Coal mine microbial cemented filling material and preparation method thereof

A microbial glue and filling material technology, which is applied in the field of mine filling materials and microorganisms, can solve the problems of increasing the cost of cemented filling materials, consuming large energy, polluting the environment, etc., and achieves the effects of avoiding negative effects, less environmental pollution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

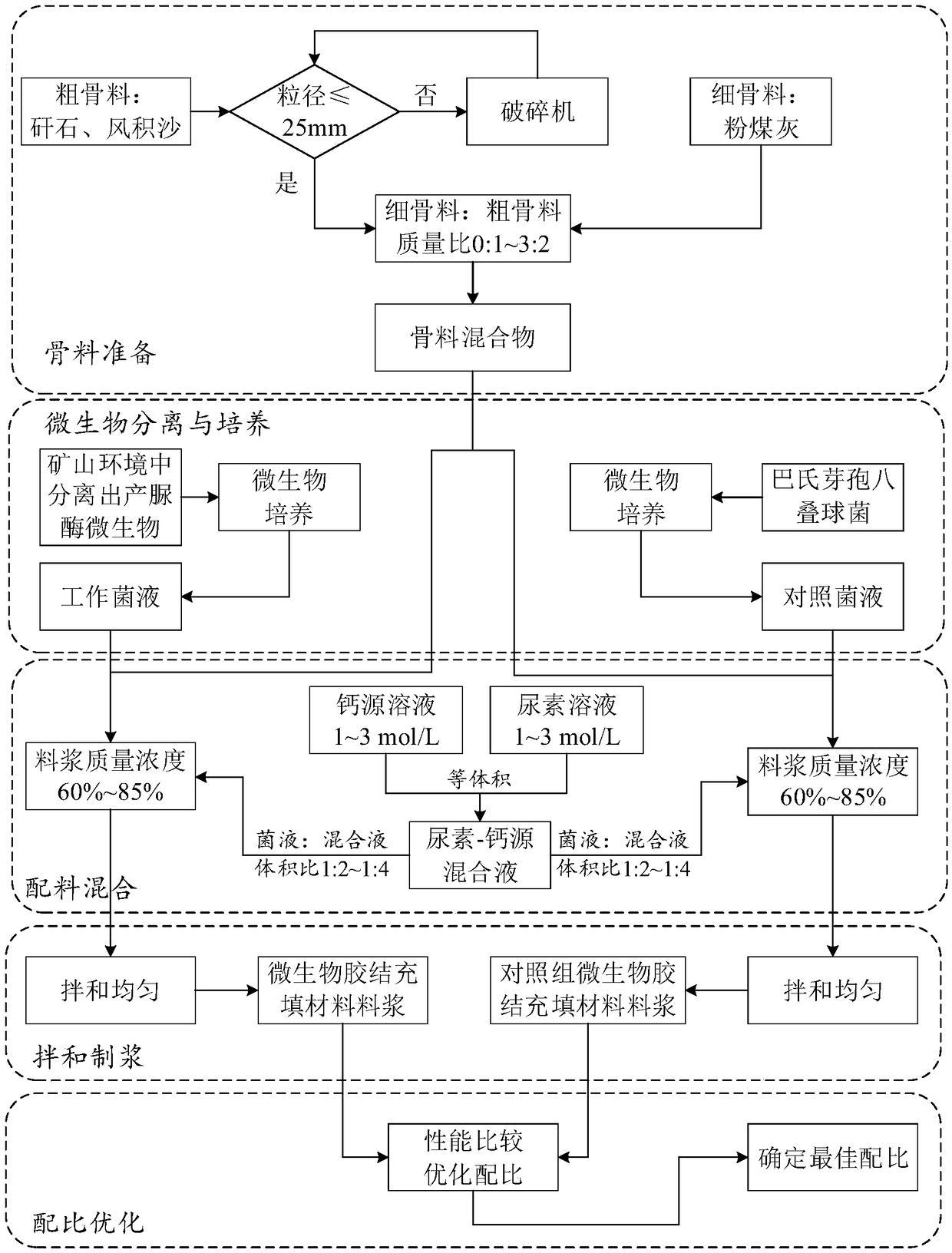

[0032] Such as figure 1 Shown, a kind of preparation method of coal mine microbial cement filling material of the present invention comprises the steps:

[0033] (1) inoculating a single colony of urease-producing microorganisms isolated from the mine environment into a fermentation medium, and fermenting and culturing at 25° C. to 37° C. for 12 to 60 hours to obtain a working bacterial liquid;

[0034] (2) inoculating a single colony of the urease-producing microorganism Sporosarcina pasteurii in the fermentation medium, and fermenting and culturing at 25° C. to 37° C. for 12 to 60 hours to obtain a control bacterial liquid;

[0035] (3) Prepare urea and calcium source solutions with a concentration of 1 to 3 mol / L respectively, the urea solution and the calcium source solution have the same molar concentration, and mix them in equal volumes to make a urea-calcium source mixed solution;

[0036] (4) Select one of fly ash, gangue or aeolian sand as aggregate; or use fly ash a...

Embodiment 1

[0042] In this example, the urease-producing microorganism Bacteria A and the microorganism Sporosarcina pasteurii isolated from the mine environment were used to prepare cemented filling materials for coal mines, calcium chloride dihydrate was used as the calcium source, and aeolian sand was used as the aggregate , including the following steps:

[0043] (1) Inoculate a single colony of the urease-producing microorganism Bacteria A isolated from the mine environment into a fermentation medium, and ferment and cultivate it at 30°C for 24 hours to obtain a working bacterial liquid;

[0044] (2) Inoculate a single colony of the urease-producing microorganism Sporosarcina pasteurii in the fermentation medium, and ferment and culture it at 30° C. for 24 hours to obtain a control bacterial liquid;

[0045] (3) prepare respectively the urea solution that concentration is 2mol / L and the calcium chloride dihydrate solution that concentration is 2mol / L, and mix according to equal volum...

Embodiment 2

[0052] In this example, the urease-producing microorganism Bacteria B and the microorganism Sporosarcina pasteurii isolated from the mine environment are used to prepare cemented filling materials for coal mines. Calcium chloride dihydrate is used as the calcium source, and gangue is used as the coarse aggregate. Fly ash is used as fine aggregate, which specifically includes the following steps:

[0053] (1) Inoculate a single colony of the urease-producing microorganism Bacteria B isolated from the mine environment into the fermentation medium, and ferment and culture it at 30°C for 24 hours to obtain a working bacterial liquid; cultivate Sporosarcina Sporosarcina under the same conditions pasteurii, to obtain the control bacterial solution;

[0054] (2) prepare respectively the urea solution that concentration is 1.5mol / L and the calcium chloride dihydrate solution that concentration is 1.5mol / L, and mix according to equal volume and make urea-calcium chloride mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com