Anti-pollution high-efficiency vibration filtering separation device

A technology of filtration separation and vibration filtration, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of the function and efficiency of the filtration separation system, the decrease of ultrafiltration membrane water production, and the pollution of filtration and separation media, etc., to achieve The effects of long backwashing cycle, improved separation efficiency and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

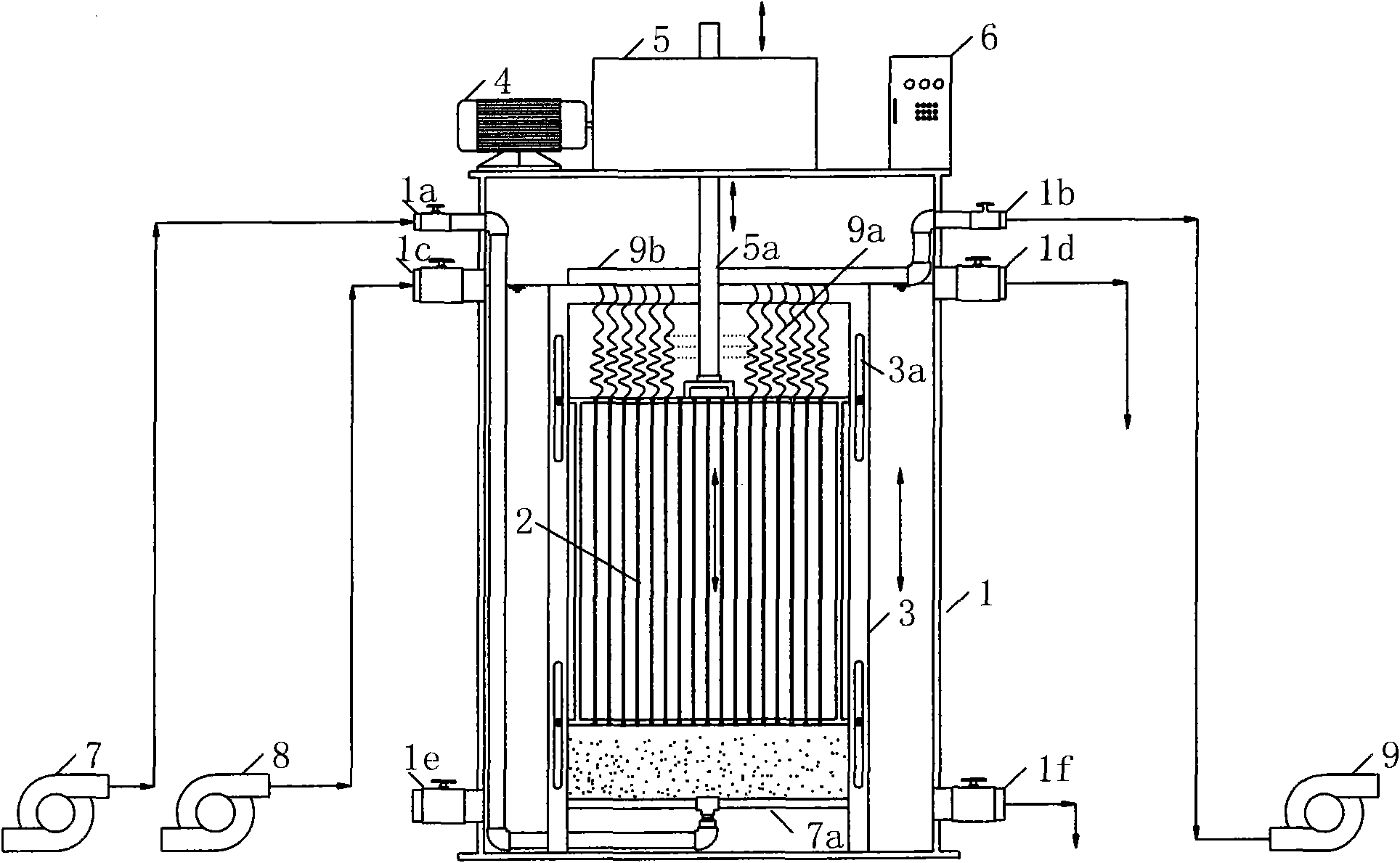

[0035] Such as figure 1 Shown, the present invention is used for MBR sewage treatment process. The mixed liquid container 1 is made of welded steel plate, the mixed liquid in the mixed liquid container 1 is a mixture of mud and water, the lifting unit 8 is a sewage pump, the water inlet is domestic sewage, the air supply unit 7 is a blower, and the air distribution pipe 7a is a perforated air distribution pipe , The filtration separation unit is a flat membrane, a total of 17 pieces form a module. The flat membrane vibrates in the vertical direction, the vibration frequency is 1 time / 2s, and the amplitude is 30% of the vertical length of the flat membrane. The power mechanism 4 is an electric motor, the motion conversion mechanism 5 is a reduction box and a ball screw power conversion mechanism, the control unit 6 is a PLC control box, and the suction unit 9 is a high-pressure centrifugal pump. The concentrated liquid discharged from the discharge port 1f is excess sludge. ...

