Charge tube end plate

a technology of end plates and end plates, applied in the direction of explosive charges, fluid removal, borehole/well accessories, etc., can solve the problems of poorly fractured formation, damage to the tubing or casing, and often undetected misalignmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

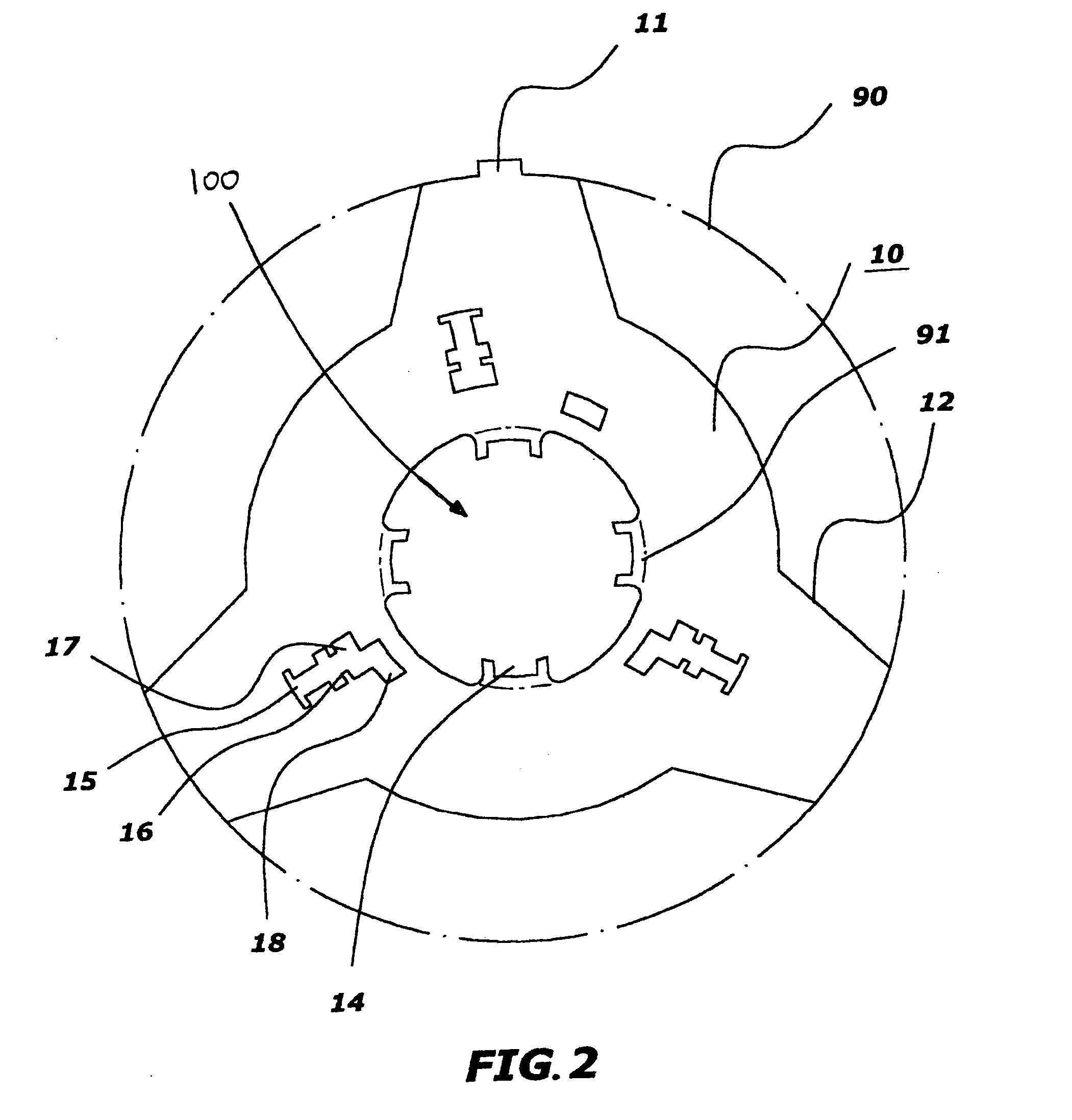

[0024] Generally, the present invention provides a method and apparatus for assembling and loading perforating guns for downhole use. In particular, the present invention provides an end plate that can be produced at minimal cost, and that will prevent misalignment when used with one of a number of charge barrels of different design diameters for different applications.

