Construction method of steel plate pile cofferdam

A technology of steel sheet pile cofferdam and construction method, which is applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems such as difficulty in absorbing mud, long construction period and high risk when the steel sheet pile is inserted into the cofferdam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings of the description.

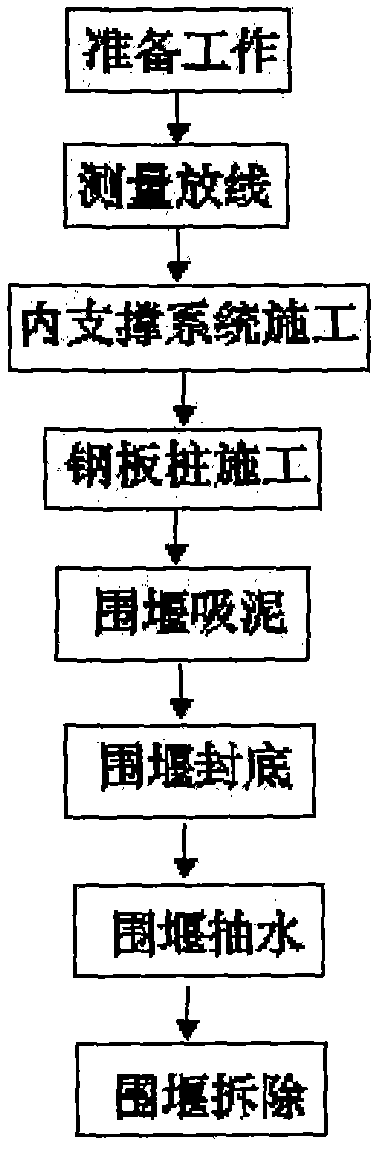

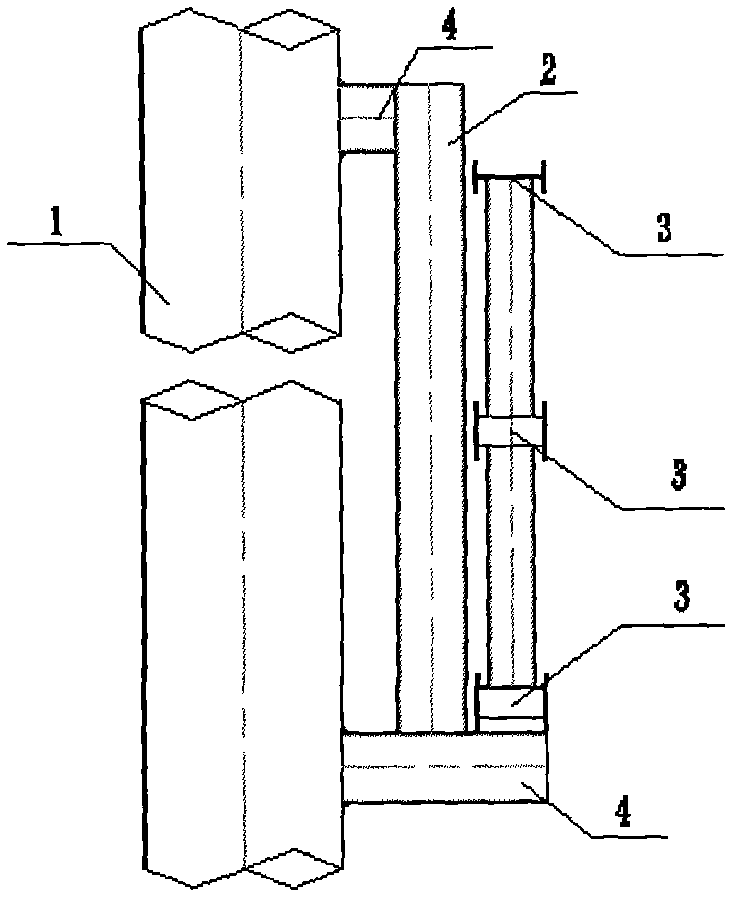

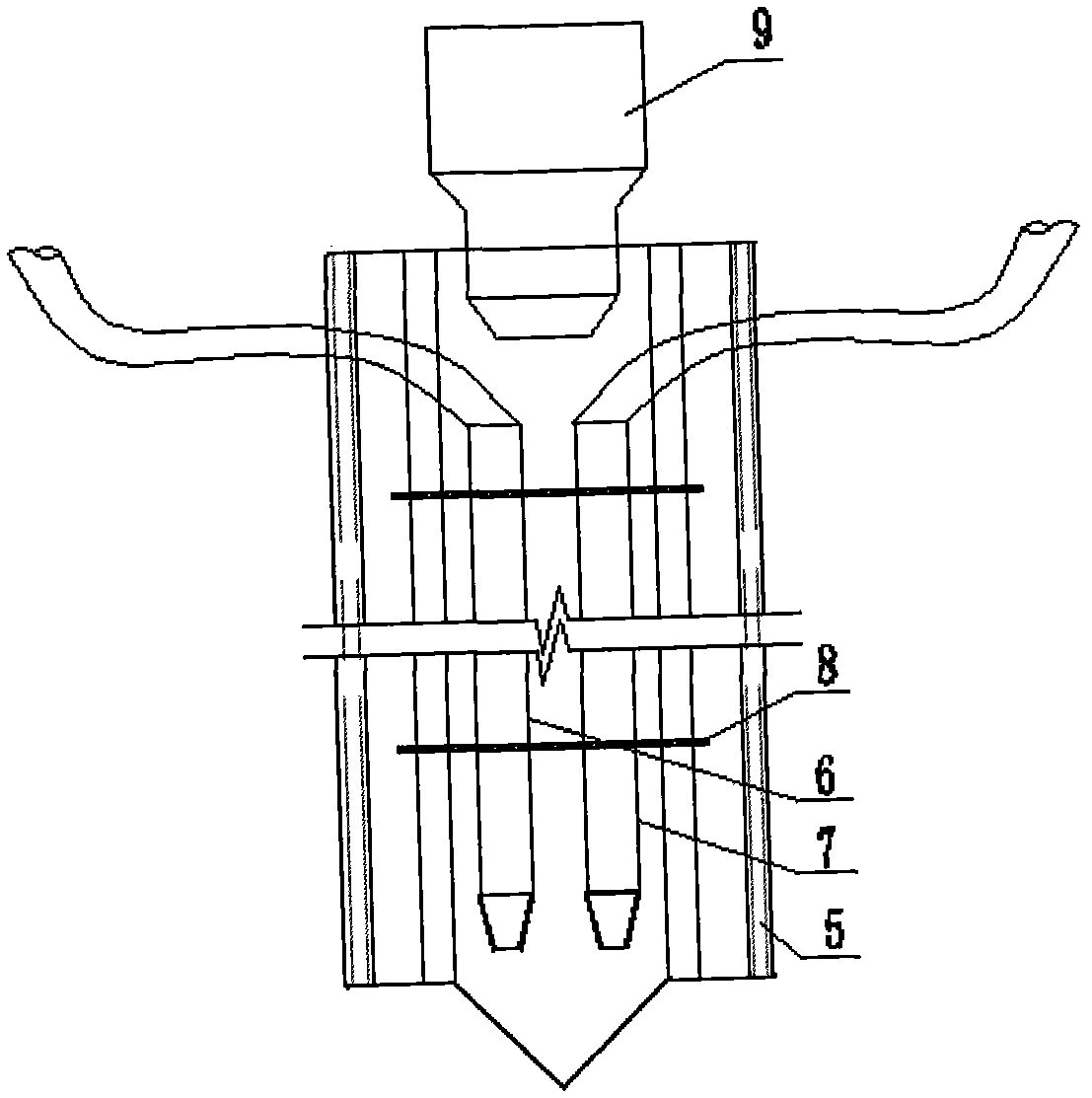

[0049] Such as Figure 1-7 Shown, a kind of construction method of steel sheet pile cofferdam is characterized in that: described construction method comprises the following steps: (1) construction preparation work; position, measure and set out the four corner points of the cofferdam, and lay positioning piles at the corner points as the control points for the positioning of the steel sheet pile cofferdam; The construction of the internal support system composed of beams and joists; (4) The inner support of the enclosure is first welded and assembled and lowered as a whole, and then the steel sheet pile construction is carried out; (5) The cofferdam sucks mud; (6) The bottom of the cofferdam is sealed; (7) The cofferdam The weir is pumped to clear the base; (8) The cofferdam is removed.

[0050] Preparations include:

[0051] (1) Design preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com