Reliable, modular, production quality narrow-band high rep rate F2 laser

a production quality, modular technology, applied in the direction of pulse technique, optical radiation measurement, active medium material, etc., can solve the problems of increased variation in the output laser pulse energy, excessive wear and failure of blower bearings, and noise produced by the laser environment, so as to achieve reliable, modular and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

A preferred embodiment of the present invention can be described by reference to the drawings.

Modular Laser Design

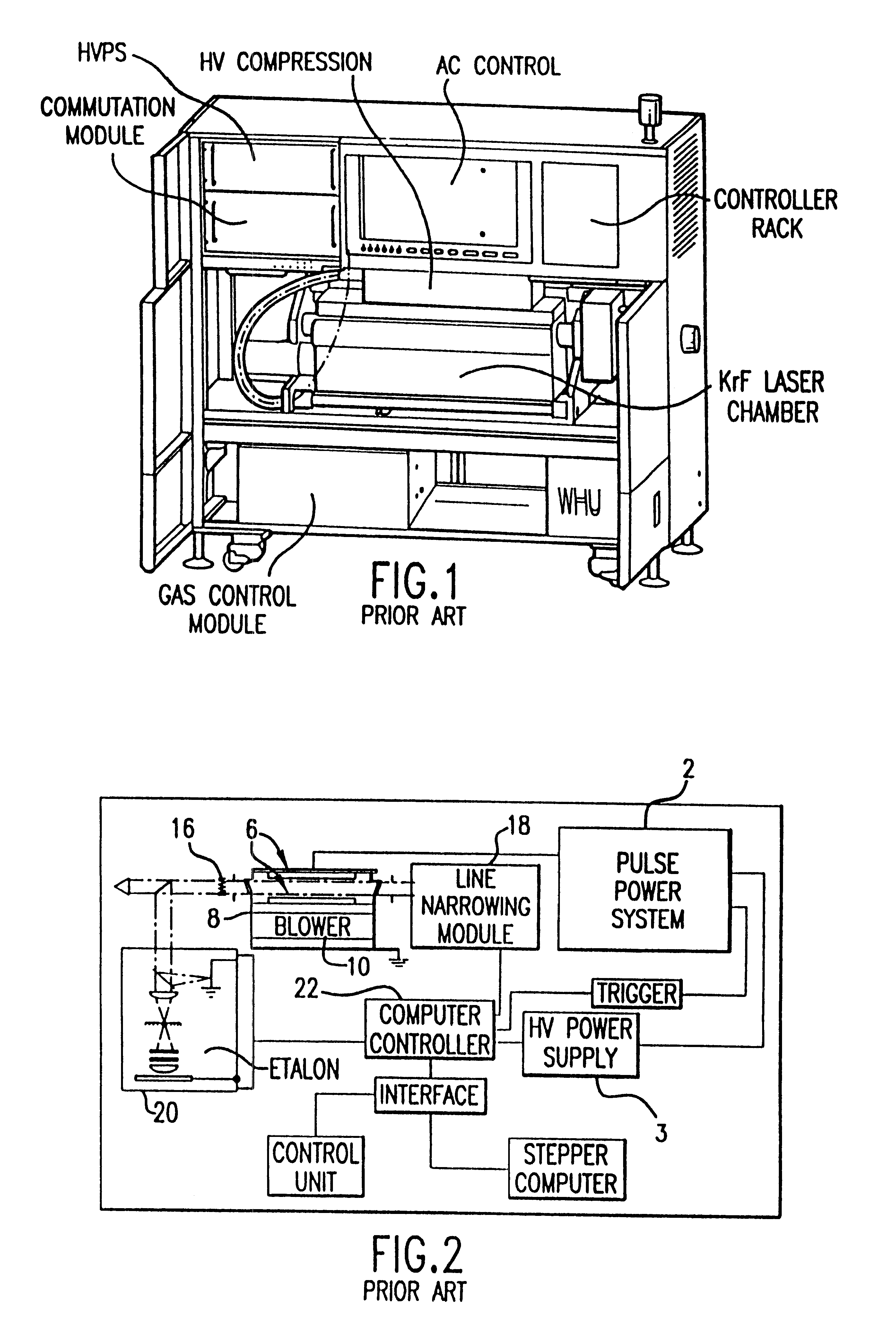

A front view of a preferred embodiment of the present invention is shown in FIG. 4 respectively. This drawing emphasizes the modular nature of their particular invention which allows very quick replacement of modules for repair, replacement and maintenance. The principal features of this embodiment are listed below corresponding to the reference numbers shown on FIG. 4. 201 Laser enclosure 202 Gas module 203 Cooling water supply module 204 AC / DC distribution module 205 Control module 206 Line narrowing module 207 Compression head 208 High voltage pulse power supply module 209 Commutator module for pulse power supply 210 Metal fluoride trap 211 Laser chamber 213 Wavemeter module 214 Automatic shutter 216 Output coupler 217 Blower motor 218 Metal fluoride trap power supply 219 Status lamp 220 24 volt power supply 221 Chamber window 222 Gas control flexible connection 224 V...

