Precontrol top upward access cut-and-filling stopping method

A technology of approach filling and pre-controlled roofing, applied in ground mining, underground mining, special mining, etc., can solve the problems of low mining intensity and labor productivity, small stope production capacity, and many operating cycles, etc., to improve production efficiency and production capacity, good safety, and low dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] The pre-control top-up filling mining method uses two layers as a mining unit. First, the upper layer is mined, which is the top layer, and measures are taken to strengthen the roof, and then the lower layer is mined, which is the recovery layer. The two layers are mined After that, filling is carried out; after all the upper and lower layers of the stope are mined and filled, the upper layer is raised to the upper two layers, and the specific steps are as follows:

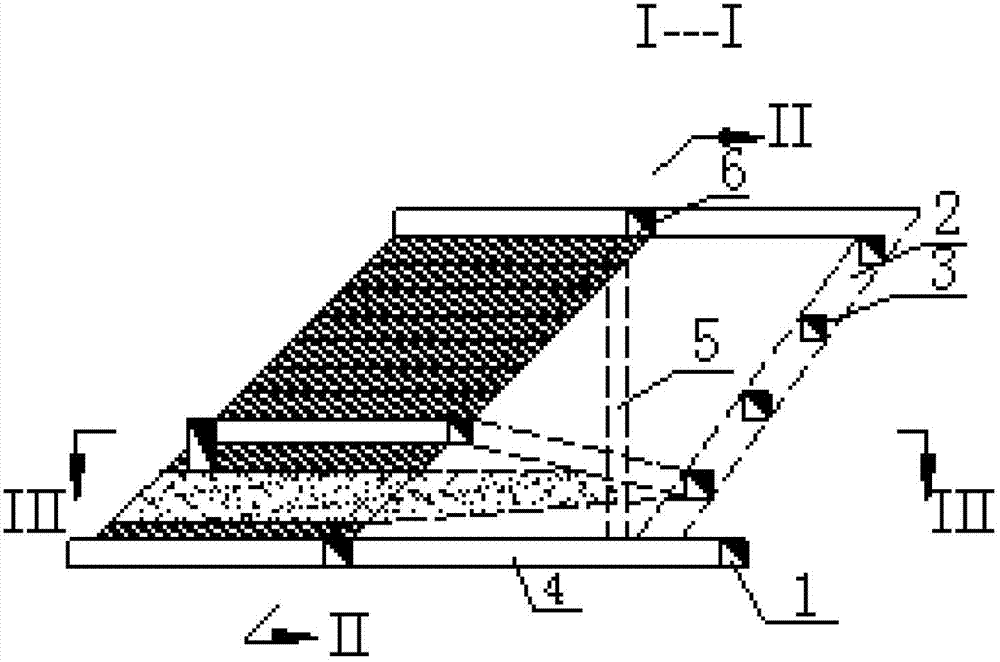

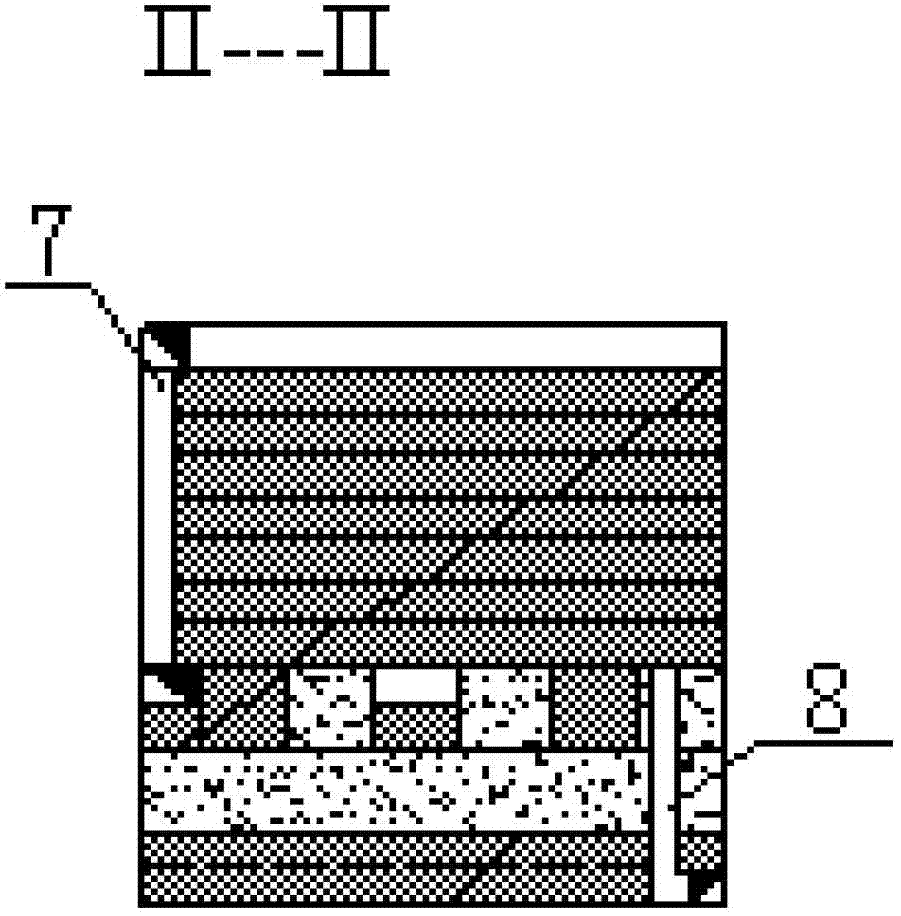

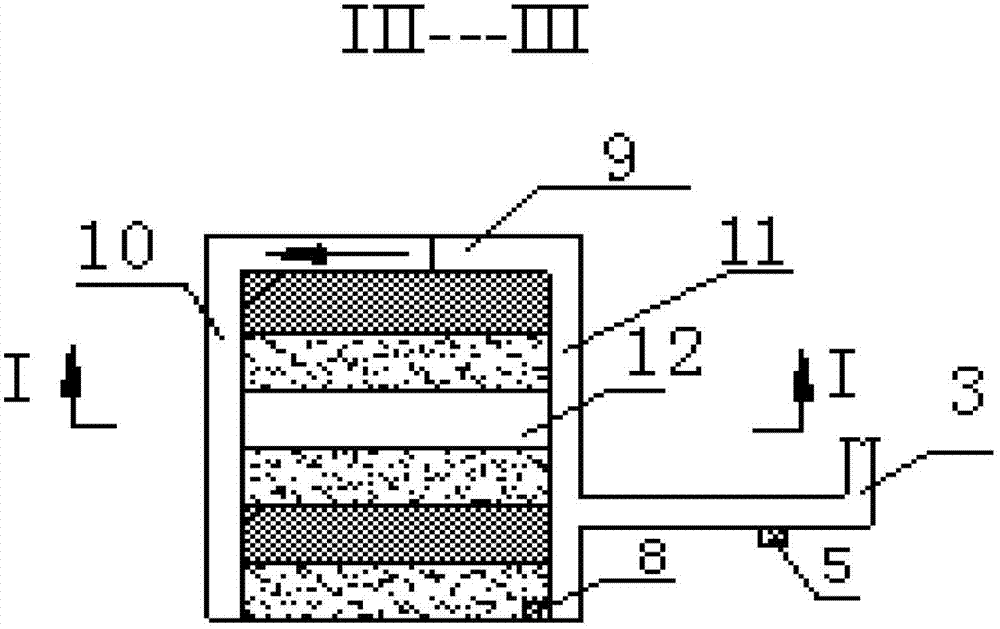

[0020] 1), see figure 1 , figure 2 with image 3 , the route is arranged vertically to the orebody strike

[0021] The main mining projects include ramp 2, piercing vein 4, stage transportation entry 1 and filling return entry entry 6, etc. From the entrance 3 of the ramp to the upper and lower walls of the ore body, the upper wall contact entry 10 and the footwall contact entry 11 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com