Method for plugging cast-in-situ concrete slab or base-plate crack with microbe-sedimented calcium carbonate

A technology of calcium carbonate and microorganisms, which is applied in building construction and construction, can solve problems such as corrosion of concrete and steel bars, and achieve the effect of consistent thermal expansion coefficient and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

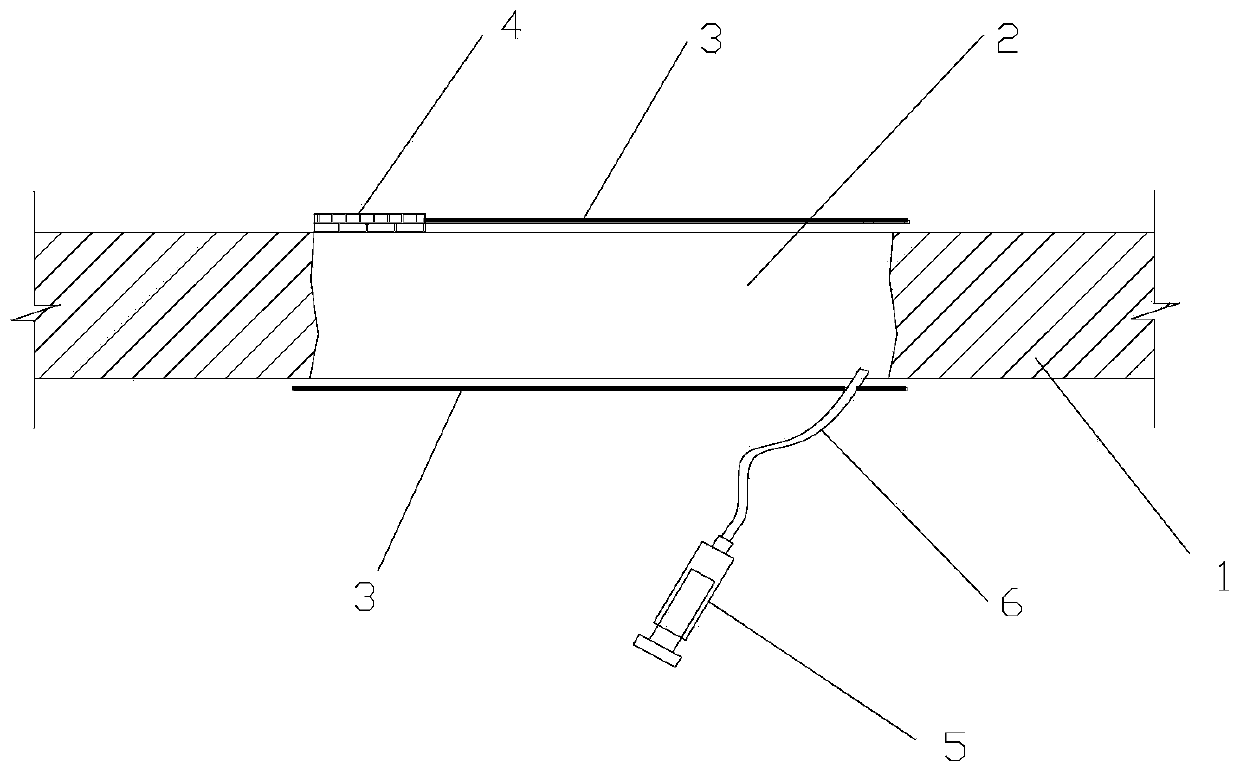

[0045] The method for plugging cracks in cast-in-place concrete slabs by microbial deposition of calcium carbonate comprises:

[0046] A. Preparation of plugging materials

[0047] (1) The preparation of calcium source solution provides calcium ion for calcium carbonate deposition; The present invention selects calcium nitrate (Ca(NO 3 ) 2 ) solution or calcium acetate (Ca(CH 3 COO) 2 ) solution, the concentration is 1mol / L;

[0048] (2) the preparation of nutrient salt solution provides nutrients for the growth and reproduction of microorganisms, and the present invention selects urea (CO(NH 2 ) 2 ) solution, the concentration is 1mol / L;

[0049] (3) preparation of microorganisms, the present invention adopts Bacillus pasteurianum, adopts fermentation tank to cultivate. Fill the fermenter with pure water, and add the following substances per liter of water to prepare a culture medium solution: 20g / L of yeast extract, 10g / L of ammonium sulfate, 2g / L of sodium hydroxide ...

