Tunnel type composite anchorage

A tunnel-type anchorage technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as poor tunnel-type anchorage, achieve the effect of improving bearing capacity and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

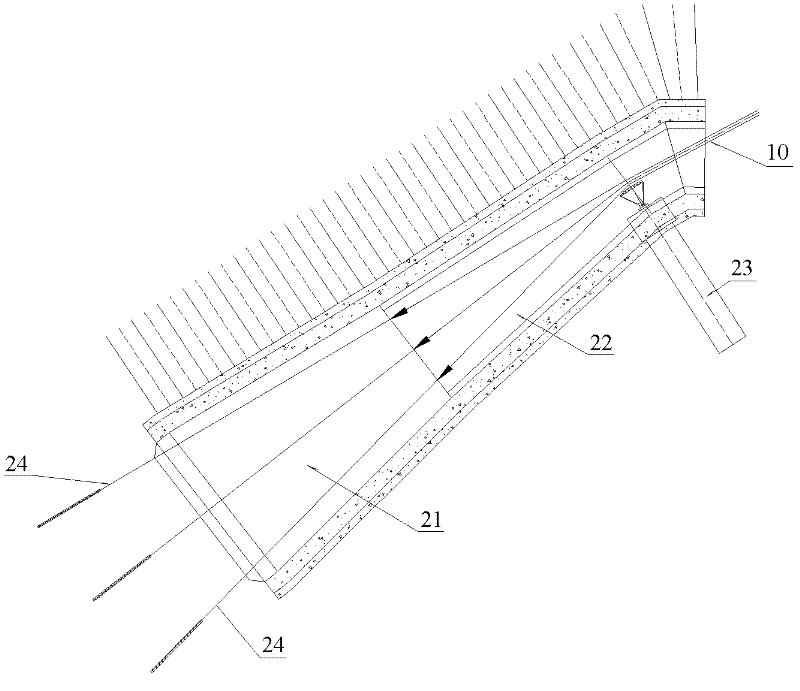

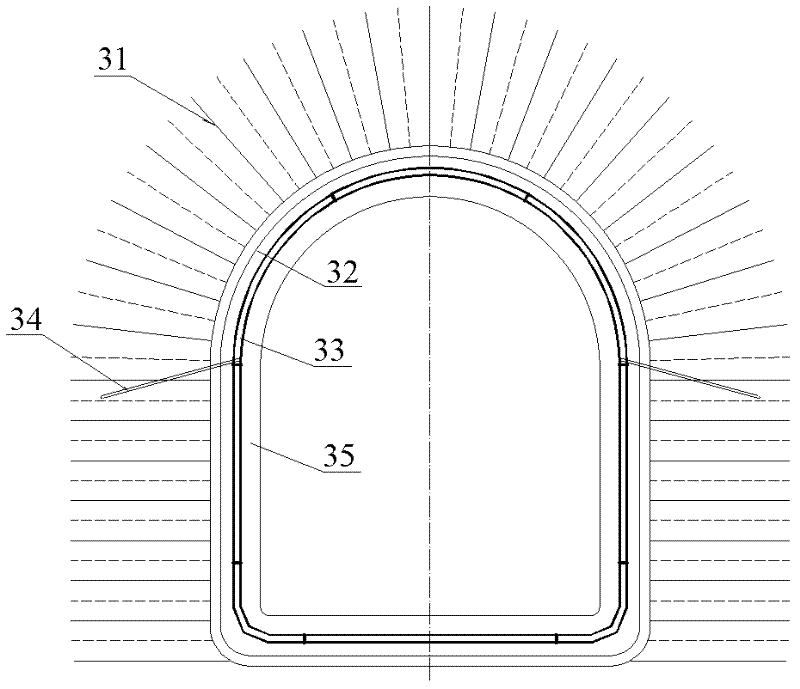

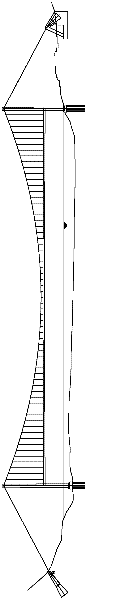

[0015] refer to figure 1 and figure 2 , the tunnel-type composite anchor of the present invention includes a tunnel, an anchor plug body 21 and a front anchor chamber 22, the anchor plug body 21 is formed by filling and pouring concrete in the inner section of the tunnel, a buttress 23 is arranged in the front anchor chamber 22, and the main cable 10 The scatter saddle on the top of the buttress 23 is spread out and anchored to the front anchor surface of the anchor plug body 21 . The tunnel is provided with bolts 31 that penetrate from the surface of the bedrock into the surrounding rock at intervals on the vault section and the sidewall sections on both sides, and the primary support structure and secondary lining 35 are sequentially set inward from the surface of the bedrock. Anchor rod 31 can adopt segmental self-advancing type anchor rod in anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com