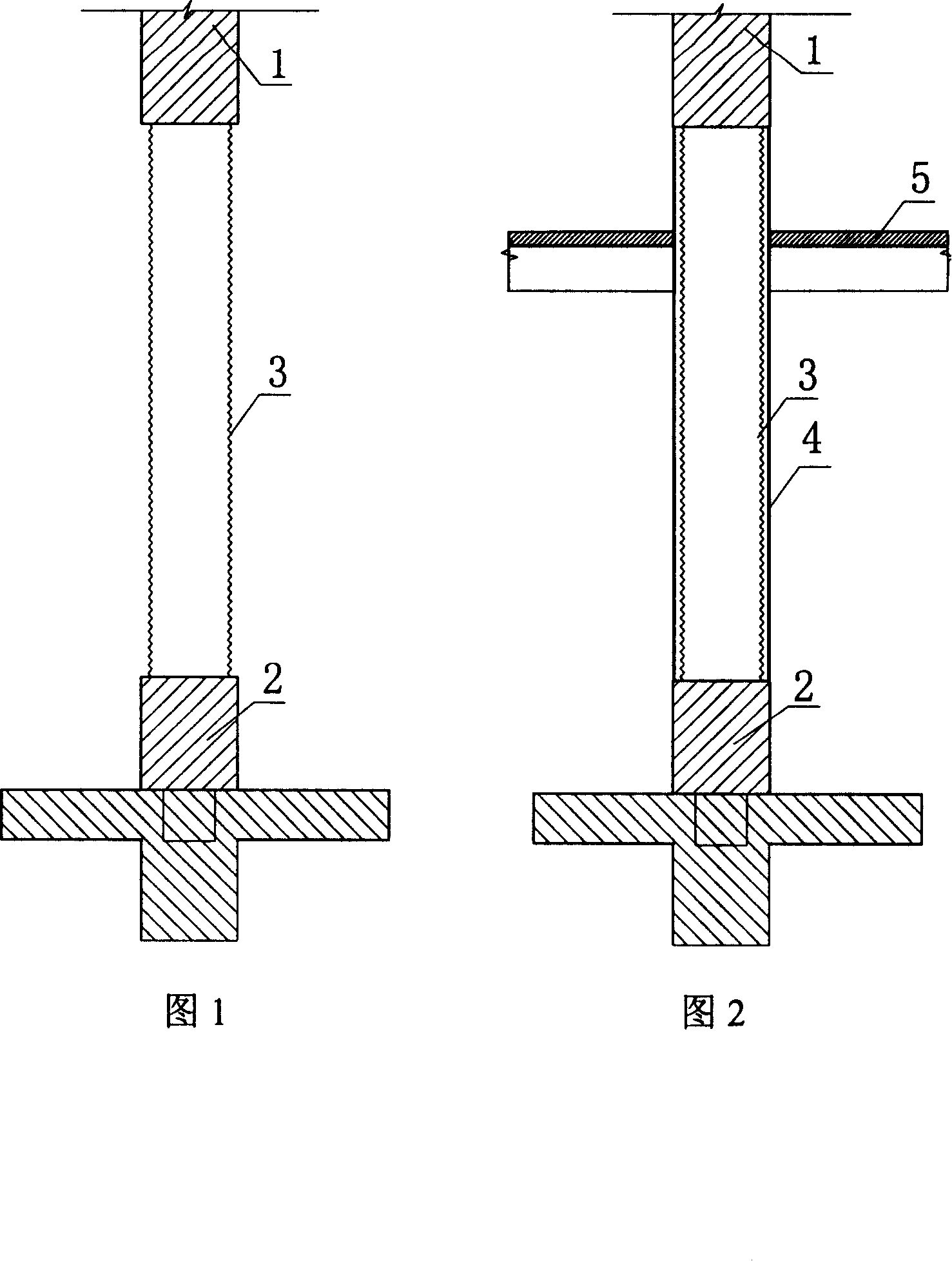

[0018] (1) Carry out chiseling construction on the structural columns to be reinforced, and clean the structural surface: as shown in Figure 1, after the reinforcement construction of the upper structural concrete column 1 and the lower structural concrete column 2 is completed, the original structural floor of the middle layer is removed, And chiseling the concrete structural column 3 to be reinforced in the middle layer, fully watering and pre-wetting the concrete structural column 3 in the middle layer 24 hours in advance, so as to ensure that the column body in the grouting section is in a wet state before grouting, and clean up the garbage .

[0019] (2), as shown in Figure 2, assemble steel formwork 4 on the periphery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com