A Symmetrical Double-Motion Platform Pressing Mechanism for a Horizontal Flat Die Cutting Machine

A double-acting platform and flattening technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of vibration, obvious fluctuation, and limited improvement of production efficiency, so as to improve the working environment and eliminate noise. Pollution, improve the effect of die-cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

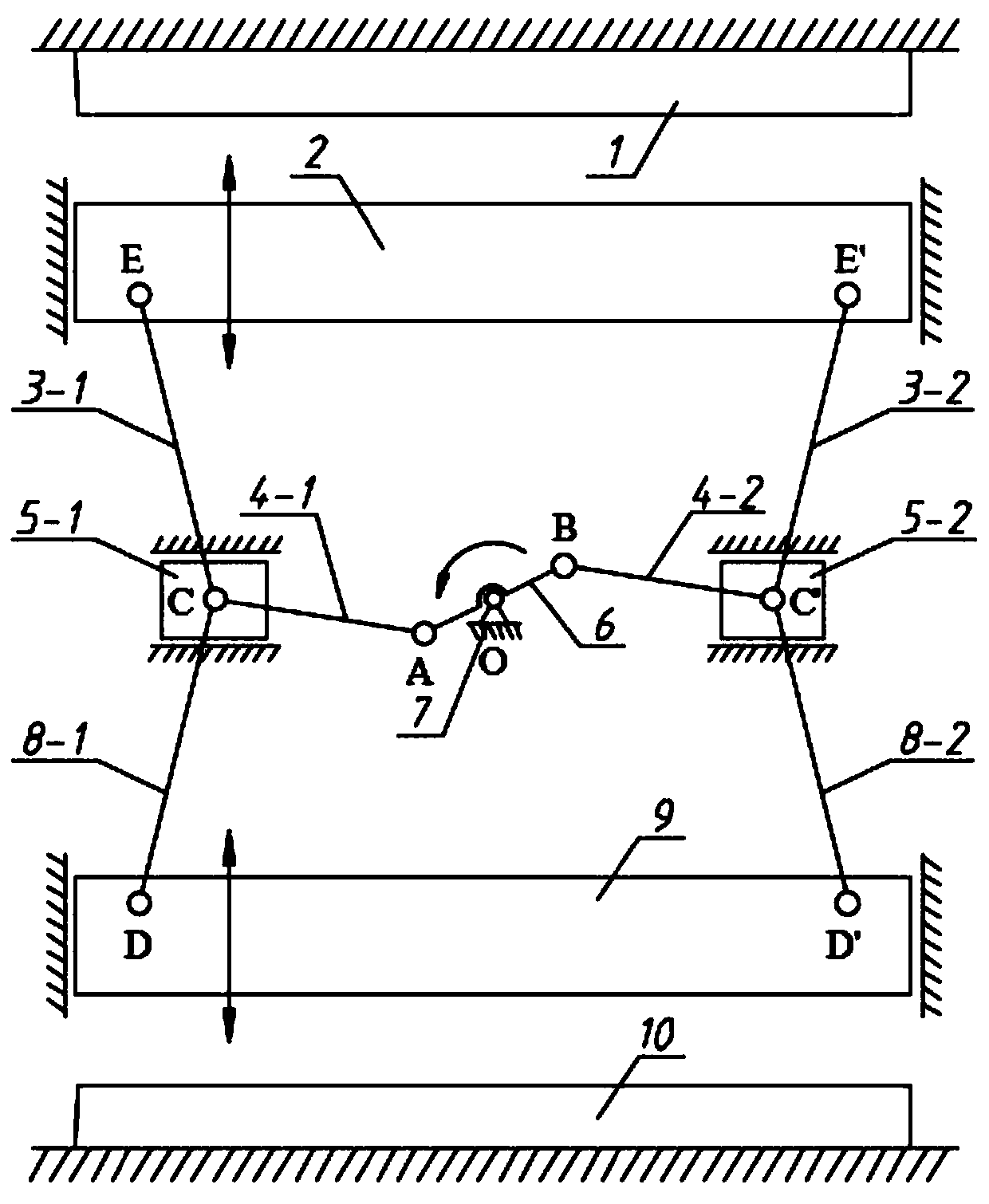

[0021] Embodiment 1, with reference to figure 1 , a symmetrical double-action platform pressure mechanism of a horizontal flat die-cutting machine, including a crankshaft 6, a left connecting rod 4-1 and a right connecting rod 4-2, the crankshaft 6 is connected to the horizontal flat die-cutting machine through O The fuselage 7 is hinged, the left end of the crankshaft 6 and the right end of the left connecting rod 4-1 are hinged at point A, the left end of the left connecting rod 4-1 is hinged at point C on the left slider 5-1, and the left slider 5-1 is installed on On the horizontal guide rail of the fuselage 7, the left slider 5-1 and the lower end of the left upper toggle lever 3-1 are hinged at point C, and the left slider 5-1 and the upper end of the left lower toggle lever 8-1 are hinged at point C; the right end of the crankshaft 6 The left end of the right connecting rod 4-2 is hinged at point B, the right end of the right connecting rod 4-2 is hinged at point C' on ...

