High-efficiency automatic mass detonator card waist bayonet machine

A technology of waist clipping and mass firing, applied to detonators, offensive equipment, etc., can solve the problems of increasing difficulty in adjusting the waistband position, single waist or bayonet, inconvenient maintenance, etc., and reduce the production workshop and area of detonators. , The effect of compact equipment and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

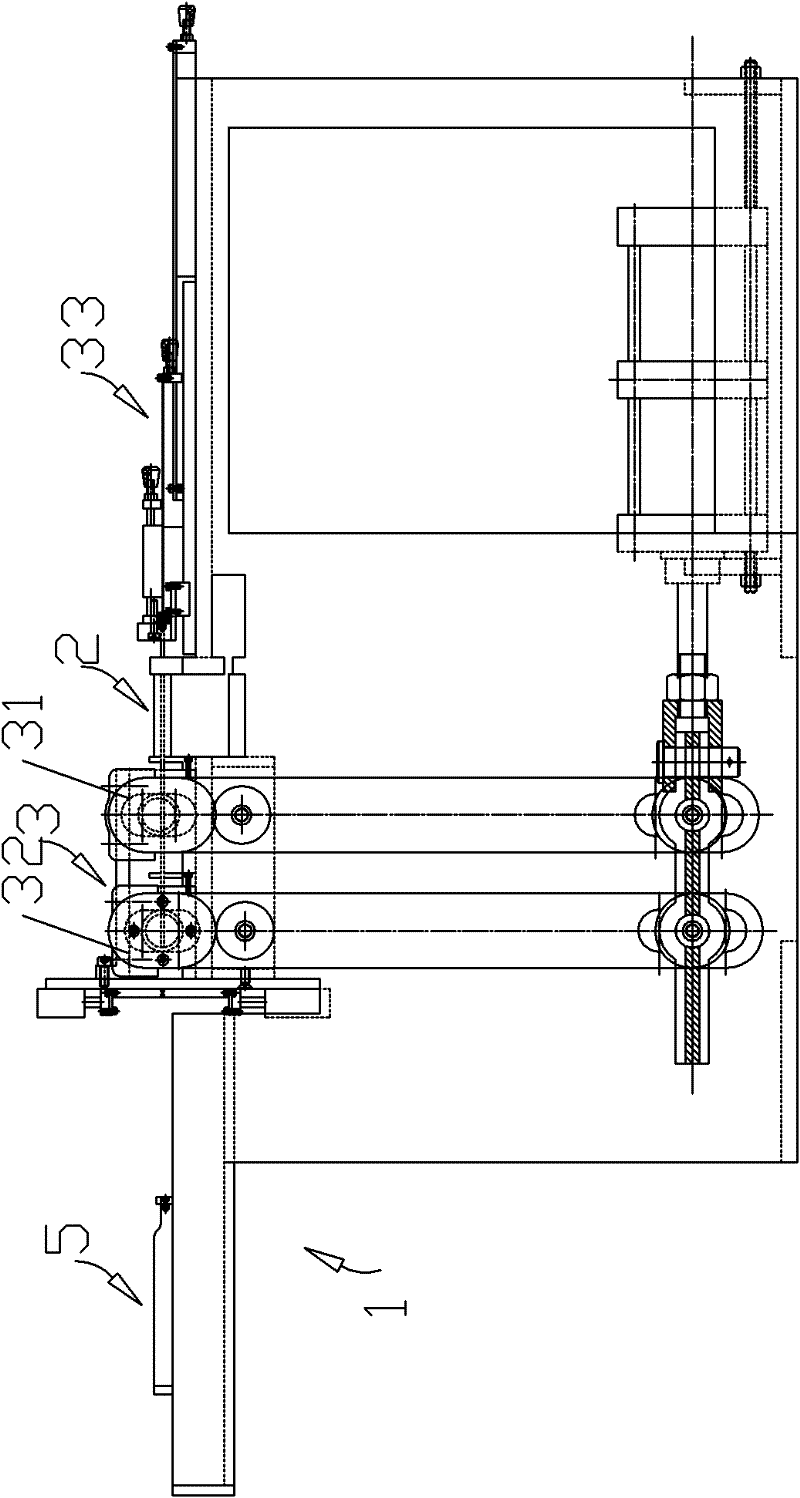

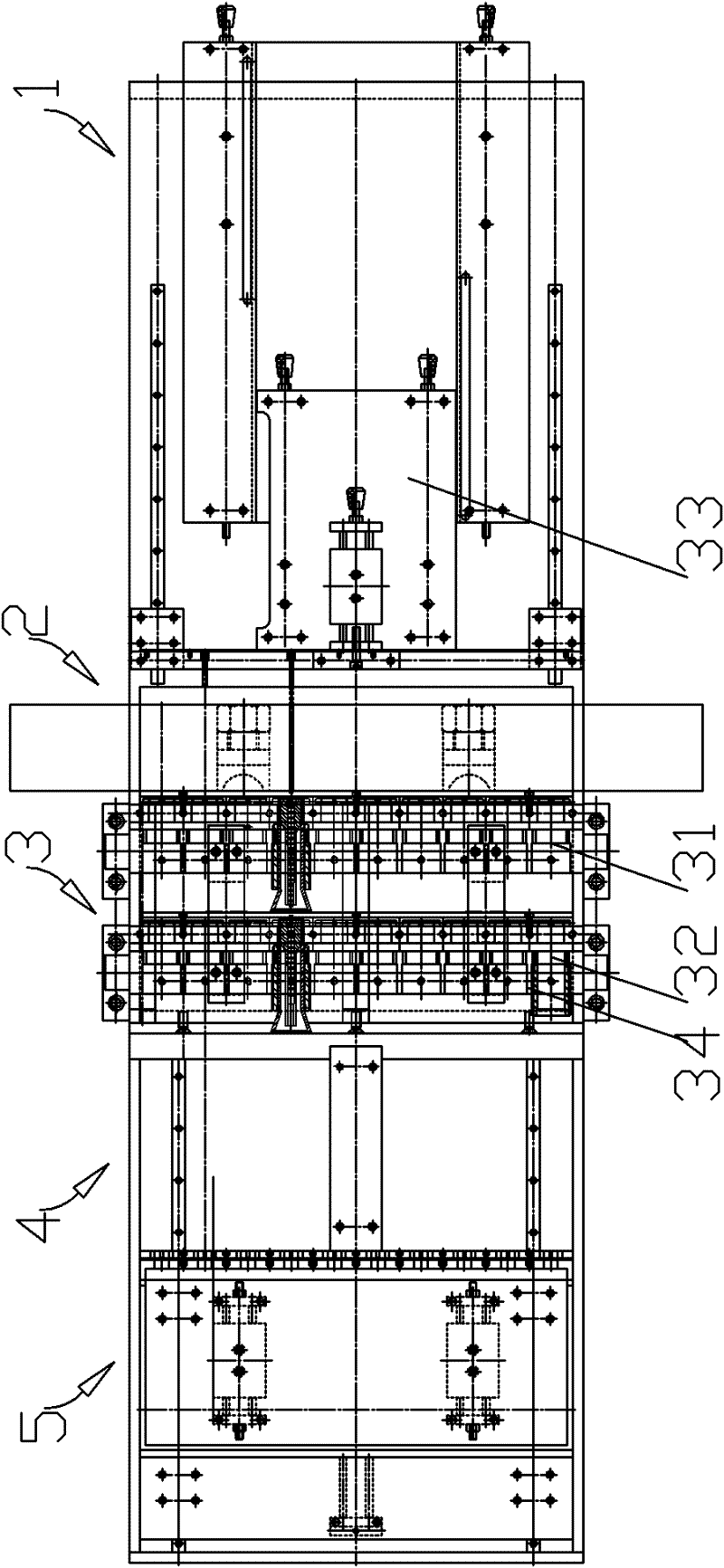

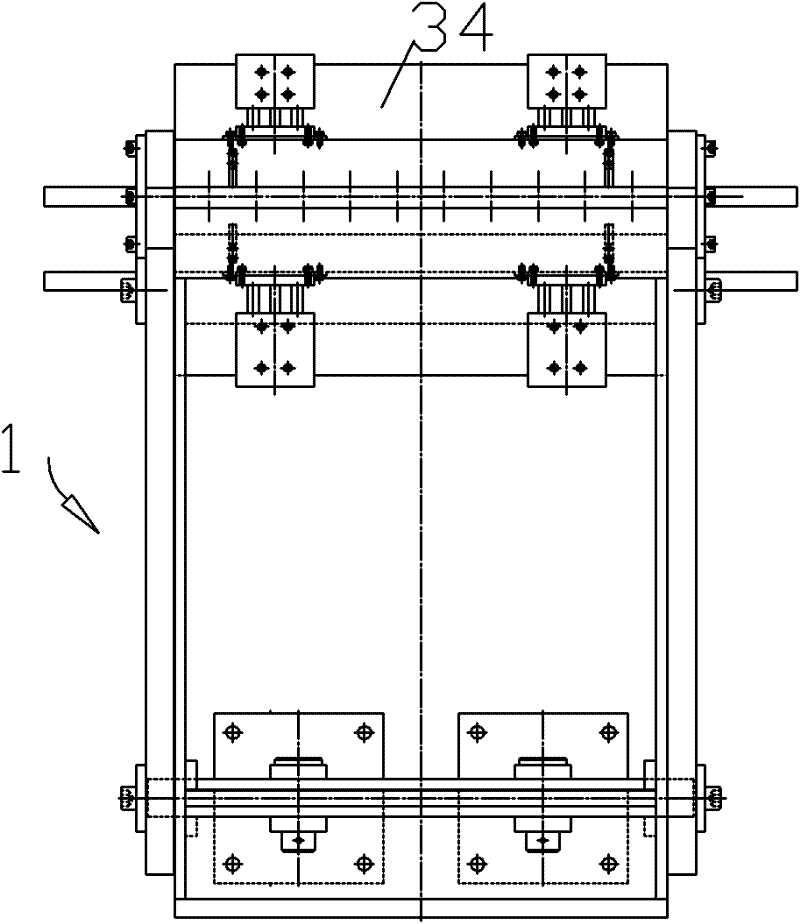

[0039] refer to figure 1 , figure 2 , image 3 As shown, a high-efficiency automatic mass detonator card waist bayonet machine is mainly composed of a frame 1, a special mold 2, a group hair card waist bayonet mechanism 3, a wire feeding mechanism 4, a payoff reel 5 and other parts and the prior art electric or Pneumatic control device constitutes; Wherein the group hair card waist bayonet mechanism 3 mainly comprises components such as waist card device 31, bayonet device 32, push tube device 33, guiding device 34.

[0040] The special-purpose mold 2, the group-issue card waist bayonet mechanism 3 and the wire feeding mechanism 4 are arranged on the platform of a frame 1, wherein the group-issue card waist bayonet mechanism 3 and the wire-feeding mechanism 4 are installed on the frame 1 The middle and rear parts; the special mold 2 is embedded between the waist device 31 and the push tube device 33 of the group-issue card waist bayonet mechanism 3, and the special mold 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com