Tunnel excavation method for extending existing single-hole tunnel into double-arch tunnel

A technology for tunnel excavation and existing tunnels. It is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of increasing the span of a single tunnel, unstable surrounding rock, and large changes in the entrance and exit elevations, so as to save construction time. , The effect of less two-way traffic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

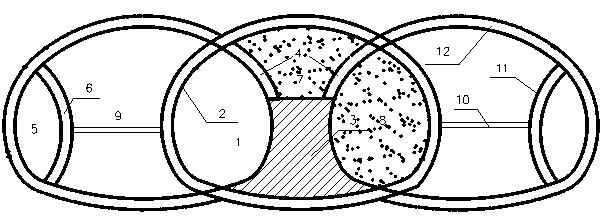

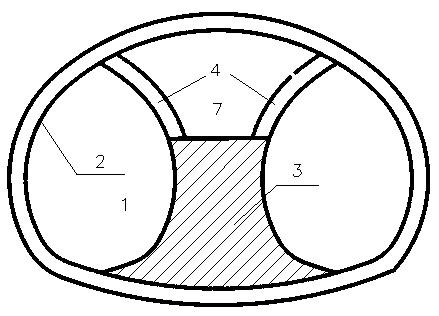

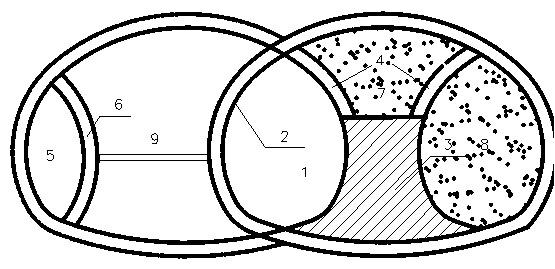

[0016] The features and application process of the present invention will be further described in detail below in conjunction with the accompanying drawings, in order to facilitate the understanding of technical personnel in the same industry. In order to facilitate the description, on the premise that the height of the existing tunnel cavity is greater than that of the partition wall cavity, the new cavity adopts double side wall guides. The cave method is combined with the upper and lower steps method for construction, and the details are as follows:

[0017] attached Figure 1-3 The marks 1-12 respectively represent: 1 the existing single tunnel, 2 the primary support and secondary lining of the existing tunnel, 3 the middle partition wall, 4 the new tunnel support structure, 5 the left tunnel support structure, 6 the left tunnel side wall Temporary support for the pilot tunnel, grouting filling on the upper part of the 7th middle partition wall, 8th existing tunnel filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com