Down-lying, bed-contacting and sinking control technologies of super large steel cofferdam

A technology of lowering the cofferdam and super-large steel, which is applied in the direction of construction and infrastructure engineering, etc., can solve the problems of difficult control of super-large steel cofferdams, difficulties in subsidence accuracy, and easy tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] When the high tide level of the day is selected, the cofferdam sinking construction operation is carried out. Through the joint action of the lifting system and the horizontal guide device, coupled with the principle of batch sinking and batch water injection in the cofferdam wall warehouse, the cofferdam sinks under control .

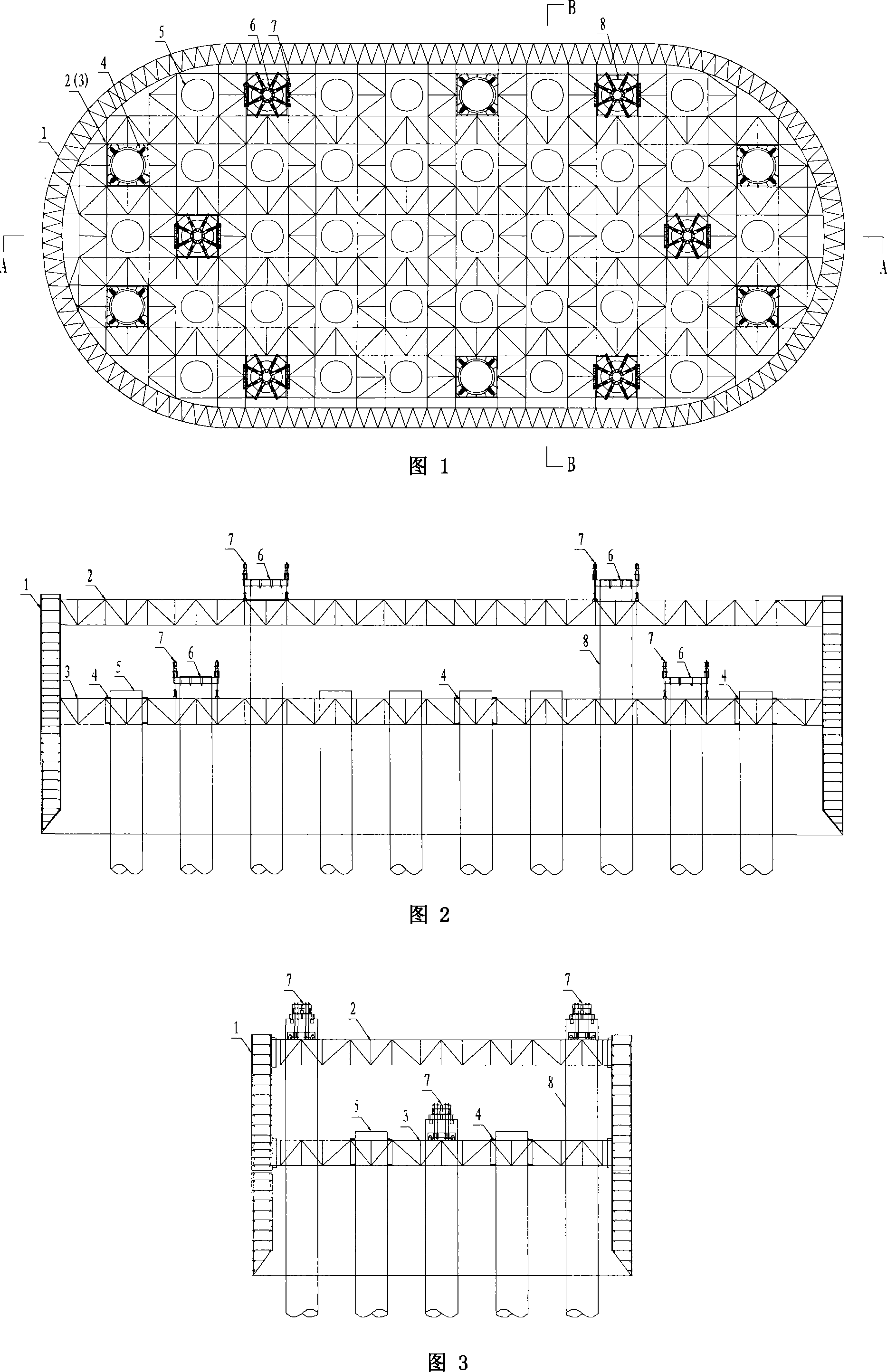

[0030] The structure and working mode of the present invention are described in detail below according to the accompanying drawings