Embodiment 2

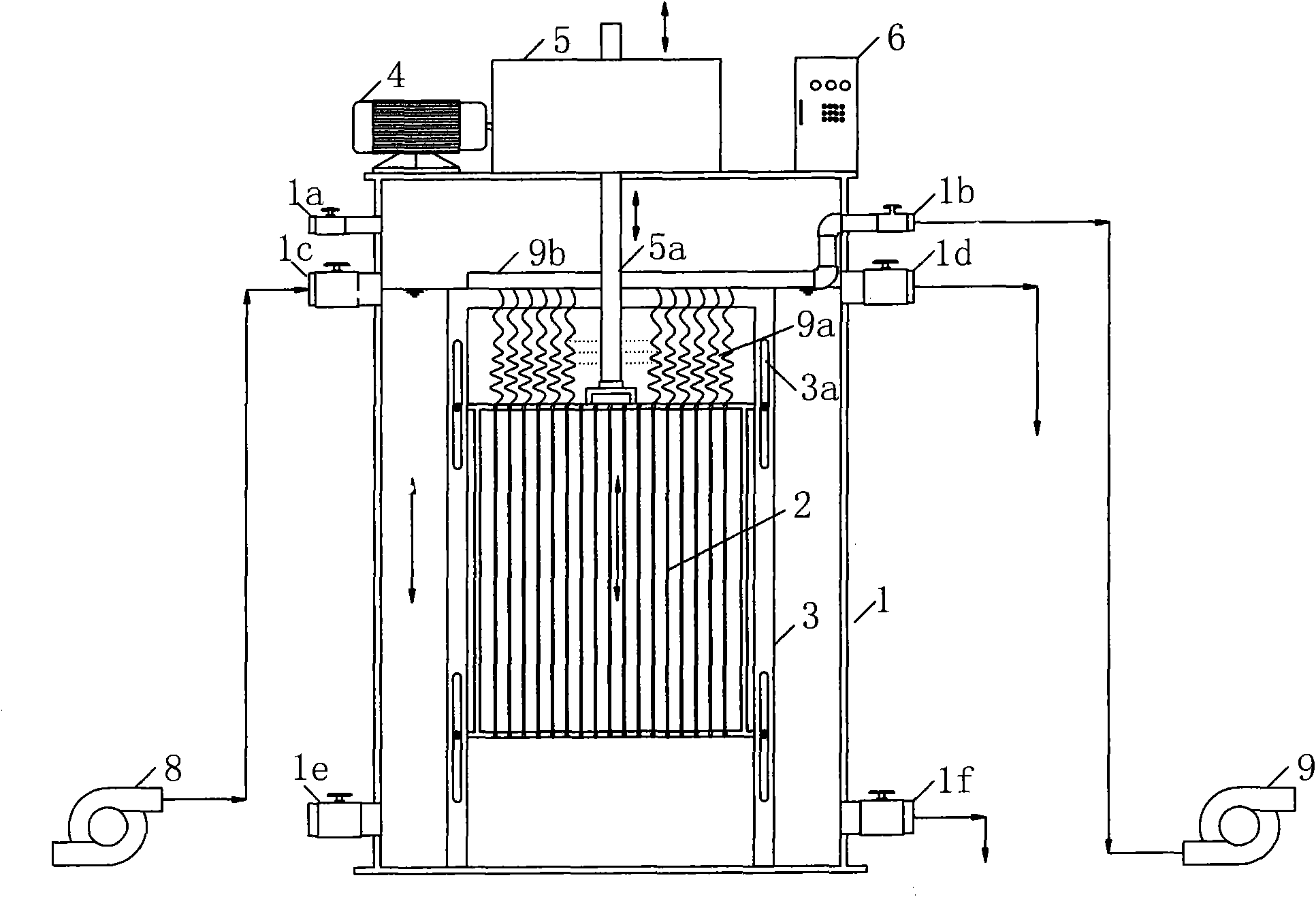

[0038] Such as figure 2 As shown, the present invention is used for the mud-water separation of the hydrolytic acidification process, and no air supply unit is provided here. The mixed liquid container 1 is welded by steel plate, the mixed liquid in the mixed liquid container 1 is a muddy water mixture, the lifting unit 8 is a sewage pump, the incoming water is domestic sewage, and the filtration and separation unit is a flat membrane, a total of 17 pieces constitute a module. The flat membrane vibrates in the vertical direction, the vibration frequency is 1 time / 3s, and the amplitude is 20% of the vertical length of the flat membrane. The power mechanism 4 is an electric motor, the motion transformation mechanism is a reduction box and a ball screw power transformation mechanism, the control unit 6 is a PLC control box, and the suction unit is a high-pressure centrifugal pump. The concentrated liquid discharged from the discharge port 1f is excess sludge. In this embodimen...

