Robot welding workstation

A robot welding and workstation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large floor space, many station settings, inability to realize integrated production, etc., to double the work efficiency , to prevent rotation, the effect of accurate placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

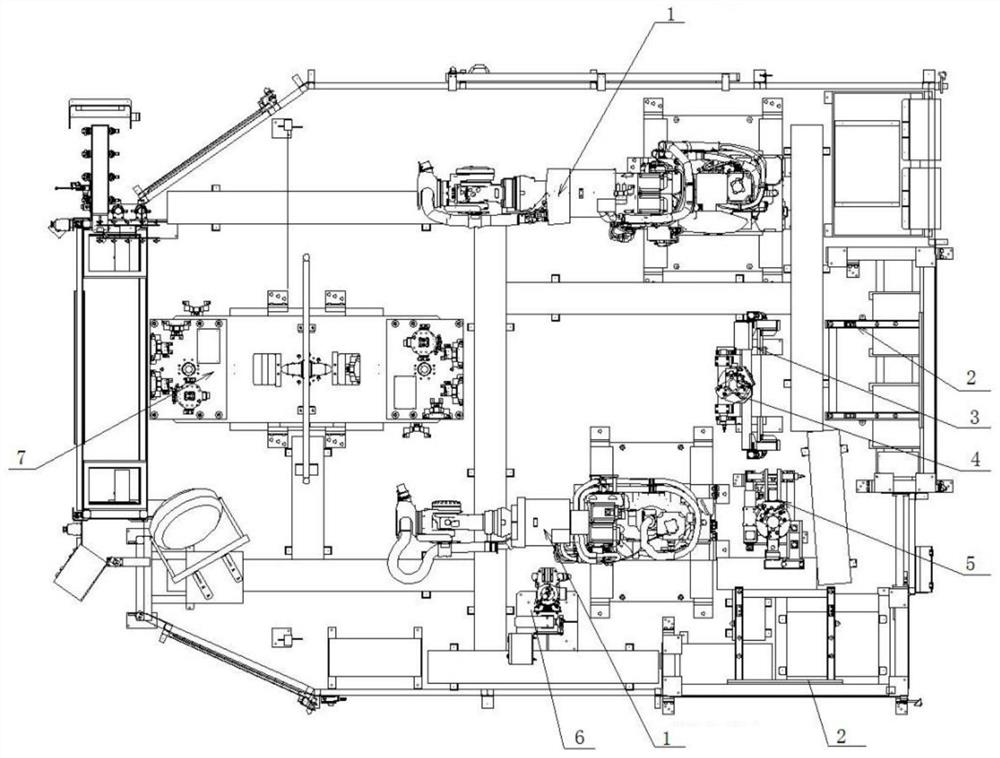

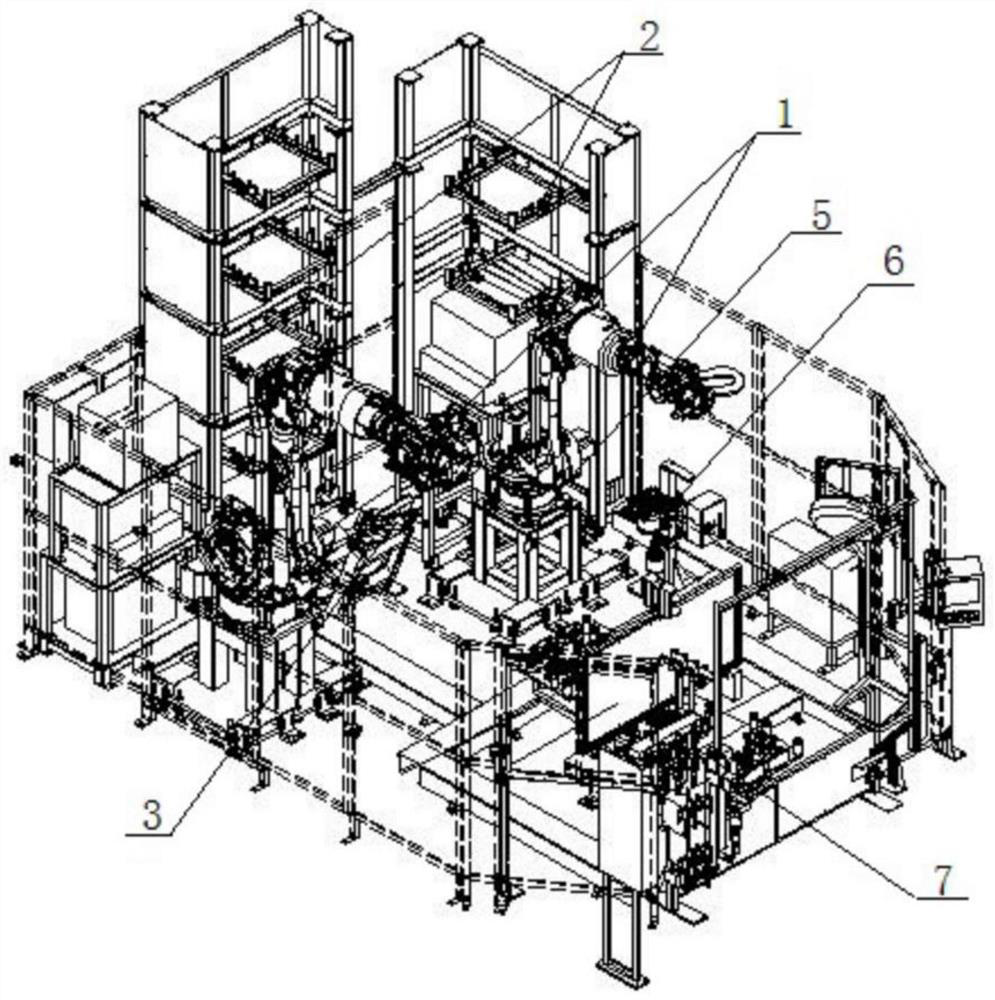

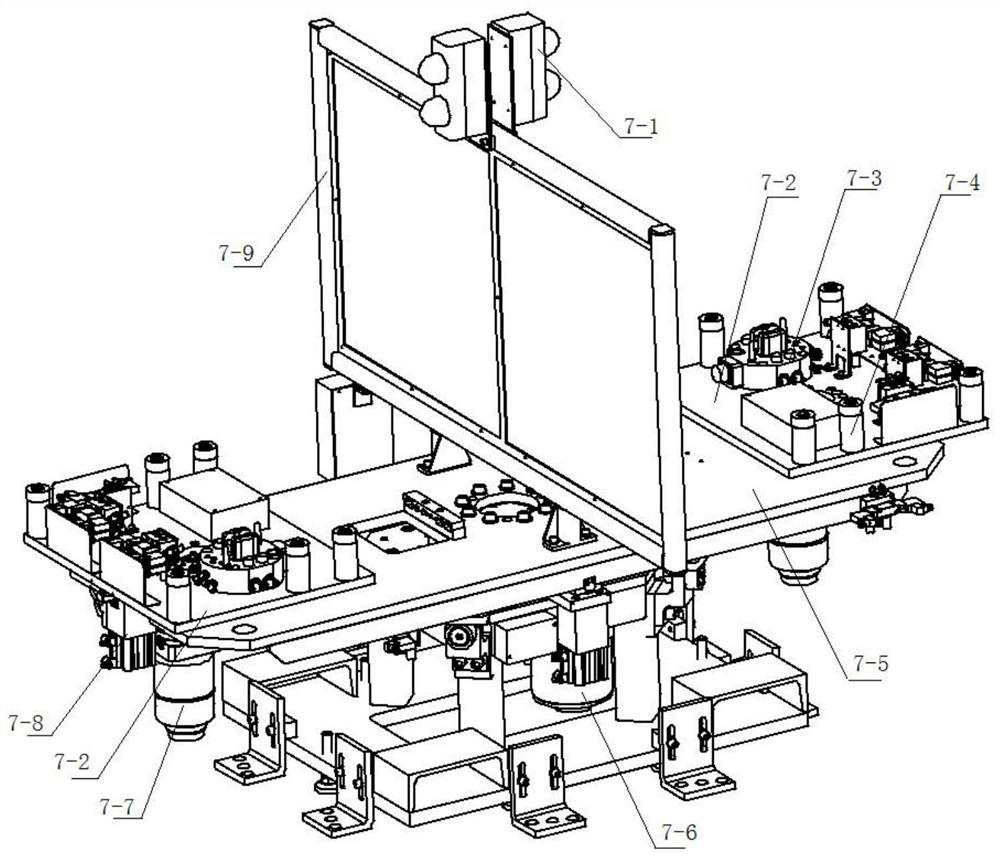

[0026] A robot welding workstation includes a fence and two welding robots 1 installed in the fence, a workpiece placement rotary table 7, a jig placement shed 2, a welding torch placement rack 5, a jig transfer tool placement rack 3, and an electrode grinder. Two welding robots are arranged in parallel and at intervals, and the workpiece is fixed in the middle of one side of the two welding robots to place a rotary table for placing the workpiece to be welded. Install two fixture placement sheds near the two welding robots on the other side of the two welding robots, and install a welding torch placement rack for placing welding torches between the two welding robots next to the fixture placement shed and for placing fixtures for transfer T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com