Premix material for friction material and processing method thereof

A technology of friction materials and processing methods, applied in the field of friction materials, can solve the problems of high surface hardness of friction materials, reduce friction coefficient, and easily generate noise, etc., and achieve the effects of improving friction efficiency, reducing wear rate, and adjusting surface hardness

Inactive Publication Date: 2010-08-25

焦龙

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of these non-metallic mineral powders as lubricants can reduce the friction coefficient, but it also brings some negative effects, such as high surface hardness of friction materials, greater wear, and easy to generate noise, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

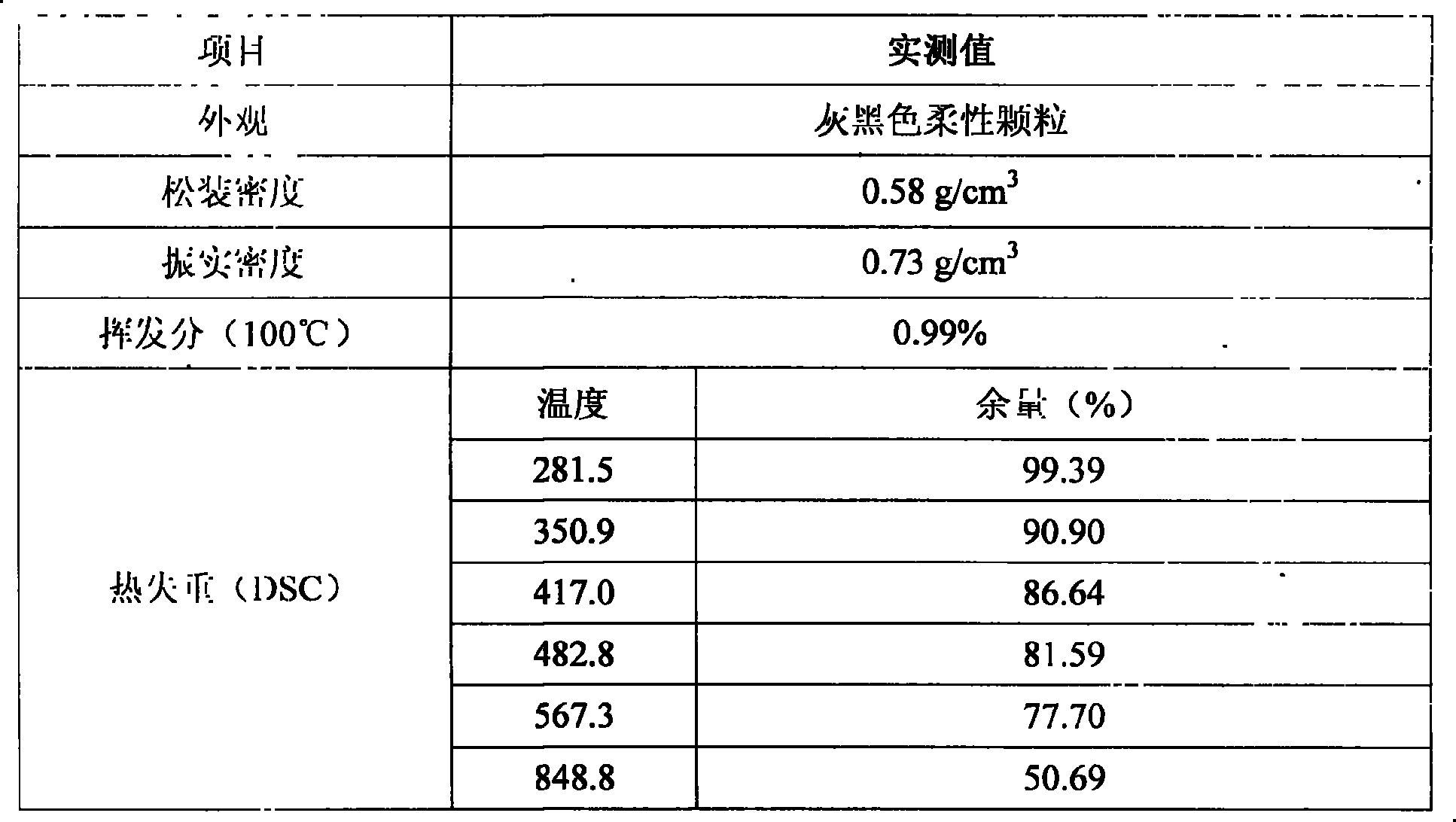

Embodiment 1

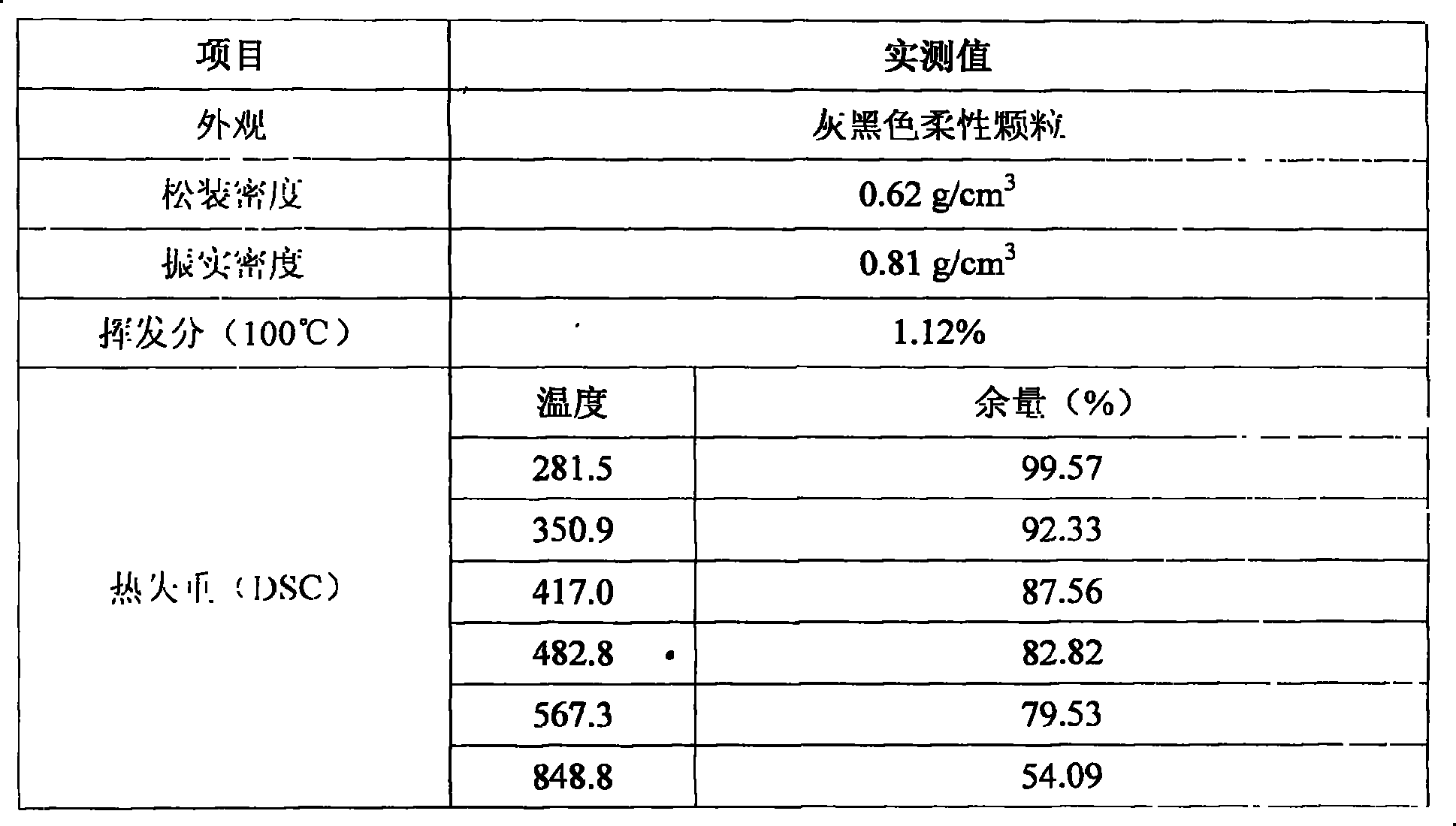

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a premix material for a friction material and a processing method thereof. The premix material comprises the following components in percentage by weight: 45 to 70 percent of natural crystalline flake graphite, 15 to 30 percent of jute fiber, sisal fiber or a mixture of the two, 4 to 8 percent of nitrile butadiene rubber, 8 to 12 percent of ethylene propylene terpolymer, 0.5 to 3 percent of zinc oxide, 0.8 to 1.5 percent of sulphur and 0.7 to 1.5 percent of accelerator M. The nitrile butadiene rubber, ethylene propylene terpolymer, zinc oxide, natural plant fiber, natural crystalline flake graphite, accelerator M and sulphur are sequentially added into a rubber fining mixer to be mixed and then the raw materials are crushed into grains with a crushing machine so as to obtain the finished product. The premix material for the friction material has the advantages of effectively regulating the surface hardness of the friction material product, improving the friction effect, reducing the abrasion and improving the comfort of the friction material during use.

Description

technical field The invention relates to friction materials used in various braking or transmission systems, in particular to a premixed material for friction materials and a processing method thereof. Background technique Any mechanical equipment and vehicles must have braking and transmission systems. Friction material products are key components of these systems, and their friction and wear performance is directly related to the operation and efficiency of mechanical equipment or vehicles, as well as the safety of equipment and personnel. , its importance is self-evident. Friction material is a functional composite material with its friction and wear performance as its main working property. Its composition can be generally divided into four parts according to its function: matrix, reinforcement, friction performance modifier and filler. Among them, friction modifiers can be divided into two categories according to their functions: friction enhancers and lubricants. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K3/14C08L1/02C08L23/16C08L9/02C08K13/04C08K7/00C08K3/04

Inventor 焦龙余小成蒋小强

Owner 焦龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com