Construction method of structural system of river under no-cutoff working condition

A technology of construction methods and working conditions, applied in underwater structures, infrastructure engineering, excavation, etc., can solve problems such as existing problems and great influence on the surrounding environment, and achieve the simplification of construction technology, reduction of construction equipment scale, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

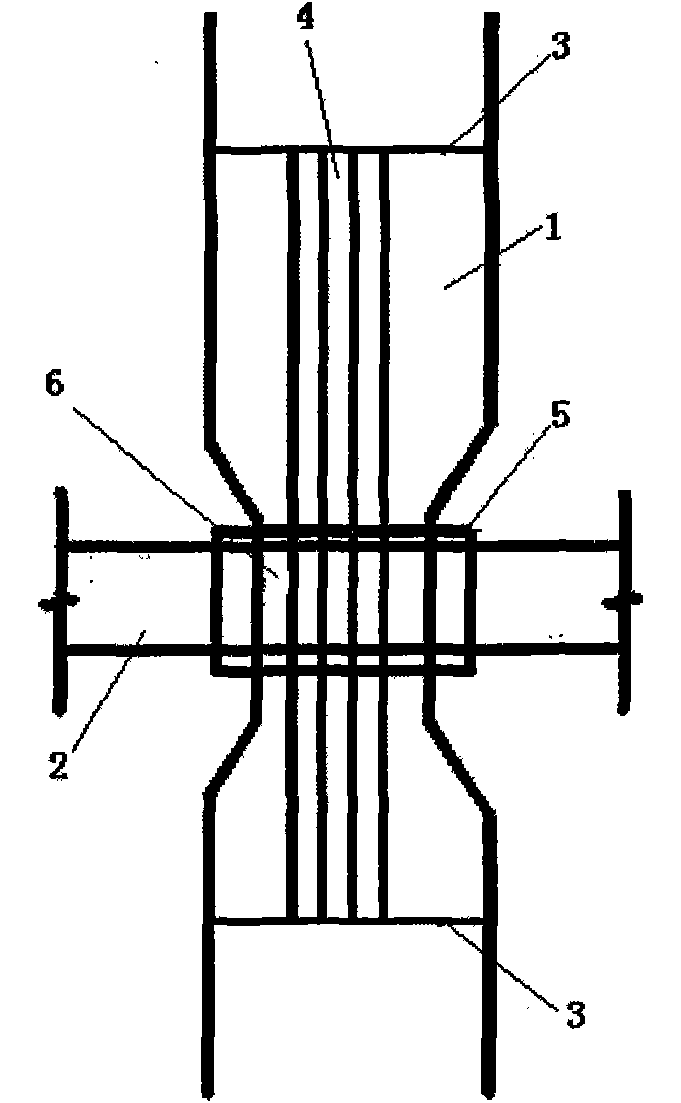

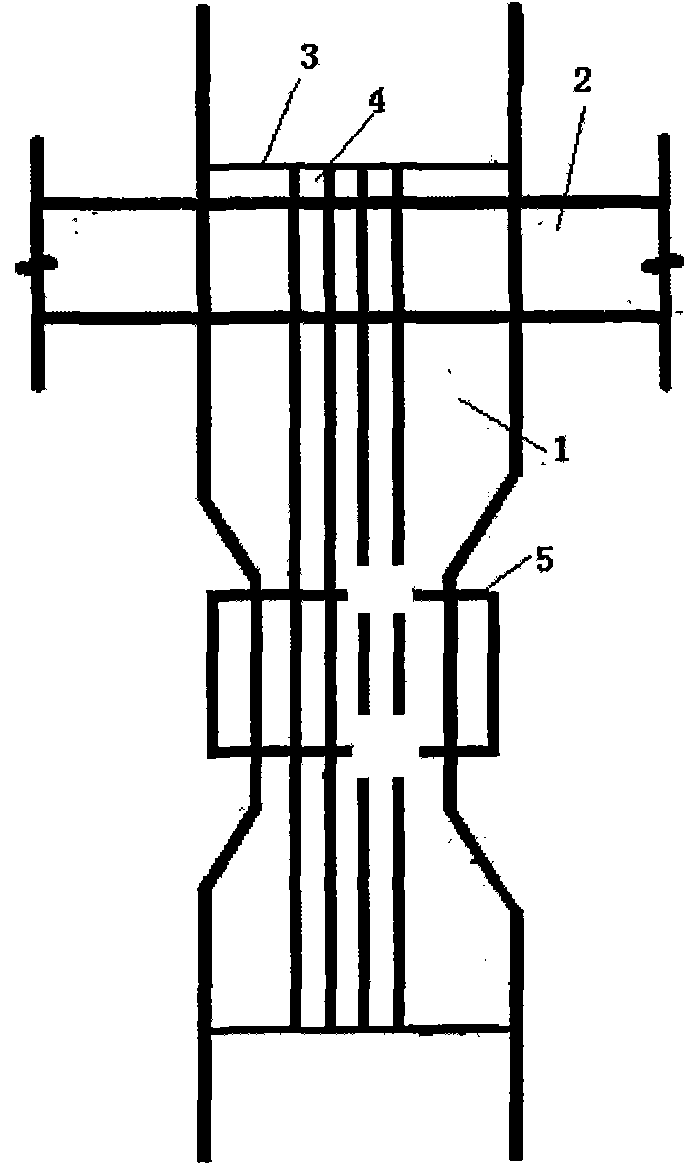

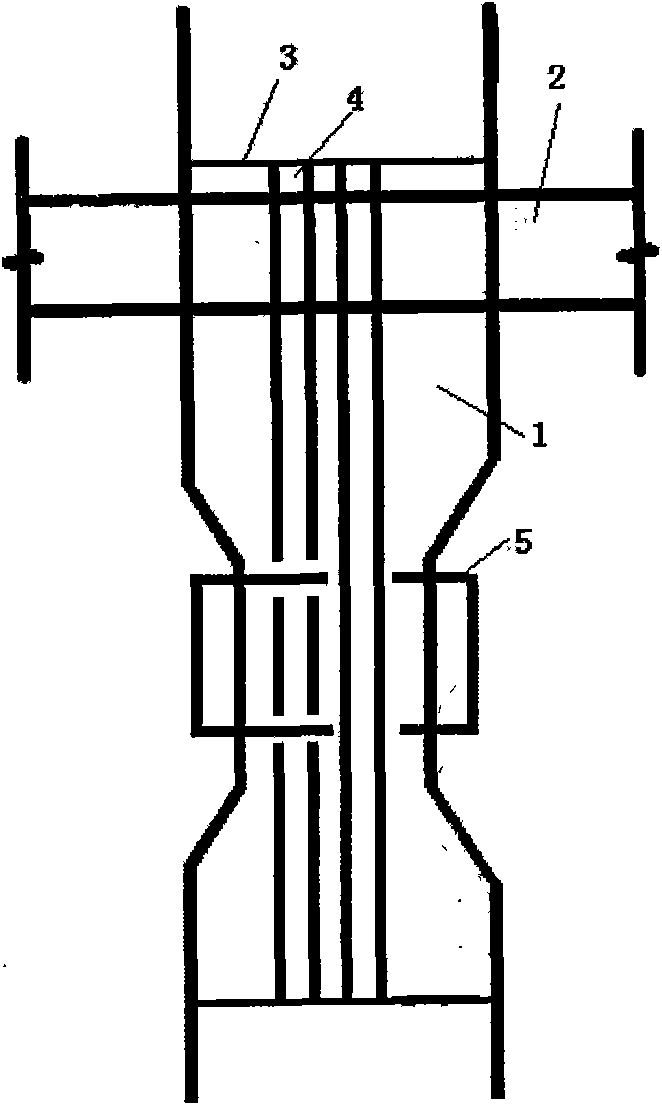

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] The construction method of the structural system under the continuous flow working condition of the present invention, the specific construction process is as follows:

[0029] Steel sheet pile cofferdam construction→steel sheet pile cofferdam→throwing and filling bagged sandbags→installation of diversion pipe for water flow→river backfill construction→cofferdam grouting reinforcement→Hanoi access road construction and river crossing pipeline burial→both side traffic access construction→Part 2 A road overturning → demolition of the old bridge → demolition of the superstructure of the old bridge → demolition of the substructure of the old bridge → construction of the channel structure → reinforcement of the ground wall and groove wall → cutting of the initial half of the diversion pipe → initial enclosure construction → restoration of the diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com