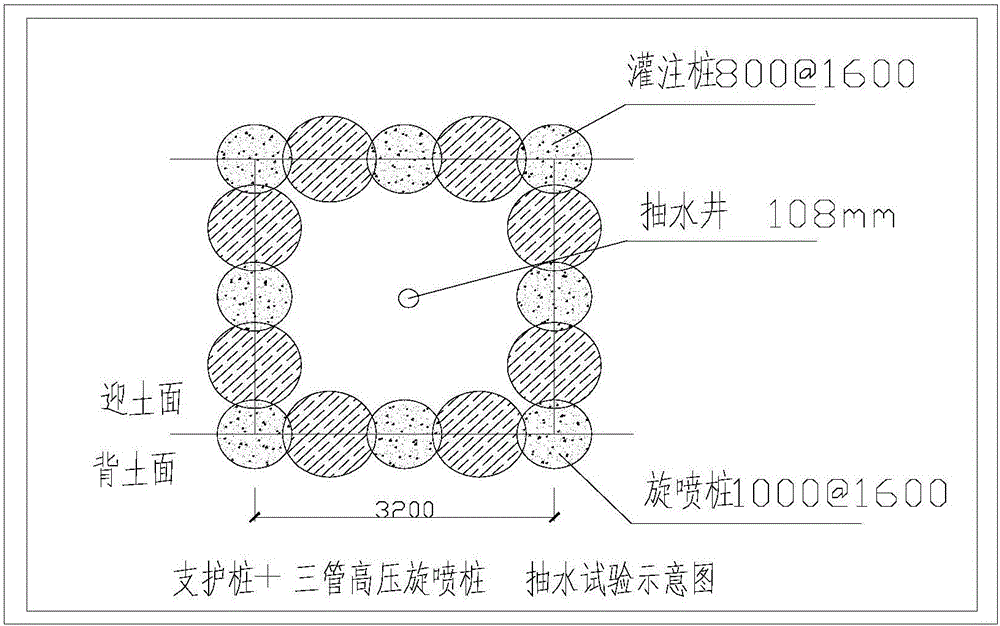

Construction method for deep foundation pit with support piles and three-pipe high-pressure jet grouting piles

A technology for high-pressure rotary jetting piles and construction methods, which is applied in basic structure engineering, excavation, sheet pile walls, etc., can solve problems such as difficulty in driving into the international market, backward construction methods, and outdated equipment, and achieves reduced construction operations and reasonable engineering. Cost, ensuring normal use and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

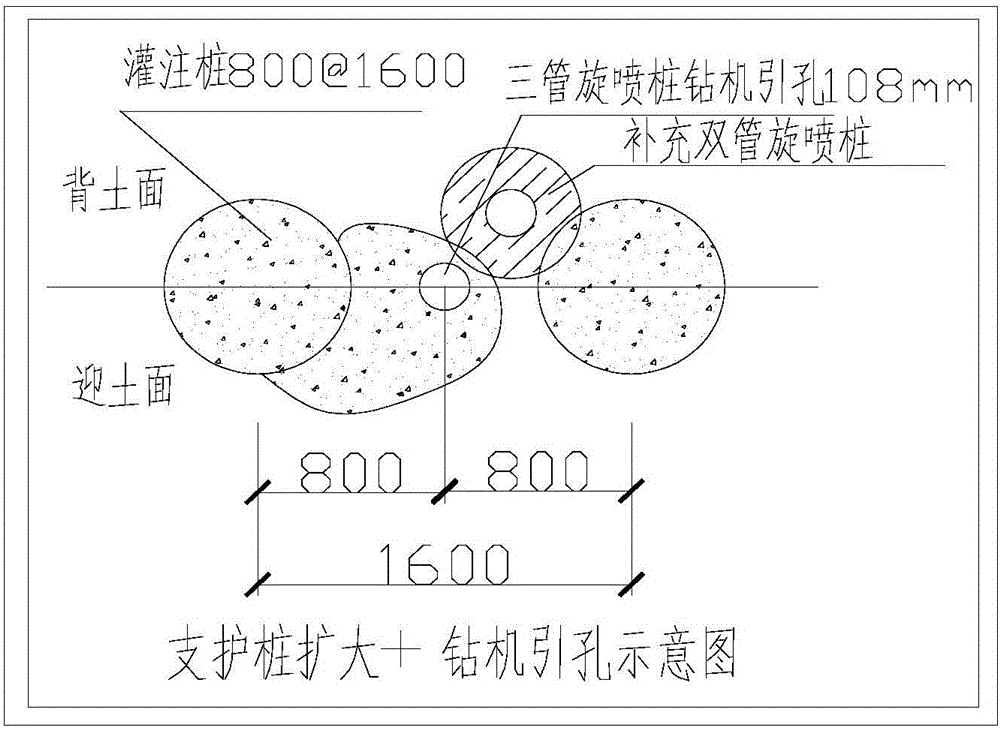

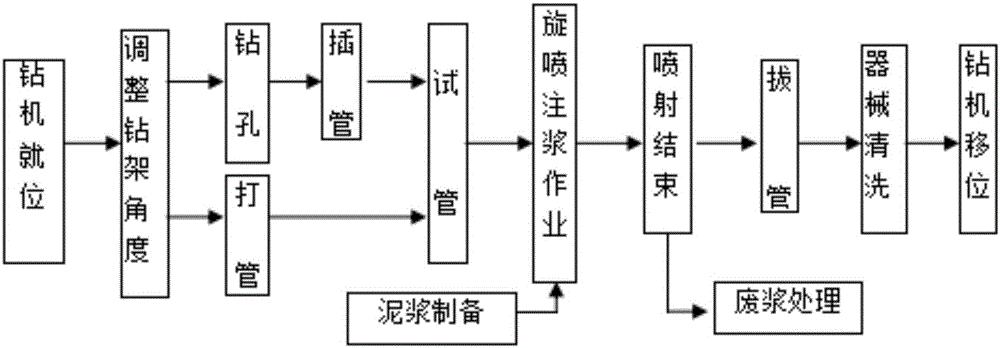

[0033] In an embodiment of the present invention, a construction method of a support pile and a three-pipe high-pressure jet grouting pile deep foundation pit is specifically described as follows.

[0034] 1. Construction technical requirements and arrangements

[0035] (1) In the construction process, first carry out the construction of support piles (cast-in-situ piles), and then construct the rotary grouting piles. First use the drill hole to lead the hole and record the formation conditions. If there is a large change from the design conditions, corresponding design change measures must be taken. In order to avoid the phenomenon of stringing holes and slopping, high-pressure jet grouting piles need to be skipped for construction, and the construction of adjacent piles can only be carried out after the cement slurry has finally set.

[0036] (2) Slurry formula: According to the situation of various strata on site, the high-spray grouting material is PC32.5R composite Portl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com