A continuous automatic drying and curing device

A curing device and automatic technology, which is applied to the device, coating, pretreatment surface, etc. for applying liquid to the surface, can solve the difficulty in achieving tightness at the inlet and outlet, and reduce the utilization rate of the interior space of the curing room. , low work efficiency and other problems, to achieve the effect of compact and reasonable overall structure, easy replacement and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiments are described below with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

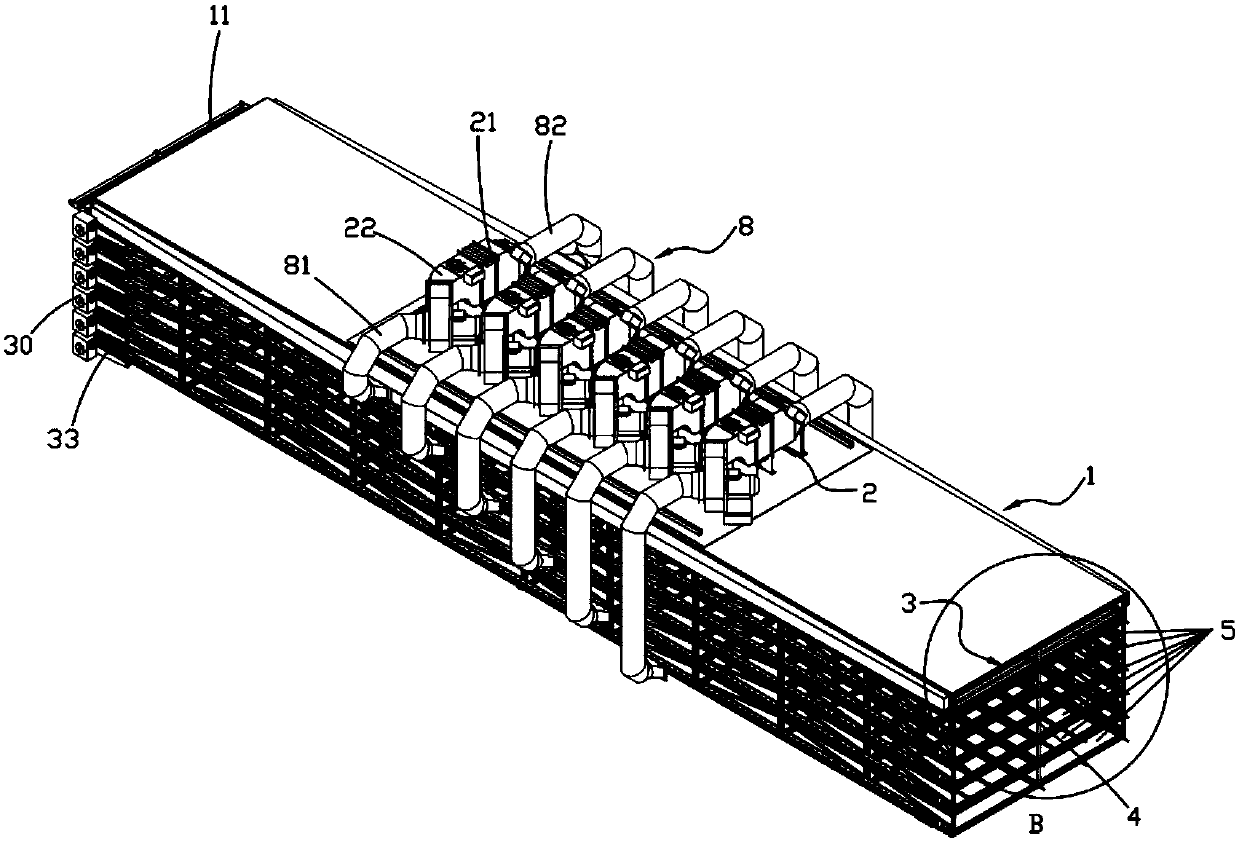

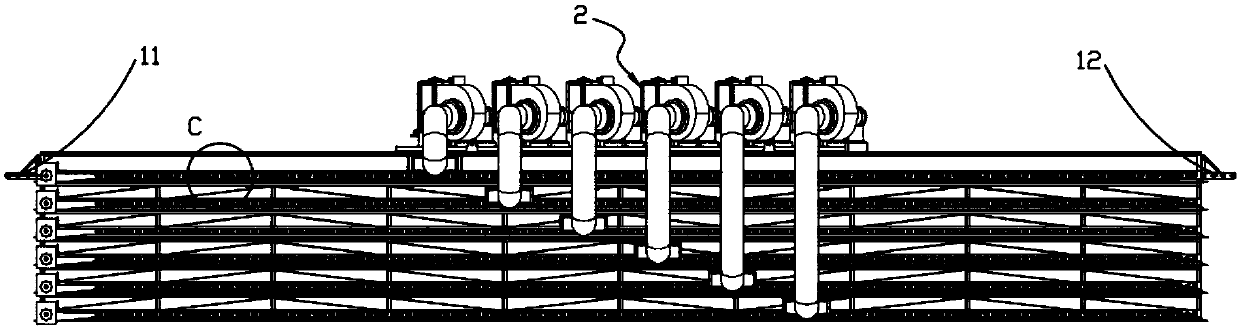