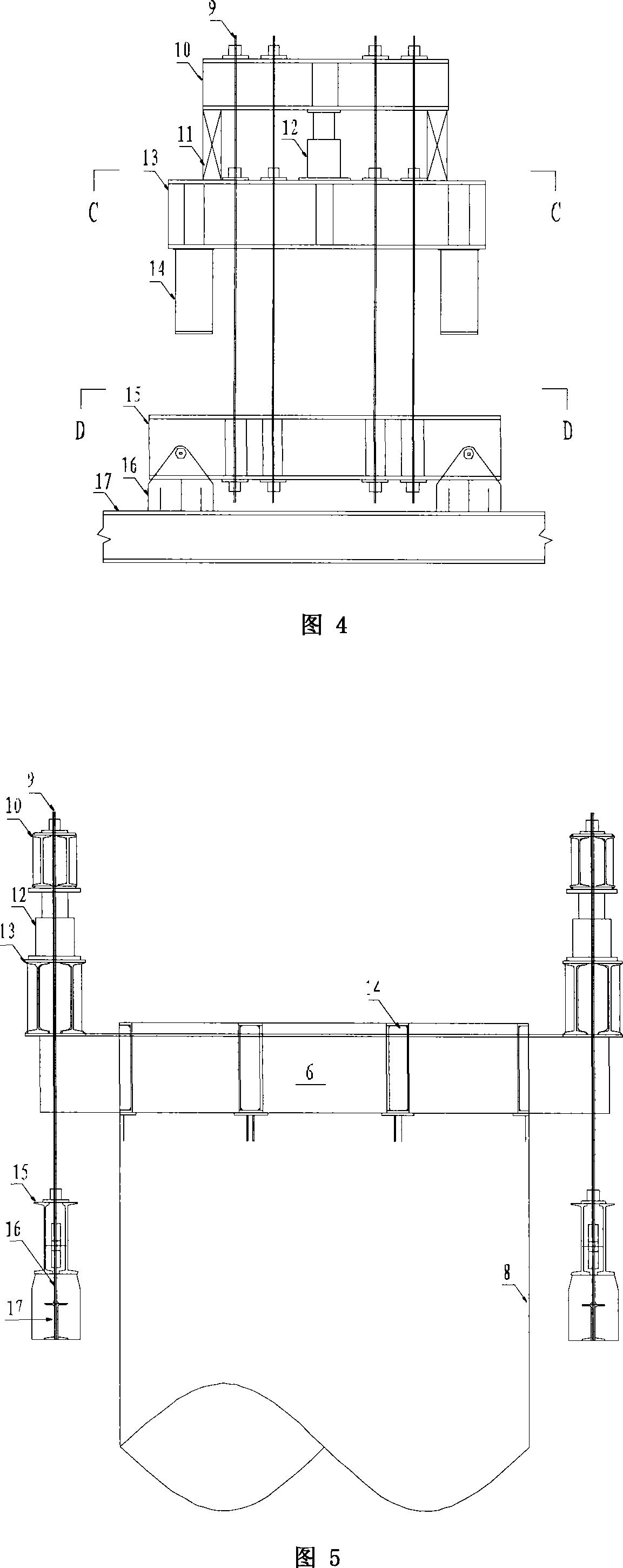

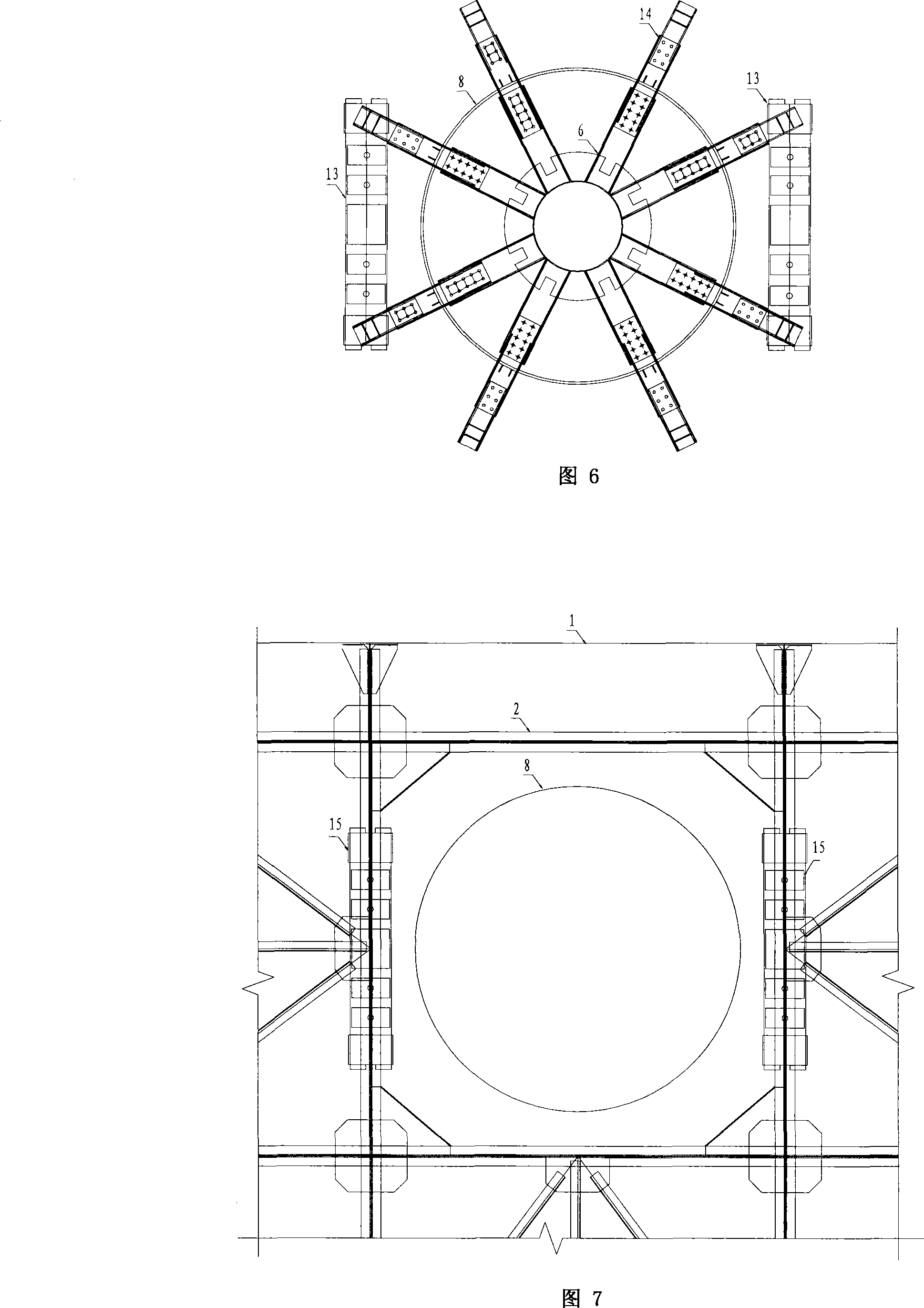

[0031] 1. The lifting system is composed of casing top hanging pile 6 and lifting device 7. The pile hanging on the top of the casing is the pile hanging equipment used on the original drilling platform; the lifting device is composed of a distribution beam (i.e. pole beams 10, 13, 15), a jack 12 and a finished rolled threaded steel bar 9. During on-site construction, it can be used on the pole Temporary pads 11 are set between beams 10 and 13 for safety.

[0032] Referring to Figures 4, 5, 6, and 7, in the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com