Gob natural fire control method

A natural fire and goaf technology, applied in dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of limited fire prevention effect, low recovery rate of top coal, poor operability, etc., to improve fire prevention and extinguishment The effect of ensuring smooth mining and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

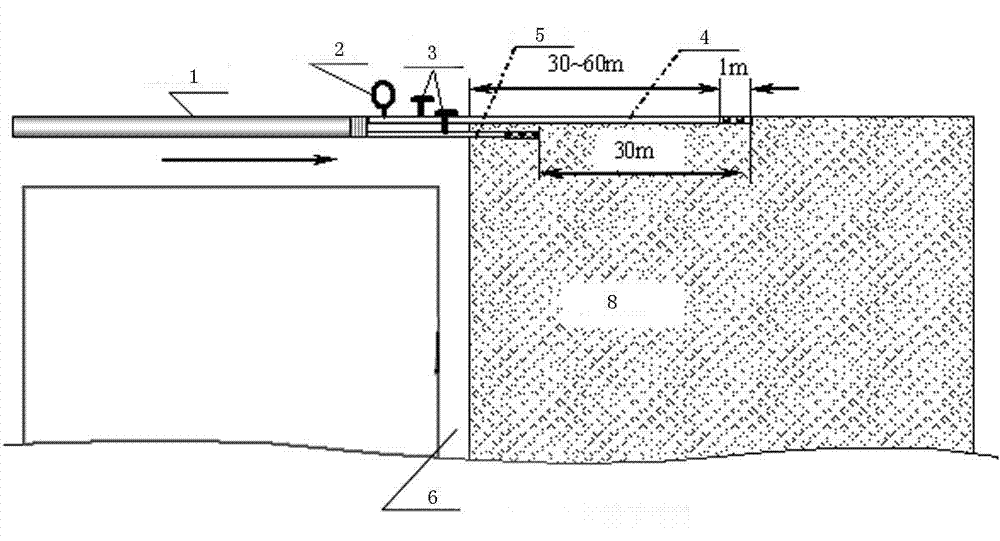

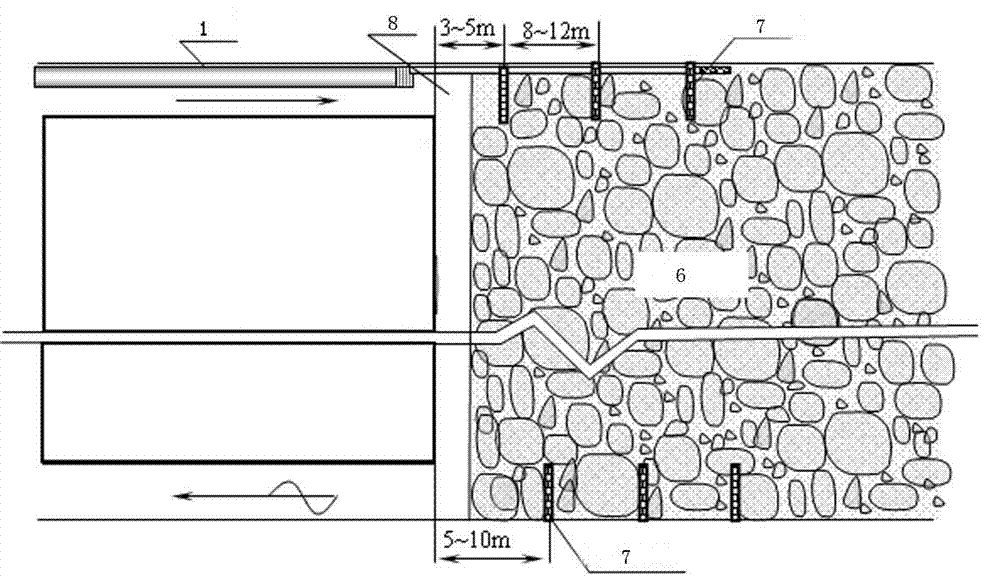

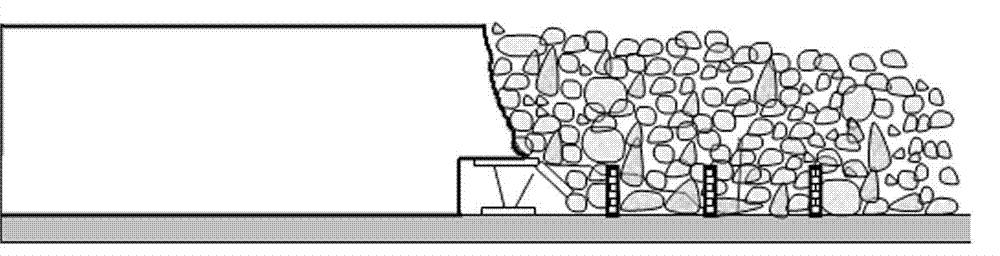

[0026] A method for preventing and controlling natural fire in a goaf according to the present invention, comprising:

[0027] (1) Nitrogen injection, the nitrogen injection point is 30-60 meters away from the working face, and the liquid nitrogen volume is 2000m 3 / h;

[0028] (2) Reduce the air leakage in the goaf, reduce the pressure difference of the working face, control the pressure difference of the working face within 120Pa, and block the air inlet and return air sides of the goaf in areas where the cantilever beam is formed by the roof and cannot fall tightly Leakage, timely seal the Hengchuan goaf;

[0029] (3) Accelerate the advancing speed of the working face, and the progress of the working face is 4m / d;

[0030] (4) Improve the recovery rate and control the thickness of the remaining coal below 1.3 meters.

[0031] Taking the 8101 working face of Tongxin Coal Mine of Tongmei Group as an example, the protected technical solution required by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com