Underground draining and grouting process in thin bedrock and thick loose sand layer rich water areas

A technology of thick loose and thin bedrock, applied in drainage, wellbore lining, underground chamber, etc., to avoid loss, save cost, and improve recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

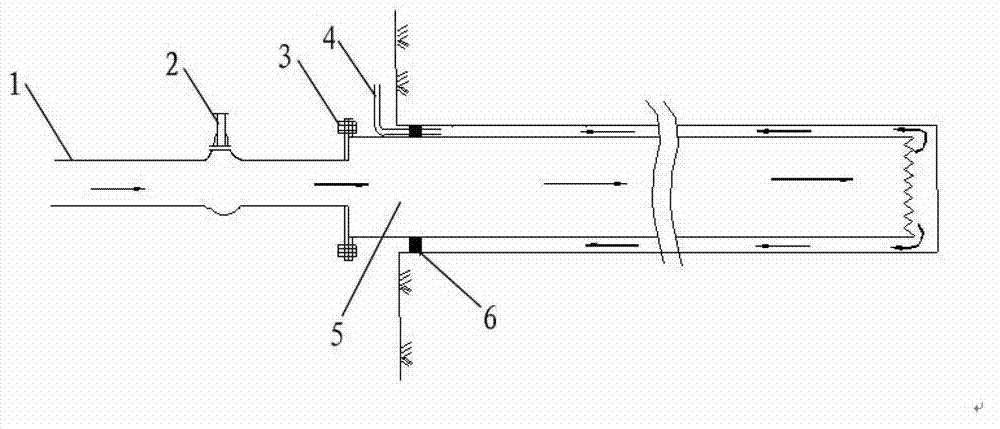

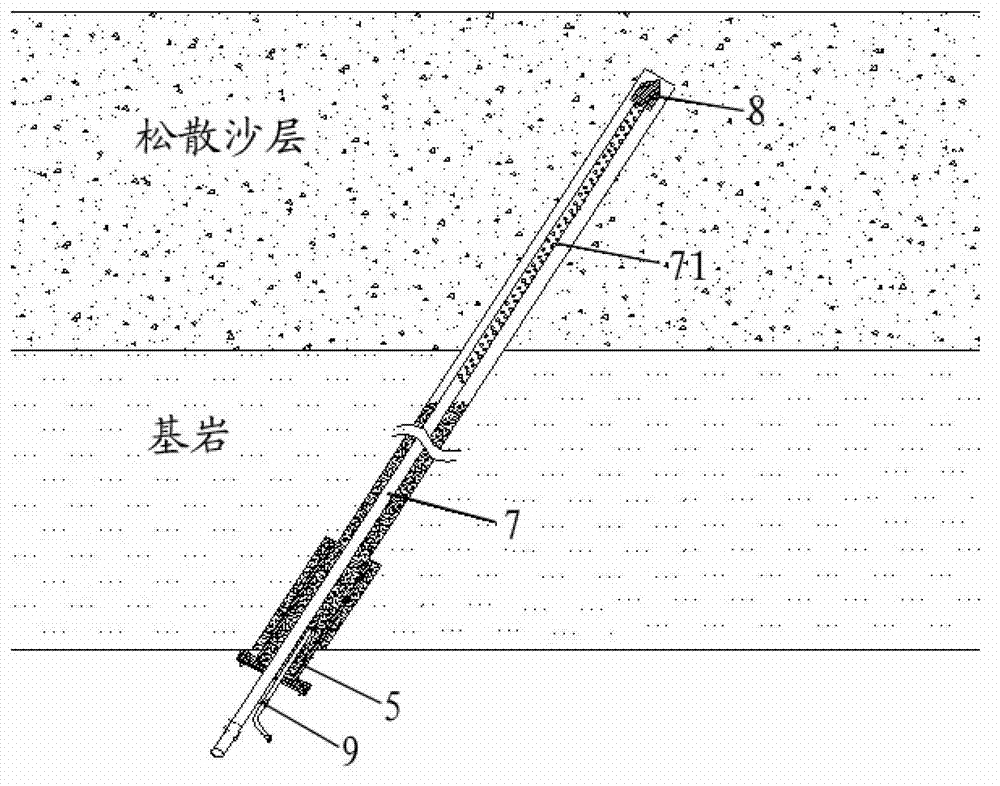

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] For the water-rich area with thin bedrock and thick loose sand, in order to ensure the safe mining of the coal seam below this area, it is proposed to carry out grouting consolidation on the loose sand layer with strong fluidity, so that the loose sand layer is consolidated into Overall, increase the thickness of the roof, and loosen the sand layer for poor connectivity to consolidate it into blocks, reducing the amount of water gushing sand in the roof caving zone during mining at the working face. The specific process is as follows:

[0030] The first step is to carry out tunneling construction: construct tunneling in the coal seam below this area to provide a working place for underground grouting. Preferably, the exploration lanes are arranged according to the following principles: (1) The angle between the exploration lanes and the working face is 15-30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com