Embodiment 2

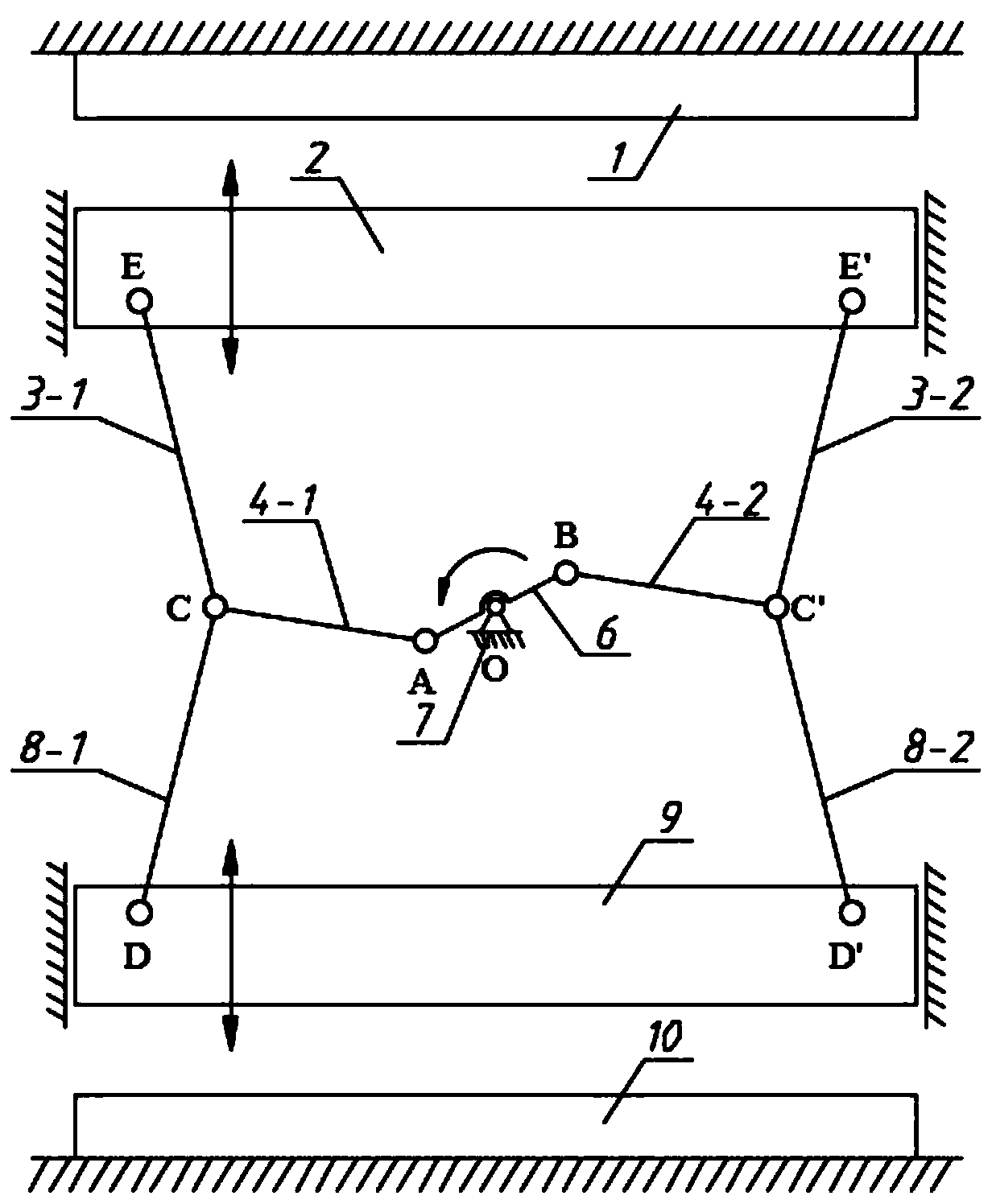

[0028] Embodiment 2, with reference to figure 2 , the left end of the left connecting rod 4-1, the lower end of the upper left toggle rod 3-1, the upper end of the lower left toggle rod 8-1 are directly hinged at point C, the right end of the right connecting rod 4-2, the lower end of the upper right toggle rod 3-2, the right The upper end of the lower toggle 8-2 is directly hinged at point C', and the left slider 5-1 and the right slider 5-2 are removed, which has the same motion effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com