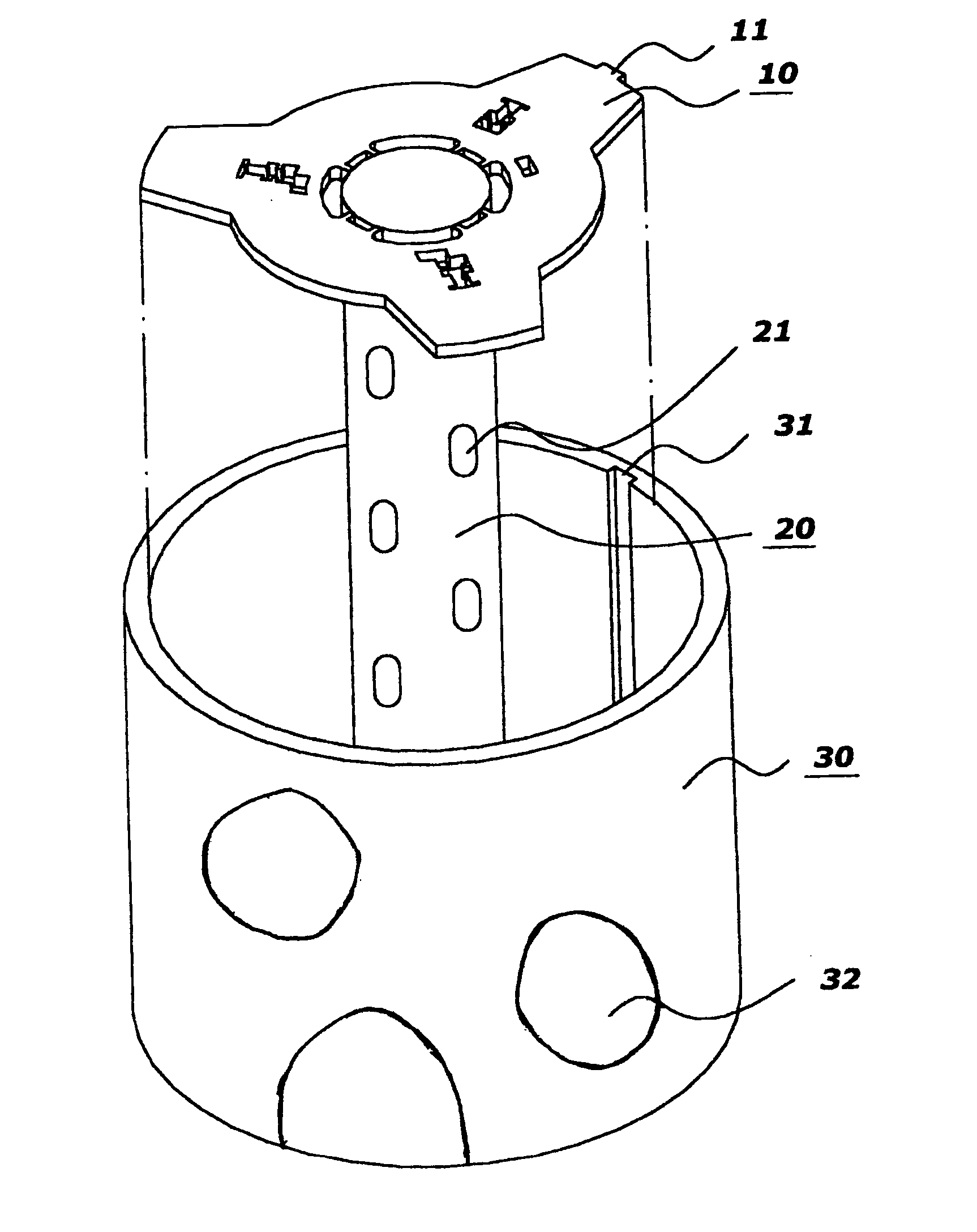

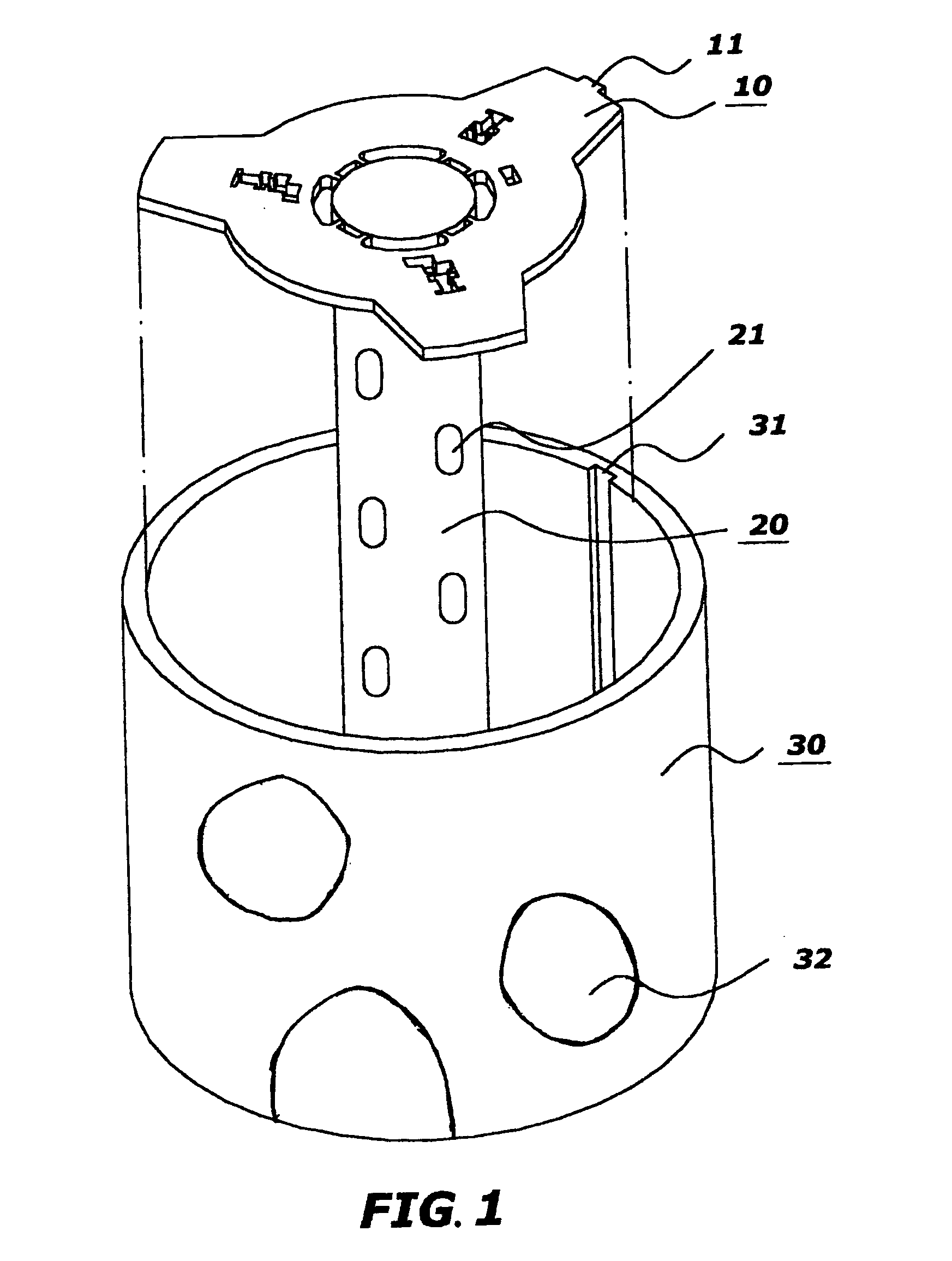

[0025] With reference to FIG. 1, a perforating gun is shown during assembly. A plate member in the form of end plate 10 is attachable to the assembled charge tube 20, preferably by welding, which is slid into the perforating gun barrel 30. It is critical for proper operation that the charge tube 20 be properly substantially aligned in the perforating gun barrel 30 to line up the charges 21 with the weakened or scalloped portions 32 of the perforating gun barrel 30. The end plate 10, therefore, includes an alignment system in the form of alignment tab 11, and the perforating gun barrel 30 includes an alignment groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com