Simulation experiment platform of compacting system of solid-filling coal mining solid material

A solid material and system simulation technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as unforeseen filling and mining problems, poor predictability of filling effect, difficulty in filling parameter optimization, etc., and achieve remarkable engineering results , Simple structure, good simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

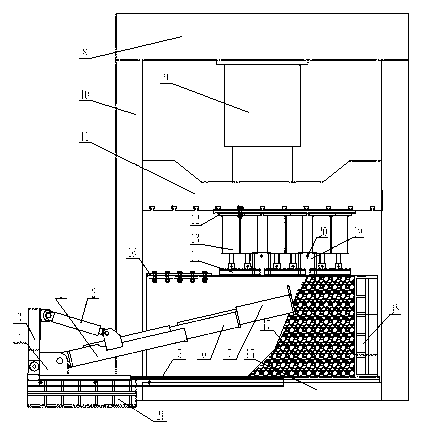

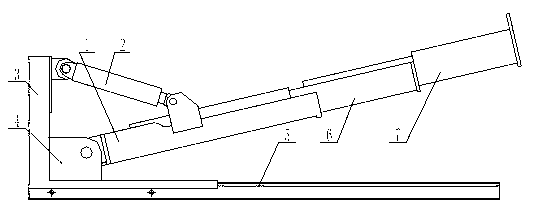

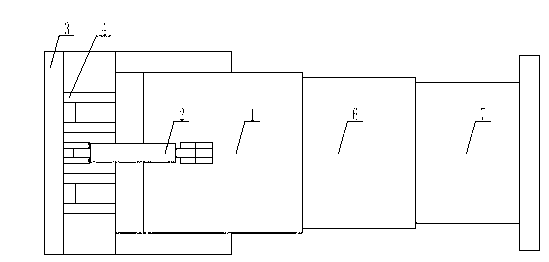

[0021] Such as figure 1 As shown, the solid filling coal mining solid material compaction system simulation experiment platform of the present invention is mainly composed of a power supply system, a compaction system, a loading system, a data acquisition and processing system, a base 21 and a box-shaped frame 18. The loading system is designed On the box-shaped frame 18, the tamping system is fixed on the base 21 on one side of the frame box body 18; the power supply system includes a control box and an oil pump that supplies oil pressure to the loading system and the tamping system respectively; Supply source power, one road in the hydraulic pump station provides oil pressure to the press cylinder 9 and loading cylinder 13 in the loading system, the loading cylinders 13 are in 2-3 groups, and each group of loading cylinders 13 is connected to a loading se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com