Biological adhesive as well as preparation method and application thereof

A bio-adhesive and initiator technology, used in applications, adhesives, surgical adhesives, etc., can solve the problems of no adhesive effect and insufficient gel consistency, and can expand application methods, avoid using procedures, and expand Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of above-mentioned bioadhesive, comprises the steps:

[0044] Step 1, component a is formulated into an aqueous solution;

[0045] Step 2, component b is formulated into an aqueous solution;

[0046] Step 3. When in use, the aqueous solution of step 1 and the aqueous solution of step 2 are mixed by physical methods, and the physical methods include spraying, coating, injection, vortex, shaking or magnetic stirring.

[0047] The adhesive also includes component c: osmotic pressure regulator or / and component d: preservative or / and component e: essence, wherein the osmotic pressure regulator includes sodium chloride, potassium chloride, One or more of calcium chloride.

[0048] The preparation method of above-mentioned bioadhesive, comprises the steps:

[0049] Step 1, preparing component a, part of component c or / and part of component d or / and part of component e into an aqueous solution;

[0050] Step 2, preparing component b, remaining compone...

Embodiment 1

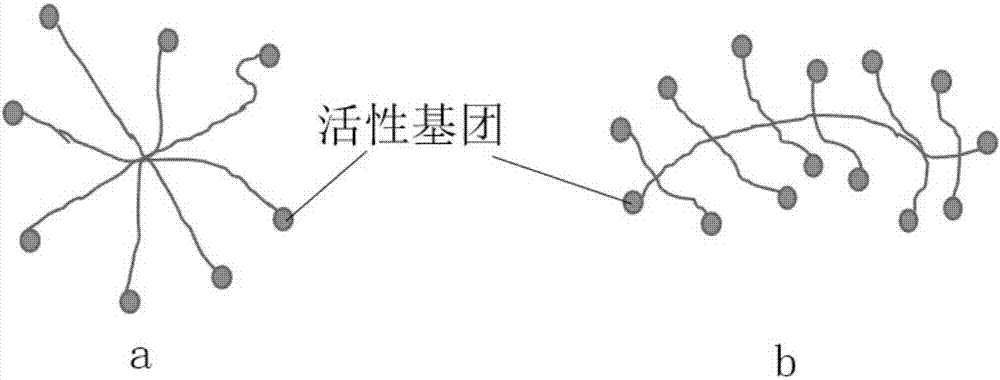

[0054] Preparation of Star Polymers Containing a Large Number of Amino Functionalization at the Terminals

[0055] Step 1: Using the principle of Michael addition, 60 parts by mass of acrylate and 10 to 20 parts by mass of ethylenediamine are dissolved in 100 parts by mass of methanol at -7 to -3°C. After fully reacting at 25°C for 24 hours, unreacted chemical substances and methanol were removed by continuous rotary evaporation to obtain an intermediate product A (tetramethyl ester polyamide). The molecular terminal of the intermediate product A contained 4 methyl ester groups.

[0056] Step 2: Using the principle of transesterification, mix and dissolve 20 parts by mass of intermediate product A and 80-160 parts by mass of ethylenediamine at -7-3°C in 200 parts by mass of methanol, and react at 18-25°C After 48 hours, unreacted chemical substances and methanol were removed by continuous rotary evaporation to obtain a star compound G-4 (tetraaminopolyamidoamine) with 4 amino ...

Embodiment 2

[0059] Preparation of Four-armed Polyethylene Glycol Star Polymer with Polyamino-modified Terminals

[0060] Dissolve 10 parts by mass (MW=2000) of four-arm polyethylene glycol acrylate (Xiamen Sinobanger, 4-armPEG-AA), 2 to 6 parts by mass of ethylenediamine at -7 to -3°C In 100 parts by mass of DMF solvent, react at 18-25°C for 24 hours, purify and remove unreacted chemical substances and solvents, and obtain aminated four-armed polyethylene glycol with 8 amino groups at the end, ie I-8.

[0061] Similarly, using the principle of Michael addition and transesterification in Example 1, changing the input amount, ratio, and reaction time of raw materials, it is possible to obtain aminated tetramethylammonium chloride with 16, 32 or more amino groups at the end. Arm polyethylene glycol star polymer, namely I-16, I-32....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com