Embodiment 3

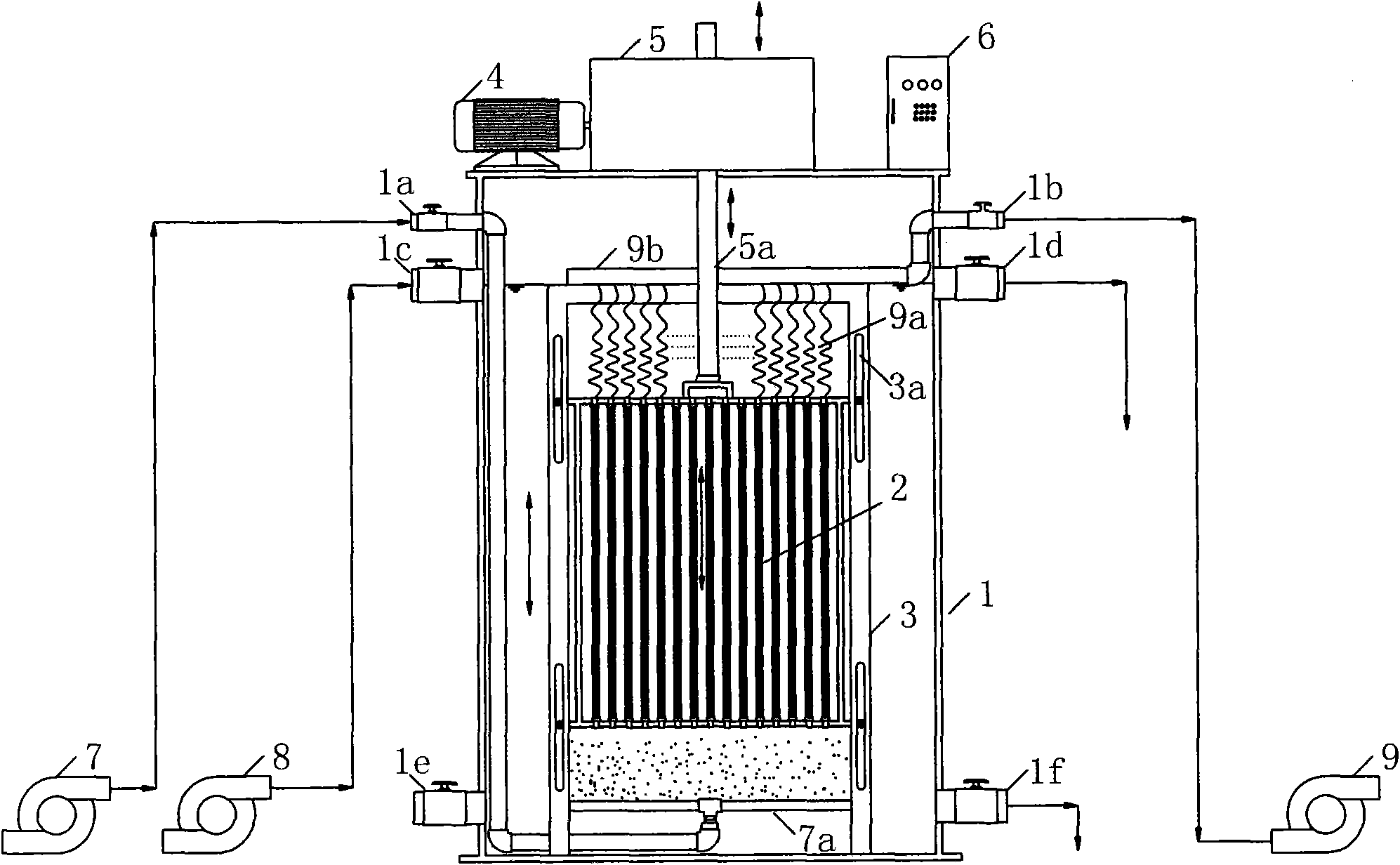

[0041] Such as image 3 As shown, the present invention is used for collecting and separating algae in surface landscape water bodies. The mixed liquid container 1 is made of steel plate welding, the mixed liquid in the mixed liquid container is algae water mixed liquid, the lifting unit 8 is a centrifugal pump, the water inlet is the landmark landscape water where algae bloom occurs, and the air supply unit 7 is a blower. The air pipe 7a is a perforated air distribution pipe, and the filtration and separation unit is a hollow fiber membrane module, 15 groups in total. The hollow fiber membrane vibrates in the vertical direction, the vibration frequency is 1 time / 1s, and the amplitude is 25% of the vertical length of the hollow fiber membrane module. The power mechanism 4 is an electric motor, the motion transformation mechanism is a reduction box and a ball screw power transformation mechanism, and the control unit 6 is a PLC control box. The concentrated liquid discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com