Full glass bulb LED lamp and assembling method thereof

A technology of LED lamps and LED light sources, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of separate setting of driving modules, heat dissipation of the whole lamp, etc., to achieve good heat dissipation effect, reduce gram weight, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

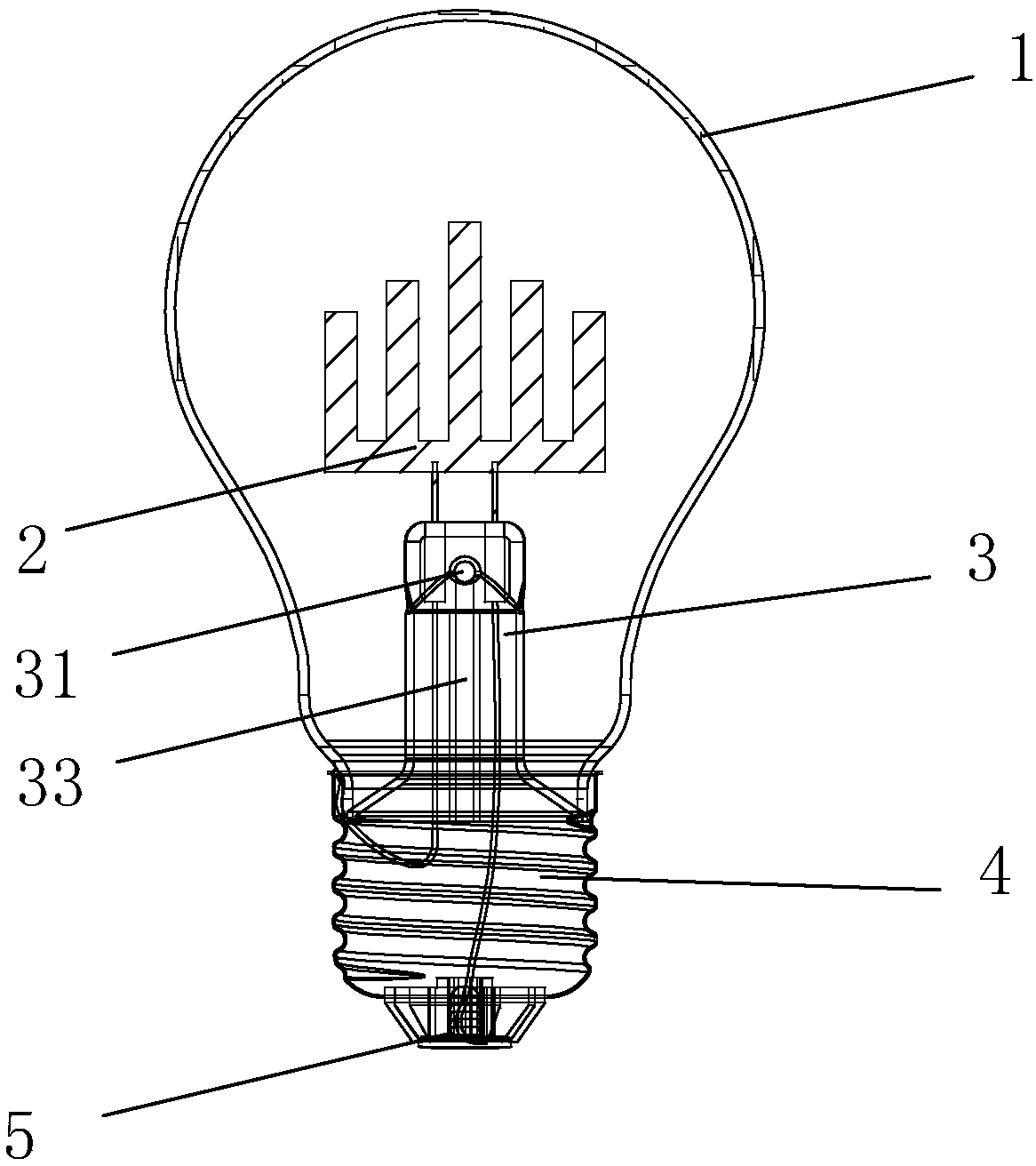

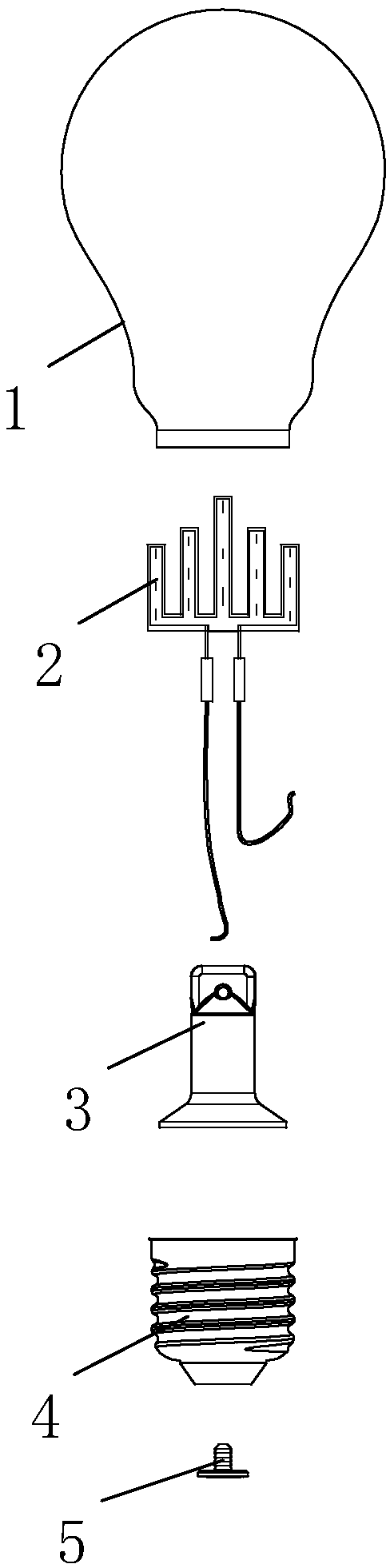

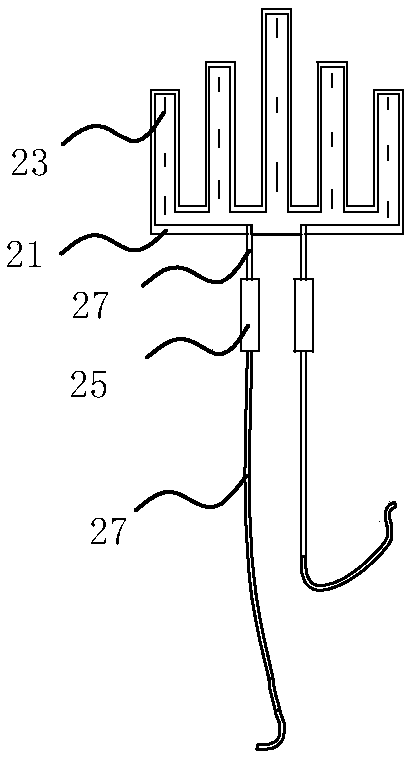

[0034] Please check Figure 1-3 , the glass full-bubble LED lamp of this embodiment adopts the model A60, and includes a bulb shell 1 and an E27 lamp cap 4. The bulb shell 1 and the lamp cap 4 shown in the figure are enclosed to form a cavity, and a light source module 2 and a stem are arranged in the cavity 3. The cavity is filled with inert gas or a mixture of inert gas to enhance heat dissipation;

[0035] The stem 3 is hollow and made of glass. The bottom of the stem 3 is provided with a trumpet-shaped opening. The maximum outer diameter of the opening corresponds to the diameter of the bottom of the bulb 1. The opening is welded and fixed on the At the bottom of the bulb 1, the stem 3 is erected in the bulb 1; the stem 3 is provided with an air-filling hole 31, and the inflation hole 31 communicates with the exhaust rod 33, and the exhaust rod 33 is arranged on the stem 3 and extend downwards to the opening; the lower end of the exhaust rod 33 is open in the processing s...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is: this embodiment adopts the P45 type glass full-bulb lamp, please refer to Figure 5 , wherein the substrate 21 of the light source module 2 is fan-shaped, specifically a circle with a part removed, and the part cut off is the bottom of the substrate 21 to ensure the stability of the light source module 2; at the same time, the LED light sources 23 are packaged on the substrate at linear intervals 21, coated with fluorescent substances.

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is: this embodiment adopts the B35 type glass full-bulb lamp, please refer to Figure 6 , the characteristic of this type of lamp is that the bulb shell 1 is in the shape of a candle, and the inner volume of the bulb shell 1 is small, so the light source module 2 of this lamp is designed as a candle shape matching the shape of the bulb shell 1, and a part of the bottom of the substrate 21 is cut to become a parallel line to ensure the stability of the assembly. More LED light sources 23 can be provided on the upwardly extending part of the candle-like substrate 21 to make up for the lack of width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com