Automatic detonator assembly process and special related apparatus

An automatic assembly and detonator technology, applied in the direction of detonators, offensive equipment, etc., can solve the problems of low production efficiency and remote operation of employees

Inactive Publication Date: 2015-06-17

北京全安密灵科技股份公司

View PDF1 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Such bayonet equipment is more common, because it is a single manual operation by a single person, and employees cannot operate remotely, resulting in not only low production efficiency, but also frequent occurrence of safety accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0052] According to the foregoing, in view of the most complicated automatic assembly production of electronic detonators, the present invention is further described in detail by taking the automatic assembly production line of electronic detonators as a specific example:

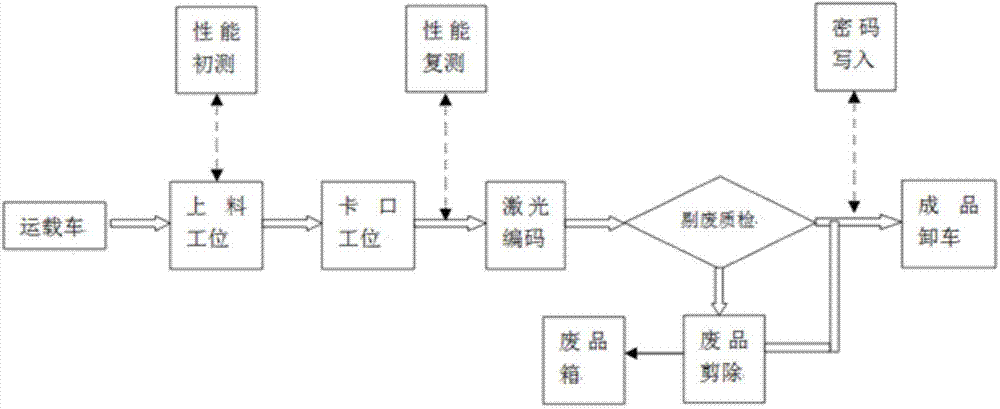

[0053] as attached figure 1 The electronic detonator automatic assembly technological process realized by the specific embodiment 1 of the present invention is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

