Light handling trolley

A kind of handling trolley, light technology, applied in the direction of lifting device, etc., can solve the problems of crawler chassis cumbersome, slow running speed, high manufacturing cost, achieve the effect of rational and efficient use of installation space, product performance improvement, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

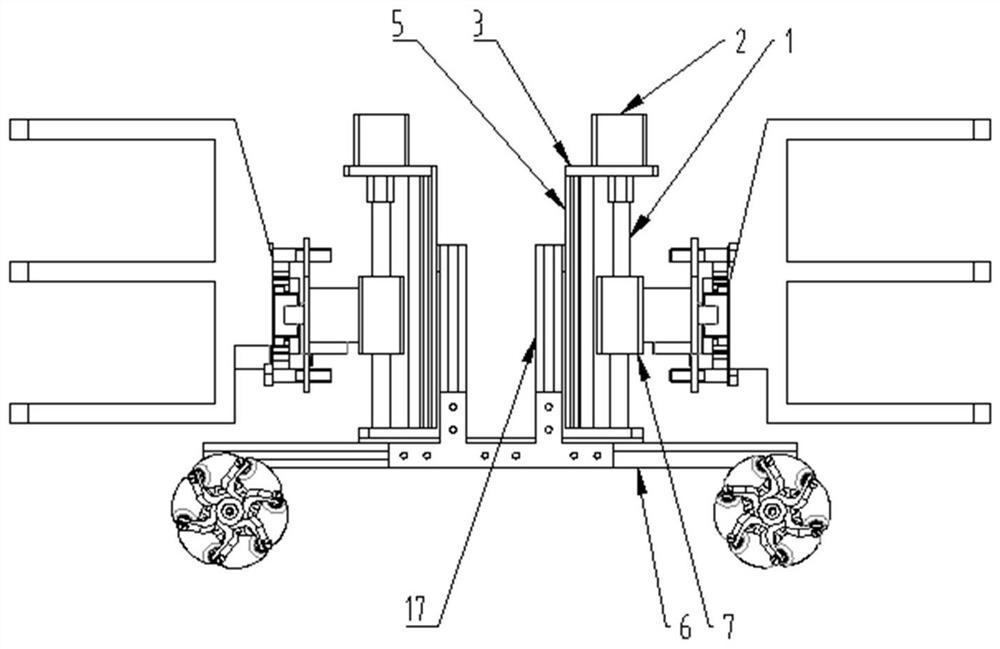

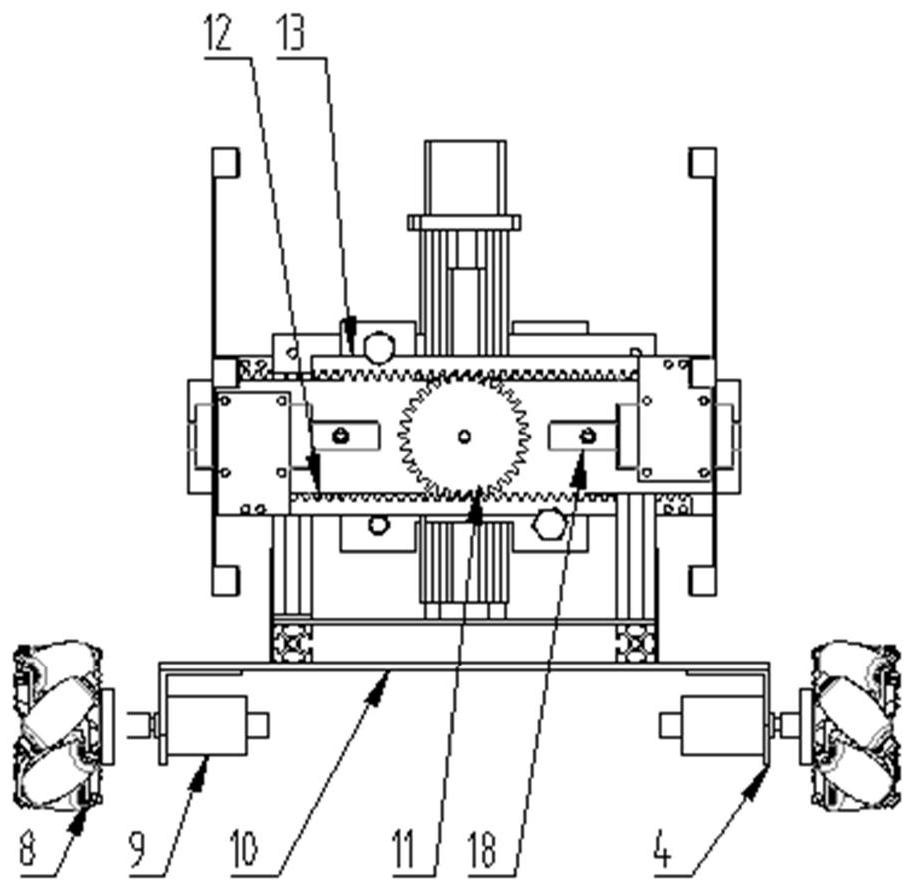

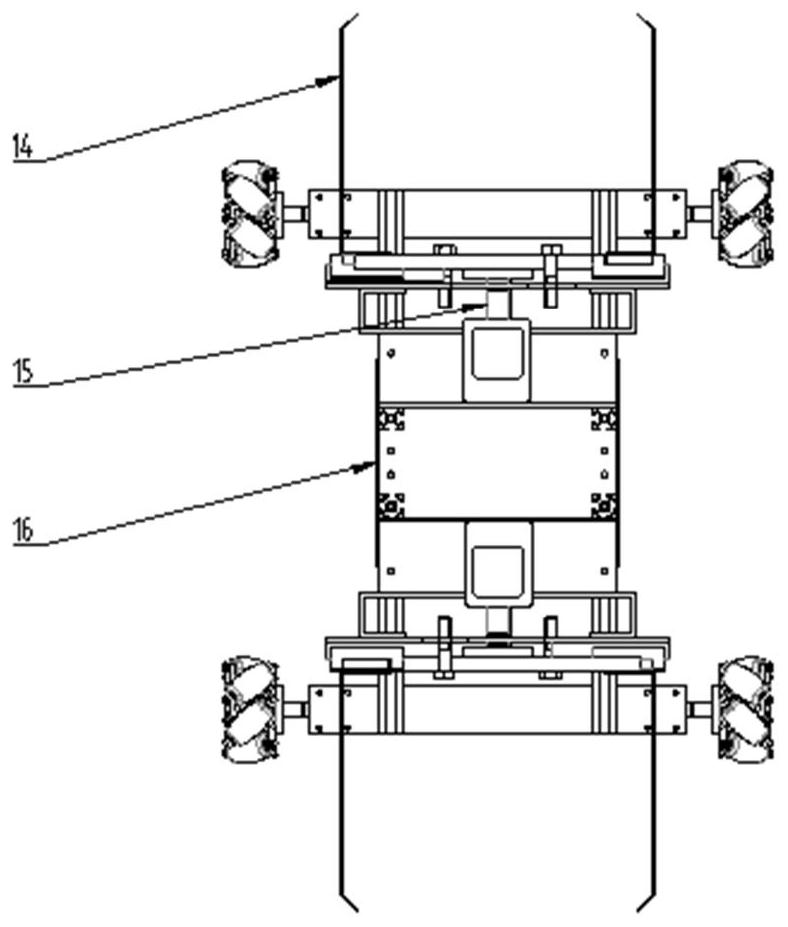

[0028] The invention realizes the high-efficiency and flexible lifting functions of the crane through the design of the three-part system of movement, lifting and clamping. Relying on mecanum wheels and four-wheel drive to realize the movement of the whole vehicle. The two sets of lifting systems installed at the front and rear of the vehicle use the slider screw mechanism to realize the lifting action. The rack and pinion mechanism is used to realize the opening and closing of the hand grip, and complete the grabbing action of the goods. The control signal is given through the switch and rocker of the remote controller to realize the control of the crane.

[0029] mechanical parts, such as Figure 1 to Figure 4 shown.

[0030] control part, such as Figure 5 control system shown.

[0031] Relying on the STM32F407 chip of STMicroelectronics and the FLYSKY aircraft model remote control, the corresponding remote control of the actions of various parts of the mechanism is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com