Testing device and testing method for simulating hydraulic fracture characteristic of concrete bedrock contact surface

A technology of hydraulic splitting and test device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc. The effect, the process is simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

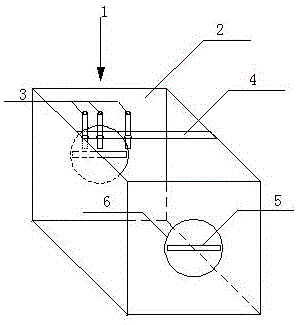

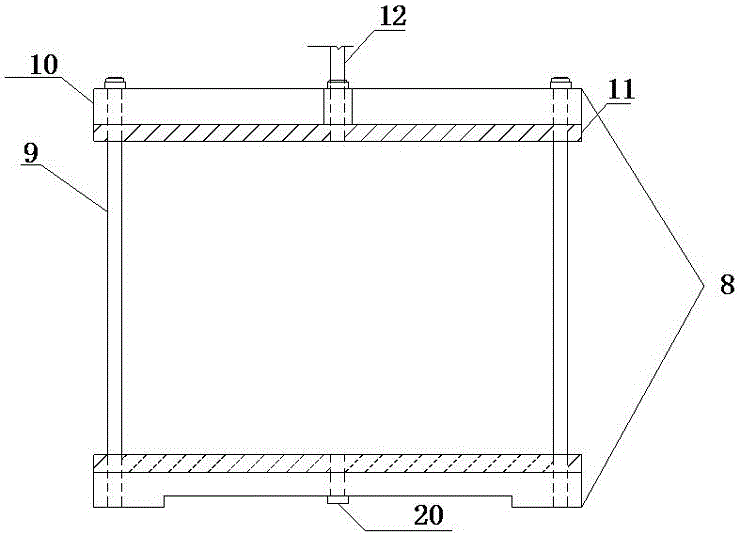

[0055] The mold is used for the preparation of the concrete bedrock test piece, and the concrete bedrock test piece has an initial crack of the test piece at the contact surface of the concrete bedrock.

[0056] The mold includes a bottom plate and four side walls, and the side walls and the bottom plate are detachably connected; the four side walls and the bottom plate are enclosed to form a central cavity, and the shape of the central cavity is the same as that of the concrete bedrock test piece.

[0057] The mold is preferably made of plastic material, and the mold is preferably a square box, preferably a cube box in this application, and the side length of the cube box is preferably 150 mm.

[0058] A circular hole is respectively provided at the central parts of the side walls corresponding to the two positions of the mold, and a rotatable disk is arranged in each circular hole, and the radius of the disk is preferably 4-6 cm.

[0059] The center of each disc is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com