Heavy-load right-angle rail changing RGV device and rail changing operation thereof

A trolley, right-angle technology, used in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of adding one transfer, long construction period, and inconvenient changing of walking routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the above-mentioned technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

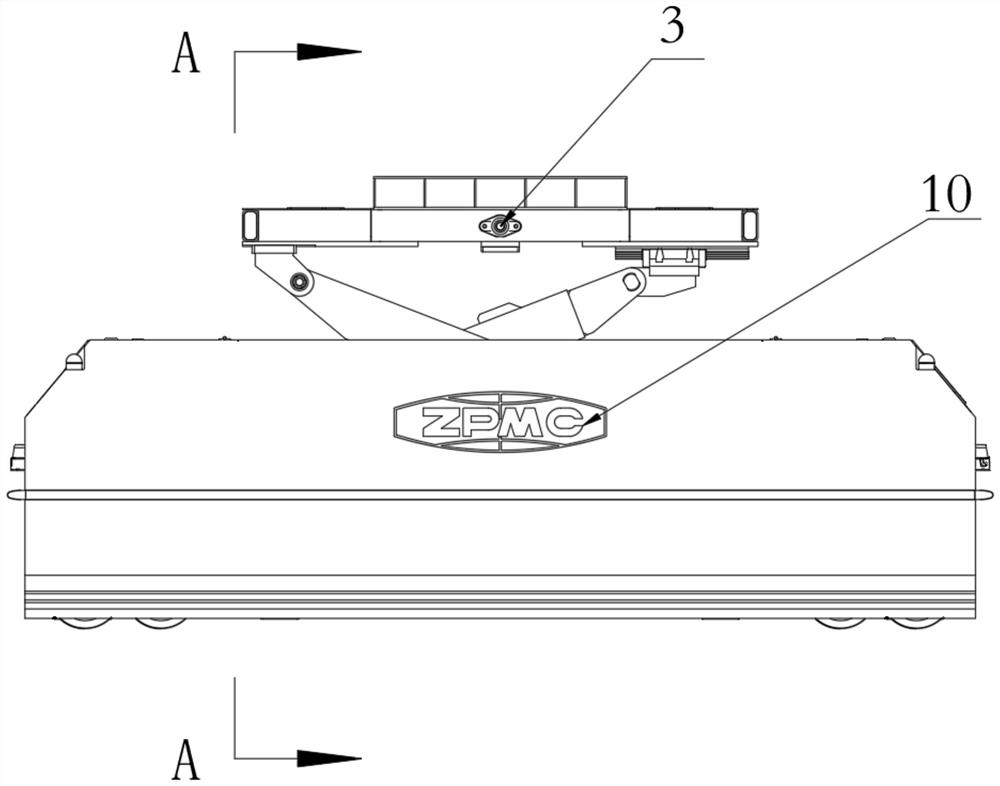

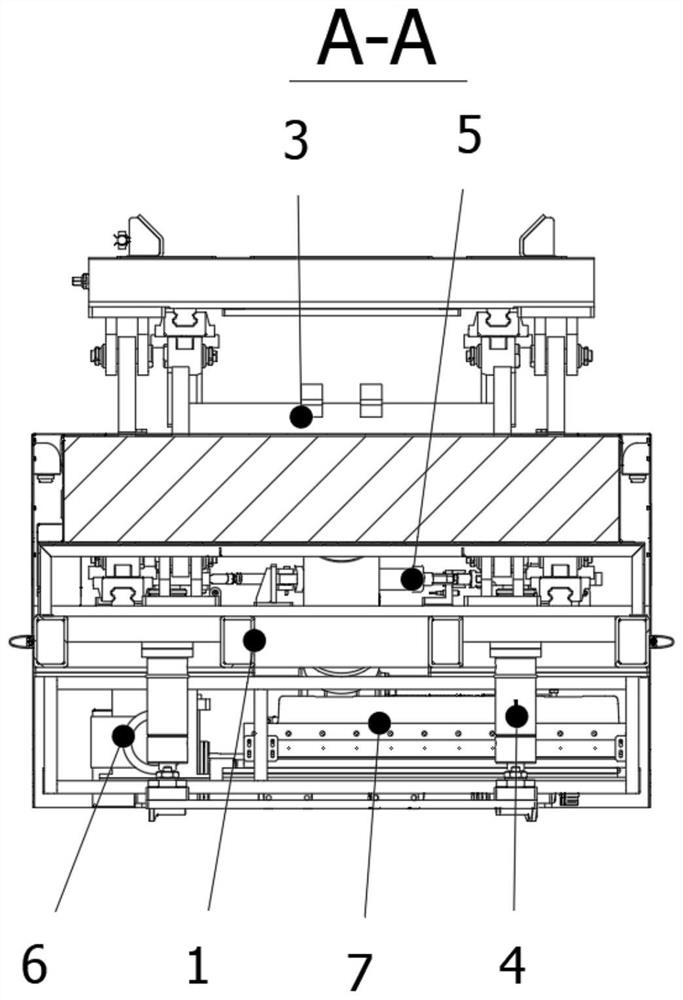

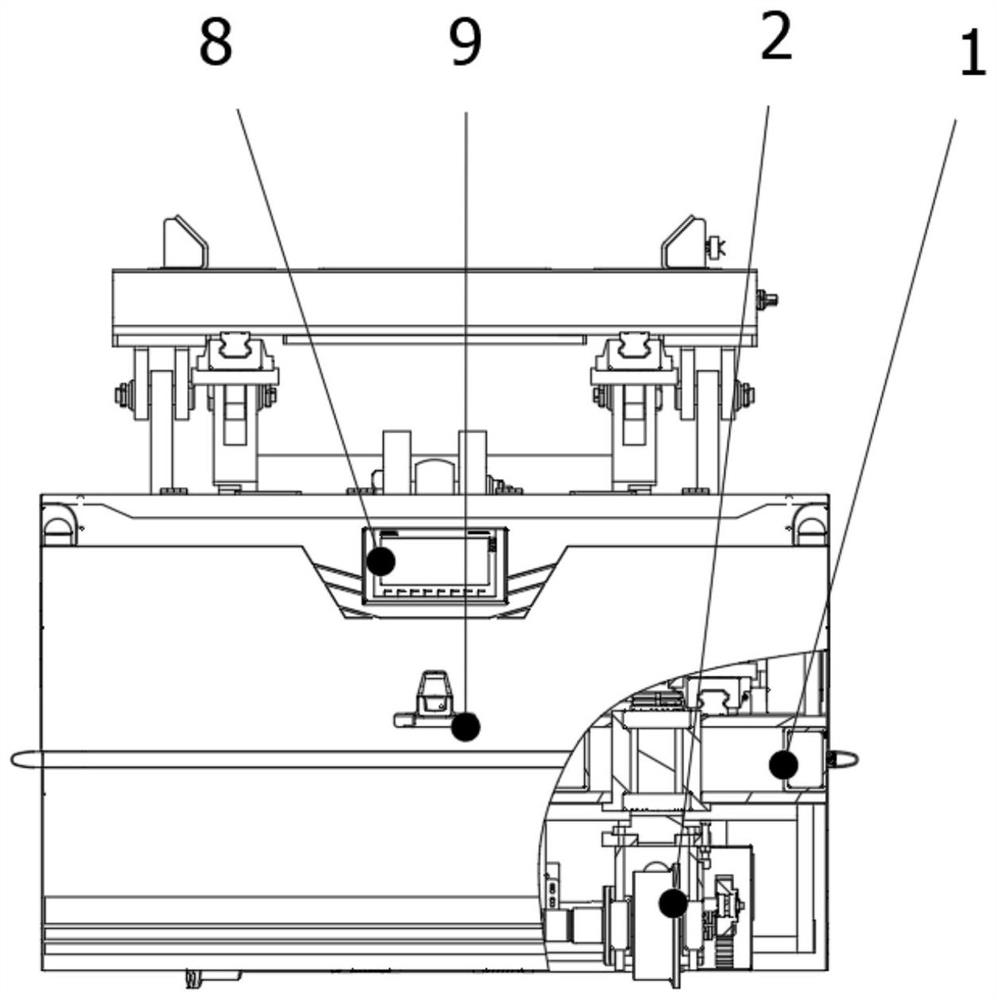

[0045] Please combine Figure 1 to Figure 9 As shown, a heavy-duty right-angle track-changing RGV car device provided by the present invention includes a car body structure 1, a servo double wheel set 2, a hydraulic jacking centering platform 3, a car body hydraulic jacking mechanism 4, and a steering mechanism 5 , hydraulic station 6, lithium battery system 7, electric control system 8, safety system 9 and car body shell 10.

[0046] The servo double wheel set 2 is locked and connected to the car body structure 1 by shafting nuts, the hydraulic jacking centering platform 3 is connected to the car body structure 1 by fixing bolts, and the car body hydraulic jacking mechanism 4 is connected to the car body structure by using fixing bolts. Below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com