Embodiment 2

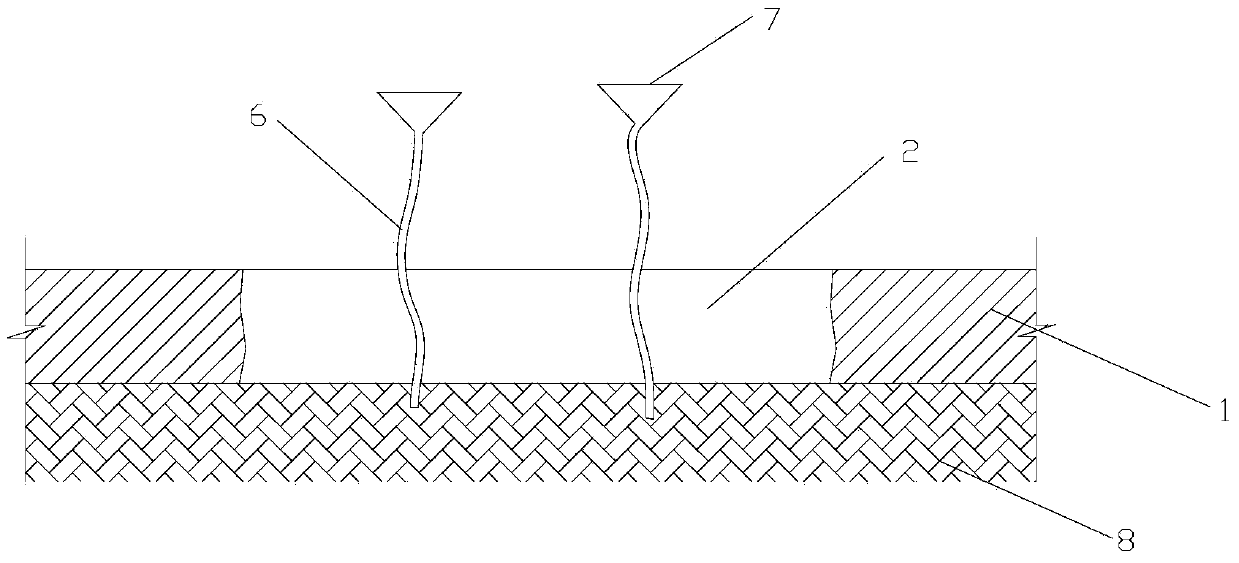

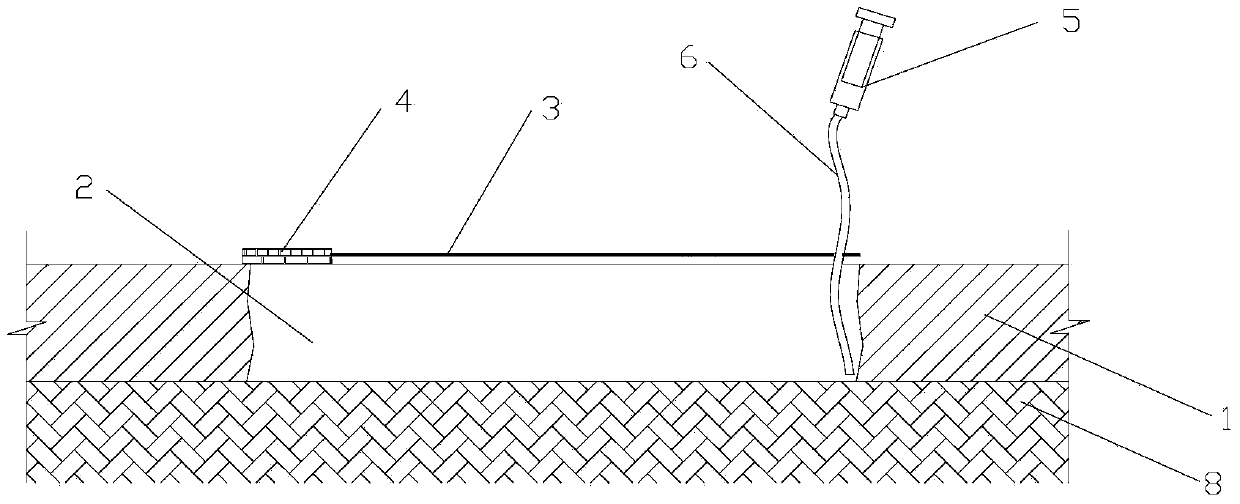

[0057] A method for microbial deposition of calcium carbonate to plug cracks in the base plate of cast-in-place concrete slabs, comprising:

[0058] A. Preparation of plugging materials

[0059] (1) The preparation of calcium source solution provides calcium ion for calcium carbonate deposition; The present invention selects calcium nitrate (Ca(NO 3 ) 2 ) solution or calcium acetate (Ca(CH 3 COO) 2 ) solution, the concentration is 1mol / L;

[0060] (2) the preparation of nutrient salt solution provides nutrients for the growth and reproduction of microorganisms, and the present invention selects urea (CO(NH 2 ) 2 ) solution, the concentration is 1mol / L;

[0061] (3) preparation of microorganisms, the present invention adopts Bacillus pasteurianum, adopts fermentation tank to cultivate. Fill the fermenter with pure water, and add the following substances per liter of water to prepare a culture medium solution: 20g / L of yeast extract, 10g / L of ammonium sulfate, 2g / L of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com