Double-rowed cofferdam and method for manufacturing the same

A manufacturing method and technology of cofferdams, which are applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as small rigidity, large deformation, and difficulty in ensuring water-stopping effects at interfaces, and achieve good water-stopping performance, reasonable cost, and The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

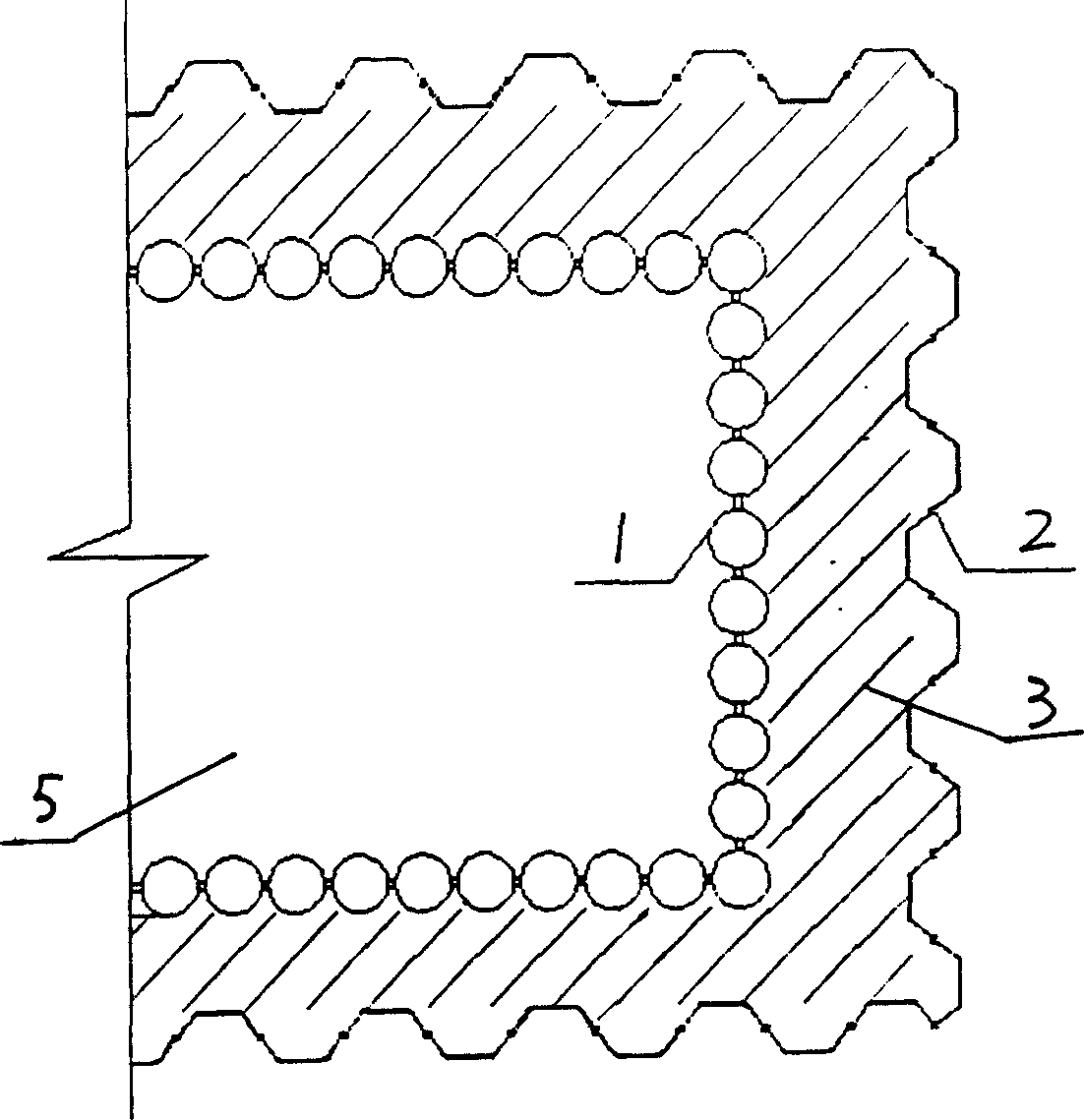

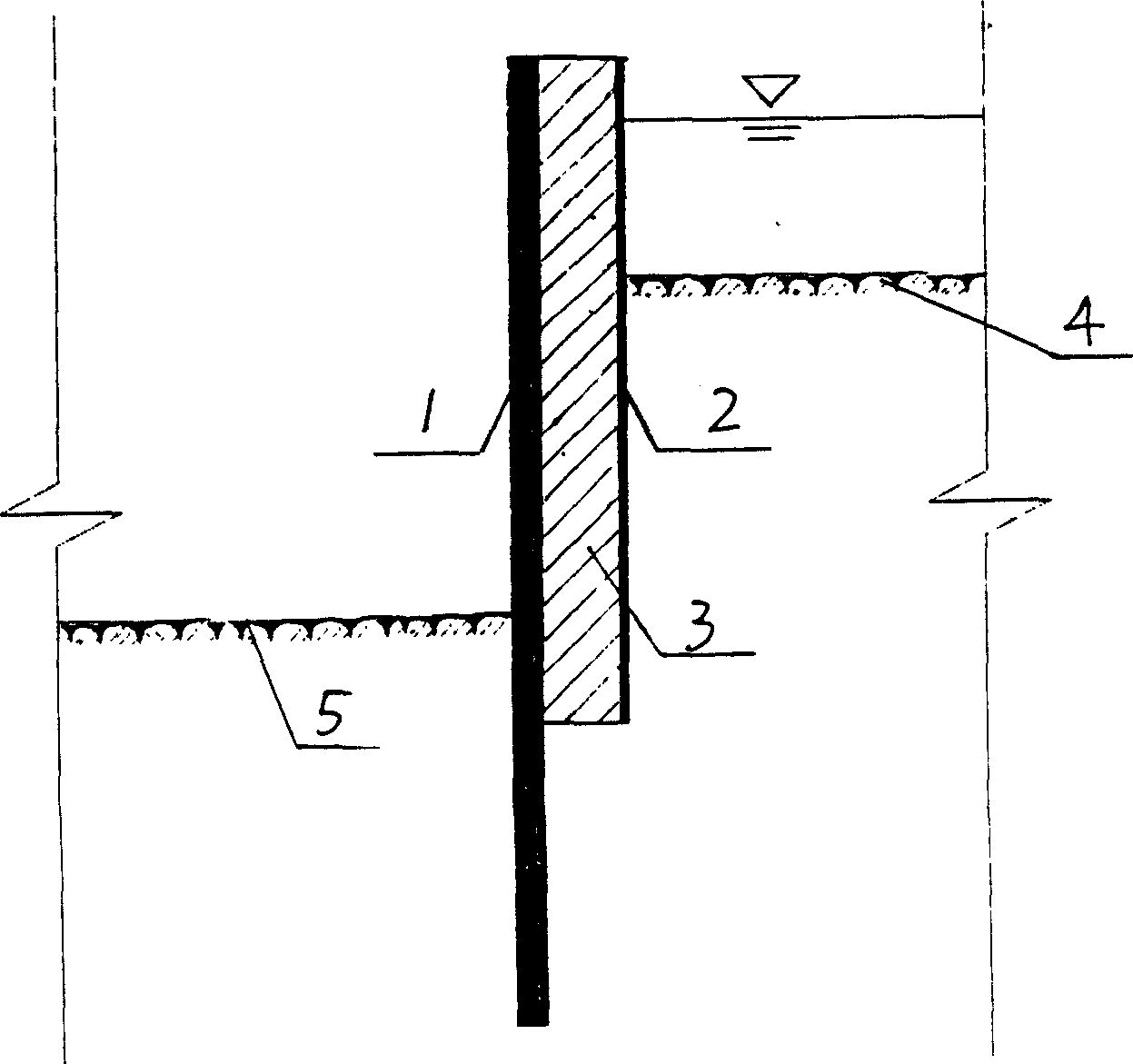

[0011] In the figure, 1 is a steel pipe pile cofferdam, 2 is a steel sheet pile cofferdam, 3 is a water stop curtain, 4 is a river bed, and 5 is a foundation pit.

[0012] A double-row cofferdam, which includes a row of steel pipe pile cofferdams 1, is characterized in that a row of steel sheet pile cofferdams 2 are arranged outside the steel pipe pile cofferdams 1, and earthwork backfill is carried out between the two rows of cofferdams, And carry out reinforcement, form water-stop curtain 3. The form of reinforcement can be rotary spraying or grouting reinforcement to form a water-stop curtain. The distance between the steel pipe pile cofferdam 1 and the steel sheet pile cofferdam 2 is between 0.5m and 2.5m. Among them, the steel pipe pile cofferdam calculates its pile sinking depth according to the design of the foundation pit enclosure structure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com