Efficient mechanical mining method for gently-inclined thin ore bodies

A mining method and thin ore body technology, which is applied in the field of mining and construction of rare and valuable mineral resources, can solve the problems of high waste rock mixing rate in the footwall, high labor intensity, and large ore dilution loss rate, etc., so as to reduce labor costs and Effects of labor intensity, reduction of operating procedures and workload, reduction of dilution loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

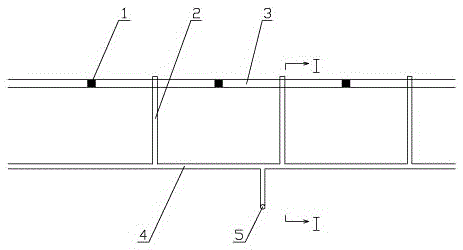

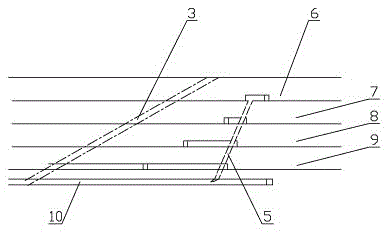

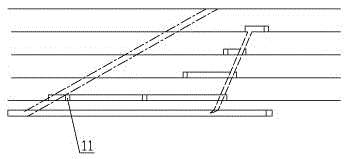

[0037] see figure 1 and figure 2 , the present invention is a mechanized high-efficiency mining method for a gently inclined thin ore body. Firstly, the middle section of Mine 3 is divided from bottom to top into four subsections: first section 9, second section 8, third section 7 and fourth section 6. section, and reserve an 8m bottom pillar in the middle section of the ore body, with a subsection height of 12m, and a stepping height of 3m in the middle section of the ore body; Set up the transportation roadway 10, and set up the mining quasi-slope and the ore shaft 5 respectively upwards along the transportation roadway, then set up the stope connecting road 2 in the middle of the ore block, and the stope connecting road connects each ore block recovery unit with each sub-level roadway ;Finally, the ore block is divided, each mining unit is arranged along the ore body trend, the length is 60m, the width is the thickness of the ore body, and the height is the middle section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com