Integral turbine outer ring connection structure and turbine engine

A connection structure, integral technology, applied in the direction of engine function, engine components, machine/engine, etc., can solve the problems of uneven thermal deformation of the outer ring of the turbine, and the thermal stress cannot be fully released, and achieves the guarantee of the turbine blade tip clearance, guarantee The effect of uniform performance and radial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

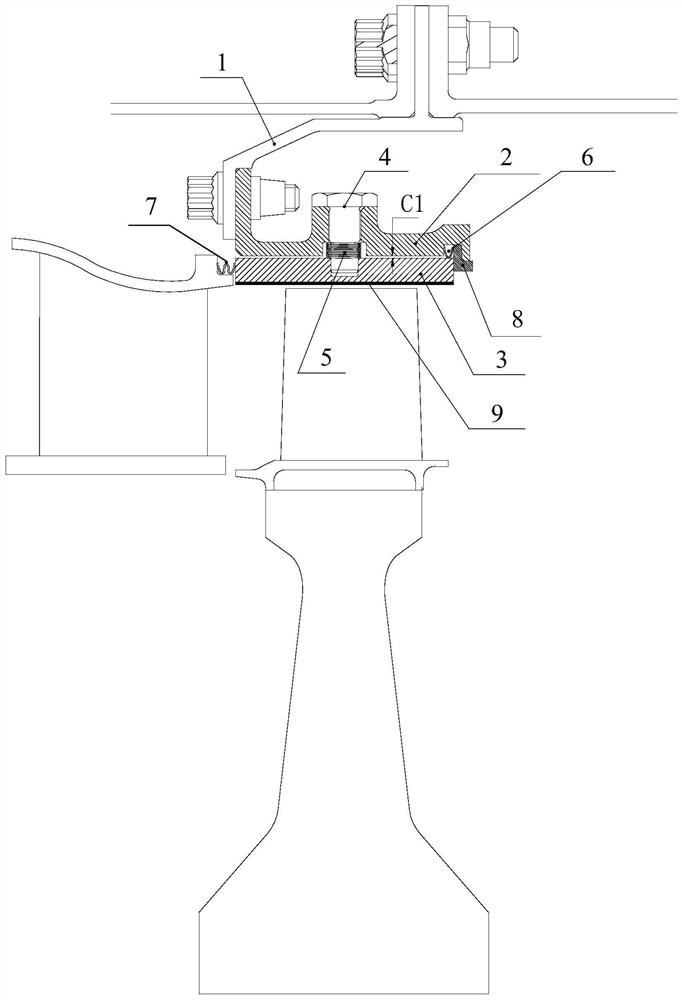

[0028] refer to figure 1 , the preferred embodiment of the present invention provides a kind of integral turbine outer ring connection structure, this connection structure comprises: turbine casing 1, turbine casing 1 is provided with support ring 2 and the turbine outer ring 3 that is connected with support ring 2, turbine A radial gap for releasing the thermal stress of the turbine outer ring 3 is provided between the outer ring 3 and the support ring 2, and a plurality of radial gaps are provided between the turbine outer ring 3 and the support ring 2 to buffer the radial deformation of the turbine outer ring 3 and make the turbine outer ring 3 radially deformed. An elastic member with more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com