Pile sinking method of Synchronization grouting static pressure precast pile

A technology of simultaneous grouting and prefabrication of piles, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve problems such as the difficulty of driving static piles, and achieve the effect of shortening construction period, improving efficiency, and reducing pile tonnage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Before the pile is pressed, the grouting fluid is configured first,

[0029] Side pile grouting fluid: 1 part of water, 1 part of cement, 0.1-0.2 part of bentonite, 0.05 part of retarder, and stir evenly;

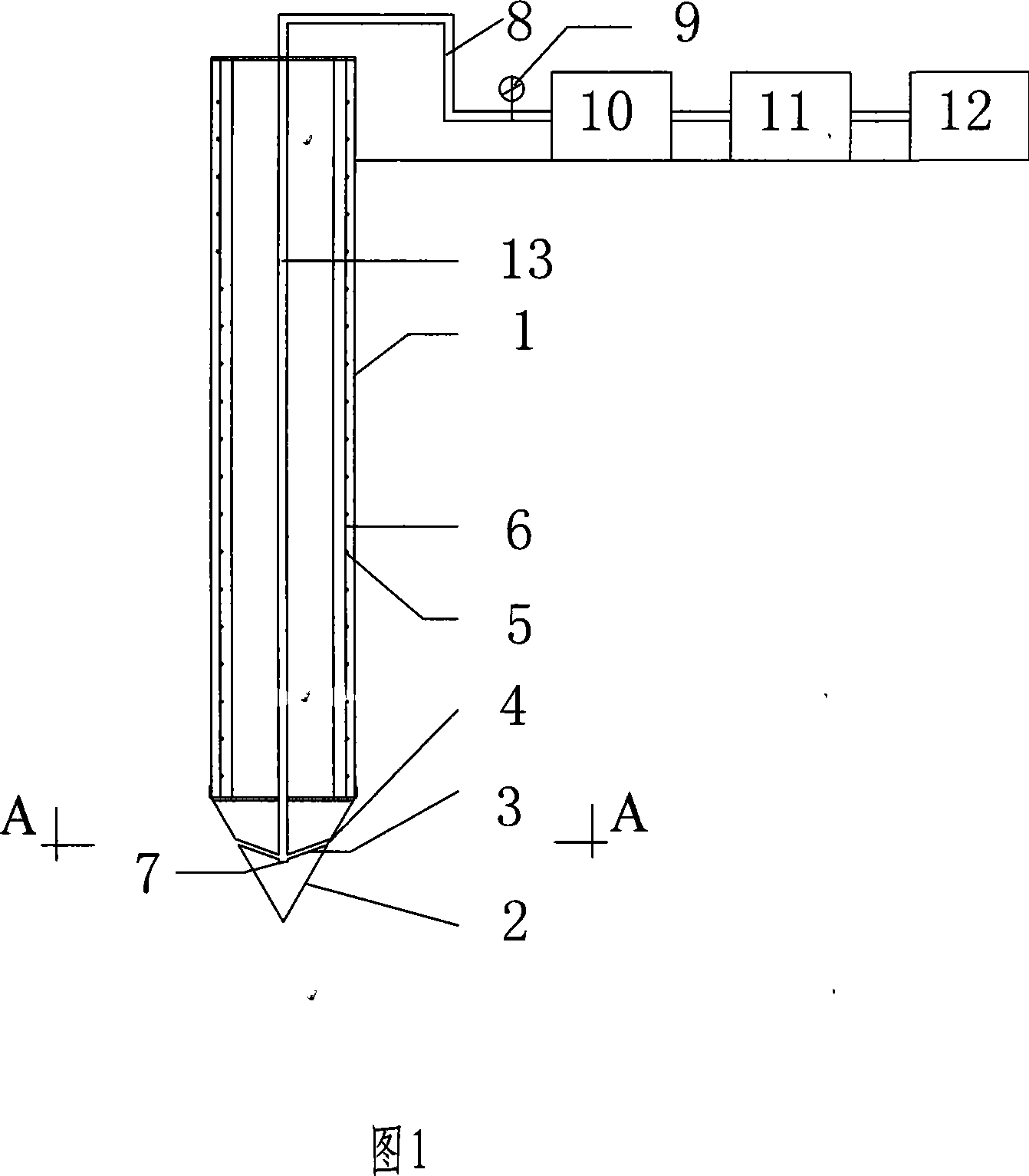

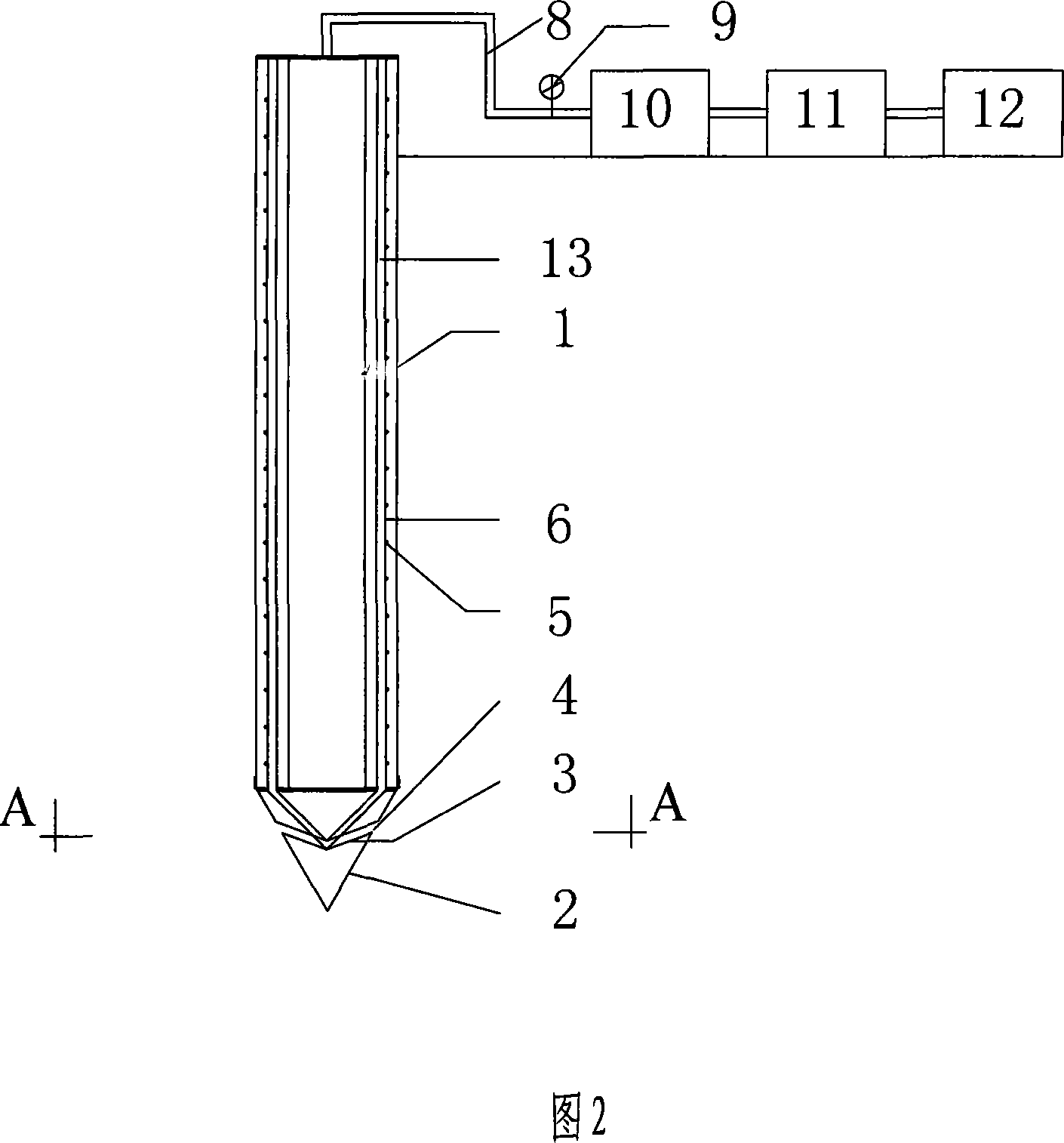

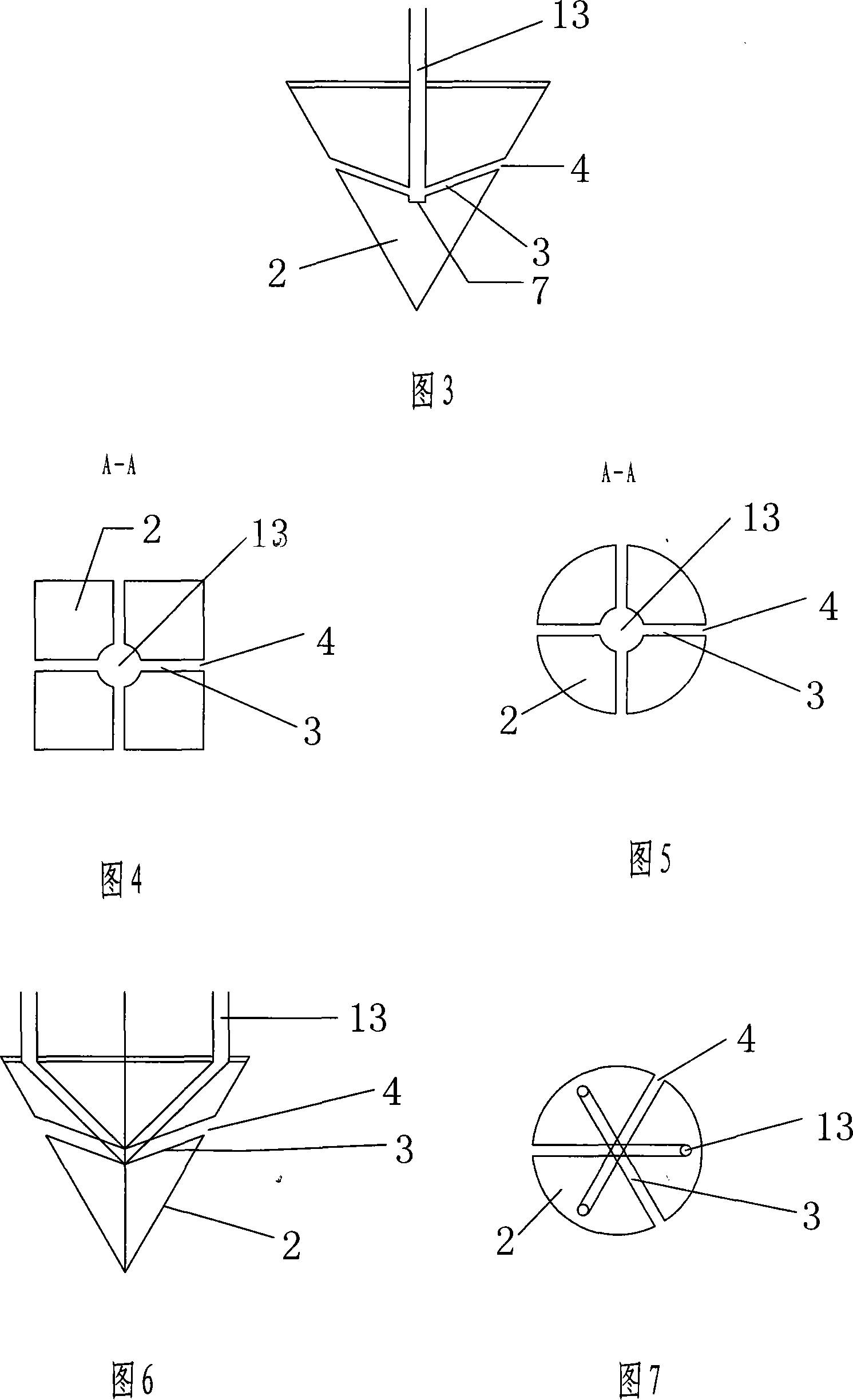

