Full-automatic chain running machine

A fully automatic and chain technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of low processing efficiency, low safety performance, low degree of automation, etc., to improve processing efficiency, improve production safety, and reduce human waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

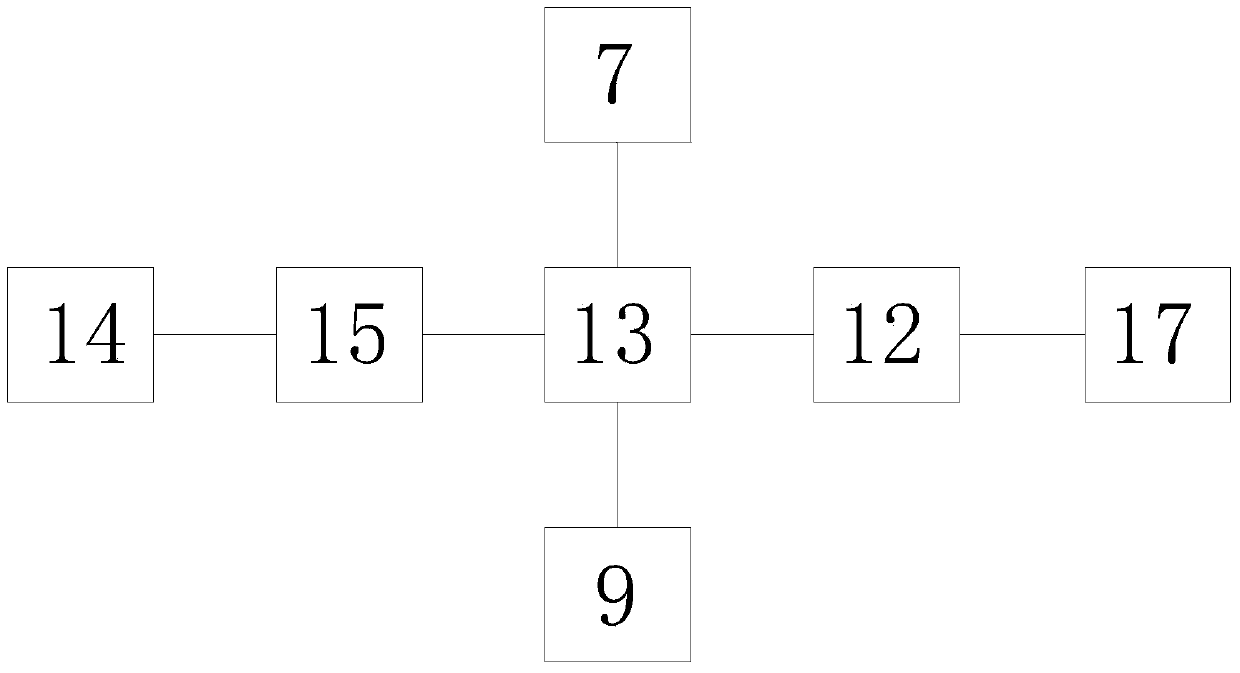

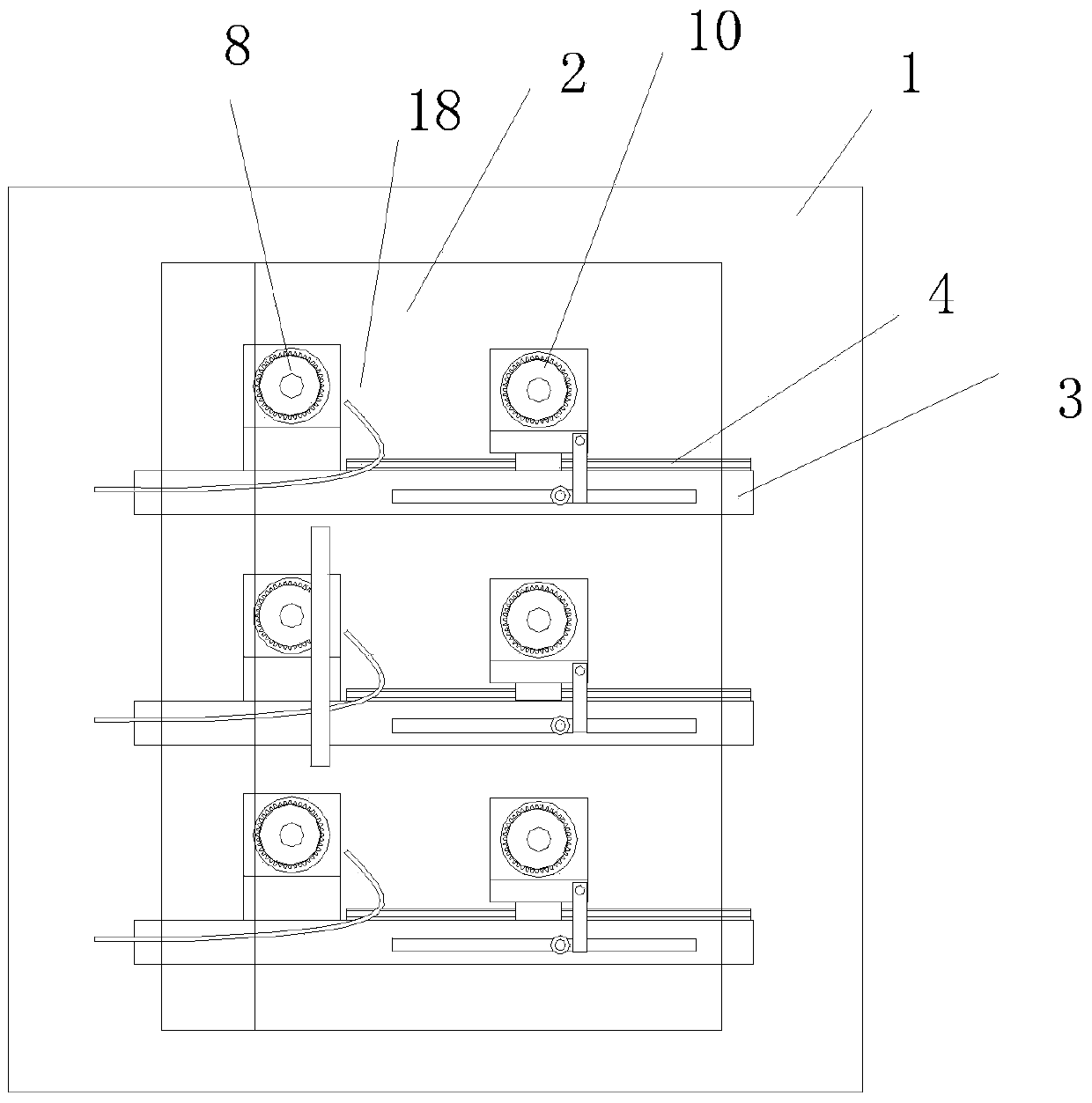

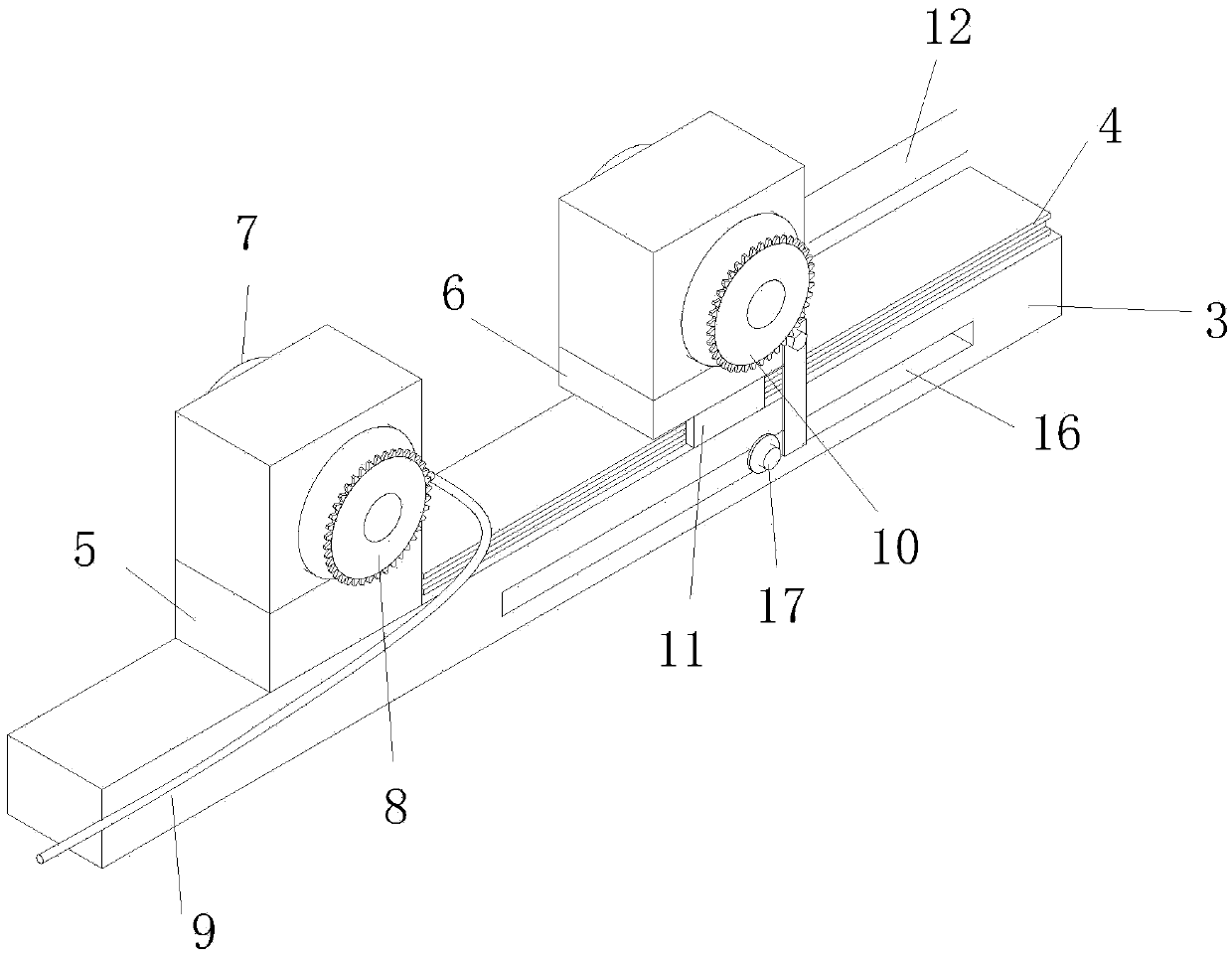

[0014] Embodiment: a kind of fully automatic chain running-in machine, constitutes as Figure 1-3 As shown, it includes an airtight box body 1. The front part of the box body 1 is provided with a sliding door 2. The sliding door can automatically move back and forth. The box body 1 is provided with multiple sets of running-in mechanisms. The elongated support seat 3 is provided with a slide rail 4 on the support seat 3, and one end of the slide rail 4 is provided with a fixed seat 5, the slide rail 5 is provided with a slide seat 6, and the fixed seat 6 is provided with a motor 7, and the motor 7 The output end is provided with a driving sprocket 8, and the fixed seat 5 is provided with an oil injection device 9; the sliding seat 6 is provided with a driven sprocket 10, and the lower part of the sliding seat 6 is provided with a chute 11 matched with the slide rail 5, so that The sliding seat 6 is also connected with a pushing device 12; the motor 7, pushing device 12 and fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com