Environmental protection inorganic powder material and polymer composite modified emulsification asphalt grouting material

An inorganic powder material and emulsified asphalt technology, which is applied in the field of highway maintenance, waterproofing and reinforcement engineering, can solve the problems of poor overall effect, short duration, insufficient performance, etc., and achieve improved waterproofing effect. The effect of prolonging the service life and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

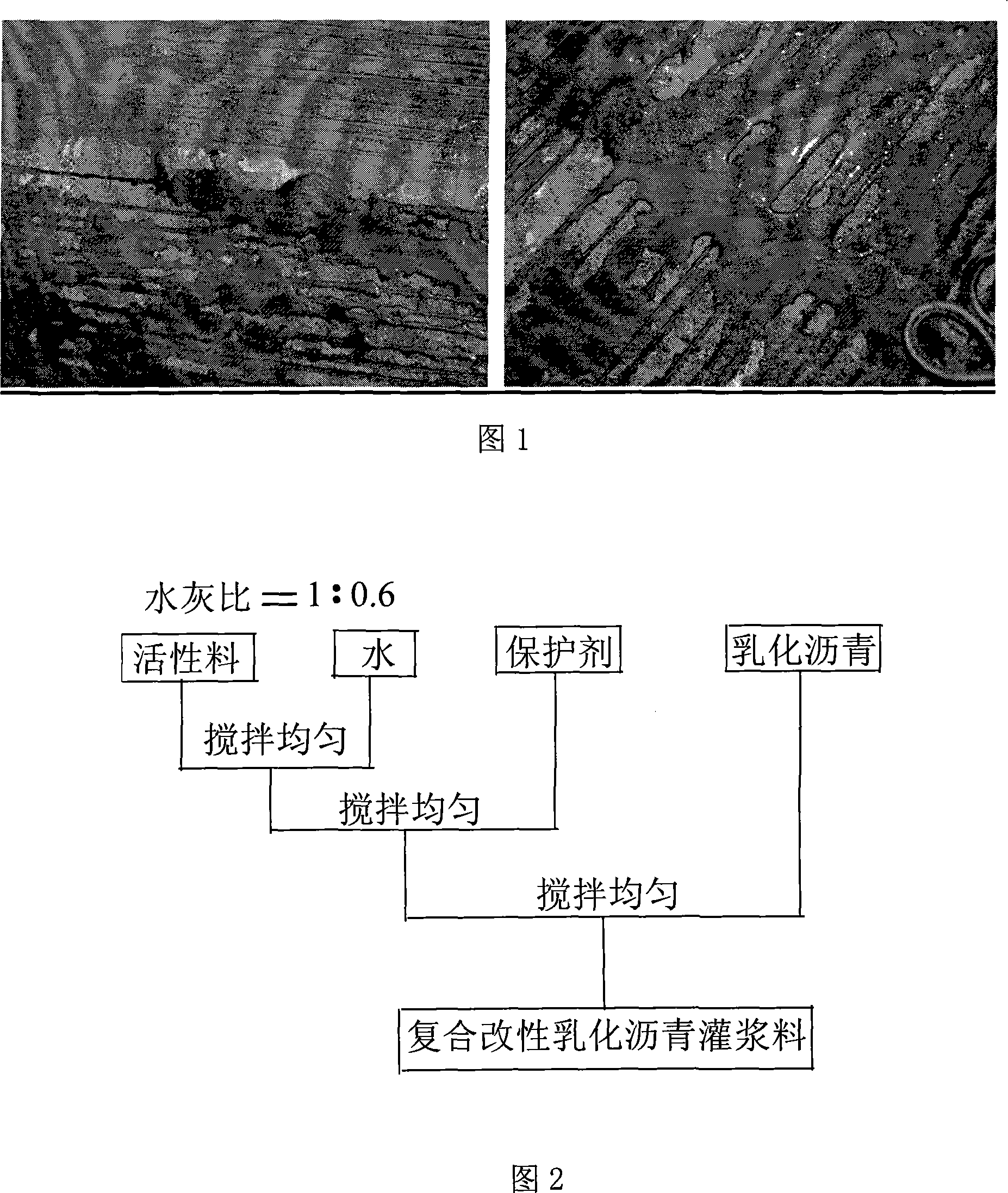

Image

Examples

Embodiment 1

[0021] Embodiment 1: Inorganic powder material and polymer composite modified emulsified asphalt for rigid pavement are used for filling and supplementing strong grouting material, and its composition in parts by weight is: emulsified asphalt: inorganic powder material: protective agent=30:70 : 15.

[0022] The emulsified asphalt is commercially available, and its solid content is in the range of 30wt.%-70wt.%.

[0023] The composition of the inorganic powder material (active material) in parts by weight is: cement: mineral powder: quartz sand = 6:2:2 and uniformly mixed.

[0024] The mass ratio of the protective agent is composed of: cationic rubber powder: polymer emulsion: polyethylene glycol: bentonite: defoamer: amphoteric surfactant: calcium chloride: water=100:200:100:400:1:4 : 10:80; wherein the cationic rubber powder is cationic acrylate rubber powder, the polymer emulsion is cationic acrylate emulsion, the defoamer is silicone powder defoamer, and the amphoteric sur...

Embodiment 2

[0026] Embodiment 2: Inorganic powder material and polymer composite modified emulsified asphalt filling and reinforcing grouting material, its composition in parts by weight is: emulsified asphalt: inorganic powder material: protective agent = 35:70:15.

[0027] The parts by weight of the inorganic powder material (active material) consist of: cement: mineral powder: fly ash=6: 2: 2 uniformly mixed to get final product; described emulsified asphalt and protective agent, production process are all the same as in Example 1 same.

Embodiment 3

[0028] Example 3: Inorganic powder material and polymer composite modified emulsified asphalt waterproof grout, its composition in parts by weight is: emulsified asphalt: inorganic powder material: protective agent = 70:30:20.

[0029] The parts by weight of the inorganic powder material (active material) components are composed of: cement: mineral powder: fly ash = 6: 3: 3, mix it uniformly to get final product; the emulsified asphalt and protective agent, production process All the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com