Combined cofferdam of steel slab pile and steel pipe pile an method for manufacturing the same

A technology of combining cofferdams and manufacturing methods, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of difficult to guarantee the water-stop effect at the interface, deformation, and low rigidity, so as to achieve convenient construction and reduce workload. , the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments.

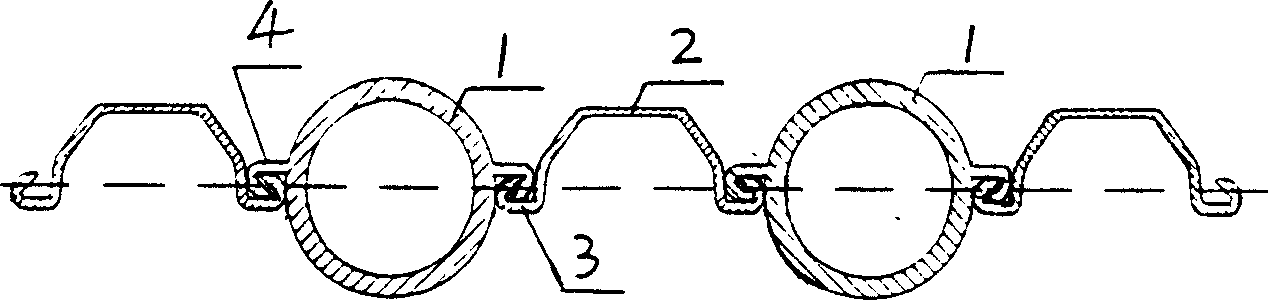

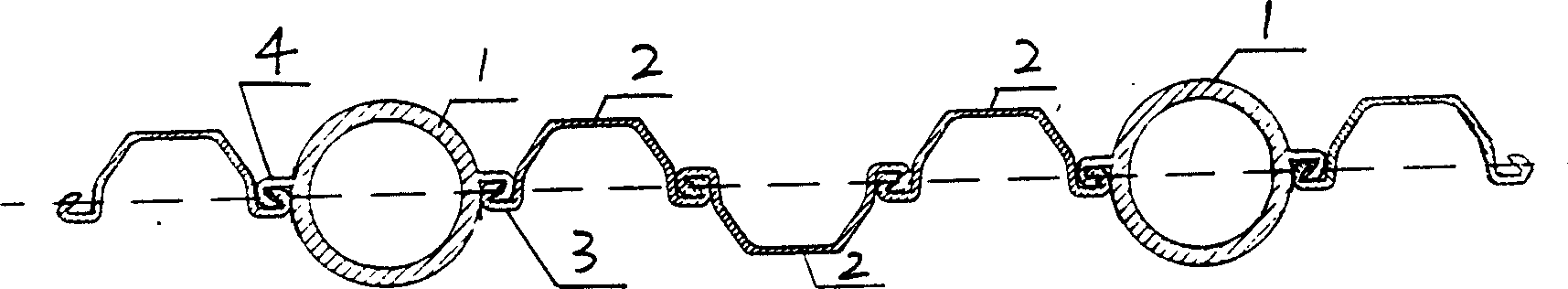

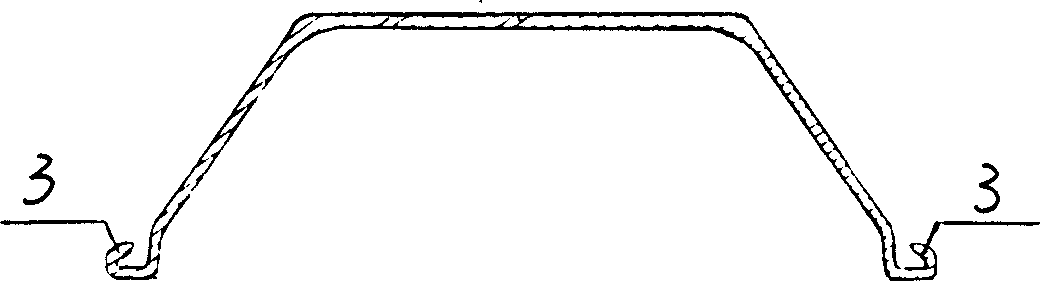

[0013] A combined cofferdam of steel sheet piles and steel pipe piles is characterized in that at least one steel sheet pile 2 is arranged between two steel pipe piles 1, and adjacent steel sheet piles 2 and steel pipe piles 1 are connected by tongues and grooves. The length of the pile 1 and the steel sheet pile 2 is the same, and the length is 10-50m, and the pile sinking depth of the steel pipe pile 1 and the steel sheet pile 2 is the same, and the pile sinking depth is 5m-40m. The specification of the steel pipe pile 1 used in the present invention is φ400~φ1500 (diameter / mm), the specification of the steel sheet pile 2 is No. III (400×150×13.1) or No. IV (400×170×15.5) steel sheet pile, steel pipe The structure of pile 1 and steel sheet pile 2 is as follows image 3 with Figure 4 Shown. In the present invention, 1 to 3 steel sheet piles 2 can be arranged between tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com