Technology for degrading bast fiber lignin and application thereof

A technology of lignin and hemp, which is applied in the regeneration of pulping liquid, the use of microorganisms/enzyme cellulose treatment, textiles and papermaking, etc., can solve the problems of long time, low yield, low fiber degree, etc., to avoid Emissions and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

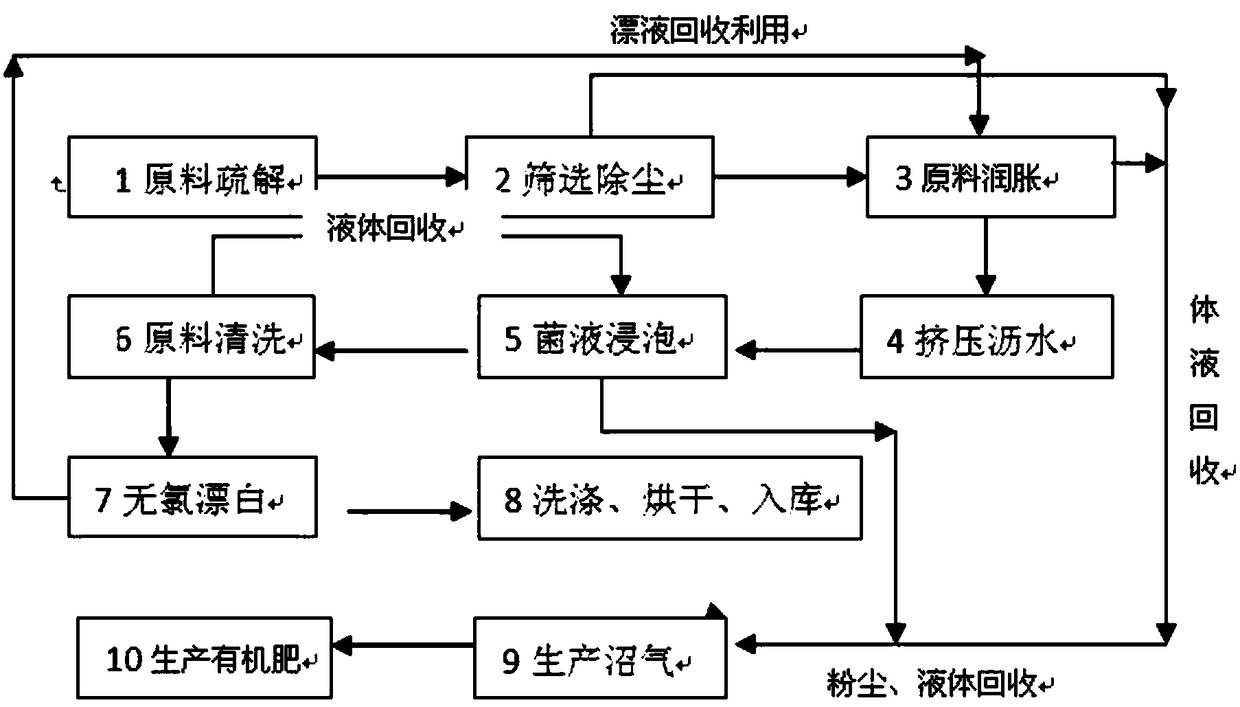

Method used

Image

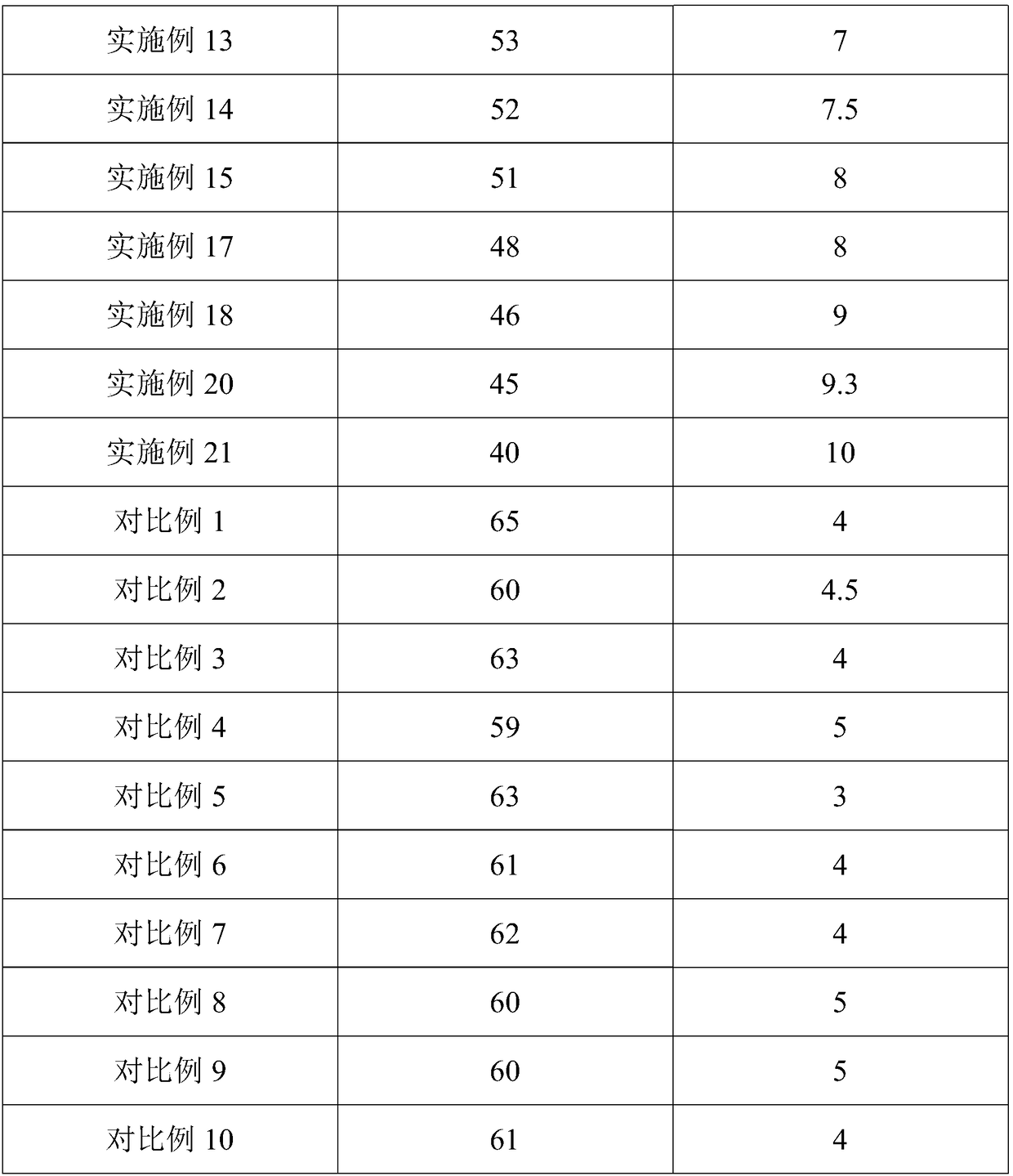

Examples

Embodiment 1

[0032] This embodiment provides a composite flora, including Acinetobacter lwoffii with the preservation number CGMCC NO.5973, Wickerhamomyces anomalus with the preservation number CGMCC NO.5975, Chrysosporium Phanerochaete chrysosporium and Pleurotus ostreatus as described Acinetobacter lwoffii, Wickerhamomyces anomalus, Phanerochaetechrysosporium The quantity ratio of Pleurotus otreatus (Pleurotus otreatus) is 0.5:3:0.8:4 and is formulated into an aqueous solution, and the concentration sum of all bacterial species in the bacterium liquid is controlled by 10 7 pieces / ml.

Embodiment 2

[0034] This embodiment provides a composite flora, including Acinetobacter lwoffii with the preservation number CGMCC NO.5973, Wickerhamomyces anomalus with the preservation number CGMCC NO.5975, Chrysosporium Phanerochaete chrysosporium and Pleurotus ostreatus as described Acinetobacter lwoffii, Wickerhamomyces anomalus, Phanerochaetechrysosporium The quantity ratio of Pleurotus otreatus (Pleurotus otreatus) is 2.5:0.5:3:1 and is formulated into an aqueous solution, and the concentration sum of all bacterial species in the bacterium liquid is controlled by 10 11 pieces / ml.

Embodiment 3

[0036] This embodiment provides a composite flora, including Acinetobacter lwoffii with the preservation number CGMCC NO.5973, Wickerhamomyces anomalus with the preservation number CGMCC NO.5975, Chrysosporium Phanerochaete chrysosporium and Pleurotus ostreatus as described Acinetobacter lwoffii, Wickerhamomyces anomalus, Phanerochaetechrysosporium It is 1:2:1:3 to be mixed with aqueous solution with the quantity ratio of Pleurotus otreatus (Pleurotus ostreatus), controls the sum of the concentration of all bacterial classifications in described bacterium liquid 10 8 pieces / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com