embodiment

Preferred Embodiment

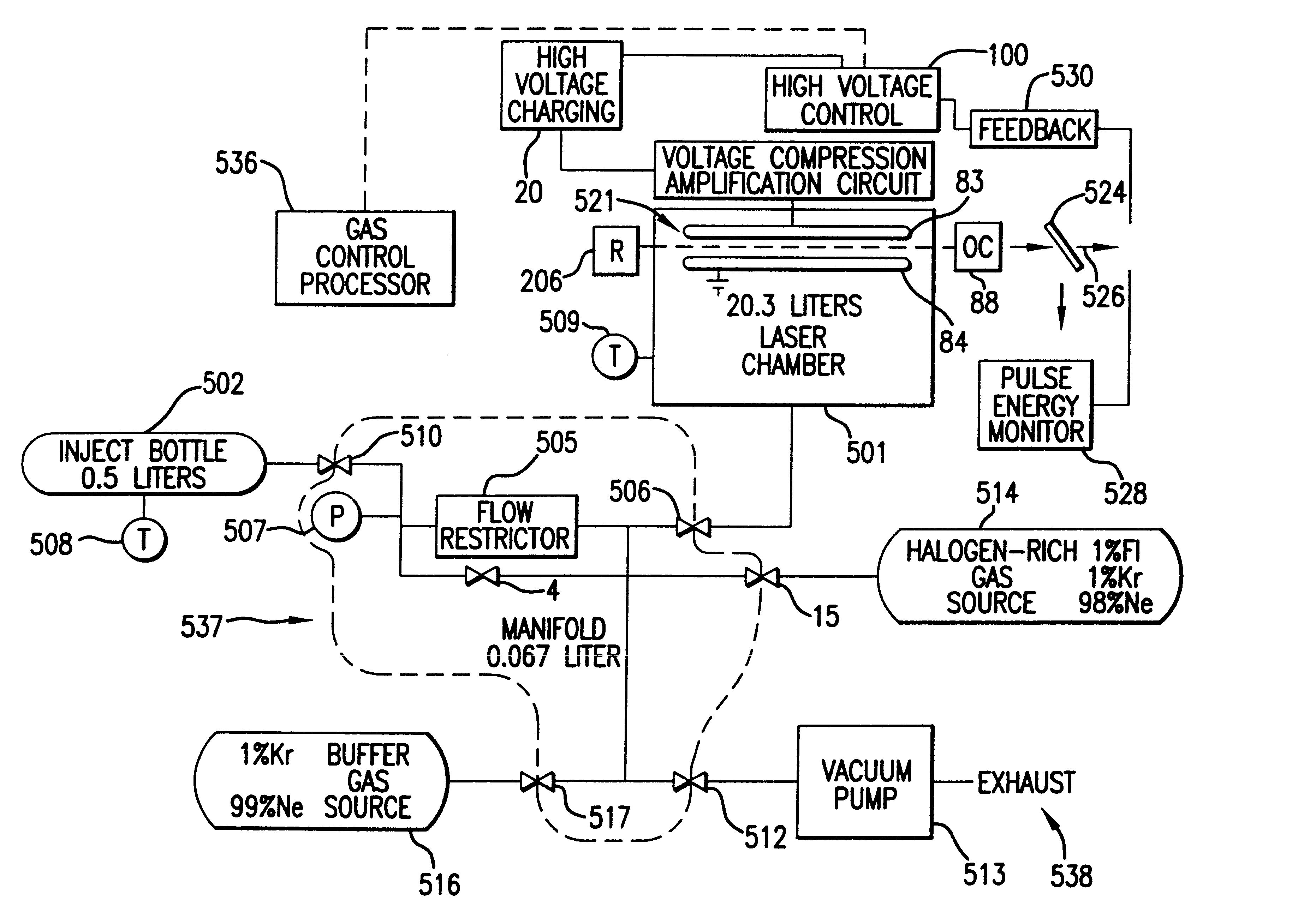

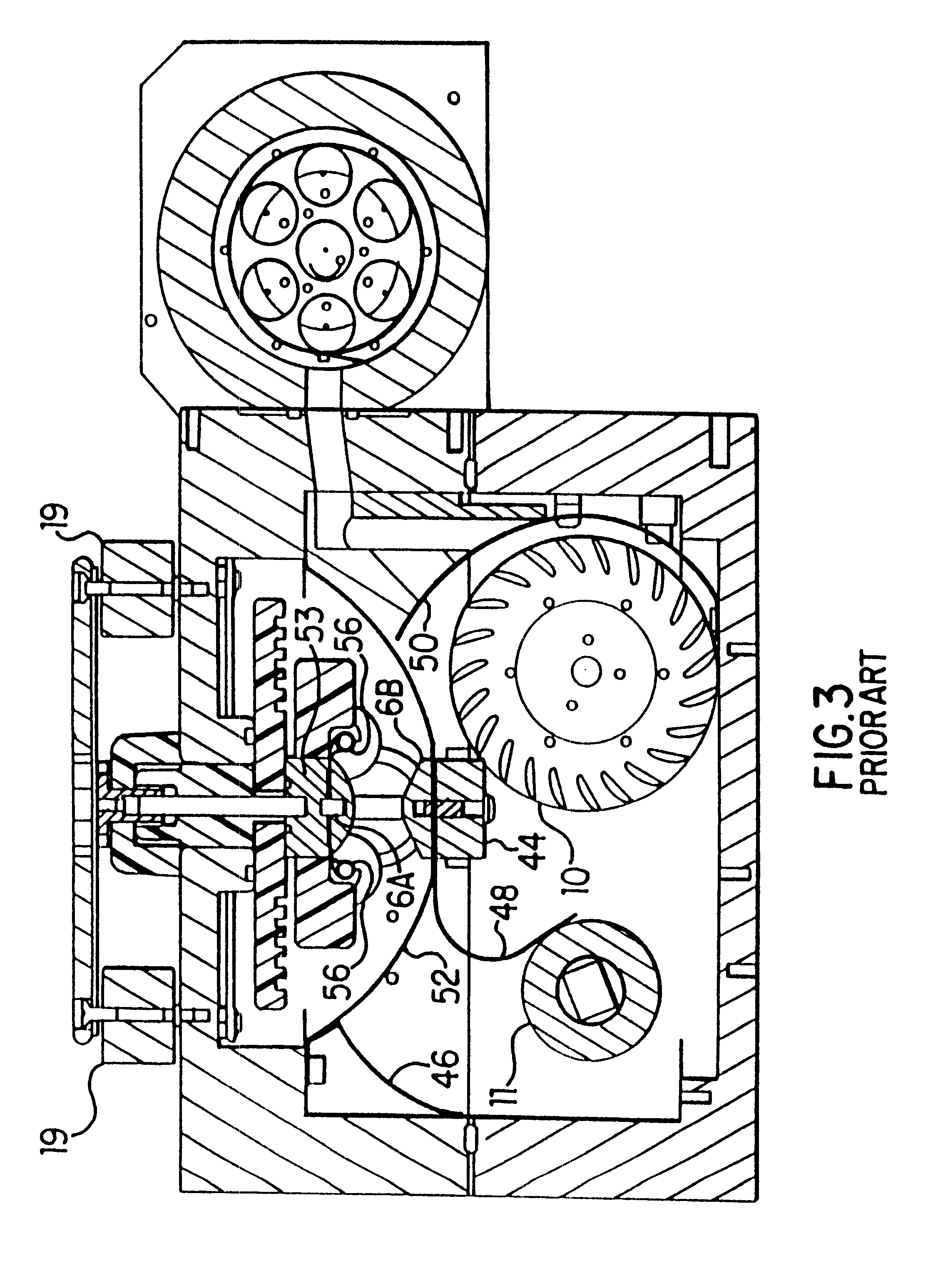

A preferred embodiment of the present invention is an improved version of the laser described in FIGS. 1, 2 and 3. This preferred embodiment includes the following improvements: 1) A single tube larger preionizer replaces the prior-art combination of a two-tube preionizer to provide improved efficiency, better preionization and improved laser gas flow between the electrodes; 2) A silicon-free fan blade which may be a one-piece machined blade; 3) The solid-state pulse power system has been modified to produce faster rise time, providing more consistent pulses, and improved laser efficiency at higher voltages; 4) More precise control of the charging voltage of the pulse power system; 5) A computer controller programmed with a new algorithm providing a much improved control of pulse energy and burst energy; and 6) Electrode spacing has been reduced to 10 mm.

Chamber Improvements

Single Preionizer Tube

As shown in FIG. 6, a single larger preionizer tube 56A has replaced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com