Comprehensive performance testing device for rolling ball bearing

A technology of rolling ball bearings and comprehensive performance, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as increased difficulty in processing and assembly, signal processing interference, and complex structure of the test device, so as to simplify the assembly and test process, simplify the structure of the device, and improve The effect of trial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0025] This embodiment provides a rolling ball bearing comprehensive performance test device, which simultaneously obtains the dynamic change process of three operating parameters of the rolling ball bearing during operation: friction torque signal, vibration signal and temperature signal, and is easy to process and assemble with little interference.

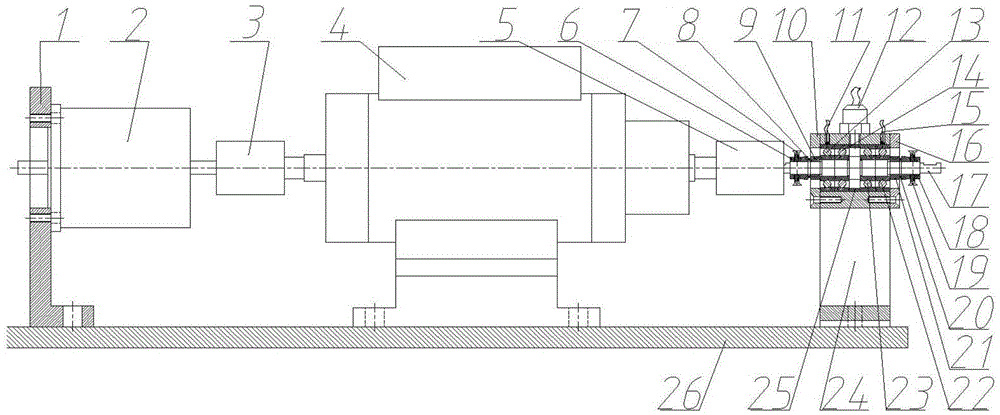

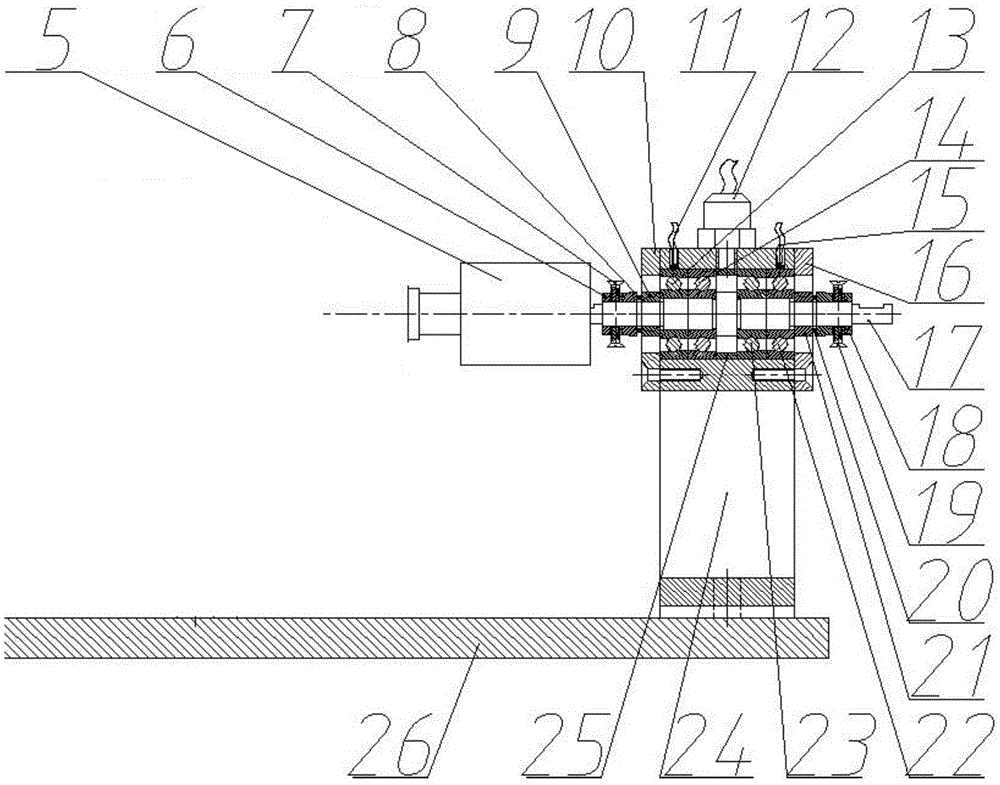

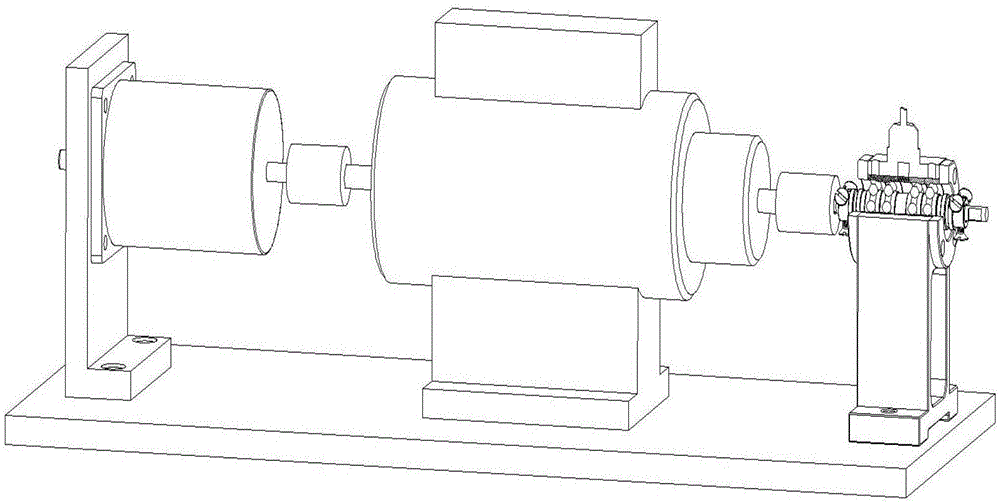

[0026] The specific structure of the test device is as follows: figure 1 , figure 2 with image 3 As shown, it includes: a motor support, a motor 2, a torque sensor 4, two temperature sensors, an acceleration sensor 12, an axial load loading device and a test bearing. The test bearings are two pairs of rolling ball bearings, that is, two pairs of rolling ball bearings are tested simultaneously by the test device.

[0027] The motor support includes a horizontal support 26 and a vertical support 1 fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com