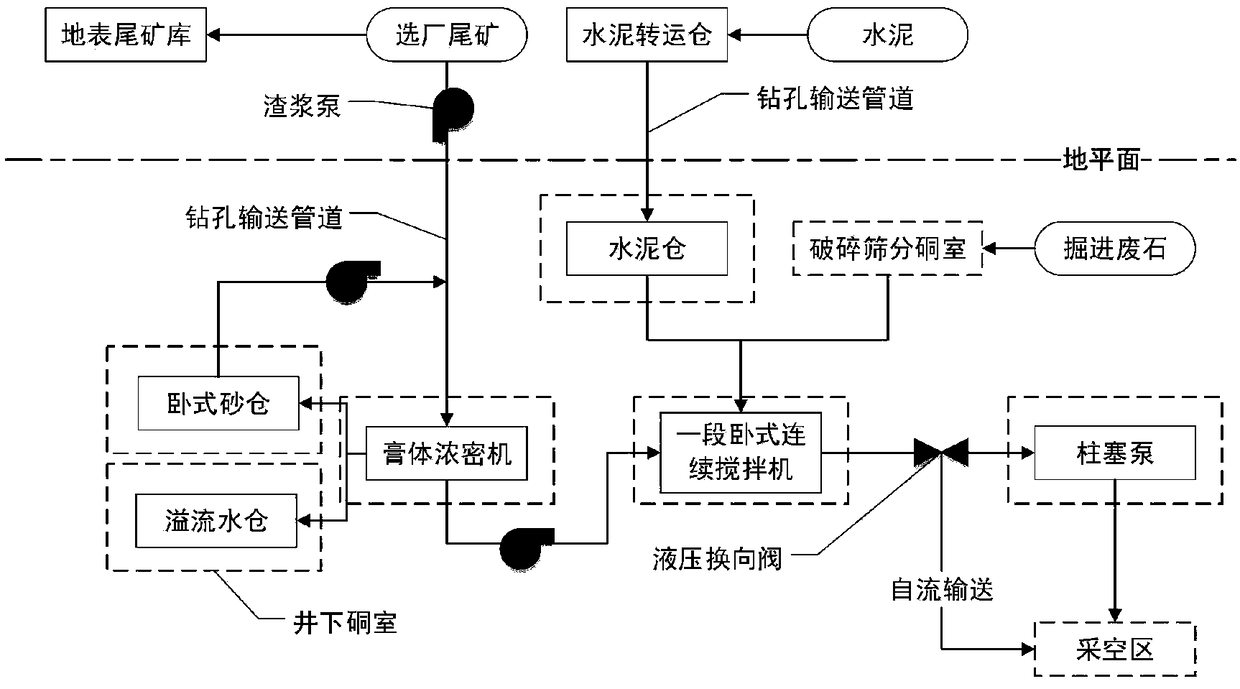

Underground all tailings-waste gypsum filling system and filling method

A technology of full tailings and waste gypsum, which is applied in filling materials, safety devices, earthwork drilling and mining, etc., can solve the problems of filling drilling wear and other problems, and achieve the goals of avoiding severe wear, reducing the loss of conveying resistance, and reducing infrastructure investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A copper-zinc mine has been mined underground for many years, and has been developed to the middle section of -827 m, with a maximum mining depth of more than 1300 m. It mainly adopts the open-field and subsequent filling mining method and the upward horizontal layered filling mining method. The filling materials used in the mine are mainly ore dressing and grading tailings, excavation waste rock and cement. Coarse-grained tailings over 200 mesh are sent to the mixing drum by electric rakes and screw conveyors, mixed with auxiliary materials such as cement and river sand, and then sent to the middle stages of production by filling boreholes, with a filling concentration of about 50%-60%.

[0044] With the excavation of the development system, the ore body continues to lie eastward, the vertical height difference of the filling pipeline reaches 1020 meters, and the horizontal distance of the stope reaches 2000 meters. It can be filled with low concentration (about 50% ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com