[0030] Pile end grouting fluid: 1 part of water, 1 part of cement; then start to press the pile, make the static pressure pile machine in place and level; use the static pressure machine to place the grouting hole 2, the pile tip 1, and the grouting conduit 5. Prefabricated concrete square piles or pipe piles 4 are pressed into the ground. When the tip of the pile is pressed into the soil for 1-2m, the grouting pump is started to inject the side pile grout, and the pile is pressed while grouting. The amount of grout injected during the process must be able to wrap the pile body to form a mud film of a certain thickness; after the prefabricated pile is pressed into the design depth, continue to press the grout, and inject the grout at the pile end until ...

Embodiment 2

[0032] Embodiment 2: Before the pile is pressed, the grouting fluid is configured first,

[0033] Side pile grouting fluid: 1 part of water, 2 parts of cement, 0.1-0.2 parts of bentonite, 0.03 parts of retarder, and stir evenly;

[0034] Pile tip grouting fluid: 1 part of water, 1 part of cement;

[0035] Then start to press the pile, make the static pressure pile machine in place, leveling; adopt the static pressure machine to press the prefabricated concrete pile or pipe pile 4 with the grouting hole 2 pile point 1 and the grouting conduit 5 into the ground, when the pile point After being pressed into the soil for 1-2m, start the grouting pump to start grouting, inject the grouting slurry for the side piles, and press the piles while grouting. A certain thickness of mud film; after the prefabricated pile is pressed into the design depth, the grouting is continued, and the grouting liquid at the pile end is injected until the grouting amount of the prefabricated pile reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com