Compound reinforcing method capable of rapidly falling-silt, promoting-seepage, prepressing, reinforcing and blow filling soft clay

A soft clay and fast technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of long treatment period of soft soil foundation, long distance of sand and gravel, and tight construction land, so as to shorten the construction period. , The effect of reducing engineering cost and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

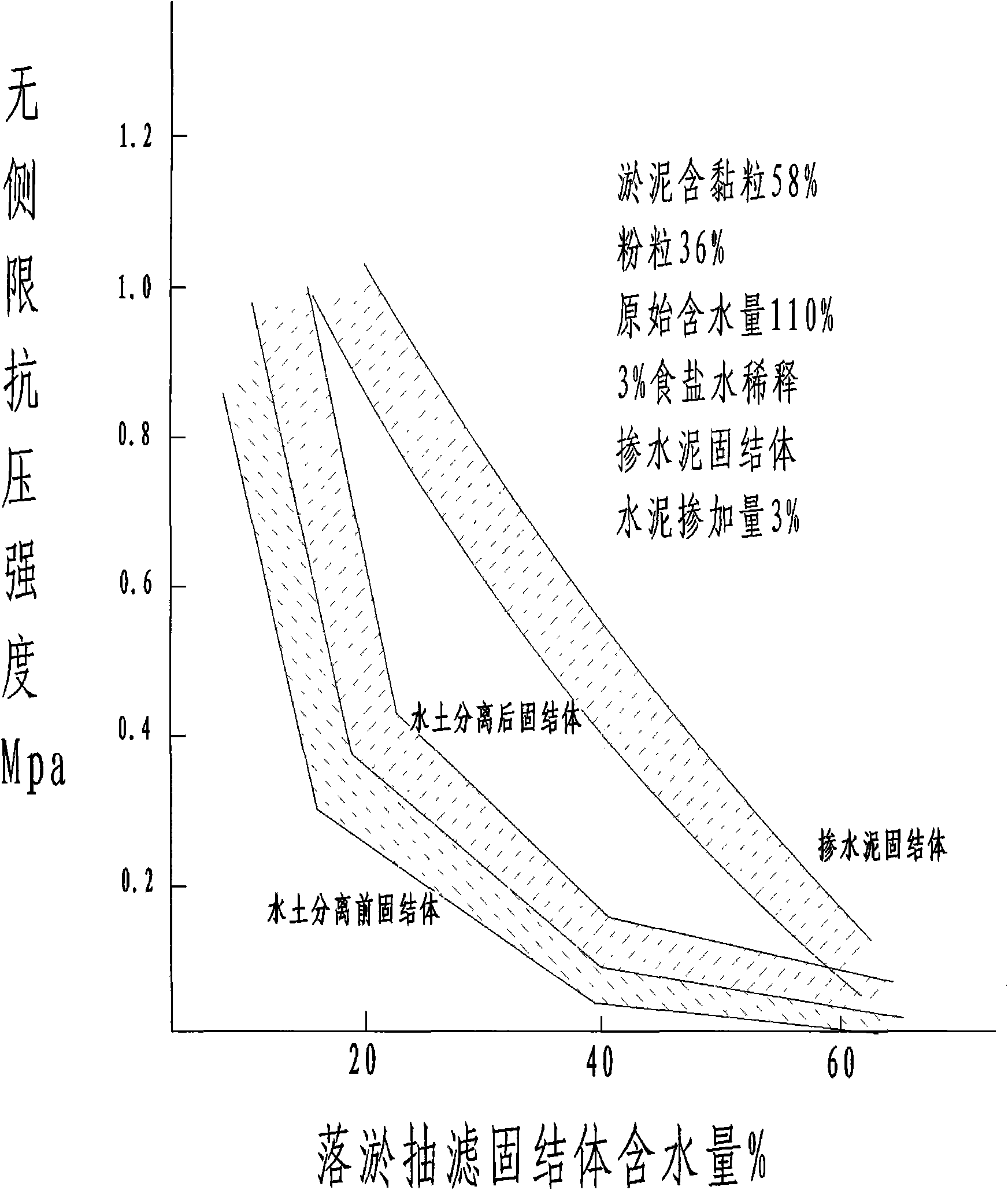

Embodiment 1

[0030] In the laboratory, the improved small-scale specific resistance tester was used to carry out the suction filtration test, and the mud of Ningbo Dongqian Lake was used to prepare 300% (solid content accounted for 25%) concentration mud, and the coagulant was polyaluminum chloride (PAC), polypropylene Amide (PAM), PM, 5#, mannitol, chitosan, ferric chloride, alum, polyferric chloride and additives cement and lime. The test vacuum degree of the specific resistance tester is set at 40-80KPA, and the suction filtration time is 0.5-24 hours, and the effect is considered by the water output. The test results prove that PAC, PAM and cement additives have a more significant effect of water release after flocculation, and the strength of the soil is the highest with the addition of cement.

Embodiment 2

[0032] In the laboratory, the suction filtration test was carried out using an improved small specific resistance tester.

[0033] Take Ningbo Dongqian Lake sludge to prepare 300% (solid content accounts for 25%) concentration mud. The dosage is 50-300PPM, the dosage of PAC is 500-2000PPM, the test vacuum of the specific resistance tester is set to 80KPA, and the suction filtration time is 24 hours. The effect of PAM is considered by the water output after water and soil separation. The test results prove that amphoteric PAM is the most effective for mud drainage, followed by cationic, anionic and nonionic.

[0034] Take Tianjin Dagang silt to prepare mud with a concentration of 300% (solid content accounts for 25%). The coagulants are PAC and PAM. The amount of PAM added to the mud is 20-200PPM, and the amount of PAC added is 200-1000PPM. The test vacuum degree of the instrument is set to 80KPA, and the suction filtration time is 24 hours. The effect of PAM is considered by ...

Embodiment 3

[0037] Take Dalian silt to prepare 300-900% (solid content accounts for about 10-25%) concentration mud, the dilution water is tap water and salted (salt) tap water, and salted tap water is used to simulate seawater, and the coagulant is PAC and PAM, PAM The mixing amount in the mud is 20-500PPM, and the mixing amount of PAC is 0-3000PPM. Tap water with salt and tap water without salt are used as dilution water. The former can significantly reduce the dosage of water-soil separation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com