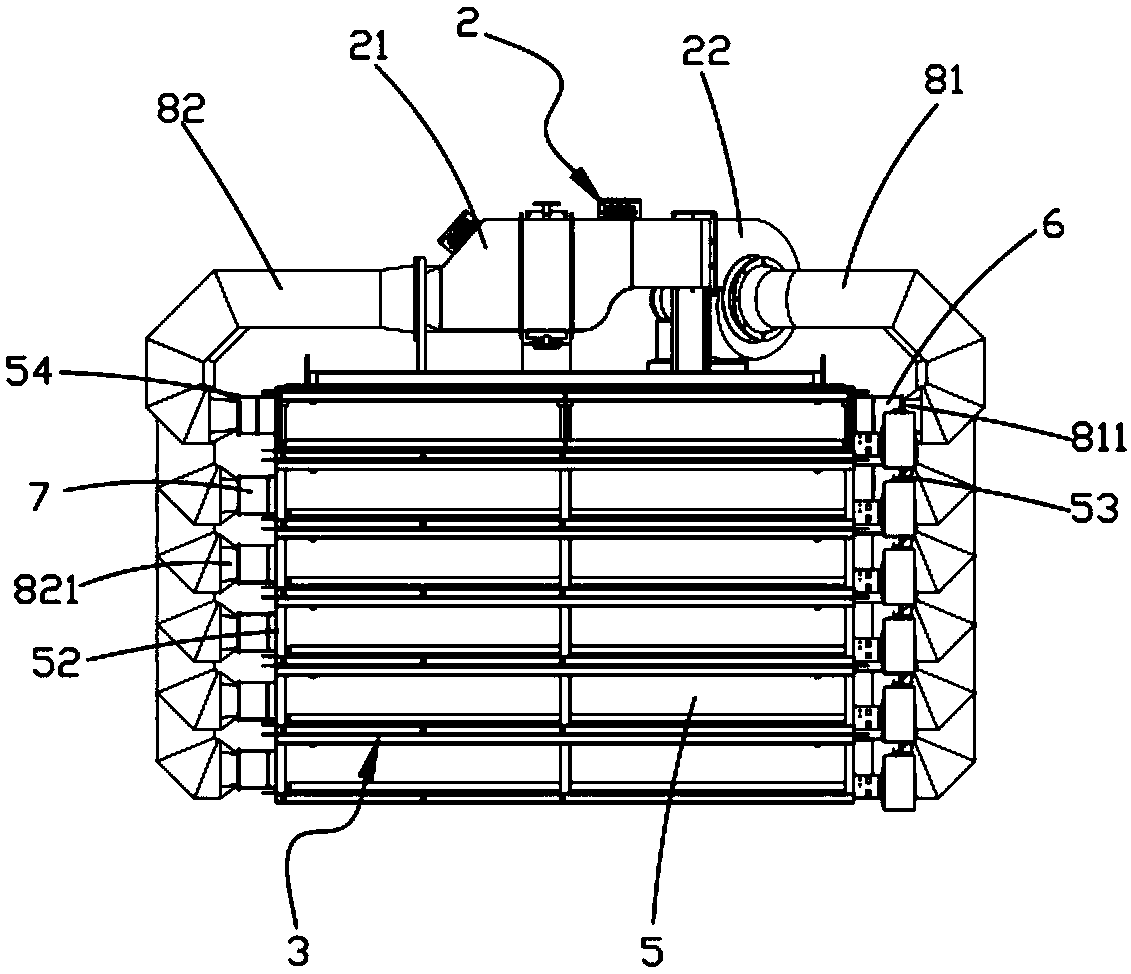

[0034] Such as figure 1 As shown, a continuous automatic drying and curing device includes a curing room 1 with heat insulation function and a heat exchange system 2 arranged above the curing room 1, and a temperature control device is also arranged in the curing room 1 , a humidity control device and an exhaust device, the heat exchange system 2 includes a humidification heater 21 and an exhaust unit 22 for sending heated air and water vapor into the curing room 1; the interior of the curing room 1 is set At least two groups of horizontal conveying units 3 arranged in layers from top to bottom, each layer of convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com