Intelligent production management method

A management method and intelligent production technology, applied in data processing applications, resources, computing, etc., can solve problems such as difficulty in ensuring product quality, low efficiency, and high work pressure for quality inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

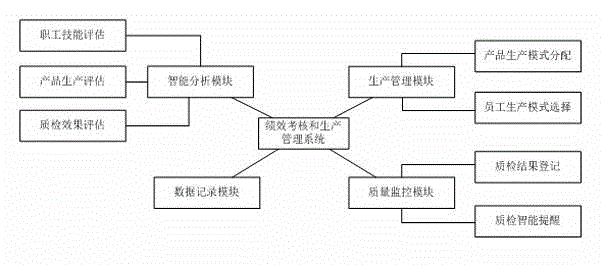

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The intelligent production management side of the present invention includes an intelligent production management method, which is characterized in that it includes the following steps:

[0023] (1) Informatization data collection

[0024] Data collection is completed through various forms of system terminals, in which the production status of workers can be manually entered or automatically registered through embedded devices installed on the workstations, and the results of production efficiency and product quality inspections can be checked by the production team leader. Or the hand-held terminal in the hand of the quality inspector to record, and the final quality random inspection results can be submitted through the personal computer terminal in the quality inspection room;

[0025] (2) Professional data analysis

[0026] The intelligent management center system displays the relationship between workpiece production efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com