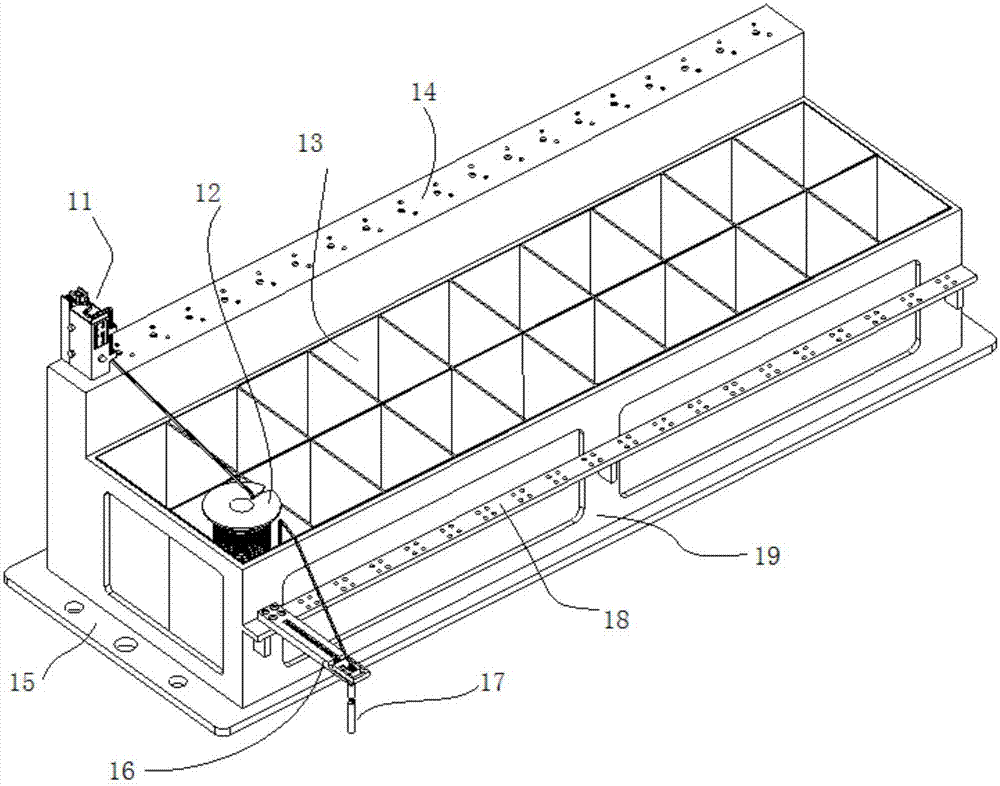

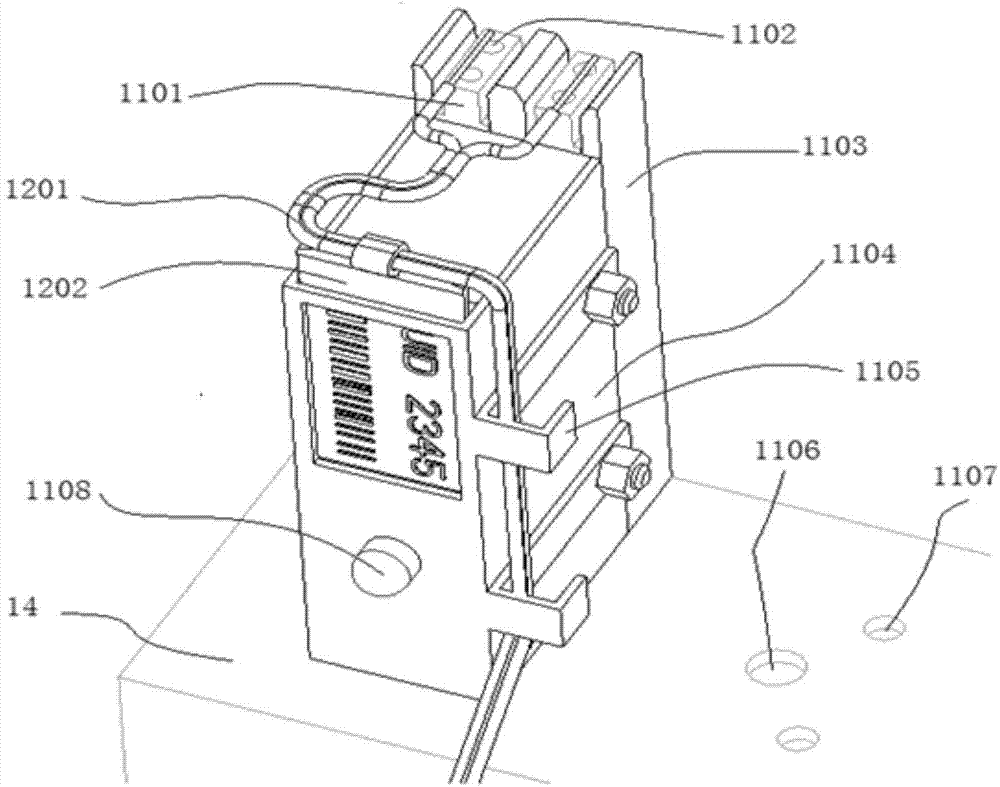

The present invention provides an automatic production line assembly process with functions of artificial detonator feeding, automatic bayonet assembly, laser marking, automatic detection and the like, and a special related apparatus. The simple process comprises that: at a feeding working position, a lot of igniters are fixed on a special transporting trolley in columns by a staff; the transporting trolley moves along a conveying track, and the integrated igniter and a detonator shell are integrally pressed by a bayonet at an automatic bayonet assembly working position; at a laser marking working position, the detonator is engraved and marked during advancing; the bayonet appearance and the laser marking quality are detected through the machine vision, and if the unqualified product exists, the unqualified product is automatically removed, the transporting trolley returns to the unloading working position, the finished product is taken out by the staff, the transporting trolley returns to the feeding working position so as to complete the one production process; and a plurality of the same transporting trolleys perform pipeline operations so as to form the automated detonator production line. The process of the present invention has characteristics of high automation degree, high production efficiency, human-machine isolation operation, high safety, and good application prospects.

Description

technical field [0001] The invention belongs to the field of pyrotechnics production technology and special devices, and is mainly used in the automatic assembly production line of detonators, including the production line process flow and related special devices with functions such as manual feeding, automatic assembly bayonet, laser marking, automatic detection and the like. technical background [0002] In the field of detonator production, a mechanized production line is often used to put the primary explosives, high explosives, and reinforcing caps required for detonation into the detonator shell, and then use a square container to temporarily store a plurality of such basic detonator bodies. At the bayonet station, put such a basic detonator shell into the bayonet manually or mechanically, and then put the igniter with sealing plug and foot line or plastic detonator (for convenience of description, hereinafter referred to as integrated igniter) ) into the detonator she...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C06C7/02

Inventor 银庆宇赵昆龙刘海军

Owner 北京全安密灵科技股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com